07/10/2020 Author: VT-METALL

Issues discussed in the material:

- Description of cold metal working

- Common types of cold metal forming

- Pros and cons of cold metal working

- A little about chemical processing of metal

- Labor protection rules for cold metal processing

Cold metal processing has been in demand for a long time and is not going to lose its position yet. This is explained by the not too high cost of equipment relative to other options, as well as the huge potential of the method. However, there are more than enough other advantages here.

However, before starting work, you need not only to become familiar with the capabilities of a particular metalworking method, but also to have a good understanding of what exactly should be the output. One or another method of changing the technical characteristics of a material is selected depending on the specific situation, and cold metal processing is no exception.

Description of cold metal working

The cold working method of metal involves deformation to which the workpiece is subjected at a temperature less than the recrystallization point or at normal (room) temperature. The degree and depth of impact on the workpiece largely depends on the plasticity of the metal.

In practice, of all cold working methods, metalworking works, which are united by the concept “mechanical processing of metals,” are most often used.

This is a fairly large group in which all methods use a hard, sharp tool that mechanically acts on the workpiece. In this case, as a result of the separation of layers of material, the shape of the product changes. The difference between the size of the final product and the initial workpiece is called allowance.

There are several types of mechanical processing:

- Turning. In this case, a cutter is brought to the workpiece fixed on a rotating base - it removes the metal, creating a part with the dimensions specified in the design documentation. In this way, products are obtained that have the shape of a body of revolution.

- Drilling. In this case, a drill is brought longitudinally to a fixedly fixed workpiece, which rotates around its axis and then slowly plunges into the part. This type of processing is used to make round holes.

- Milling. The difference between this type and drilling lies in the working surface. If the drill has only the front end, then the cutter also has a side surface. In addition, the cutter has the ability to move in different directions (right, left, forward and backward). This type of processing helps to create a product that has the shape required by the designer.

- Planing. The workpiece is fixedly fixed on the base, and the cutter moves back and forth relative to it. Each pass of the tool removes a layer of metal from the part. Some units operate with a stationary cutter on a moving product. This type of processing is used to make longitudinal grooves.

- Grinding. The process is carried out using an abrasive material that rotates or the surface of the workpiece is processed longitudinally in a reciprocating motion, removing thin layers of material from it. In this way, the product is prepared for coating.

In addition to the above, cold metal processing includes:

- Deformation by shear or shear - punching, trimming, cutting and perforating, as well as transverse, longitudinal cutting, etc.

- Bending – at an angle, roller straightening, rod bending, flanging.

- Pressure processing - embossing, cold forging, rolling and stamping, riveting, knurling, notching, carving, etc.

Disadvantages of Cold Working

1) Only ductile metals, such as low carbon steel, can be cold worked. 2) Residual stresses arise, which are not always favorable. Excessive cold working of metal leads to embrittlement. To restore the plasticity of the metal, annealing is required. 3) The grain structure of the metal is distorted and fragmented - heat treatment is required. 4) It is easy to process only relatively small products - large ones require considerable effort.

Common types of cold metal forming

Most often, cold processing of a material refers to only one of its methods - pressure. Let's look at the varieties of this process.

- Forging.

This is a high-temperature process in which the part is heated to the optimal forging temperature - individual for each grade of metal. The following forging methods exist:

- on hammers (steam, hydraulic, pneumatic);

- manual.

Hammer forging (otherwise known as machine forging), as well as manual forging, are free processing options. They have this name because there is no restriction of the metal during the action of equipment or tools on it.

Stamping is a non-free forging. The reason lies in the die matrix, which constrains the workpiece. Under the influence of the tool, the product takes on its shape.

Forging is often used for small production volumes - single or small-scale. A forging is produced by heating the product and placing it between the hammer heads. Backings are made by crimping, axing or rolling.

- Rolling.

Rolling is the plastic processing of metal in a cold state by crimping. It takes place in a rolling mill using rotating rolls. It is used to reduce the cross-section of a part, as well as to create the required profile. Currently, three rolling methods are used:

- Longitudinal. Through it, the largest number of products are manufactured. During the processing process, the rolls compress the part passing between the divergently rotating rolls, leaving a thickness that is equal to the gap between the latter.

- Transverse. Bodies of rotation (for example, cylinders, balls, bushings, etc.) are processed in this way. The part does not produce translational movements.

- Transverse helical. The method combines the two previous ones. Used for the production of parts that are hollow from the inside.

- Drawing.

This is cold metal processing, the technology of which consists in drawing a part with a round (shaped) profile through a die. This is how the wire is made. The wire rod (a workpiece having a larger diameter) is pulled between the dies, resulting in a wire of small diameter.

The drawing process is classified:

- By type: dry, when the wire is pulled through soap powder, and wet, when a soap emulsion is involved in the process.

- For surface treatment: roughing and finishing.

- By frequency of transitions: single and multiple. The latter are carried out in several transitions, and the cross-section of the part is reduced gradually.

- By temperature: hot and cold.

- Pressing.

This process allows you to work with brittle metals by squeezing them through the holes of the matrix using a press.

The method is used for the production of solid or hollow profiles from materials such as aluminum, magnesium, titanium alloys, copper. Parts are used for aircraft and vehicles, for example, they make suspensions, blades, pipes, etc.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

There are cold and hot pressing. For ductile materials such as copper, tin, and pure aluminum, cold metal processing is used. For refractory materials and alloys, such as metals containing titanium, nickel, etc., hot processing is used, that is, tools and parts are heated before pressing.

The process makes it possible to obtain products with different configurations, for example, with a periodic (constant) profile, external or internal ribs, etc.

Production takes place on special presses where matrices can be changed. The material used to manufacture the matrices is stamped steel with high heat resistance.

- Volumetric stamping.

This is a method that allows you to produce a part using a die, parts of which restrict the flow of material.

Two types of dies are used: closed and open.

Open ones have a gap of moving parts through which flash (excess metal) is removed. It is removed mechanically during final processing of the part. Open dies can be widely used for processing workpieces of various weights without placing special requirements on them.

Closed dies have no gap, so the metal remains inside the mold without forming flash. For such a process, it is necessary to carefully calculate the volume of the part.

- Sheet stamping.

It is used to produce products from a strip, sheet or tape of metal that was obtained by rolling.

In production, two types (groups) of operations are used:

- division - cutting, cutting and punching;

- form formation - spreading, drawing, embossing, flanging, bending, etc.

For sheet stamping, hydraulic and crank presses are used. The tool used is stamps with such basic parts as punches and dies.

The stamped product, as a rule, does not subsequently require mechanical modification. To do this, the dimensions of the punches and dies are carefully calculated in accordance with the technical requirements and only then put into production.

Sheet stamping is used in almost all areas of industry. This method makes it possible to produce parts with high precision. These can be small products for microelectronics, or car body parts. Cold processing of metals by cutting and pressing is extremely in demand.

Quenching, tempering and cold treatment

⇐ PreviousPage 8 of 30Next ⇒Hardening is a heat treatment process in which a part is heated to a certain temperature, maintained at this temperature and quickly cooled.

Parts made of hypoeutectoid steel are heated to a temperature 30-50 °C higher than the values corresponding to the GS line,

and hypereutectoid steel parts - up to a temperature 30-50 °C higher than the values corresponding to the

PSK

(Fig. 9).

The quality of hardening is greatly influenced by the cooling rate of the parts.

In practice, the cooling rate of heated steel varies depending on the type of cooling (hardening) medium, which is water and mineral oil.

Superficial

This is called hardening, in which the hardness of only the surface layers of parts increases, while the structure of the core remains unchanged. During surface hardening, the part is heated to the temperature of conventional hardening with a gas flame, an electric contact source, high-frequency currents or in an electrolyte. According to the heating method, hardening is divided into flame, electric contact, high-frequency and electrolyte.

During flame hardening

(Fig. 10) the surface layers of the part are heated with an oxygen-acetylene flame to the hardening temperature and then quickly cooled with a stream of water. Flame surface hardening is used to harden the surface of large parts made of steel and cast iron.

Electric contact hardening

subject cylindrical parts. The essence of this method is that an alternating electric current of industrial frequency (50 Hz), low voltage (2-6 V) and high strength (current equal to 400-500 A per 1 mm roller width). At the point of contact of the roller with the product, a large amount of heat is released, under the influence of which the surface of the product is heated to the hardening temperature. Cool the product with a stream of water directed at the roller.

Rice. 10. Scheme of flame surface hardening:

1 - product; 2

— oxygen-acetylene torch;

3 — tube for water supply; 4

- hardened layer

High frequency hardening

consists of heating the surface of a part with high-frequency currents (up to 100 kHz or more) in special electric inductors and subsequent cooling with water. High-frequency hardening is the most highly productive, economical and most common method of surface hardening of parts. It allows you to give parts higher mechanical properties than when hardening by other methods, and to avoid warping and oxidation of parts. In addition, with this method, the depth of hardening can be precisely adjusted.

Electrolytic hardening

consists of heating the surface of the part to quenching temperatures and cooling them in electrolytic baths. An aqueous solution of sodium carbonate, sodium hydroxide, sodium sulfate, etc. is used as an electrolyte. The hydrogen shell formed around the part has strong resistance to the passage of electric current and heats up to 1800-2000 °C. As a result, the surface of the part is heated to the hardening temperature within a few seconds. After heating, the current is turned off, and the part is cooled in this electrolyte or transferred to a special quenching bath.

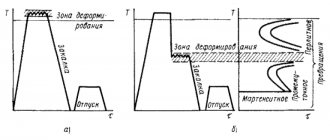

Tempering consists of heating hardened steel to a temperature below the critical Ac1

holding at this temperature and subsequent cooling (usually in air).

The purpose of tempering is to increase the toughness of hardened steel while maintaining a sufficiently high tensile strength, to reduce internal stresses after hardening and to obtain more stable (stable) structures. Tempering is applied to hardened steels with the structure of tetragonal martensite and retained austenite. Both structures are unstable and tend to transform when heated into a more stable state with a change in volume. At a temperature of 100-200 0 Stetragonal martensite forms the structure of cubic martensite (tempered martensite). At a temperature of 200-300 °C, retained austenite transforms into tempered martensite. Heating steel above 350 °C leads to the decomposition of martensite into a ferrite-cementite mixture.

Depending on the heating temperature of hardened steel, the following types of tempering are distinguished: low, medium, high.

Low Vacation

— heating of hardened steel to 250 °C to reduce internal stresses while maintaining high hardness. This tempering is used mainly for tools and products that must have high hardness and wear resistance, including cemented products.

Average vacation —

heating of hardened steel in the temperature range of 350-450

°C,

which leads to a decrease in hardness and an increase in the viscosity of steel compared to low tempering. In addition, a more stable microstructure of troostite and troostosorbite is formed. Medium tempering is used for springs, dies, springs, impact tools, etc.

High holiday

— heating of hardened steel in the temperature range of 450-650 °C, which helps to obtain the highest viscosity while maintaining a sufficiently high strength. As a result of this tempering, the hardness of the hardened steel is greatly reduced and a sorbitol structure is formed. In practice, hardening of machine parts for martensite followed by high tempering for sorbitol is widely used. This process is called improvement. Tempered sorbitol with a granular form of cementite has higher strength and viscosity than quenched sorbitol with a lamellar form of cementite.

Cold treatment - tempering at temperatures below zero. It consists of processing hardened products with cold at temperatures of the order of 80 ° C and below. Cold treatment is based on the fact that retained austenite, located in the structure of hardened steel at low temperatures (about 80°C and below), disintegrates as a result of the occurrence of internal stresses. This method increases the hardness of the cutting tool, stabilizes the dimensions of measuring instruments, etc. In industry, special installations are used in which liquid oxygen (-183 ° C), liquid nitrogen (-195 ° C), and a mixture of solid carbon dioxide (dry ice) are used as coolers. with denatured alcohol (-78.5 °C).

Non-metallic materials.

The rapid development of all industries, as well as increasing the reliability and quality of manufactured machines and products, required the creation of new materials. Non-metallic materials - plastics, rubber, glass, wood, etc. are used in almost all industries. The widespread use of non-metallic materials in mechanical and instrument making is due to their valuable specific properties.

Plastics are characterized by low density, relatively high mechanical strength, high chemical and corrosion resistance, and good dielectric properties. Plastics are the most important structural materials of modern technology. They are used in mechanical engineering and instrument making not only as substitutes for ferrous and non-ferrous metals, but also as independent engineering materials. As a result, saving a large amount of expensive non-ferrous metals is achieved, increasing the durability of parts working under friction and in aggressive environments, reducing the weight of products and machines, and reducing the labor intensity of manufacturing parts.

Plastics

Plastics are high-molecular synthetic materials of organic origin obtained from natural or synthetic resins (polymers). Almost all plastics have low density (0.9-2.3 g/cm3). By using plastics, the weight of structures can be significantly reduced. On average, they are 5-6 times lighter than ferrous metals and copper-based alloys. Many plastics are characterized by high strength, good anti-corrosion properties, water resistance, non-flammability, etc.

In addition to natural or synthetic resins, called binders, plastics include fillers, plasticizers, dyes, lubricants, hardening accelerators, etc.

Binders

connect the components of plastic and determine its basic properties.

Natural resins exist in finished form (amber, copal, shellac, etc.) or are formed by simple processing of natural raw materials (asphalt, bitumen, etc.)

Synthetic resins are obtained from waste gases of coke production, natural gas, etc. Synthetic resins include polystyrene, polyethylene, polyvinyl chloride, phenol-formaldehyde resins (phenoplasts), urea and melamine-formaldehyde resins (aminoplastics), etc.

Depending on the production process, a distinction is made between polymerization resins, obtained by combining simple low-molecular substances (monomers) into high-molecular substances (polymers) without releasing any substances, and polycondensation resins, obtained by combining simple dissimilar monomers into polymers with the release of by-products : water, ammonia, hydrogen chloride, etc. Polymerization resins include polyvinyl chloride, polystyrene, polyethylene, etc., polycondensation resins include phenol-formaldehyde, urea- or melamine-formaldehyde and other resins.

Fillers

improve the physical and mechanical properties of plastics and reduce the consumption of more expensive binders. According to their structure, they are divided into powder, fibrous and layered. Powder fillers include: wood and quartz flour, ground mica, etc.; to fibrous - flax, fibrous asbestos, fiberglass, etc.; for layered ones - cotton fabric, paper, foil, wood veneer, fiberglass, asbestos fabric, etc.

Plasticizers

improve ductility, increase flexibility and reduce brittleness of plastics. They do not enter into a chemical combination with binders, but dissolve them. These include: camphor, dibutyl phthalate, etc.

Dyes

Give plastics the necessary color. They must be resistant to temperature, not change color in atmospheric conditions, color materials well and not react with them. Nigrosin, minium, etc. are used as dyes.

Lubricants

substances facilitate the pressing of plastics, preventing them from sticking to the walls of the mold. These include stearin, wax, paraffin, etc.

Accelerators

hardening promotes rapid hardening of plastics. These include dimethylaniline, cobalt naphthenate, manganese naphthenate, etc.

Plastics are classified according to various criteria. Depending on the changes they undergo when heated, plastics are divided into thermosetting and thermoplastic. Thermoset

When heated and under simultaneous pressure, plastics first soften and partially melt, and then turn into a solid and insoluble state.

Products made from these plastics cannot be recycled. Thermoplastic plastics

soften when heated, harden when cooled, and are suitable for re-softening. Products made from these plastics can be recycled.

Based on their mechanical properties, plastics are divided into rigid, semi-rigid and soft. Hard

plastics have an amorphous structure, high hardness and elasticity, but low ductility.

Semi-rigid

plastics have a crystalline structure with amorphous areas, fairly high hardness, elasticity and ductility.

Soft

plastics have a crystalline structure, high ductility, but low hardness. These are soft and elastic materials.

Based on the number of components included in plastics, they are divided into simple and complex. Simple

Plastics are made up of natural or synthetic resins (polymers).

To improve their physical and mechanical properties, plasticizers are sometimes added to them. Simple plastics include, for example, polystyrene and polymethimethacrylate. Complex

plastics consist of binders, fillers and plasticizers. Other substances are introduced depending on the nature and purpose of the plastic. Most of them are complex.

According to their purpose, plastics are divided into the following groups:

1) structural

— intended for the manufacture of structures and machine parts;

2) decorative and finishing

and

facing

- intended for decorative finishing and cladding of structures;

3) electrical insulating

— have good dielectric properties, they are used as electrical insulating materials;

4)anti-corrosion

— have increased chemical resistance in corrosive environments, used as anti-corrosion materials;

5)anti-friction

— have a low coefficient of friction, used for the manufacture of sliding bearings;

6)friction

— have a high coefficient of friction, used in braking devices;

7)sound

and

thermal insulation

- they have the ability to conduct sound and heat poorly and serve as sound and heat insulating materials.

Based on their chemical nature, the main plastics are divided into the following types: polyolefins, styroplasts, fluoroplastics, polyvinyl chlorides (polyvinyl chlorides), polyacrylates and polymethacrylates, phenolics (polymethylenephenols), polyamides, celloplasts, etc.

⇐ Previous8Next ⇒

What makes your dreams come true? One hundred percent, unshakable confidence in your...

System of Protected Areas in the USA The study of specially protected natural areas (SPNA) in the USA is of particular interest for many reasons...

WHAT HAPPENS IN ADULT LIFE? If you are still connected to your mother in the wrong way, you are avoiding separation and independent adult existence...

What does the IS operation and maintenance department do? Responsible for the safety of data (copying schedules, copying, etc.)…

Didn't find what you were looking for? Use Google search on the site:

Pros and cons of cold metal working

Let's look at the benefits first:

- The metal's ductility and strength limits increase.

- The hardness of the material increases while ductility decreases.

- Surface quality increases, as do dimensional tolerances.

- The hardness of materials whose structure cannot become stronger during heat treatment increases.

However, there are a number of disadvantages:

- Cold working is used exclusively when working with ductile metals, such as mild steel.

- Residual stresses resulting from processing are unfavorable for the metal, as it can become brittle. To restore plasticity, it is necessary to anneal it.

- The manifestation of fragmentation and distortion of the grain structure of the metal is likely. Correction requires heat treatment.

- Cold processing is easy to use for small-sized products, while large workpieces require a lot of labor, time and energy.

Cold processing of steel

Cold treatment consists of immersing hardened parts for some time in an environment with a temperature below zero. After this, the parts are taken out into the air.

The holding time during cold treatment is determined by the time required to completely cool the entire part and equalize the temperatures across the cross section.

Cooling of the product to negative temperatures is carried out in a mixture of solid carbon dioxide (dry ice) with alcohol, which gives cooling to -78.5°, or in liquid nitrogen (-196°).

In addition, refrigeration units are used that make it possible to change the temperature of the working chamber within wide limits.

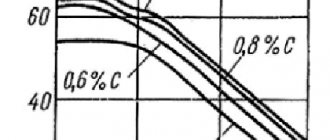

Cold treatment is used for steels in which residual austenite remains after quenching (carbon steel containing more than 0.6% C, alloy tool steel).

The result of cold metal processing

As a result of cold processing, due to the transformation of retained austenite into martensite, hardness and wear resistance increase, and therefore this type of processing is used in the manufacture of tools.

In addition, cold processing stabilizes the dimensions of parts, and therefore this treatment is used for measuring tools and precision machine parts

Heat treatment defects

Metal defects arise as a result of an incorrectly selected or incorrectly carried out heat treatment mode. The most common defects are: overheating, burnout, decarbonization of the surface layer.

Overheating is the heating of a metal to a temperature exceeding the critical temperature. Overheating causes increased growth and a sharp decrease in the strength properties of the metal. Increased grain growth can also occur in the case of annealing at a given temperature, but subject to an increase in its duration.

Burnout is the heating of metal, causing oxidation of grain boundaries and loss of plastic properties. Overburning is an irreparable defect. Decarburization of the surface layer is a metal defect that occurs during heat treatment in the presence of an oxidizing atmosphere in the furnace space. In this case, the carbon that is part of the steel* burns out and grains of pure iron—ferrite—are formed on the surface of the steel. This leads to a decrease in the strength properties of the surface layer. The depth of the decarburized layer is determined by metallographic analysis of the microstructure of the metal sample.

A little about chemical processing of metal

It’s a bit of a stretch for experts to classify chemical processing as cold work. Before painting or to obtain any effect, metals are treated with various compounds. One of their main diseases is rust. It significantly worsens the properties of products, so it is important to prevent or remove any signs of corrosion from metal surfaces.

Chemical treatment is a process that is designed to help remove the surface layer using chemical reactions and then protect the metal from rust. There are solutions that help form oxide (or other) compounds. As a result, a film is formed on the surface, the quality of which depends on the processing temperature, the chemical composition of the product and the period of its exposure, as well as on how well the product was prepared for this procedure.

Chemical treatment is used to increase strength, protect against rust, and therefore increase the service life of the product.

There are a number of chemical treatment methods. Let's highlight the main ones:

- Spraying the solution - occurs at low pressure of the jet of the substance with which the metal is treated.

- Immersion in solution - the product is placed in the active substance for a certain period of time.

- Hydroblasting with a solution - occurs only with the use of appropriate equipment.

Deep etching or chemical milling is used in metallurgy, mechanical engineering, etc. for products that are made of thin material whose surface has a complex configuration, or when processing many small products.

There are other methods. For example, galvanizing, oxidation, fluoridation, nitriding, anodizing, chrome plating, bluing, etc. Science does not stand still; new methods of chemical processing are appearing every day.

Occupational safety during cold metal processing

During cold processing, workers may be exposed to harmful and sometimes dangerous factors. This may be high voltage of the electrical network, moving parts of units and equipment, movement of mechanisms and machines, etc. The cause of most industrial accidents that occurred during work on metal processing equipment is its complete or partial non-compliance with safety requirements.

All moving parts of machinery that could cause injury should be guarded or located so that they cannot be touched by workers. It is also possible to use other methods of protection, for example, the use of two-handed control.

There are types of equipment in which it is impossible to fence (or use other means of protection) the places where the employee is likely to come into contact with the moving elements of the units. In this case, the structure must be equipped with an alarm that turns on simultaneously with the start of the machine. Additionally, various safety signs and hazard-signaling colors can be used. Emergency buttons or other means of emergency stopping of equipment should be installed near moving parts that are not visible to the employee. This should be done when workers are in dangerous proximity to moving parts of the installation.

However, it is necessary not only to comply with the requirements for safe operation of equipment, but also to properly organize the workspace. All workplaces should be located so that lines for transferring loads by lifting units do not pass over them.

Workspaces must be equipped with platforms on which tables, racks, containers and other storage facilities for materials and workpieces, equipment and semi-finished products, as well as waste and finished products are located. Specialists involved in technological operations and observing the rules of cold metal processing should be able to work as conveniently and safely as possible.

Wooden ladders ≥ 60 cm wide from protruding elements of the equipment must be located along the floor along all equipment.

Storage of blanks and finished products should be carried out in specially designated areas - work surfaces should not be cluttered. All parts must be installed thoroughly, ensuring easy mooring when using lifting equipment. Stacks cannot be higher than 100 cm. Aisles should always be left clear.