Understanding the terminology

In general, everything here is not as difficult as it might seem. What these materials have in common is the presence of a pattern, but their manufacturing technologies differ radically. The legendary Indian damask steel is, unfortunately, a lost technology: it was once passed down orally and was so carefully hidden that it was completely lost several centuries ago. The production of damask steel was not cheap, and already in the 17th century, affordable and sufficiently high-quality industrial steel began to appear, so the demand for damask steel fell and then completely disappeared. Everything we know about it (partly thanks to history, partly thanks to the experiments of the Russian metallurgist Pavel Petrovich Anosov) fits into a couple of phrases - damask steel was exceptionally strong, sharp and, of course, legendaryly beautiful. In Rus', damask steel was often called kharalug (horolug), or kharaluzhnaya (horoluzhnaya) * steel, although in fairy tales we often encounter the term “damask steel” itself.

* You can find one or the other spelling. Perhaps the option taken out of brackets would be more correct, since, firstly, it is precisely this one that is found in ancient sources, in the same “Tale of Igor’s Campaign”, and secondly, it preserves the letter “a” in the common Turkic root “hara” /“kara” (“black”).

By the way, about fairy tales and epics. They attribute almost magical properties to damask blades, but it is wrong to think that this is some kind of non-existent, fairy-tale metal. In fact, damask steel was simply the best option for its time. Practical tests of even the best samples that have survived to this day show properties close to ordinary inexpensive carbon steels of modern manufacture. However, in the Middle Ages, the bulk of blades were made from such low-quality raw materials that even such properties seemed mystical and magical to contemporaries.

At one time, Anosov, in the first half of the 19th century, managed to create an alloy that fully met all the characteristics of damask steel. Although, of course, we cannot know for sure how similar the technology and composition discovered by our metallurgist are to the “original”. The fact is that there were several technologies for producing damask steel even in ancient times: it is not known for certain whether Anosov recreated one of them or came up with his own.

The damask steel blade of the Turkish saber is what we call historical damask steel

And now we come to the actual clarification. Historically, there were two main technologies for producing patterned steel. One of them involved casting, the other involved welding and forging several types of steels together; the first retained the name damask steel, and the second began to be called damask.

So:

- Cast damask steel is patterned steel in the historical sense we are familiar with, produced by casting and forging methods.

- Welded damask steel (or Damascus) is patterned steel produced primarily by forging methods.

High-quality weapons were made from special “damask steel” ingots called wootz. It was the beauty of the damask pattern that was associated with its magnificent properties. But wootz was expensive and difficult to produce, which spurred the search for technologies for creating patterned blades by alternative means. What is now called Damascus began to be produced specially, by folding and forging several layers of blanks from different types of steel. The new material was not inferior in strength to damask steel, and in appearance it turned out to be much more beautiful than cast damask steel.

Now, a little more about the types of damask steel and types of damascus - we will make this division because we classify materials according to different principles: regarding damask steel, we will talk about the alloying elements in its composition, and regarding damascus, we will also talk about several technologies.

Application area

When exclusively edged weapons were used on the battlefield, damask steel was highly valued.

Only wealthy warriors could afford a blade made of such material. Today, damask steel is used in the production of blades, mainly for collectible edged weapons. The popularity of damask steel is primarily associated with the rather unusual pattern that is obtained on the surface of the metal. Damascus steel is not widely used in other areas of industry This is due to the fact that it is significantly inferior to alloyed compounds in almost all respects. In addition, the complexity of manufacturing the metal increases its cost.

Types of cast damask steel: high-carbon and stainless alloys

One more important note about damask and damask that is worth making right now. In their chemical composition, they most closely resemble the high-carbon steels we are used to, but with a very heterogeneous composition, and this means both increased strength and toughness, and susceptibility to rust. Carbon and stainless steel, as we know, are not just two steels with different compositions. The difference is rather vague - the whole point is whether the material contains alloying elements that increase the corrosion resistance of steel, and in what quantities.

So, normally damask steel corresponds to what we call carbon steel, but a modified chemical composition (adding a significant amount of chromium - from 14% or more) while maintaining the physical structure gives us the so-called stainless damask steel. It retains the properties of strength and hardness inherent in ordinary cast damask steel, and products made from it are almost as easy to sharpen. But a product made from it, like any hand-forged product, is incredibly expensive.

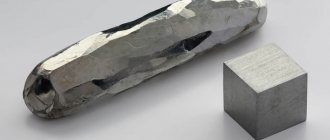

On the left is ordinary cast damask steel with a high carbon content; on the right - a stainless steel composition with conventional damask steel casting technology

Main types of knives and scope of application

Damask steel is used in the manufacture of the following types of knives:

- all-metal,

- with fixed blade,

- folding.

As for the scope of application, the models can be divided into knives for hunting, fishing, tourists, and military. Throwing models and collectible weapons stand separately. Knives for collectors can be very expensive - valuable wood, precious stones, metals, natural horn are used to make them, not to mention the manual work on each knife.

Eight types of welded damask steel (damascus)

With Damascus, everything is much more interesting: there are at least eight varieties of welded damask steel, also known as Damascus. Before we get to them, it's worth making a quick note.

In principle, it is possible to create stainless Damascus. To do this, you need to assemble a package of steel alloyed with the necessary additives and start welding it in a vacuum, laying it in layers and unforging it, and then repeating this cycle again. Technically, this is quite difficult, but modern technologies successfully cope with the task, as exemplified by chef’s knives with patterned stainless steel linings.

Kanetsugu kitchen knife from the Tojiro range with patterned steel handles

"Wild" Damascus

This is the same damask that is obtained if the master does not use special tools and technologies, that is, if the process occurs naturally. Sheets of steel with different chemical compositions are folded together, welded and unforged; then they are cut in half, folded again, and all actions are repeated. The result is layered steel. If its forging does not have a clear plan, then the pattern turns out disordered, or “wild”.

“Wild” and simple damask are two subtypes of the technique, which has no characteristic features, but is the usual overlay of layers on top of each other, followed by free-style forging

Stamp Damascus

When making this type of patterned steel, the blacksmith uses a tool called a stamp: thanks to it, a beautiful pattern appears on the surface of the layered Damascus plate, not very reminiscent of the pattern on plain Damascus. Depending on the stamp's pattern, it may resemble a ladder, the growth layers of a tree cut, the surface of water in the rain, or a combination of these patterns.

Stamp Damascus is produced using a special tool - a stamp.

Mosaic Damascus

Mosaic damasks are often distinguished not only by the technology of forging, but also by the composition itself - the package is assembled in the manner of a mosaic from steel blanks of different shapes and compositions so that as a result of overlaying and forging, such a characteristic pattern is obtained.

The mosaic on the surface of this type of Damascus is the “merit” not of technology, but of the correct selection of steel package

Mosaic Powder Damascus

One of the most difficult types of damask; a technology that is rarely practiced in Russia.

To create a blade like the one in the photo, you need to prepare a cliche with a certain slotted pattern made of steel. Then the cliche is filled with powdered steel, which, when etched, will contrast with the base, and under the influence of high temperatures and pressure it turns into a monolith. Now from this ingot it is possible to forge a blade using conventional technology, welding or alternating patterned layers with each other.

Powder mosaic damascus is a rare phenomenon in Russia

Twisted Damascus

Twisted Damascus, also known as Turkish, is created by twisting a piece of several welded rods around itself. The pattern will depend on the number and composition of steels in the original package, the angle of twist and the depth of the cut. As with mosaic technology, from the resulting “twist” you can then unforge a blade using conventional technology, welding or alternating patterned layers with each other.

Twisted Damascus (aka Turkish) gets a characteristic pattern when the blacksmith twists the workpiece several times during the forging process

Mosaic end damascus

The technique for making this type of damascus is somewhat different from others. A patterned mosaic of parts of various shapes and different steels is applied to a blade made of homogeneous steel. Then the workpiece is boiled under a vacuum press. Thus, no folding or torsion is used in its manufacture. When a fully forged block is ready, the plates that previously served as the basis for assembling the mosaic are cut off from it.

The side covers of such damascus are sections from a finished forged block

Fiber Damascus

Another foreign method of forging Damascus. Its composition is no different from the standard one, and neither is the beginning of unchaining. But about halfway through the process, the blacksmith turns the workpiece 90 degrees and begins to unforge it again. This is how characteristic “short” (compared to ordinary) divorces are obtained.

The short “fibers” of this type of damascus are the result of a special technique where the blacksmith turns a half-forged piece and starts all over again.

Multi-row Damascus

This is a view, rather, not of a material, but of a finished product, that is, a blade. Strips of damask of different designs (mosaic, twisted, etc.) are placed side by side and forged together in order to create a visually impressive combination of patterns. The composition and manufacturing technique of these strips often differ: closer to the cutting edge, a durable and sharp type of damascus is placed, and closer to the butt, a durable and tough type with especially beautiful patterns is placed.

It is more correct to call the blade itself multi-row, not Damascus

What to look for when choosing

To remain completely satisfied with the purchase of a damask steel knife, you need to pay attention to:

- A chaotic drawing on a dark background - lines and dots should be clear and large, but not symmetrical. Smooth and symmetrical lines are a characteristic of cheaper Damascus steel.

- The ringing of monolithic damask steel is clear and long. If the blade is not solid (layers, fluctuations of various types), the sound will be low and short.

- A responsible manufacturer always indicates the purpose of the blade - the dimensions and parameters must match. The hunting blade is longer, the fishing and tourist blade is shorter, with a folding design.

- The assembly must be of high quality without gaps, burrs, etc.

- Documentation - warranty card, certificate (confirmation that this knife is a non-bladed weapon).

- Case/case.

Sharpening features

Damask steel is extremely strong, so sharpening it at home is not easy. It's better to entrust it to a pro. Such blades are sharpened with diamond stones, or a hard stone can be used. As for the sharpening angle, you should stick to 30-45 degrees, the thickness of the edge should not exceed 0.5-1 mm.

Sharpening a damask knife.