How do you know when it's time?

There are many factors that indicate that it is time to clean your well. In order to achieve the best results when performing this work, it is important to know the cause and root of the problem. There are several signs:

- unpleasant odor;

- color;

- the presence of impurities, etc.

The most common problems:

| Problem | Consequences and causes |

| Silting | As a result, the liquid becomes cloudy. Clay and sand deposits are observed at the bottom |

| Oil film | Sign of petroleum products. The reason may be depressurization of the mine |

| Rusty water | This is explained by the large amount of iron in the liquid. |

| Bacteria | When water from a source is rarely used, bacteria grow in it. The cause may be household waste that has fallen into the mine, such as animals/birds, etc. |

| Unpleasant smell | One of the reasons is sewage infiltration |

| Green water | The cause may come down to algae. Germinate when exposed to large amounts of sunlight |

| Muddy water | In most cases, the reason for this is a failed bottom filter. |

Cleaning is also required when you notice a decrease in the fluid level. In almost all cases, this work can be done independently, without the involvement of specialists.

Causes of pollution

The main reason for changes in the quality of produced water is the infrequent use of the facility. The bottom becomes covered with silt, the liquid becomes brown and has an unpleasant odor. Clogging can also occur for some other reasons.

Poorly closing lid of the structure

You need to open the well only before extracting water. At other times, the water pump must be covered, otherwise fallen leaves, debris and dirt will enter the tank. The cover also protects the structure from ultraviolet rays, which accelerate the growth of aquatic plants.

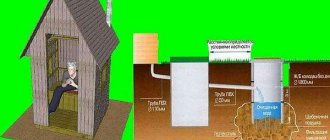

Improperly made melt water seal

This part of the system is a waterproof layer laid around the perimeter of the upper concrete element. The normal thickness of the seal is at least 0.5 m. If the clay blind area is not properly arranged, melt water containing animal feces, soil and dirt will penetrate into the well.

Seam rupture.

Seam rupture

Even if the joints between concrete rings are sealed well, freezing of the soil leads to the formation of gaps. Through the resulting defects, groundwater containing foreign inclusions and runoff penetrates into the well. Filling the gaps with a concrete solution containing liquid glass helps prevent tank contamination.

Offset of rings of the structure

The divergence of the elements of the lower part of the structure occurs due to the movement of soil layers. The upper rings move as a result of soil freezing. In the first case, the gaps are repaired using a cement mixture, in the second, the parts are tightened with thick wire and pins.

How often will it be correct?

Ideally, once a year. The spring season is predominantly chosen.

Advice : even if you don’t experience any of the signs listed above, preventive cleaning will get rid of possible problems.

Regardless of whether you carry out preventive maintenance or routine cleaning of the source, it should be done on time, when the snow has completely melted. Otherwise, there is a risk that the drained liquid will return to the source through the high water.

When it's time to clean the well

The following signs indicate the need for cleaning:

- the appearance of an unpleasant taste and odor in the produced water;

- change in the color of the liquid, the appearance of foreign inclusions;

- the formation of soft plaque on the walls of the structure;

- drop in pressure and rate of water flow into the well.

Water quality must be assessed at least once every 12 months. The procedure is carried out in spring or autumn. Water testing for the presence of harmful inclusions is carried out in specialized institutions. The yellow color of the liquid indicates an increase in iron content, green indicates increased proliferation of microorganisms.

Methods for cleaning a mine in a country house from silt and dirt

There are two main methods:

- To go down.

- Don't go down.

In the first case, serious precautions must be taken to complete the work. But you can achieve a better result, because you can really see what is happening at the bottom of the source.

The second method is a safe method. To solve the problem, special pumping and other equipment is used.

Carelessness can be fatal for a worker. There are a number of measures you should definitely take:

- You should not do the work yourself: at least three people.

- When descending into a mine, a safety rope attached to the belt must be used.

- Before starting, make sure there are no gases.

- If tools fall from above, the worker below must press as tightly as possible against the wall. Moreover, work should be carried out wearing a protective helmet.

- It is unacceptable to stand at the bottom of a well at one point for a long time.

- You should not cleanse those who have heart problems.

- The ladder used must have a platform at the bottom and be securely hooked to the top with a rope.

- Use reliable equipment, including a bucket, rope, etc.

Manual cleaning: what needs to be prepared?

Prepare the following tools, materials and clothing in advance:

- Safety rope.

- A long staircase. Instead, you can use a rope swing with a board tied at the bottom.

- Durable bucket.

- Metal brush.

- Cable for lifting a bucket.

- Cable for lifting and holding a ladder.

- Slings.

- Drum for raising water.

- Winch.

- Rubber boots.

- Helmet.

- Protective waterproof overalls.

A complete set of everything you need will allow you to carry out the work quickly and efficiently.

The process of cleaning a mine made of concrete rings with your own hands

Let's take a closer look at how to do this correctly, without using a pump. All work consists of several successive stages, such as:

- Pumping out.

- Inspect and clean the bottom filter.

- Analysis and repair of joints between reinforced concrete rings.

- Mine cleaning.

The first step is to solve the pumping problem. The easiest way is to use a pump. If it is missing, then pumping is done with buckets. A very long and labor-intensive process. In the latter case, a winch and a drum are installed to lift the buckets.

Advice : this work should be done one at a time, because one person will be under a serious load. It is important to reach the conveyor so that the liquid is continuously pumped out.

You can pump out liquid with a pump within a couple of tens of minutes, but the same work using buckets will require several hours.

The next step is cleaning the walls of the shaft. Lower the ladder into it and secure it. You need to start working from top to bottom.

For cleaning, a metal brush or some kind of scraper is used; some use a hoe. Very convenient as they have a long handle.

Having cleaned the walls of the shaft, it is necessary to begin cleaning the bottom of the well. First, sand, silt, dirt, etc. are scooped out using buckets. Once you fill it, you give a signal to remove it. Gradually the bottom will be cleared of silt and other contaminants. The condition of the bottom filter must be checked. If necessary, it can be replaced or the existing one washed.

The condition of each seam between the reinforced concrete ring should be inspected. If there are cracks or the existing mortar is peeling off, then you should completely remove the old putty, prepare a new mortar and seal the joints with it. Also, everything is covered with a waterproofing material, which is allowed in direct contact with clean water.

At the end of the work, the entire mine is disinfected. You can use ten percent bleach and a bucket of water. Having mixed them, you simply coat the walls with this composition. In this way, disinfection occurs, and all existing microorganisms will simply die out.

Sand well pump

High-performance centrifugal pumps of the Grundfos type are not suitable for sand wells - a uniform, powerful flow of pumped water will not only quickly drain a low-yield well, but will also pull a large amount of sand to its water intake part, reducing the flow rate.

vibration pumps "Baby" type

The most suitable pump for a sand well is the much less efficient “Malysh” vibration pump. Such a pump, unlike the centrifugal Grundfos, is less sensitive to solid particles entering the mechanism. In addition, the constant vibration of the “Malysh” pump regularly shakes the mesh filter, knocking off stuck particles and clearing the way for water.

The internal diameter of the strainer must be no less than the internal diameter of the casing pipe. In this case, the pump can be lowered directly into the water intake area. As a result, the vibrations emanating from the mechanism will better clean the filter mesh.

How to clean clay without going down into it?

A special self-priming pump is used. Difficulties may arise when performing work, as layers of gravel, sand, and crushed stone form at the bottom. If the well is not cleaned in a timely manner, these layers will become compacted among themselves. A high-power pump is required that can quickly pump out liquid.

Important : if you use a weak pump, you can provoke even greater contamination of the well. Moreover, the device itself will simply burn out under heavy load.

The work begins with the following:

- Lower the pump to the bottom for cleaning.

- It dives to a distance from the bottom to one meter, maybe half a meter.

- Then the pump turns on and the dirt is pumped out.

- Afterwards, the liquid from the pump should be directed back into the shaft. The jet will break up all sediments at the bottom.

It is extremely important to lift the device to the surface from time to time in order to clean the filters. The process is repeated until clear liquid comes out or until no large inclusions remain.

Before disinfecting water in a well, you can take it to the laboratory for testing.

Tip : You can use a clamshell bucket to automate the process.

Features of using a grab bucket

A grab is a structure consisting of two buckets. In the center they are connected by oblong-shaped hinge levers. A chain or cable is attached to the edges of the buckets, which will pull to close the grab bucket. It will be good if it is light in weight.

Using a grab bucket completely eliminates the need to go down into the mine yourself. Its use will allow you to lift silt, sand and other dirt from the bottom of the source. The work can be done virtually alone, but it will be easier with assistants.

Before using it, the liquid must be completely pumped out. Then the work is carried out in the following sequence:

- The grab bucket is suspended by a cable.

- During descent, silt is captured (due to its falling under its own weight).

- Then pull the cable and the buckets will close. A locking ring is installed to prevent them from opening when lifted.

- Next, the grab is lifted by a cable to the surface.

- The buckets open. All trapped silt, sand and the like are removed from them.

This tool is considered optimal for cleaning the bottom of a well.

When to clean a well

There can be a lot of reasons for contamination of a well, depending on how it is used, whether it is open or with a house, what kind of soil is on the site, etc. We will list you some of the most common causes of pollution:

- Silting of the well due to infrequent water intake;

- Remains of insects, frogs, mice and other living creatures that accidentally fell into the well;

- Colonies of mushrooms growing in a well due to dampness;

- Buckets, chains and other metal and plastic objects that were accidentally dropped into the well;

- Wooden panels rotted from time to time at the bottom of the well (most often made of aspen).

These are just some of the reasons for well contamination, due to which the quality of water deteriorates and wells become unusable. For our part, we recommend cleaning the well at least once every few years (2-3 years). This is not so expensive, but you will always know that the water in the well will not unexpectedly disappear and will be clean. Timely cleaning of the well will allow you to avoid the cost of digging a new well in the future.

The health of those who use it for drinking depends on the purity of the water in the well. If you live in your house all year round and constantly use a well to collect water (drinking, watering, filling a pool, etc.), then the water is updated quite often, which is good. However, most often wells are used only in the summer season, that is, when people arrive at their dacha. In the second case, cleaning the well will be required faster than in the first, since the water in the well is renewed very rarely. If you do not live permanently, then the water may simply become silted and will no longer be suitable for consumption. Also, siltation of a well can directly affect the water level, as silt will clog the water channels at the bottom of the well.

But those who use water from a well constantly should not relax, since here, too, periodic cleaning of the well is still advisable. It is precisely needed so that there are no unpleasant surprises with the appearance of various contaminants in the water or a drop in the water level, without which normal daily life is not possible.

How is a well cleaned?

Determining the cost of well cleaning services over the phone is quite difficult, since visually we cannot see the level of current contamination.

For a rough estimate of the cost, you can email us a photo of the inside of the well, but in practice you need to go down into it to see the whole picture. Therefore, it is better to check its condition on the spot. The main stages that are carried out during well cleaning:

- Pumping water from the well, if there is any in it;

- Inspection of the well shaft and its bottom, searching for faults and causes of contamination;

- Removal of bottom sediments, that is, cleaning the bottom of the well;

- Washing the walls of the well using a high pressure washer;

- Well bottom filter device;

- Disinfection of the well using special means (at the request of the customer).

- Installation of a good well house to protect the well from precipitation, insects, etc.

Just a few steps and we will put your well in perfect order, and you will again enjoy your natural water

It doesn’t matter to us in which district of the Moscow region the well is located, because we are a mobile team of well workers and we come to any district, be it Chekhovsky, Serpukhovsky, Odintsovo, Naro-Fominsky, Dmitrovsky, Zaoksky and any other. Below on the map you can see where we have already worked and what our work looks like

Disinfection, cleaning products

There are several disinfection methods that can be used to disinfect water in a well.

White

The volume of whiteness should be calculated based on one can per ring. After treating all the walls of the shaft with this solution, you should leave it for a day. The head must be covered with plastic film.

Tip : When disinfecting a home well using bleach or chlorine, be sure to buy protective gloves and a respiratory respirator.

After a day, all accumulated liquid should be pumped out. If necessary, you can pump it out several times during the week.

Potassium permangantsovka

Simple potassium permanganate will allow for high-quality disinfection of country wells with drinking water. One tablespoon of potassium permanganate is needed per bucket. Dilute it by mixing thoroughly. Pour the entire product into a source to clean it of bacteria. Afterwards you need to wait about two hours, closing the head. After the time has passed, pump out the water. You can pour it into the garden; this composition will be beneficial for the soil.

Bleaching powder

If the liquid in the source has been contaminated with bacteria or contaminated with organic matter, then a bleach solution is used. One liter of water requires 20 milligrams of bleach.

Coloration of water due to rock characteristics

Ideally, drinking water should be clear, but when passing through several layers of soil, it can be filtered or dissolve various substances. From iron it becomes reddish, from limestone it becomes white, peat bogs give it a brownish color.

In addition to tint, impurities can add fatness to water, an unpleasant odor and taste, and form a film on the surface. After checking the chemical composition, you can select special filters and water treatment systems that will improve the quality of the water, making it suitable for drinking. Carbon and pressure filters are used to remove organic matter.

There is no need to worry if the water remains cloudy after cleaning. Any work inside the shaft disrupts the internal balance of the well. It is simply impossible to remove all soil particles from the bottom. The water will settle and calm down for several weeks.

Preventative work

It is recommended to do this up to three times a year: in winter and at the end of summer, when the liquid level drops, but provided that the source is used intensively.

Potassium permanganate, iodine, or another drug described above can be used as prophylactic agents. Some tablets may also be used. But for this you need to read the instructions for their use.

What is the price?

If you are unable to cope with the task, you can contact specialized companies. Approximate prices in rubles:

- cleaning a mine up to five rings deep - about 5 thousand;

- repair and sealing of one seam - about 300;

- waterproofing one seam - about 300;

- source pumping – about 2.5 thousand;

- disinfection with manganese – about 3 thousand.

In any case, the cost will be determined individually, because each case is unique (region, distance from the city, etc.). You can focus on these prices before contacting specialists. As for the work guarantee, it is approximately one year. This is true if the source is not used so intensively. If it is the main source of water, you will have to clean it twice a year.

How to eliminate and prevent siltation of a well

Everything described above indicates an existing malfunction, and you need to deal with it, and not with the consequences. You can read tips on how to clean a well from sediment with your own hands, how to rinse it of sand, or call a drilling crew, they will come and clean it. This will restore the original depth, but after a while the situation will repeat itself. Your well will forever become clogged with sand until the cause is eliminated. Cleaning a well with your own hands is quite dangerous, because you can drop something, it will get stuck there, and you will have to pay the drillers 30,000 rubles to come out and try to get this thing. Just an attempt, no one will guarantee that you will be able to get it, but you will have to pay money for wasting time and moving equipment.

- A working well does not require cleaning throughout its entire service life!

It is useless to clean the well; neither citric acid, nor a compressor, nor anything will help you; repairs are required here.

To eliminate siltation , you need to call the drillers, they will come, establish the cause, casing, cementing, covering... It is expensive, takes a lot of time, and not all drilling crews will agree to take on this work.

Not every company has the necessary experience or is willing to spend time on it. They would rather drill a well somewhere and earn more money. There is no point in restoring shallow wells; it is cheaper to drill a new one. Preventing siltation is very simple - you don’t need to order drilling from companies that bought a drilling rig yesterday, wrote customized reviews, and today they are “experienced craftsmen with 10 years of experience.” Unfortunately, there are a lot of them.