Temperature selection for hardening

The decision at what temperature to harden the metal is determined by the chemical composition of the steel.

There are two types of hardening:

- full;

- incomplete.

Based on the diagram of critical points, one can see that hypoeutectoid steel during the process of complete hardening should be heated above the Ac3 point by 30–50 degrees C. As a result, the steel will have a homogeneous austenite structure. Subsequently, under the influence of the cooling process, it will turn into martensite.

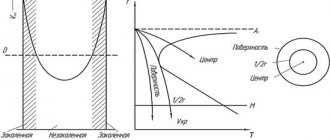

Figure No. 1. Critical points .

Incomplete hardening is more often used for tool steel. The purpose of incomplete hardening is to reach a temperature at which the process of formation of excess phases takes place. Heating of steel occurs in the temperature range from Ac1 - Ac2 . At the same time, some amount of ferrite remaining after hardening of the steel will remain in the martensite structure.

To harden hypereutectoid steel, it is better to maintain a temperature 20–30 degrees higher than Ac1 - incomplete hardening. Because of this, cementite will be retained during heating and cooling, which increases the hardness of martensite. When hardening, hypereutectoid steel should not be heated above the specified temperature. This may affect hardness.

Methods of hardening steels

In practice, various cooling methods are used depending on the size of the parts, their chemical composition and the required structure (diagram below).

Diagram: Cooling rates for different methods of hardening steels

Continuous hardening of steel

Continuous hardening (1) is a method of cooling parts in one environment. After heating, the part is placed in a quenching medium and left there until completely cooled. This technology is the most common and is widely used in mass production. Suitable for almost all types of structural steels.

Hardening in two environments

Quenching in two environments (speed 2 in the figure) is carried out in different quenching environments, with different temperatures. First, the part is cooled in the temperature range, for example, 890–400 °C, for example in water, and then transferred to another cooling medium - oil. In this case, the martensitic transformation will already occur in an oil environment, which will lead to a decrease in the leash and warping of steel. This hardening method is used for heat treatment of stamping tools. In practice, the opposite technological technique is often used - first the parts are cooled in oil and then in water. In this case, the martensitic transformation occurs in oil, and the parts are moved into water for faster cooling. This saves time on implementing the hardening technology.

Step hardening

During stepwise quenching (speed 3), the product is cooled in a quenching medium having a temperature higher than the martensitic transformation temperature. In this way, a certain isothermal holding is obtained before the transformation of austenite into martensite begins. This ensures uniform temperature distribution over the entire cross-section of the part. This is followed by final cooling, during which the martensitic transformation occurs. This method produces hardening with minimal internal stress. Isothermal holding can be done just below the temperature Mn, after the start of the martensitic transformation (speed 6). This method is more difficult from a technological point of view.

Isothermal hardening of steels

Isothermal hardening (speed 4) is done to obtain the bainitic structure of the steel. This structure is characterized by an excellent combination of strength and plastic properties. During isothermal hardening, parts are cooled in a bath of molten salts, which have a temperature 50–150 °C above the martensite point Mn, maintained at this temperature until the end of the transformation of austenite into bainite, and then cooled in air.

When hardening onto bainite, it is possible to obtain two different structures: upper and lower bainite. Upper bainite has a feathery structure. It is formed in the range of 500-350°C and consists of lath-shaped ferrite particles <1 µm thick and 5-10 µm wide, as well as thin cementite particles. The structure of upper bainite is characterized by higher hardness and strength, but lower ductility. Lower bainite has a needle-like martensite-like structure and is formed in the range of 350-200 °C. Lower bainite consists of fine particles of ε-carbides located in ferrite platelets. The bainite transformation never goes to completion. The structure always contains martensite and retained austenite. More preferable, in terms of performance characteristics, is the lower bainite structure. Products with such a structure are used in car construction, where parts experience shock-tensile stresses. The bainite hardening technology requires special hardening equipment. Additional materials on this technology can be found in the article “Technology of hardening for bainite.”

Cold treatment (5) is used for steels in which the temperature of the end of the martensitic transformation Mk is below room temperature.

High-speed steels, cemented parts, measuring instruments, and other particularly precise products are subjected to cold treatment. You can read more about this non-standard method of heat treatment in the article “Cold processing of steel parts”