One of the most common methods of heat treatment of metals is steel hardening. It is with the help of hardening that the required characteristics of the finished product are formed, and its incorrect implementation can lead to excessive softness of the metal (non-hardening) or to its excessive fragility (overheating). Our article will talk about what proper hardening is and what needs to be done to achieve it.

Steel hardening

What is the hardening of metal?

The ancient blacksmiths knew that the effect of high temperature on metal can change its structure and properties and actively used this in practice. Subsequently, it was scientifically established that hardening of products made of steel, which involves heating and subsequent cooling of the metal, can significantly improve the mechanical characteristics of finished products, significantly increase their service life and even ultimately reduce their weight by increasing the strength of the part. What’s noteworthy is that hardening parts made from inexpensive steel makes it possible to give them the required characteristics and successfully use them instead of more expensive alloys.

The meaning of the process, which is called hardening of steel alloy products, is to heat the metal to a critical temperature and then cool it. The main goal pursued by this heat treatment technology is to increase the hardness and strength of the metal while simultaneously reducing its ductility.

There are various types of hardening and subsequent tempering, differing in modes of implementation, which determine the final result. Hardening modes include the heating temperature, the time and speed of its implementation, the time the part is kept in a state heated to a given temperature, and the speed at which cooling is carried out.

The most important parameter when hardening metals is the heating temperature, upon reaching which the atomic lattice is rearranged. Naturally, for different grades of steel, the critical temperature value is different, which depends, first of all, on the level of carbon content and various impurities in their composition.

After hardening, both the hardness and brittleness of the steel increases, and a layer of scale appears on its surface, which has lost a significant amount of carbon. The thickness of this layer must be taken into account when calculating the allowance for further processing of the part.

Iron-carbon phase diagram

When hardening products made of steel alloys, it is very important to ensure a given cooling rate of the part, otherwise the already rearranged atomic structure of the metal may go into an intermediate state. Meanwhile, too rapid cooling is also undesirable, as it can lead to the appearance of cracks on the part or to its deformation. In order to avoid the formation of such defects, the cooling rate after the temperature of the heated metal drops to 200 degrees Celsius is somewhat slowed down.

To heat parts made of carbon steel, chamber furnaces are used, which can heat up to 800 degrees Celsius. For hardening certain grades of steel, the critical temperature can be 1250–1300 degrees Celsius, so parts made from them are heated in a different type of furnace. The convenience of hardening steel of these grades lies in the fact that products made from them are not subject to cracking when cooled, which eliminates the need for preheating.

You should take a very responsible approach to hardening parts of complex configurations that have thin edges and sharp transitions. To prevent cracking and warping of such parts during the heating process, it should be carried out in two stages. At the first stage, such a part is preheated to 500 degrees Celsius and only then the temperature is brought to a critical value.

Heating of steel during hardening with high frequency currents

For high-quality hardening of steels, it is important to ensure not only the level of heating, but also its uniformity. If the part is massive or has a complex configuration, it is possible to ensure uniform heating only in several approaches. In such cases, heating is carried out with two delays, which are necessary so that the achieved temperature is evenly distributed throughout the entire volume of the part. The total heating time also increases if several parts are placed in the oven at the same time.

Tempering and aging of metal

By hardening steel, the fragility of the product and its hardness increase. Tempering the metal is another necessary procedure, during which it becomes more ductile, but at the same time its strength and hardness are slightly reduced. Vacation is carried out gradually and at a lower temperature.

Tempering is a type of heat treatment that is used for products hardened to a critical point, during which the structure of the steel changes. How this process occurs: the metal is kept in a heated state for a certain period of time, and then slowly cools in the open air. Tempering is carried out to reduce internal stress, increase the ductility of the metal and prevent its brittleness.

If you harden steel without changing its crystal lattice, you can prevent the brittleness of the metal, but you will also get problems with its hardness. The hardness of a product can be increased using another heat treatment process - metal aging, during which the supersaturated solid solution decomposes.

With the help of aging, the required hardness and strength of the hardened metal is achieved. There are three types of aging:

- natural – a type of heat treatment that occurs during aging under natural conditions; during natural aging, the strength of the metal automatically increases and its ductility decreases;

- thermal – this is aging, which is impossible without exposure to high temperatures; in this case, overaging may occur when the characteristics of the metal reach their peak and then begin to gradually decrease;

- deformation - this type of aging involves plastic deformation of a hardened alloy, which has the structure of a supersaturated solid solution.

How to avoid scale formation and decarburization during quenching

Many steel parts are hardened after they have been finished. In such cases, it is unacceptable for the surface of the parts to be decarburized or for scale to form on it. There are methods for hardening steel products that avoid such problems. Hardening, carried out in a protective gas environment, which is injected into the cavity of the heating furnace, can be classified as the most advanced of these methods. It should be borne in mind that this method is used only if the heating oven is completely sealed.

The photo shows the moment of hydrobeating at the hot rolling mill - descaling

A simpler way to avoid decarburization of the metal surface during hardening is to use cast iron shavings and used carburizer. In order to protect the surface of the part when heated, it is placed in a special container into which these components are previously poured. To prevent ambient air from entering such a container, which can cause oxidation processes, the outside of it is thoroughly coated with clay.

If, after hardening the metal, it is cooled not in oil, but in a salt bath, it should be deoxidized regularly (at least twice per shift) to avoid decarburization of the surface of the part and the appearance of oxide on it. Boric acid, brown salt or charcoal can be used to deoxidize salt baths. The latter is usually placed in a special glass with a lid, the walls of which have many holes. Such a glass should be lowered into the salt bath very carefully, since at this moment a flame flares up on its surface, which dies out after a while.

There is a simple way to check the quality of deoxidation of a salt bath. To do this, a regular stainless steel blade is heated in such a bath for several minutes (3–5). After the salt bath, the blade is placed in water to cool. If after such a procedure the blade does not bend but breaks, then the deoxidation of the bath was successful.

Volumetric hardening of thick-walled workpieces

Coolant selection

The future quality of your part depends on the choice of cooling medium:

- ordinary water is used as a cooling medium for simple carbon steel parts;

- for products of complex shape, caustic soda is used in a 1:1 ratio, the finished solution is heated to 50-60 degrees;

- For parts with thin walls made of any type of steel, oil is chosen as the cooling medium.

Steel with carbon, which has a complex composition, is cooled in two types of coolers - first in water and then in an oil bath. It is necessary to move products from one environment to another at maximum speed.

Cooling steel during hardening

The basis of most coolants used in hardening steel products is water. It is important that such water does not contain impurities of salts and detergents, which can significantly affect the cooling rate. A container containing water for hardening metal products is not recommended for other purposes. It is also important to take into account that running water cannot be used to cool the metal during the hardening process. The optimal temperature for coolant is 30 degrees Celsius.

Hardening steel products using ordinary water to cool them has a number of significant disadvantages. The most important of them is cracking and warping of parts after they have cooled. As a rule, this cooling method is used when cementing metal, surface hardening of steel, or heat treatment of parts of a simple configuration that will later be subjected to finishing.

For products of complex shapes made from structural steels, another type of coolant is used - a 50% caustic soda solution heated to a temperature of 60 degrees Celsius. After cooling in such a solution, the hardened steel acquires a light shade.

It is very important to follow safety precautions when working with caustic soda; be sure to use a hood placed above the bathtub. When a hot part is lowered into a solution, vapors are formed that are very harmful to human health.

Hardening steel in a muffle furnace

The best coolant for thin-walled parts made of carbon steels and products made of alloys are mineral oils, which provide a constant (isothermal) cooling temperature, regardless of environmental conditions. The main thing to avoid when using such a technical fluid is getting water into it, which can lead to cracking of parts during their cooling. However, if water does get into such a coolant, it can be easily removed from it by heating the oil to a temperature above the boiling point of water.

Tempering steel using oil as a coolant has a number of significant disadvantages that you should definitely be aware of. When oil comes into contact with a hot part, vapors are released that are harmful to human health; in addition, the oil may catch fire at this moment. An oil bath also has the following property: after its use, a residue remains on the parts, and the coolant itself loses its effectiveness over time.

All these factors should be taken into account when hardening metals in an oil environment and the following safety measures should be taken:

- immerse parts in an oil bath using tongs with long handles;

- carry out all work wearing a special mask made of tempered glass and gloves made of thick fabric with fire-resistant properties or rough leather;

- reliably protect your shoulders, neck, chest with work clothes made of thick fire-resistant fabric.

Oil bath cooling

To harden certain grades of steel, cooling is carried out using an air flow created by a special compressor. It is very important that the cooling air is completely dry, as the moisture it contains can cause the metal surface to crack.

There are methods for hardening steel that use combined cooling. They are used to cool parts made of carbon steels that have a complex chemical composition. The essence of such hardening methods is that the heated part is first placed in water, where in a short time (a few seconds) its temperature drops to 200 degrees, further cooling of the part is carried out in an oil bath, where it should be moved very quickly.

Volumetric heat treatment

You can order volumetric heat treatment services by phone,

| Sales Department Manager Mezentsev Yuri Vladimirovich |

Heat treatment by hardening according to the depth of impact on the product is divided into surface and volumetric (full). Volumetric hardening is necessary in cases where it is necessary to change the structure of not only the surface layers, but also the entire metal from which the product is made.

Hardening of steel is carried out by heating to a temperature 30-50°C higher than the temperature of hypereutecoid steel, subsequent holding at this temperature and cooling. The purpose of this procedure is to obtain increased wear resistance and improve physical and mechanical properties, in particular hardness. Hardness increases as a result of the transformation of the structure into nonequilibrium solids:

- martensite,

- sorbitol,

- troostitis.

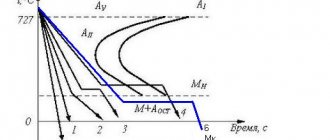

The quality of volumetric heat treatment by hardening depends on the correct choice of mode, that is, heating temperature, holding time and cooling rate. The hardening temperature, for example for carbon steels, is selected using the alloy phase diagram.

To counteract the occurrence of stresses and cracks, heating is carried out gradually, slowly. The heating time is selected depending on factors such as the chemical composition of the steel grade, the size and shape of the product. For heating in salt baths, it is recommended to choose a speed of half a minute per 1 mm of cross-section, and for heating in an electric furnace - about 20 minutes per 1 mm of cross-section. The duration of exposure required for the final transformation of pearlite into austenite should be related to the entire heating time as 1 to 4. The critical quenching rate is the value of the cooling rate at which the result is either a martensitic steel structure, or a martensitic with retained austenitic structure. For hardening most steels, oil is used as a cooling medium, but for medium-carbon steels it is better to use water at a temperature of 18°C.

Based on the cooling rate, hardening is divided into isothermal and stepwise. For heat treatment, high-frequency currents, heating in furnaces, and gas-flame heating are used. Volumetric hardening with continuous cooling is used for alloy and carbon steels, and in the first case, cooling is carried out in oil, and in the second - in water. Step hardening allows you to relieve the stresses that arise during the cooling process. This method is based on the sequential immersion of a heated part, first in oil heated to certain temperatures, and then, after a short exposure, cooling occurs in air.

During the hardening process, structural and thermal stresses arise in the steel. The occurrence of thermal stresses is associated with uneven cooling, and structural stresses are associated with an increase in volume due to the transformation of some structures (austenitic) into others. An incorrectly selected hardening mode leads to warping, the appearance of areas with lower hardness, oxidation, cracks, etc.