Home / Consumables

Back

Reading time: 2 min

0

1265

Welding using argon is very popular among professional workers. With this type of welding work, the quality of the seams is many times higher, they are beautiful and durable.

To carry out such work you need to have a special material called filler metal wire.

Here you will find detailed information about what argon welding is and how to properly use filler wire, how many types and what they are.

- Basic data

- Selection of filler material

- Exploitation

- Let's summarize

Basic data

Filler wire is a special material with a small cross-section, which can consist of both different metals and artificial polymers.

The additive is very long, so it can be found in stores in the form of a coil. It is measured in kilograms. The type of filler material depends on the metal or polymer from which it is made.

Wire for welding work with metal products in an argon environment is a separate type. It is used when working on an automatic or semi-automatic machine.

Not only can an additive be made from this material; sometimes it is used to create electrodes.

The use of filler wire for welding with argon facilitates the replacement of electrodes and creates smooth seams. The filler wire acts as a conductor between the welding current and the arc; it ignites the latter and maintains constant combustion.

Over time, the material is melted and mixed with the main workpiece. When mixing the workpiece and wire, the chemical and physical characteristics of the seams are improved.

The composition of the filler wire can contain any metal, since during operation it must be of the same metal as the workpiece itself.

Accordingly, if you are working with aluminum parts, the filler wire material should also be aluminum. Sometimes such wire is called filler rods for argon-arc work with aluminum and its alloys.

If you need to weld stainless material, then the composition of the wire should be based on anti-corrosion steel. These examples are highly generalized; we will cover all the details below.

Stainless steels

Corrosion-resistant steels are more difficult to weld than black steels due to their more complex physicochemical properties. Firstly, stainless steel has a higher electrical conductivity, so higher currents than usual will be needed, approximately 15%. Secondly, alloying with chromium from 13% (which makes steel resistant to corrosion) can cause problems. For example, when welding thin-walled stainless steel, which is more common than thick-walled, it is important to organize gas protection for the reverse side of the seam, the reverse bead. Chromium oxides cause cracks. If you welded an expensive car exhaust system from AISI 304 steel and the seam was protected only from the outside, over time your system will fall apart. To protect the seam inside the pipeline, argon is injected into it, and the open ends are closed with plugs.

Austenitic steels type 12Х18Н10Т (AISI 321); 08Х18Н10 (AISI 304) is welded with stainless steel rod ER-308 (analogues SV-06Х19Н9Т, SV-01Х19Н9, SV-04Х19Н9). Steels of type 12Х18Н10т are also called “food grade stainless steel”, since the optimal proportion of chromium and nickel provides resistance to aggressive environments, such as organic acids formed during the processing of some industrial food crops. Steels of this type are often found in everyday life. The weld metal ER-308, which has a similar chemical composition, is also not afraid of acidic and other “unfriendly” environments. The low carbon content in ER-308 wire reduces the risk of intergranular corrosion, the process of corrosion along the grain boundaries of the metal. The silicon and manganese content has a positive effect on the formation and crystallization of the weld pool.

Mechanical properties of ER-308:

- Yield strength, Rp0.2 390 MPa;

- Tensile strength, Rm 600 MPa

- Elongation A5 42%

- Impact strength, J 120

The next class of steels is chromium-nickel-molybdenum type st.10Х17Н13М3Т, st.03Х17Н14М2; 15Х14Н14М2ВФБГ; 08Х16Н13М2В. They are used more often in industry, in everyday life much less often. Thanks to alloying with molybdenum, they become resistant to even more aggressive acidic environments (sulfuric, orthophosphoric acids, etc.). Molybdenum prevents local corrosion, hot cracking, increases the operating temperature of structures and mechanisms and increases impact strength at ultra-low temperatures. Stainless steel rod ER-316 (domestic analogue Sv-04Х19Н11М3) is used as a filler material for these steels .

Mechanical properties of ER-316:

- Yield strength 480 MPa

- Tensile strength 630 MPa

- Elongation 33% KCV

- +20°С 175 J

- — 110°C 150 J

- -196° C 110 J

A question is often asked about welding stainless steel at home: is it necessary to purchase an expensive inverter-type power source for this? It’s not at all necessary; you can weld stainless steel using a regular MMA welder (see our Review Store). Some of them, however, have an MMA/TIG mode switch, but even those inverters that do not have this feature can be adapted for argon arc welding: purchase an additional valve torch, an argon cylinder and a pressure reducer. Welding on such a homemade argon machine has its own characteristics, but if you take them into account, you can work quite well. The main thing is not to start welding on the product; prepare a graphite backing for this. If you start on a product, the tungsten electrode will be enough for a couple of ignitions, then you will have to sharpen it. It is also necessary to complete the process on graphite.

Go to menu

Selection of filler material

Since the range is quite extensive, novice welders may encounter some difficulties. Materials differ in manufacturers, brands, and diameters. What choice to make from all this?

The first step is to find out the type of work. Will you be producing or welding metals? Or work with soldering plastic parts? Having found the answer to this question, you will already move forward.

For example, you are going to carry out argon welding of metals. Find out what kind of metal you are going to weld. In this case, you need not just a type of metal, but a specific brand.

Once you determine that you have a steel billet, you may be faced with a dozen more different types of steel.

Once the brand becomes known to you, you can begin choosing materials.

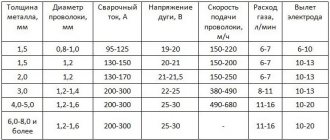

The diameter of the additive must correspond to the thickness of the workpiece. The thicker the part, the larger the diameter. Often the values of wire diameter and metal thickness coincide.

It doesn't matter who the manufacturer is. The main thing is what were the conditions during storage and transportation of the additive to the store. Most likely, you will not be able to find out this information one hundred percent.

Therefore, it is better to purchase from a trusted store, and if possible, then go to an official representative. Representatives usually follow all storage rules and you don’t have to worry about this.

Types of wire for stainless steel 12x18n10t

To weld stainless steel parts, it is necessary to use argon arc welding and an additive made of the same material. It may have different properties that may be suitable for other cases. Long products are produced from steel 12×18N10T. The filler material of this grade must meet the requirements of GOST 18143-72.

Welding filler wire has found its use in the mechanical engineering and food industries, construction, etc. It has not only high corrosion resistance, but also resistance to chemically aggressive environments. It contains a sufficient amount of chromium, which protects it from rust.

For welding work, products produced using cold drawing technology are used. It has a fairly low price and at the same time, this treatment preserves all its properties. This wire ensures the quality of the seam when processing any material.

Stainless steel wire 12Х18Н10Т

Thus, water supply systems are often assembled from pipeline fittings made from this grade of steel. When assembling and repairing, it is considered optimal to use a welding additive of the 12Х18Н10Т brand.

This steel grade is available in several versions. For its production, hot or cold rolling technologies are used. They make it possible to obtain a product with a diameter from 0.2 to 6 mm. When using wire of this brand, it is necessary to take into account that it can change some of its parameters based on the diameter.

Welding stainless steel parts is a complex technological process and if its rules are violated, the result can be a large number of substandard products. To avoid this, it is necessary to make the right choice of wire material. Wire made from steel 12Х18Н10Т is a specific product and quite possibly may not be suitable for most types of alloy steel. The main rule for choosing a material for welding is the identity of the chemical composition. The good thing about wire made from this wire is that the industry produces a wide range of products and, as a rule, there are no problems with selection. By the way, when welding, pre-heating and gradual cooling may be required. Heating is carried out using a gas burner.

Exploitation

The choice of filler material is not the most important element when working with argon media. You also need to understand welding technology and what its standards are. The technology itself is based on the use of argon gas to form seams.

For this type of welding, filler wire and electrodes are used. Electrodes may or may not be consumable. We will consider the use of non-consumable electrodes, since this method is more popular.

For welding in argon, automatic and semi-automatic machines are used. The additive is filled into the feed mechanism, then the desired mode is set and it passes into the welding zone.

Scope, purpose

Chemical elements that make up materials such as stainless steels, cast irons, titanium alloys, aluminum alloys and other non-ferrous metals actively interact with air . Naturally, nothing good can be said about the quality of such seams. The problem of connecting the above materials can be solved by protecting the connection zone with the inert gas argon. In this case, no special treatment of the seam is required after the process is completed.

Titanium welding wire 7 mm. VT1-00sv. Photo BVB-Alliance

The use of argon arc welding in car repairs makes it possible to extend the service life of repaired parts. Products of complex configurations manufactured with its help receive a marketable appearance immediately after welding. Processing seams for such parts is practically impossible, and high-quality connection is a technological way to solve the problem.

Let's summarize

This is all the basic information that will help you work with argon gas. When selecting filler materials, consider what metal you are going to work with.

The additive can be used to mix with the workpiece and to form a joint using only the additive material.

Do you have experience with welding in an argon environment? What filler material did you choose? Have you had any problems during welding work?

Leave your comments and share your experience. Maybe your story will help beginners avoid serious mistakes. Productivity at work!

Flux cored wire for semi-automatic machine

Flux-cored wire for semi-automatic machines, also known as flux-cored wire, is used without protective gas. It is made in the form of a tube that contains flux. Its weight can range from 15 to 40% of the product weight.

Flux wire can be used for welding on stainless steel, aluminum, copper, titanium, and steel. In addition to semi-automatic welding under normal conditions, this wire is used for welding under water, connecting reinforcement, and forcibly creating a seam. However, according to professionals, it is impossible to fill a hollow tube with powder if there are no pores in it. Therefore, it cannot be guaranteed that the welding zone will be completely continuous and super strong. In addition, it is necessary to thoroughly clean metal surfaces from the resulting slag. Used primarily in the down position.

With all its shortcomings, you need flux-cored wire for a semi-automatic machine without using gas if:

- It is planned to use high current density (approximately 200 A per mm2),

- You have a lot of work ahead of you.

Wire for welding steels

Most often, filler wire is purchased in stores for gas welding of steels. Note that this wire is manufactured according to the same standards as for arc welding. Therefore, there is no difference between wire for gas and for RDS welding. For ordinary welding of most types of steel, wire made from low-carbon and alloy steel is used. For welding critical and especially critical structures, it is recommended to use low-alloy wire.

If you need to achieve the best quality of welds or surfacing seams, then use manganese and silicon-manganese wires. These include brands Sv-08GS, Sv-08GA, Sv-08G2S, Sv-10G2. When using these brands, the seams are strong and reliable. They are resistant to mechanical damage.

When working with low-alloy steel, purchase the same low-alloy wire, but with chromium content. The resulting seams have a high tensile strength. But when welding high-alloy steel, wire should be selected with a similar chemical composition.