Grinder chainsaw: attachments, homemade products, alterations

The desire to improve an existing tool comes for a reason. The main goal of such an experiment is to save money. Indeed, why buy several tools if you can use different attachments and make a multifunctional tool.

The grinder is known to every household homeowner, because with its help you can cut metal, stone, and polish the surface. But trees cannot be cut with such a device; difficulties arise due to the small diameter of the disk. So craftsmen come up with various attachments that make working in the garden much easier.

Miter saw

Trimming, that is, cross-cutting boards or bars at right angles, turns out better if you use a special device.

You can also make such a machine from a grinder with your own hands.

- To do this, a grinder with a disk for wood is fixed on a rotating bar perpendicular to the direction of the length of the board so that the plane of the disk is directed strictly vertically. One attachment point should be located in the area of the gearbox, and the second should be at the opposite end of the machine.

- The gearbox housing has threaded holes for attaching standard handles. Using the corners and these holes, the grinder must be attached to the moving part of the machine.

- The back of the body is attached to the board with a clamp. The blade guard can be used on any power tool of a suitable size.

- Closer to the vertical support you need to secure the thrust angle. It should be located strictly perpendicular to the plane of the disk, both in the vertical and horizontal directions.

The spring at the rear end of the bar is used to return the miter saw to its original position after finishing the cut. The horizontal table must have a transverse groove into which the disk fits when cutting the board. The diameter of the disk is chosen based on the width of the boards. This way, trimming can be done in one go. The main thing is that the inner hole of the disk must coincide with the mount on the gearbox axis.

When working on such a machine, it should be taken into account that the drive power is not intended for heavy loads. Therefore, the rotating disk must be brought smoothly to the surface of the part being cut, and the cut must be made without strong pressure.

Why do they resort to a homemade option?

Often, homemade versions of tools or improvement of existing ones are done out of a desire to save money. Using improvised means and parts left over from equipment or machinery that has fallen into disrepair, craftsmen skillfully make various devices, such as, for example, a chain saw from an angle grinder.

The second reason can be considered the desire to have a multifunctional tool that will help facilitate numerous tasks on the farm. The undeniable advantage of such a homemade device is the space saving. After all, an additional attachment takes up much less space in a shed or garage than a full-fledged device.

For remodeling, you can use absolutely any brand of grinder. The only point worth paying attention to is that the factory attachments may only fit a limited number of models, so when purchasing, be sure to check whether your angle grinder is suitable for the selected attachment.

Hand power saw

A manual electric circular saw made from a grinder is obtained by replacing the standard cutting disc with a wood cutting disc.

True, this option is suitable for short cuts of sheet materials or cutting thin slats. When cutting long lengths or on thick bars, there is a danger of the disc skewing and jamming. It will be much easier to hold the saw if the handle is not positioned perpendicular to the axis of the tool, but is made an extension of the body.

It is not recommended to remove the protective cover, as it will prevent sawdust from getting into your face.

Craftsmen also make a hand-held chain saw from a grinder. True, such a tool is dangerous for the user: the absence of a chain stopper can lead to unpredictable consequences. In addition, the chain is not lubricated, which leads to rapid wear.

Factory attachments

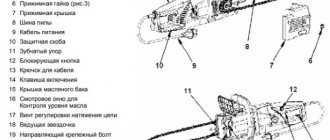

Now on sale there are special attachments for grinders in addition to discs. The grinder comes with a device that can be used to turn it into a chain saw in a short time. Supplied in two separate boxes containing an angle grinder and a chain saw.

Set of nozzles

The estimated cost of this set is $83.

Stationary circular

You can use a grinder as a working mechanism in stationary conditions. The bed in this case will have a slightly different design. The stationary option implies the presence of free space and a large amount of work. Therefore, the entire structure can be made more solid, more massive, and, therefore, more reliable.

The frame of the bed can be made from a corner using a welded joint. Bolted and other types of detachable fasteners lose their grip due to constant vibration, and the structure begins to wobble.

A desktop made of a wide board or thick plywood is attached to the top of the metal frame. The workpiece will move along it. The stop angle is equipped with a movable mount for adjusting the cutting width.

It would be nice to provide for adjusting the height of the table or the distance of the disk above its surface - then it will be possible to cut out longitudinal grooves in the board.

On the side of the machine there are controls: a socket and on/off buttons. In the stationary version, it makes sense to exclude the key on the body of the angle grinder from the diagram. If there is enough space, a high-power sander can be used as a drive.

How to make a sawmill from an angle grinder is shown in this video:

The nuances of using a homemade circular saw

You should not lose sight of the fact that the grinder’s main purpose is as an angle grinder. Therefore, when using it as a homemade circular saw, you need to pay attention to the nuances.

- The duration of continuous cutting should not exceed 15-20 minutes to avoid overheating of the engine.

- The standard guard on the blade is not suitable for a circular saw. The protective casing can be used from a real circular saw or made independently.

It should be remembered that the rotation speed of the sander can be more than 10,000 revolutions per minute - this is several times higher than the speed of woodworking machines. At this speed, the wood begins to smoke. In addition to the unpleasant odor, fire may occur.

Peculiarities

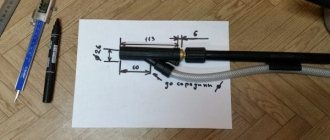

It’s worth considering right away: all experiments with angle grinders should be carried out only by people who are thoroughly versed in this technique. Otherwise, the consequences may turn out to be unpredictable (and hardly pleasant for the “inventors”). To use a grinder for sawing, you will need a special handle, a protective device and a special type of disk. A typical chain saw attachment for an angle grinder includes:

- a tire attached to the tool;

- handle;

- an asterisk mounted on the shaft;

- a set of fasteners and tools for working with them;

- shield isolating the user.

It’s worth considering right away: all experiments with angle grinders should be carried out only by people who are thoroughly versed in this technique. Otherwise, the consequences may turn out to be unpredictable (and hardly pleasant for the “inventors”). To use a grinder for sawing, you will need a special handle, a protective device and a special type of disk. A typical chain saw attachment for an angle grinder includes:

- a tire attached to the tool;

- handle;

- an asterisk mounted on the shaft;

- a set of fasteners and tools for working with them;

- shield isolating the user.

How to make a casing with your own hands?

In addition to a stationary machine for cutting wood, you can make a mobile version of it. To do this, first of all, you need to make a protective casing. The circular casing is one of the most important safety elements. It performs several functions simultaneously:

- Protection of the operator’s limbs from accidental contact with the saw blade;

- Removal of chips from the work table;

- Straight cutting direction.

It is made of metal sheet with a thickness of at least 1 mm. To do this, in addition to the workpiece itself, you will need an angle grinder with a cutting and sharpening wheel, a welding inverter and a drill with a set of bits. The manufacturing procedure is as follows:

- On a metal sheet it is necessary to mark the side walls of the casing, a strip for making a jumper and cut them off using a grinder;

- Using a drill with a metal bit installed on it, cut through holes in the side walls of the future casing;

- In one of the workpieces, use an angle grinder to make a longitudinal hole;

- Sand the workpieces using a flap disc;

- Weld a 10 mm wide metal strip around one end of the pipe. It will act as a clamp, so welding only along the lower part of the circle will be sufficient. For convenience, you can insert a piece of metal pipe into the hole;

- In the upper right corner of the second workpiece, use a drill with a metal cutting bit to cut a ventilation hole;

- Using a welding inverter, weld the workpieces and the metal strip together;

- To fix the casing with the body of the angle grinder, cut and weld a metal bracket;

- Using a metal strip, two corners and a pin, assemble the movable housing mount. After this, it is necessary to weld the corners to the plate;

- Weld an M10 bolt to the opposite part of the casing. Cut a fork from a metal sheet and weld it to the base on the opposite side of the casing;

- Weld two long nuts to the top and side of the casing. They will serve as the basis for installing the handle;

- Weld a pipe cut at an angle to the ventilation hole;

- After this, you can fix the grinder in the mounting hole and use a metal cutting disk to make a through cut in the base plate. After this, it is necessary to expand the hole to an acceptable size;

- If desired, the casing can be painted and work can begin.

Necessary materials for making at home

The manufacturing technology of this type of machine is very simple. This does not require the involvement of a specialist or the use of a special tool. If you have the desire and enough free time, you can do the assembly work yourself. Regardless of the required performance, the main materials for manufacturing the machine are:

- Angle grinder, also known as grinder;

- Wooden blocks;

- OSB sheet;

- Hardware;

- Electric outlet;

- Electrical cable with plug;

- Switch.

A more reliable method is to use metal corners to make the table frame. In this case, not only does the cost of raw materials increase, but the manufacturing process also becomes more complicated. This is due to the cost of rolled metal and the use of a welding machine to connect metal parts. The price of a machine with such a table is approximately 2000 - 2500 rubles higher than with a wooden one.

The approximate cost of a machine with a wooden base, a grinder with a power of 1000 W and a disk diameter of 125 mm is 4000 - 4500 rubles. The minimum cost of a similar factory-assembled machine is 11,000 rubles, and the average is 18,000.

Manufacturing a stationary machine with a table

There are many options for making a stationary machine for cutting wood from an angle grinder; the article discusses the best ones. The simplest option is a machine with a wooden table in the form of a support. To make it, you must perform the following steps:

- The table frame is assembled from chipboard using screws, the corners are reinforced with wooden blocks;

- A tabletop is made from OSB sheet or plywood according to the dimensions of the frame. Screwed around the perimeter using screws. To ensure that their caps do not interfere with work, chamfers must be made in the holes. First, you need to cut a rectangular hole at the exit point of the disk;

- It is necessary to mount the body of the grinder to the back side of the tabletop using bars and metal brackets. The power keys located on the handle are also rigidly fixed with brackets;

- Then a socket is mounted inside the frame, which is connected to the plug of the grinder. To turn on the tool, a switch is installed on one of the outer sides of the case, connected at one end to an internal socket, and at the other to an electrical power cable. For greater convenience, you can attach legs made of wooden beams to the table;

Since the rotation speed of the grinder's cutting disc exceeds 9000 rpm, strong friction and charring of the wood surface may occur during operation. To avoid this, you can install a rheostat in the electrical circuit of the machine, which will smoothly regulate the speed of rotation of the disk. It is better to mount it between the switch and the internal socket of the machine.