Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console.

Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm. More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions. The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system. Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.

How to straighten without a machine?

At home, the wire is straightened for grounding, lightning protection and some other work. It is unlikely that in everyday life you can find a high-quality roller machine that can straighten wire with a cross-sectional diameter of more than 2 mm - it is expensive, and the process itself is quite labor-intensive. Purchasing special equipment also does not make any sense if the need to unwind the rod is one-time. Therefore, in order to straighten metal wire from a coil or coil, you can use the nodal tension method. For this purpose, a certain sequence of actions should be performed.

One end of the rod is firmly fixed to something bulky, heavy and solid. For example, they wrap it around a power pole or a strong tree with a trunk diameter of at least 25 cm.

After this, the wire is unwound on the ground by hand, stretching it as much as possible. A loop is formed from the other end of the wire unwound in this way and fixed in a device that can be pulled with great force - that is, this device must move a certain distance.

To secure the resulting straight shape, the wire must be left in this taut state for a short period - from 10 minutes to half an hour.

For such work, you can use a variety of devices - this directly depends on the parameters of the cross-section of the rod. So, for a product with a diameter of less than 2 mm, scrap steel, as well as the combined physical efforts of a couple of strong men, will be more than enough. And also in this case you can use a mechanical winch. But rods with a diameter of 5 mm and above will require much more significant effort - for this they use the dynamic force of a tractor, truck or tow bar of a passenger car.

Please note that straightening a wire with a diameter of more than 5 mm if it is made of alloy steel will require not only tension to the state of a string, but also subsequent stretching. It must be carried out until the rod bursts

Typically, a break occurs at the attachment site at one end of the string - at this moment it is better to be as far as possible from the stretched wire.

How to straighten a wire?

Sometimes when working in workshops or for domestic purposes, pieces of straight wire are required. In this situation, the question arises of how to straighten the wire, because when manufactured in factories, it is packaged in rounded coils - this shape is ergonomic, it facilitates storage and further transportation. To straighten steel, copper or aluminum wire, you should make some effort and use simple devices.

§ 33. Editing metal sheets and wires

Straightening is the operation of leveling a metal sheet or wire on a straight plate by blows of a mallet (wooden hammer) or a hammer made of soft non-ferrous metals or using a wooden block (Fig. 122).

Rice. 122. Editing a metal sheet: a - with a mallet; b - wooden block

The sheet is placed on the stove and held with the left hand in a mitten, and struck with the right hand with a hammer or mallet.

If there are convex areas on the sheet, then they are placed with the convexity up and blows are applied with a hammer from the edge to the center of the convexity. At the same time, the sheet is turned.

Thin soft sheets are usually straightened with a wooden mallet or ironed and leveled with wooden blocks.

Soft thin wire can be straightened by pulling it between several nails driven into the board or bars clamped in a vice, as well as around a cylindrical mandrel (Fig. 123, a, 6, c).

Rice. 123. Straightening the wire: a - by pulling it between nails driven into the board; b - by pulling between the bars in a vice; c - by pulling around the cylinder; g - with a hammer on a flat (correct) plate

Thick wire is straightened by hitting it with a hammer or mallet on a straight plate (Fig. 123, d) or squeezing it with pliers.

The quality of straightening is checked by applying the edge of a ruler to the surface of a sheet or wire or on a straightening plate - by the size of the gaps S (clearances) (Fig. 124).

Rice. 124. Checking the quality of editing: 1 - sheet or wire; 2 — edge of the ruler; 3 - straight plate; S - gap size

Safe work rules

- Beware of cutting your hands from the sharp edges of metal sheets and wires.

- Protect your eyes from injury from the sharp ends of the wire.

- Work only with gloves.

- Protect your fingers from blows with a hammer or mallet.

Practical work No. 35 Straightening metal sheet and wire

Work order

- Prepare a workplace and tools for straightening workpieces made of thin metal sheets and wire.

- Straighten blanks of metal sheets and wire.

- Check the quality of the edit.

Control questions

- What is called straightening of metal sheets and wire? What metals are workpieces made from straightening?

- What tools and devices are used for straightening?

- Is it possible to straighten sheets between rolling rolls?

- What is the technology for straightening thin sheets of soft metals?

- Why does the wire straighten when pulled between bars, nails or around a mandrel?

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature. But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable. There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

- You can remove creases from the wire by securing both ends in your hands and starting to forcefully roll it through a pipe or door handle.

- Straightening the wire works well if its straightened sections are placed on a flat surface of the workbench. Cover it with a wooden block and start rolling it over her so that she can move freely. Just a few such rollings give quite good results.

- To straighten soft copper wire, you need to secure it at one end at a height. To the other hang a not very heavy load, such that it cannot tear it. By rotating the load clockwise and back several revolutions around its axis, you can achieve an ideal result.

- Straightening the wire will follow a similar method. If one end is secured in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will occur from slow rotation and at the same time holding the wire under strong tension. Just a few turns will be enough for complete straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, make a spinning hole in a wooden block with a diameter slightly larger than the wire one and pass one end of the rod through it. We fix this end in the chuck and begin to slowly rotate, pulling the wire through the hole.

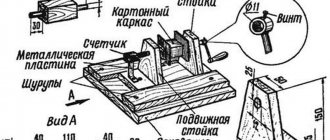

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands.

For this we need a massive wooden board measuring 500 x 120 x 50 mm. We hammer 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indentation to the diameter of the wire. The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist of simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Wire straightening machine

How to Manually Align and Straighten Wire

Sometimes, for household needs or in the workshop, you need to use pieces of straight wire for work. But the question immediately arises: how to straighten the wire? After all, it is produced in factories and immediately packaged in round coils. This form is very convenient for storage and transportation. Therefore, in order to make a metal wire straight, it is necessary to expend not only some effort, but also use a number of simple devices.

Industrial methods

In production, specialized straight cutting machines are used to straighten almost all types of metal wire. The process is based on two main methods:

- straightening by rolling through a system of 5-6 pairs of rollers, which are located sequentially in different planes so that each subsequent pair is perpendicular to the neighboring one;

- straightening by drawing through several specially made dies.

As a rule, such machines must have a special device for automatically unwinding wire from coils or coils.

To work with elastic types of wire and alloy steel rod, the production technology involves heating and tempering the steel structure of the workpiece using gas burners or high-frequency inductive heaters.

How an industrial straightening and cutting machine works can be seen in the video:

How to straighten wire without a machine

Unfortunately, at home, making a good roller machine capable of straightening wire with a diameter of over 2 mm is quite expensive and labor-intensive. Moreover, if the need for a straight wire rod is one-time.

An example of one of these devices can be seen in the photo.

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

- First you need to firmly fix one end of the wire in something massive and solid. To do this, you can wrap its end around the base of a power line pole or a strong tree with a trunk diameter of at least 25 centimeters.

- Next, we manually unwind the coil on the ground and, if possible, stretch it as much as possible.

- At the second end of the unwound wire we make a loop and secure it in a device capable of pulling it with force, that is, moving it a certain distance.

- The straightening process itself consists of slowly stretching the metal wire with great force until it becomes shaped like an ideal string. To secure the straight shape, you can leave it in this tense state for some short time, from about 5 to 30 minutes.

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

It is worth keeping in mind that straightening a wire with a diameter of more than 5 mm, made of alloy steel, will require not just tension to the shape of the string, but stretching until the wire breaks. As a rule, the rupture occurs at the attachment point on one of the ends, and for safety reasons you should not be near the stretched wire.

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature. But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable.

There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

- You can remove creases from the wire by securing both ends in your hands and starting to forcefully roll it through a pipe or door handle.

- Straightening the wire works well if its straightened sections are placed on a flat surface of the workbench. Cover it with a wooden block and start rolling it over her so that she can move freely. Just a few such rollings give quite good results.

- To straighten soft copper wire, you need to secure it at one end at a height. To the other hang a not very heavy load, such that it cannot tear it. By rotating the load clockwise and back several revolutions around its axis, you can achieve an ideal result.

- Straightening the wire will follow a similar method. If one end is secured in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will occur from slow rotation and at the same time holding the wire under strong tension. Just a few turns will be enough for complete straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, make a spinning hole in a wooden block with a diameter slightly larger than the wire one and pass one end of the rod through it. We fix this end in the chuck and begin to slowly rotate, pulling the wire through the hole.

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands. For this we need a massive wooden board measuring 500 x 120 x 50 mm. We hammer 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indentation to the diameter of the wire. The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist of simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Search for records using a filter: Select BendingProtectionForgingCuttingWeldingDrilling Select RebarSquareCircleSheetStripWirePipeAngleChannel/Beam Select AluminumBrassCopperStainless SteelTitaniumCast Iron

wikimetall.ru

How to straighten a wire: a homemade device

Sometimes neat wire rods of not very long length are required. How to align them quickly and perfectly without using a hammer? For such a case, there is a ready-made solution, which will be discussed in this video tutorial.

To make this homemade device, which will free you from the need to crumple the wire in your hands, trying to do the almost impossible, you will need a blank from a 70-gauge angle, three bearings and bolts with nuts for fastening the bearings. Two bearing units are installed stationary, and one can change position. This bearing is used to press the wire against two others during the pulling process. By changing the gap between the bearings, you can gradually narrow the space in which the wire will be located in this process.

How is alignment carried out?

A wire is inserted into the device, clamped in a vice, one end of which is clamped with a screwdriver. By pushing the rotating wire between the rollers and gradually clamping it between them, it is drawn and aligned.

izobreteniya.net

Gromovod

- - accessible and inexpensive

- — quick installation

- - always in stock

- — quick registration

- — discounts from 5 days

- - folding tripod base

- - one person management

- - ease of use

- - light and durable

- — buying as a set is cheaper!

- - alignment of wire in coils

- — electrolytic galvanization Fe/Zn12/C/T2

- - control both manually and remotely

- — bearings do not require lubrication

- — thermal protection of electric motors from overload

A truly reliable device that has never let me down. And believe me, we have enough work for him.

The price won him over. Or more precisely, value for money. So far it hasn't let me down, it works fine.

There were fears at the beginning, but completely in vain. A normal workhorse. The further it goes, the more it makes our work easier.

Still have questions? Just leave your number to receive a free consultation. Or call right now! We are available on Whatsapp, Viber and Telegram.

gromovod.ru

i-perf.ru

Our production

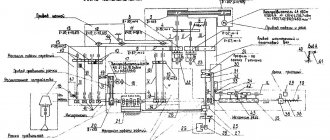

Device for leveling steel wire with a diameter of 6-10 mm and strips 20x3 30-4 mm with a manual drive. Serves for straightening galvanized steel wire with a diameter of 6-10 mm, as well as galvanized steel strip measuring 20x3 mm, 30x4 mm. Round and flat conductors are supplied in coils of 40-50 kg.

In order to efficiently install an air-termination “mesh” made of steel wire on a flat roof, it is necessary to place the wire in holders and connect the nodes using terminals. The wire is laid in cells measuring 6x6 m, 10x10, 12x12 m. In order to lay the “mesh” conductor evenly, it must be straightened from its twisted state. Galvanized steel wire 8 and 10 mm is difficult to straighten manually, especially steel with a diameter of 10 mm, and in the straightened state there will be unevenness from uneven straightening.

To lay down conductors from lightning rods on the roof, chimneys and other structures of buildings and structures, and install conductors in holders, it is necessary to lay it as smoothly as possible without bending. The reason for this is the aesthetic appearance, as well as unevenness, as a result of which the wire may come loose from the holders or the holder mount itself may be damaged.

For ease of installation, our company offers this device for straightening conductors from nine rollers, which will allow you to save time on installing lightning rods, as well as install down conductors in the shortest possible time without fear of dismantling uneven sections of wire and strip.

The design of the wire straightening machine allows you to install it at a height of 0.5 m from the roof or floor on any structure made of wood or metal, adjust the pressure of the rollers on the conductor and achieve evenness of the wire or steel strip.

Eg:

— installation on wooden pallets — 5 minutes;

- screwing screws into wood - 2 minutes;

— setting the pressure rollers for the conductor from 5 to 15 minutes;

— unwinding of a standard coil 115 m 5-7 minutes

— cutting to required lengths from 5 to 20 minutes

In total, on average, it takes up to 1 hour to unwind and prepare galvanized steel wire with a diameter of 8 mm for installation. For a building with a flat roof measuring 50x20 and 10 m high, approximately 3 coils of wire may be required, this means that in 3 hours you can prepare the conductor for laying on the roof and down conductors, without spending a working day on it.

What you need to straighten the wire

Aligning steel wire with a diameter of 4-6-8 mm is not so easy. This is especially difficult to do at home, where often there is nothing at hand except a hammer and a vice. But still, if you try, you can quickly carry out this procedure without resorting to any specialized means.

So, to align thick wire, we will need:

- A small piece of log (50 cm long);

- Electric drill;

- Long wood drill. It is very important that the diameter of the drill be slightly larger than the diameter of the steel wire that needs to be aligned. Also, the length of the drill must be sufficient to make a through hole in the log;

- Winch.

As for the winch, it can be replaced with a car. The point is to create a pulling force to straighten the thick wire, since doing this by hand will be impossible.

Methods for bending metal wire

There are several main ways to give metal wire the required shape of the finished product, so we can highlight:

- manual method of bending wire using special tools and simple devices. It is used for wire with a diameter of up to 3 mm in the manufacture of simple products in utility production or households. As a rule, it does not require virtually any financial investment or special knowledge;

- manual method of making jewelry from wire up to 2 mm in diameter. Requires special tools and devices, as well as certain knowledge and skills for working with precious metals;

- bending wire from a coil, which is based on a special device called an unwinder;

- bending wire from a metal rod;

- bending using wire rolling method;

- bending metal wire using the pushing method.

Wire without wires. Part 2: Wire Toolkit

I am sincerely convinced: to create a worthwhile thing from wire, you don’t have to buy expensive branded tools. The main thing is that they never let you down. And this article was written to suggest how to choose reliable economy class assistants.

Of course, to work with copper or silver-plated wire, you need a high-quality tool and at the same time a delicate one. But a high price is not a guarantee. In any case, all purchases need to be checked at the counter, held in your hands, tested on pieces of wire you brought with you, and see how successfully the chosen tool copes with its tasks. What are they, tasks?

Round nose pliers are used to create bends on wire, loops, curly, geometric elements and spirals, as well as rings and springs. A sign of ideal round pliers is that each of the pair of jaws must be absolutely round in cross-section. In addition, the diameter of both should also be the same. About the same as my round nose pliers, although they are also far from the standard

A sign of ideal round pliers is that each of the pair of jaws must be absolutely round in cross-section. In addition, the diameter of both should also be the same. About the same as my round nose pliers, although they are also far from the standard

While I found them, I tried different ones, including huge and long ones, but terribly uncomfortable (the first ones on the left in the photo below), professional ones for jewelers, which not only are uncomfortable to hold in your hand, but also the pliers are uneven and unequal (second from the left ) and my very first round nose pliers (black with yellow trim) - for 50 rubles. purchased at your local hardware store.

Pliers are needed both for loosening rings when paired with pliers, and for firmly gripping the wire when working with it, as well as for curling the wire into a “snail”, forming a triangular or square bend. Ideally, pliers should have a smooth inner surface so as not to scratch the wire, or with removable nylon pads, which are often used to straighten twisted wire. But you can simply wrap regular pliers with grooved internal pads with a woven-backed adhesive plaster, which is sold at any pharmacy.

Here are my scary, scary pliers!

True, I don’t use them anymore. Personally, my favorite pliers are , a type of narrow-nosed pliers/thin-nose pliers with curved jaws. It is this curved shape that is very convenient for crawling under beads or woven wires.

To cut wire, it is better not to use end cutters , which give a rough, unsightly cut. It is more convenient to use side cutters , which can “bite off” the wire even in inaccessible places. And it is important that the side cutters can bite the wire so that the cut is straight and not flattened. Mine can do that!

And it is important that the side cutters can bite the wire so that the cut is straight and not flattened. Mine can do that!

End cutters are on the left, side cutters are on the right I’m kidding, I think everyone knows the difference perfectly well

I’m kidding, I think everyone knows the difference perfectly well

If you manage to find inexpensive side cutters from the professional series (mine is from China, of course, but they served me well for several years until they became chipped, now I’m going to try Micron cutters), consider yourself lucky, because such a tool is made of durable alloys, easily cutting thin metal-containing bases - jewelry studs, pins, wire and metallized cables. True, if you are cutting steel, be prepared for the fact that even professional cutters will become chipped - like mine.

If you are doing forging, you will need a hammer - always with flat platforms, so as not to injure the material. For added safety, you can also cover them with adhesive tape. In addition to the hammer, there is an anvil , which can be successfully replaced by any other heavy metal object with a flat surface, for example, a piece of rail (if there is one lying around somewhere, let me know!) or a large sledgehammer.

To file uneven and unsightly ends of the wire, you need a needle file (jewelry or diamond - ideally) or a whetstone for sharpening knives; sometimes it is more convenient to use a glass manicure file.

From bottom to top: a nail file, a wood file and a jewelry file (of an interesting shape - not round, but slightly flattened)

Finally, stock up on a variety of cylindrical objects of varying diameters to create curves, rings, curls, and bases for rings and bracelets.

Tips: 1. sand new round-nosed pliers, pliers and duckbills thoroughly with sandpaper or even a file in those places where they will come into contact with the wire, so that irregularities and roughness do not scratch the material

2. Having gotten used to the new tool, remove it from it and throw away the metal inserts in the handles that are there so that the tool literally does not close its “mouth”. I don’t argue, sometimes it’s convenient, but mostly it interferes with work

I also have this tool -

round pliers with one jaw and a nylon nozzle on the other. They are convenient for making rings, but after using it, I still make rings using ordinary pliers. Not because I'm a conservative, it just seems that a special tool is unnecessary.

For anyone interested, I can tell you how to make a wire winder yourself - our Russian answer to a gizmo - again, a special device from America that twists wire into a spring. I didn’t come up with the home version, I found it somewhere on the Internet. In general, add yourself to the circle and contact us. Thank you for your attention! And, of course, I need your feedback like air!

I didn’t come up with the home version, I found it somewhere on the Internet. In general, add yourself to the circle and contact us. Thank you for your attention! And, of course, I need your feedback like air!

Wire bending machines

- A wire bending machine that produces parts directly from a coil. It is the most productive and economical option for mass production of wire products. This happens due to the fact that the coil of wire is installed in a special device - an unwinder, from which the metal thread enters the correct block. There it is exposed to a roller or plane mechanism, as a result of which the output takes the form of an even and straight rod. After this, the wire enters the bending unit of the machine, where, with the help of mechanical devices, it is given the required shape of the finished product. At the end of the process, the finished part is cut with mechanical scissors. Typically, such a wire bending machine can produce one type of finished product, which is determined by pre-installed mechanical devices and limited by the ability to manipulate the feed mechanism. Therefore, the shapes of products produced on such machines are not very complex in configuration, since the number of bending operations is limited to five.

- A wire bending machine for bending wire from a metal rod is a more technologically advanced method, which has a number of advantages compared to working from a coil. This is especially necessary when the finished product requires additional processing. This can be threading or stamping, which can only be done until the finished product is shaped. The disadvantages of such a machine are its need for an additional complex mechanism for feeding workpieces and relatively low overall productivity.

- The wire bending machine for bending wire using the rolling method is mainly used for the production of various round-shaped parts and various types of round springs. For example, such a machine for bending wire by rolling works due to the fact that the wire is fed through guide rollers onto a shaft of a given radius, where, due to its rotational movement, it bends around the finger a given number of times. In this case, the wire is twisted along a given radius, which has a bending finger and rolling rollers. Due to the position of the rolling rollers relative to the central shaft, the bending angle or spring pitch can be set and adjusted. A wire bending machine by rolling, like other similar mechanical devices, is capable of producing only one type of product per operation. To change the range of products, both the replacement of bending devices and commissioning work are required.

- Wire bending machine for bending metal wire using the pushing method. For certain wire parts, during their manufacture, it is necessary to give them complex shapes of certain geometric shapes, such as variable radii, irregular arcs, spiral appearance, and the like. It is not very effective to do this by running in, and sometimes it is even technologically impossible. Hence, the only possible way is to use the wire pushing method. The principle of operation is the forward movement of metal wire through a three-roll roll forming unit or a special spring-coiling device, in which the shape of the finished product is given due to the position of the rolling rollers. As a result, you can obtain any given curvature or a smooth change in the size of the radius. The main difference between rolling and other bending methods is that the equipment is more complex, requiring special knowledge during setup and maintenance.

- Straightening machines are used as an additional device in technological lines for the production of various metal wire mesh for straightening the wire and giving it a certain shape. Two technologies are used here: straightening using the rotation method using a frame and straightening using a two-plane straightening block. The two-plane block does not straighten very perfectly, but it does not twist the wire. But the rotating straightening frame has a more complex design, but many machine tool manufacturers still prefer it to the classic straightening block design.

Industrial methods

In production, specialized straight cutting machines are used to straighten almost all types of metal wire. The process is based on two main methods:

- straightening by rolling through a system of 5-6 pairs of rollers, which are located sequentially in different planes so that each subsequent pair is perpendicular to the neighboring one;

- straightening by drawing through several specially made dies.

As a rule, such machines must have a special device for automatically unwinding wire from coils or coils.

To work with elastic types of wire and alloy steel rod, the production technology involves heating and tempering the steel structure of the workpiece using gas burners or high-frequency inductive heaters.

How an industrial straightening and cutting machine works can be seen in the video:

How to Manually Align and Straighten Wire

Sometimes, for household needs or in the workshop, you need to use pieces of straight wire for work. But the question immediately arises: how to straighten the wire? After all, it is produced in factories and immediately packaged in round coils. This form is very convenient for storage and transportation. Therefore, in order to make a metal wire straight, it is necessary to expend not only some effort, but also use a number of simple devices.

Industrial methods

In production, specialized straight cutting machines are used to straighten almost all types of metal wire. The process is based on two main methods:

As a rule, such machines must have a special device for automatically unwinding wire from coils or coils.

To work with elastic types of wire and alloy steel rod, the production technology involves heating and tempering the steel structure of the workpiece using gas burners or high-frequency inductive heaters.

How an industrial straightening and cutting machine works can be seen in the video:

How to straighten wire without a machine

Unfortunately, at home, making a good roller machine capable of straightening wire with a diameter of over 2 mm is quite expensive and labor-intensive. Moreover, if the need for a straight wire rod is one-time. An example of one of these devices can be seen in the photo.

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

It is worth keeping in mind that straightening a wire with a diameter of more than 5 mm, made of alloy steel, will require not just tension to the shape of the string, but stretching until the wire breaks. As a rule, the rupture occurs at the attachment point on one of the ends, and for safety reasons you should not be near the stretched wire.

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature. But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable.

There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Search for records using a filter: Select BendingProtectionForgingCuttingWeldingDrilling Select RebarSquareCircleSheetStripWirePipeAngleChannel/Beam Select AluminumBrassCopperStainless SteelTitaniumCast Iron

Useful video

Watch the video where a man shows how to assemble a simple structure of a reinforcement bender for bending rods and squares:

The second video shows an overview of the mechanism for bending wire and curling hooks:

Conclusion

What is used for bending wire is described in detail in the article. To work with this material, you can use both simple tools and complex installations that allow you to perform a large number of operations per minute.

If you have a limited budget, you can independently make a mechanical device that will not be inferior in quality to factory products.

Offers bending machines for rebar, wire, sheet metal and pipes. Our website presents not only technical specifications, but also videos of bending machines and photos of finished products, which will allow you to better understand the production process. If you did not find the equipment you need on the website, send the technical specifications by email, we will select a machine for your tasks.

How to straighten wire without a machine

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

- First you need to firmly fix one end of the wire in something massive and solid. To do this, you can wrap its end around the base of a power line pole or a strong tree with a trunk diameter of at least 25 centimeters.

- Next, we manually unwind the coil on the ground and, if possible, stretch it as much as possible.

- At the second end of the unwound wire we make a loop and secure it in a device capable of pulling it with force, that is, moving it a certain distance.

- The straightening process itself consists of slowly stretching the metal wire with great force until it becomes shaped like an ideal string. To secure the straight shape, you can leave it in this tense state for some short time, from about 5 to 30 minutes.

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

Method No. 1

We tie one end of the wire tightly to something strong - for example, to a concrete power pole. We unwind the coil to the required length, and wind the second end to a mobile object, for example, to a car tow bar, to a tractor, or to a winch.

Having started off the car, carefully tighten the wire. It is important to stretch it well, but not to tear it. Be careful, a wire that breaks like a string can seriously injure you or people nearby.

Typically this method is used when stretching wire with a diameter of 5 mm or more.

Leave the wire taut for 30-40 minutes, or an hour. Then the wire will “remember” the new shape and become straight, straighter than ever.