Metal rod bending

Metal rods are classified as high-quality products and are usually supplied to customers in large quantities.

These large batches will have to be processed by bending specialists. Of course, on a serial, and even on a smaller scale, there can be no question of any manual bending of a rod along the radius. Firstly, this is technically impossible, and secondly, the performer will not meet the deadline. And finally, in a hurry and with the use of manual tools, defects in work are inevitable. Modern bending equipment is precise and accurate. Moreover, with any type of product: processing “traditional” rolled products with a round cross-section is as simple for it as bending a square, rectangular, hexagonal bar, as well as any non-standard-shaped profiles.

Homemade and industrial methods of wire bending

It is difficult to say where products made from wire, which is a metal thread or a thin rod, have not been used today.

Wire bending made it possible to give products any desired shape. Both using hand tools and mechanical influences on special equipment. From a physical point of view, the process of bending wire consists of simultaneous compression of the inner and stretching of the outer layers of the metal of the wire. The process can also be accompanied by a longitudinal displacement of these layers if twisting occurs. This technology for working with metal wire is widely used in many industries and in jewelry.

Bending of solid bars

In this article, by bar we mean a solid product without internal voids, that is, solid.

Although production also produces hollow rods that have internal voids and, thanks to them, are often classified as small-diameter pipes - round or profile. When passing through a profile bending machine, they exhibit different properties, and their deformation can cause serious difficulties. Unlike rolled pipes, solid rods, that is, rods, can withstand any load. Although their ability to withstand deforming forces will largely be determined by the type of material. It is known that bending a metal rod made from medium-carbon steel is easier and safer than bending from unalloyed structural steel.

Characteristics of metal bar bending

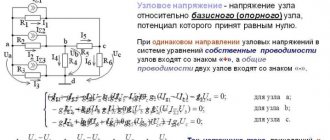

During the impact of bending equipment on metal, a phenomenon called deformation occurs.

But its character throughout the process is heterogeneous: first, elastic deformation appears, and then plastic. This change helps the rod maintain its cross-sectional shape at the bend and avoid defects. When bending a rod, it is subjected to deformation processes not as a whole, but in specific areas: so-called deformation centers appear on the workpiece. The metal fibers on the inner side of the bend experience compression and have a smaller radius of curvature than the outer ones, which experience tension. In the boundary area between the tensile and compression fibers, a so-called neutral zone is formed, which practically does not change during bending.

Bending a metal bar - features

However, this is not all the nuances of bending a rod along a radius. The accuracy of the operation and the quality of the final product can be affected by:

- metal strength;

- bending method - cold or with preheating of the workpiece;

- complexity of the form that the product must acquire.

When constructing monolithic objects “for centuries”, rolled products made from more durable steel grades are used. They are characterized by increased strength, but are extremely inconvenient to bend. If the material is not plastic, the only way to change its shape to the required shape is to heat it from 600 to 700 degrees. Thermal bending is performed on special equipment - horizontal bending machines.

Equipment for artistic metal bending – automatic and manual

To get a beautiful decorative grille for a window, or for a fence or balcony balustrade, you need equipment for cold artistic bending of metal. Let's figure out what these devices are.

1 Why do you need to bend rolled metal, and what is the best way to do it?

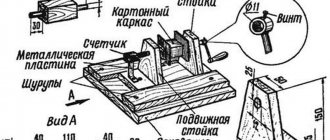

For the manufacture of canopy brackets over windows and doors, as well as for hanging wall lights and CCTV cameras, shaped elements from steel strips, as well as from rods or fittings are often used. Such parts can be ordered from a forge or from a company where rolling bending machines are installed. Or, as an option, you can make a mechanical tool for making metal ornamental elements with your own hands.

It is also important to know the operating principle of automatic devices that can be purchased to set up mass production of shaped parts.

The variety of artistic elements is small, but each option requires a separate operation. There are such form factors as a strip or rod with a spiral bend, a rod with torsion around the longitudinal axis, an element with a bend along a certain radius (to a ring) or a wave, as well as at an angle. Also, bending along a large radius is often used to add volume to structures. There are very few universal light-class devices with low and medium productivity; more often there are models that combine a complex for 2-3 types of bending.

2 Automatic machines for decorative bending

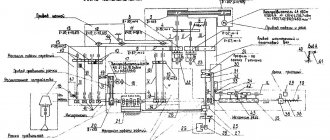

Equipment for producing decorative forms from steel strip, rod or reinforcement (as well as from pipes) can be mechanical, based on the operation of a flywheel, electromechanical, hydraulic and pneumatic. The first we will have is a machine for the simplest operation - metal rolling. Yes, the method of obtaining a small radius bend is based on this technology, that is, 3 rollers are used for the arc. However, the domestic machine “D 2 S” is multifunctional, that is, you can install an attachment for winding the “snail” with your own hands.

This equipment is considered quite simple because it does not need to be included in the production line. Instead of a driving, horizontally oriented shaft, a special template is used as an attachment, which is inserted into a chuck on the spindle. The workpiece is inserted into the clamp, after which the machine rotates the shaft to the required angle, which is set by simple programming on the remote control. The maximum diameter of the product cannot exceed 20 millimeters.

To obtain multi-turn volutes, several rotations of the spindle can be made with step-by-step replacement of nozzles, or using a prefabricated sectional template. The machine for cold artistic bending of metal “Decor 1” also works, it has a horizontal working surface with vertical spindles located on it. Rolls of various diameters or special snail templates can be inserted into the drive chuck. The equipment is equipped with a CNC control panel. Both devices start automatically and manually. The following machine can be called their budget option.

Bar bending - driven machines

On the Internet you can find many recommendations for making a device for bending a metal rod with your own hands. But, we repeat, such a mechanism, even if assembled correctly, will not be able to solve serial problems. For industrial purposes - for processing batches of workpieces - powerful drive machines are used. They:

- quite mobile;

- productive;

- do not take up much space;

- easy to set up and reconfigure;

- work carefully, creating the smoothest possible curves.

The service life of such equipment is practically unlimited. And if a breakdown occurs during operation, it can be easily corrected by replacing failed components and parts.

Wire bending machines

Mechanical machines for the mass production of parts and finished products from metal wire are widely used in industrial production. Depending on the technology used to shape the finished product, there are:

- A wire bending machine that produces parts directly from a coil. It is the most productive and economical option for mass production of wire products. This happens due to the fact that the coil of wire is installed in a special device - an unwinder, from which the metal thread enters the correct block. There it is exposed to a roller or plane mechanism, as a result of which the output takes the form of an even and straight rod. After this, the wire enters the bending unit of the machine, where, with the help of mechanical devices, it is given the required shape of the finished product. At the end of the process, the finished part is cut with mechanical scissors. Typically, such a wire bending machine can produce one type of finished product, which is determined by pre-installed mechanical devices and limited by the ability to manipulate the feed mechanism. Therefore, the shapes of products produced on such machines are not very complex in configuration, since the number of bending operations is limited to five.

- A wire bending machine for bending wire from a metal rod is a more technologically advanced method, which has a number of advantages compared to working from a coil. This is especially necessary when the finished product requires additional processing. This can be threading or stamping, which can only be done until the finished product is shaped. The disadvantages of such a machine are its need for an additional complex mechanism for feeding workpieces and relatively low overall productivity.

- The wire bending machine for bending wire using the rolling method is mainly used for the production of various round-shaped parts and various types of round springs. For example, such a machine for bending wire by rolling works due to the fact that the wire is fed through guide rollers onto a shaft of a given radius, where, due to its rotational movement, it bends around the finger a given number of times. In this case, the wire is twisted along a given radius, which has a bending finger and rolling rollers. Due to the position of the rolling rollers relative to the central shaft, the bending angle or spring pitch can be set and adjusted. A wire bending machine by rolling, like other similar mechanical devices, is capable of producing only one type of product per operation. To change the range of products, both the replacement of bending devices and commissioning work are required.

- Wire bending machine for bending metal wire using the pushing method. For certain wire parts, during their manufacture, it is necessary to give them complex shapes of certain geometric shapes, such as variable radii, irregular arcs, spiral appearance, and the like. It is not very effective to do this by running in, and sometimes it is even technologically impossible. Hence, the only possible way is to use the wire pushing method. The principle of operation is the forward movement of metal wire through a three-roll roll forming unit or a special spring-coiling device, in which the shape of the finished product is given due to the position of the rolling rollers. As a result, you can obtain any given curvature or a smooth change in the size of the radius. The main difference between rolling and other bending methods is that the equipment is more complex, requiring special knowledge during setup and maintenance.

- Straightening machines are used as an additional device in technological lines for the production of various metal wire mesh for straightening the wire and giving it a certain shape. Two technologies are used here: straightening using the rotation method using a frame and straightening using a two-plane straightening block. The two-plane block does not straighten very perfectly, but it does not twist the wire. But the rotating straightening frame has a more complex design, but many machine tool manufacturers still prefer it to the classic straightening block design.

Bending a rod on a custom machine

Bending of square rods and rolled products with other cross-sectional shapes is one of the leading areas of work in our workshop. An entire area is dedicated to it, where several serial orders can be carried out simultaneously. If you contact us, then:

- Receive high-quality rolled products of any complexity on time;

- save as much time and effort as possible, as we guarantee that your order will be completed on a turnkey basis, with shipping and delivery;

- You can order the service at a good discount if you entrust us with processing a large batch of rods.

With us you can bring to life any construction projects, even the most complex ideas. Contact us!

Working with a wire bending machine

To produce a large number of bent products from wire, various techniques can be used, each of which uses special equipment. The most common and economical method is the coil bending method.

Bending using this technology occurs in several stages.

- The wire, which is wound on coils, is fed to a two-plane roller machine, which aligns it.

- After alignment, the wire is fed to a wire bending machine, on which the product of the required configuration is formed.

- The formed product is cut off, and the entire bending cycle is repeated again.

The use of this technology allows you to fully automate the bending process and thereby achieve high productivity.

Budget wire bending machine

A wire bending machine can also look like a stationary template around which the wire is rolled using movable pressure rollers. Using such devices, bends of even the smallest radius can be formed on the surface of the wire, the value of which is comparable to the outer diameter of the workpiece. At the same time, the configuration of the product formed on such a machine can be quite complex.

The adjustable stops and variable arms of this template allow you to create many combinations of wire bends

A wire bending machine can also operate on the principle of pushing the workpiece through a system of rollers. When using such equipment, the end of the wire is connected to a special wire, which pulls the product through the working parts of the machine. A wire bending machine of this type, due to the features of its design, allows the production of products with even very complex shapes.

When leveling the wire, a wire bending machine is also used, which in this case is used for straightening. The working parts of such equipment can be straight frames or two-plane straight blocks. At the same time, rotating straightening frames are more efficient, which is why they are used in cases where leveling the surface of the wire needs to be done as smoothly and efficiently as possible.