Product advantages

Essentially, threaded rivets are hybrids of traditional nuts. But they should not be confused with exhaust vents. They have advantages, including:

- ease of installation work;

- you can reliably connect components made from fragile materials or those that have insignificant thickness (rolled sheet metal), because the rivet nut will not lead to deformation;

- if the total thickness of the products exceeds the length of the fasteners, then a one-sided fixation is made, without a through passage, and the quality of work will not be low.

Reliability of connections is achieved due to the threads located on the inside of the nuts, and on the outside of the bolts.

Types of threaded rivets

The range is quite wide, there are many classifications of fasteners. Thus, they can have a flat or countersunk head, a nut or screw thread, a round or hexagonal leg (does not allow rotation in the mounting sockets). If you take into account the purpose, then there may be:

- electrically conductive;

- having increased force (possibly indentation or stretching);

- for highly hermetic connections;

- with enlarged heads;

- with inch thread application;

- with special marks (for visual identification);

- with vibration isolation.

This list can be continued, but it is worth noting that the domestic industry produces a wide variety of rivets for different cases.

Materials used for production

The fasteners in question may have different sides. To get regular connections, buy nuts that have standard flanges. If you need to get a slight gap between the parts, it is better to use hardware with reduced or hidden sides. It is worth considering that before installation begins, the procedure of countersinking the holes into which the rivets will be placed is performed.

Threaded rivet nuts can be produced from several types of metal, in particular:

- Carbon steel. For the production of universal products and the creation of standard connections.

- Made of stainless steel. Production of hardware that will be used at high temperatures or in places with high humidity levels.

- Made of aluminum. Such rivets are distinguished by their low weight and excellent anti-corrosion properties.

- Made of bronze. This metal is used if fasteners with low spark generation rates are needed.

In some cases, neoprene polymer may be used. Products made from it are called self-installing, because installation work does not require riveting tools.

Installation process

The algorithm for installing a threaded element can hardly be called overwhelming, but it is important to know certain nuances. If possible, it is better to use a factory riveter. If desired, you can assemble it yourself; one option will be discussed below. The first step is to determine the type of metal on which the rivet will be installed. Next, you need to know what the diameter of the bolt or module that will be fixed thanks to this rivet is. According to the specified diameter, the appropriate rivet is selected. Its outer diameter is measured and a drill is selected that will be one tenth in diameter larger than the rivet. This is necessary so that the latter fits into place without much effort or obstacles.

Electric or cordless drill. The metal is drilled in the required location. After this, the fastening element is inserted into the seat. If it needs to be placed in a certain position, then it is better to hold it with your hands. For hexagonal holes, you can use special punches if we are talking about thin metal. If the thickness of the metal is greater than the length of the fastener, then the hole must be drilled a little deeper than the fastener, but there is no need to make a through penetration. After this, a rivet maker core is selected that fits the thread to the element being installed. The handles are brought together or the bolt is rotated so that part of the rivet is deformed and fixed in the hole.

Features of installation work

When you use mechanical special tools, significant physical effort will be required to obtain truly reliable connections of structural elements. The fact is that rivet nuts significantly counteract the tightening forces. A pneumatic riveter significantly simplifies the task , but its cost remains high.

If you have a special mechanical or pneumatic-hydraulic tool available, the installation process will be very simple:

- screwing the nuts directly onto the threaded rods in the riveter;

- the tool together with the hardware is turned until it stops in the hole made;

- the rod of the device is carefully pulled out, after which the fasteners are riveted independently;

- unscrewing the rod from ready-made connections.

DIY riveter

If the installation of threaded elements is required due to duty or work, then it makes sense to purchase a factory product that operates by hand force or based on a pneumatic mechanism. In most situations, the installation of such rivets is rarely required, so you can assemble the rivet gun yourself.

Bolt based

To assemble the entire structure, you will need a bolt similar to the one shown in the photo above. It can be taken from the crankshaft of a car engine. The diameter of the bolt must be such that a hole can be drilled inside it through which another bolt with a thread size that will match that used in the rivet will be inserted. The length of the second bolt must be at least 100 mm. The length of its thread should be as long as possible; if necessary, it can be additionally trimmed with a parallel tool.

Additionally, you will need a nut that will screw freely onto the thread of a bolt with a large diameter, as well as a collapsible bearing. The inner diameter of the bearing must be such that a long bolt, which will be used for clamping, can freely pass through it. The design is quite simple to assemble. To do this, you need to insert a long bolt inside a larger one in diameter. A nut is screwed onto the large bolt, and a collapsible bearing is placed onto the threads of the long bolt.

A rivet is screwed onto the long bolt and must be installed in the hole. You will need two keys to operate. One of them will hold the nut, and the second should rotate the bolt. You can simplify the task by welding a handle to the nut. The bolt rotates until the stop becomes significant. You shouldn't be too zealous. Once the result is achieved, you need to unscrew the long bolt. The bearing in this case is a stabilizer that prevents the bolt from biting inside the structure. There is a video about this riveter below.

Connection of profiled sheets

In principle, profiled sheets can be used anywhere. There are no strict restrictions as such. The main condition is the correct choice of product type and appropriate dimensions. One more nuance must be taken into account: you should definitely pay attention to such fastening elements if you plan to fasten structures, after completion of work with which access to their reverse side will be completely closed or very difficult.

For example, when working with a power (signal) cabinet, it will not be easy to dismantle the panel if the nuts screwed onto the screws turn.

Internal threads provide the opportunity to connect thin sheets of metal and steel, because the use of ordinary hardware will not give the desired result. Durability depends entirely on the parameters of the external sections. The larger the size of the fastener, the higher the reliability and strength. To connect parts whose thickness exceeds 4 mm, it is advisable to use rivets with M10 threads, 1-3 mm - M6, M8, up to 1 mm - M3.

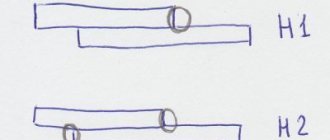

Types of tools by number of handles: one-handed and two-handed

In addition to the fact that riveters come in threaded and pull-out types, they also differ in the number of handles - one-handed and two-handed. A one-handed riveter is considered to be a tool in which one handle is movable and the other is fixed.

These are often exhaust devices that do not require much effort. They are designed for connecting rivets with a diameter of up to 6.4 mm.

Two-handed riveters are devices in which both handles are movable.

These are often threaded-type models, which require a lot of physical effort. They allow for riveted connections using rivets with a diameter of up to 14 mm.

Accordion riveters are a special type of tool that consists of one handle connected to a pressing mechanism in the form of an accordion or toad.

Such a tool also belongs to the category of traction tools, and the design cannot provide high clamping force. Accordion riveters are more expensive than conventional one-handed riveters.

All versions of hand tools are additionally equipped with swivel heads (except for the accordion), which allows riveting connections even in the most difficult to reach places.

The head of such tools has the function of moving up to 360 degrees, which greatly facilitates the use of the tool. However, the cost of such a device is 1.5-2 times higher than a conventional one with a fixed head. For home use, riveters with rotary heads are not needed, so it is not worth spending a lot of money just to have a multi-tool.

This is interesting!

Rotary rivet heads are used by specialists whose work involves the installation of sheet metal, as well as in the manufacture of structures, for example, mailboxes, etc.

How to rivet a regular rivet without a riveter using a homemade device

This device will require a short bolt or a long one that needs to be trimmed. Its cap is smoothed out from the markings by grinding. The bolt is clamped in a vice and drilled through with a 2 mm drill.

A nut is attached to it. To use the tool, a blind rivet is inserted into it from the end.

Its leg behind the head is fixed with a clamp (you can hold it with pliers, but you will need an assistant for this). For tighter contact, you can add a washer so that the clamp jaws have more area to rest.

Install the rivet into the hole. After this, supporting the cap with a wrench and rotating the nut, you can pull it out.

This is a useful life hack that will definitely come in handy for your workshop.

How to choose a quality device

Why does the question of how to choose a riveter remain relevant? After all, despite the fact that the tool belongs to the manual category, it has a fairly high cost. To save money, many buyers decide to take a desperate step - they choose cheap models. As a result, the device fails very quickly, and it turns out that the money was wasted. You should also not buy expensive models, since it turns out that the tool will simply lie on a shelf in the garage most of the time. What to consider when choosing a manual riveter - there are the following nuances:

- Device body material - do not buy plastic models.

No matter how colorfully manufacturers and sellers describe them, such instruments are toys that are only suitable for children. You need to choose devices only from high-quality steel. Reputable manufacturers indicate the type of steel used in the technical description - How much does the tool weigh? A good thread riveter has an appropriate weight, which allows it to be used for connecting rivets with a diameter of 12-14 mm

- Equipment - usually good and high-quality devices are sold complete with replaceable heads, as well as consumables.

In addition, the devices are located in special plastic, metal or wooden cases, which simplifies not only their storage, but also transportation - The manufacturer is very important, since today different manufacturers with unknown reputations appear on the market.

It is not recommended to tempt fate, so choose riveters from manufacturers such as Kraftool, Matrix, Gross, JTC, Stayer and others

This is interesting!

If you plan to use the tool frequently, then preference should be given to reinforced riveters.

They are more expensive than regular ones, but last longer and are designed specifically for long-term use. Drawing a conclusion about what types of manual riveters there are, it must be said that tie-type models are quite sufficient for home use.

A threaded tool can also come in handy, but only if you plan to work with sheet steel. Proper storage and use will increase the service life of even a budget tool model.