Toilets today have become so commonplace that not everyone thinks about their design. Although the principle of operation is quite primitive, it still arouses interest among many. Let's talk about the design of a toilet flush tank and figure out how to prevent unexpected consequences during operation.

History of origin

Cylinder toilets first appeared about 80 years ago, in the 1940s, when the cistern toilet design was first proposed. The first toilet with a flush tank appeared in England. At that time, running water had not yet become widespread, and the toilet had to be flushed manually, which caused a lot of inconvenience. Thanks to the filling tank, using the toilet and its flushing function has become much more convenient.

Later, with the advent of running water, it became even more convenient to use the filling tank; it was equipped with a filling valve that automatically shut off the flow of water from the water supply.

Over time, improvements have been made to toilet fill valves and increased water savings, but the design of the toilet and cistern remains roughly the same as it was in the 1940s.

Types of water connections to the tank

Connecting water to the drain tank can be done in two ways, such as:

- Lateral supply;

- Bottom supply.

Installation of cistern fittings

The side supply is more common due to the fact that it is easier to install; even an amateur craftsman without plumbing skills can handle such a connection. This connection is made using a flexible hose, which is led from the main riser and connected to the tank. All joints must be tightly connected. The disadvantage of this connection is that it is not very aesthetically pleasing, due to the fact that flexible hoses are visible.

The installation of fittings for a toilet cistern with a bottom water supply is a little more complicated. Therefore, to make the connection yourself, you need to put in a little effort. People who choose this connection method want their bathroom to look beautiful and not have various pipes and hoses visible. This water supply looks beautiful and aesthetically pleasing, since it is difficult to immediately notice the pipe.

Sequence of operation of the toilet cistern when flushing

When using the toilet flush function, the toilet flush handle opens the flush valve: the flush lever moves a lever to lift the flapper valve or tank ball and allow water to flow into the toilet below, flushing waste into the drain pipe.

At the end of the flush cycle, a float arm or float that moves on a vertical leg lowers, opening a special valve that allows the toilet tank to fill with water.

When the water level in the toilet reaches the required level, the float closes the toilet fill valve.

Operating principle of the drain mechanism

When you press the flush handle, the toilet flush valve opens and directs water from the cistern into the toilet. The two most common toilet flush valves used in cistern toilets are the flush valve and the ball valve.

A toilet shut-off valve is a toilet flush valve that closes the opening at the bottom of the toilet using a semi-circular flapper (usually rubber).

Similar to a toilet flush ball valve, the flapper valve pulls upward to open the flush hole in the toilet tank to direct water into the toilet.

The shape and position of the flapper is designed such that it remains in the open position until the water level in the toilet bowl drops to near empty, and then the flapper "slams" over the flush hole to stop the toilet's flush cycle and allow the toilet to fill the tank with water. .

Once the flapper valve closes, the pressure of the water filling the toilet presses the surface of the valve against the seat, holding it closed to prevent leakage.

A ball-type flush valve is a regulator that directs water from the plumbing into the toilet to flush waste.

Today, there are many models of flush valves, most often used in public places. The basic principle of operation of such a valve is to flush the contents of the toilet into the sewer with water directly from the water supply. Such toilets do not have a filling tank in their design.

The principle of operation of such a shut-off valve is to regulate the pressure of tap water and lock it using a special spring. When you press the flush lever, the valve sends water into the toilet and closes automatically as the shut-off spring moves.

How to change the flush mechanism in a toilet cistern (detailed instructions)

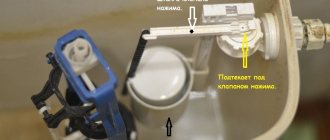

You may need to change the flush mechanism in the toilet tank if you notice that liquid is filling slowly or too quickly and is leaking into the bowl of the device.

Main reasons for replacement

All elements of the flush mechanism are interconnected, and the failure of one of them can lead to disruption of the entire system.

After prolonged use of the toilet, the quality of the flush mechanism may decrease due to dirt, hard water and wear of parts. Malfunction of the drain system in the tank occurs for various reasons:

- Constant collection of water and draining its excess mass into the toilet. The float or shut-off valve should be checked. During operation, the plastic float mechanism wears out and cracks, so it will float more slowly than necessary, and water will continuously accumulate - replacement is required.

- Another reason when liquid is continuously collected can be: bending of the metal twist or breakage of the ratchet. The first one can be straightened, but the plastic part needs to be replaced. And if the valve does not work (high water pressure), then install an additional float valve.

- If the liquid does not flow into the drain tank. This happens due to the following factors: A blockage in the flexible hose - you can check by turning off the water, disconnecting this element from the tank, and pointing its end into the toilet. If, after opening the valve, water does not flow, the tube is clogged and needs to be replaced.

- If the hole in the shut-off valve is clogged, it can be cleared using a thick wire or a knitting needle.

- The valve itself is faulty.

Required Tools

Some parts of the drain mechanism are quite fragile, so you should carefully carry out all dismantling work, without using excessive force.

To replace the internal fittings of the drain tank, you will need the following tools:

- pliers;

- adjustable wrench or wrench.

Step-by-step instruction

A complete replacement of the entire drain system will save time searching for the cause of the malfunction and will allow you to avoid possible breakdowns of old parts in the future.

Several faults may be detected in the toilet flush system, so in order not to change several parts, it is more advisable to install completely new internal fittings of the tank. The replacement algorithm is as follows:

Close the water supply valve to the tank and drain the remaining liquid. Remove the lid, if the toilet has a button, first dismantle it - unscrew it or remove the clips. Using an adjustable wrench, remove the water supply hose. Turn the upper part of the mechanism at an angle of 90° and remove it. Unscrew the fastening bolts that connect the tank and toilet bowl, and carefully lay the tank on the floor. Unscrew the fasteners from the drain and inlet valves, take out the old fittings and prepare a new one. The trigger mechanism is first placed in the washed, prepared tank; it is fixed at the bottom of the tank with a threaded cuff. Then a soft pad is placed under the hole and the tank is installed on the toilet. Align the position and screw the tank in place using the mounting bolts, doing this evenly so that there is no distortion. A rubber seal is placed on the supply valve, inserted into the tank and secured at the bottom with a threaded cuff. Before connecting the water hose, pass liquid through it (holding it over the basin) to avoid the ingress of scale particles. The water level is adjusted with a leash on the supply valve. Install the cover and screw on the bleed nut with the button.

When choosing new fittings for the drain tank, you should take into account the design features: the fitting can be installed on the side or bottom, left or right, the size of the technological holes may differ

You also need to pay attention to the quality of the material; it is better to buy parts from trusted manufacturers. If replacing drain fittings is difficult or you lack skills, it is better to contact a plumbing service

Types of valves in toilets with a tank

The fill valve allows water to enter the toilet's holding tank to refill it after the water has been flushed. Most fill valve designs also direct some water through the overflow tube into the toilet when the tank is refilled to further irrigate the toilet surface after flushing.

There are two designs of cistern toilet valves in use today: the ball valve toilet fill valve and the concentric toilet fill valve.

The float assembly in the toilet cistern activates the toilet fill valve when the water level in the toilet cistern or cistern drops to a certain level.

On concentric toilet fill valves, the float is a cylinder that moves down or up a vertical shaft as the water level in the tank falls or rises to open or close the fill valve itself.

A ball valve toilet fill valve is opened by moving a float lever rod attached to a round float ball, which lowers when the water level in the cistern changes during a flush. The ball valve valve closes when the float rises, raising the rod to which it is attached as the water level in the toilet rises to the fill line.

Problems in the mechanism and their elimination

What problems may arise during the operation of the drain mechanism? For example, water may not be filling into the tank, or the water may no longer be shut off. The reason for this phenomenon most likely lies in the fact that one of the holes is clogged. Another reason for such problems is the failure of one of the two most important parts of the mechanism - the rod or the membrane.

In any case, you will have to disassemble the device and check all the elements. They will also be thoroughly rinsed and cleaned. But it happens that the cause of malfunctions is a banal low pressure in the water supply system, or its surges within one day. In this case, the device may simply not work.

If the pressure drops too much, water will stop flowing into the tank altogether. If water must come from a suspended structure, then if the pressure is below normal, the water will not even be able to reach the filling chamber. The float will float, but it will not block the water. To cope with this situation, you may even have to enlarge the water inlets by drilling them out a couple of millimeters.

In general, the smaller these holes, the greater the pressure should be in the system. This must be taken into account if you are installing a drain mechanism, for example, in a country house. If you know for sure that you regularly experience pressure surges during the day, for example, if the water pressure in your house is maintained by pumps that are turned off at night, then it is best to pay attention to fittings with a rod valve.

That's all, we looked at the design of the toilet cistern flush valve, as well as the reasons why it may fail. Now it won’t be difficult for you to understand everything and troubleshoot problems.

The drain tank is leaking, what should I do?

As the toilet is used, when the main parts of the locking mechanisms wear out, various leaks may occur that cause inconvenience.

Thanks to special technical measures, toilet manufacturers have eliminated the possibility of overflowing the toilet tank to prevent it from leaking onto the floor. Almost all toilets have special drainage holes where water gets in if one of the elements of the filling mechanism fails. In this case, the toilet seems to be in constant flushing mode, the water flows without stopping.

If the cistern leak is insignificant, then the main inconvenience will be only the sound of water and traces of leaks inside the toilet itself. In the case where the leak is significant, additional costs for water arise - water consumption becomes significant.

Repairing a toilet tank must begin with diagnostics to find out which unit of the flushing mechanism is causing the leak.

Tank shut-off valve. Most often, a tank shut-off valve is a plastic valve with a rubber surround that closes the neck of the tank and, using water pressure, stops the flow of water. Most often, it is the drain neck of the tank that begins to leak, and the problem must be looked for either in the neck gasket or in the valve surround.

Before replacing the shut-off valve or neck gasket, you need to check for dirt. Since tap water is not completely purified, the internal parts of the toilet and all mechanisms of the flush tank may become coated with rust or dirt. Sometimes it is enough to simply wipe the rubber gasket of the toilet, or the edge of the flush valve, and it will work again.

Another reason for the failure of the drain valve is the destruction of its rubber part due to physical wear. Then all rubber parts of the drain hole and tank valve must be replaced.

Water shut-off valve. This type of valve can also fail during active use of the toilet. Today there are several types of valves - direct type - when the mechanism for opening and closing the valve is directly connected to the float, or reverse type, when the valve opens due to a decrease in pressure inside the blocking membrane. When the water pressure inside the blocking membrane decreases, the second membrane opens - the inlet one.

It is in this block that wear of the rubber membrane most often occurs, due to which the valve either begins to leak or stops closing. This type of valve is most widespread due to the high filling speed of the toilet tank, but its repair is the most difficult. Most often, either the rubber membrane or the entire locking mechanism must be replaced.

Modern diaphragm valves

The diaphragm float valve ensures fast water supply. Depending on how high-quality the fittings are selected, this process can be noisy or almost silent. Unlike older models, it overlaps very quickly.

If we remember the disadvantages of membrane inlet valves, then they also exist. The main disadvantage of using this type of valve is that for it to work effectively, constant pressure must be maintained in the water supply network.

The value of such pressure should be in the range of 0.05-0.1 MPa. Moreover, in order for such a valve not to fail quickly, the water in the system must be clean. It is clear that both of these conditions are quite difficult to achieve in some places, for example in villages or holiday villages.

Another aspect that should not be overlooked if you are considering installing a membrane-type cistern shut-off valve in your toilet is the quality of all fittings and shut-off elements. If the material used for its manufacture is not of very high quality or there were defects in production, then long-term use of the product is out of the question. This valve will have to be replaced frequently. Even repairs here will most likely be powerless. It is not possible to make a new membrane yourself.

Adjusting the water in the toilet

For two types of floats (cylindrical and ball), different methods are used to adjust the water filling level inside the tank.

The cylindrical float is adjusted by changing its position on the vertical shaft. As a rule, the vertical shaft has special slots to which the float cylinder is attached. In order to adjust the filling level of the tank, it is necessary to remove the float from the grooves of the shaft, move it to the required height, and then reinsert it into the grooves of the shaft.

To adjust the ball float, you must adjust the special inlet valve screw so that the valve closes at a lower float position. In some cases, when there is no special screw, the float rod is simply bent so that the float closes the inlet valve at a lower water level in the tank.

Types of shut-off valves and their features

Shut-off valves can have a separate or combined design. In the past, toilets used exclusively a split configuration. In it, the filler and drain valves are installed separately and function autonomously. The operation of the filler valve is regulated by a float, which, when water rises in the tank, shuts off its supply by means of a control rod. The drain assembly consists of a neck with a valve, which can be:

- air;

- mechanical.

Control is performed by operating a button, pedal, key, lever. The advantages of separate shut-off valves include the ability to replace or repair only the damaged unit. This saves costs and simplifies installation and dismantling. Therefore, such systems are still used in toilets today.

Elite class products and the latest models use a new design of shut-off valves.

In it, the drain and fill valves are connected into a common system and have a direct traction relationship. Adjusting prefabricated shut-off valves is difficult.

But with precise tuning, safe and flawless operation of the unit is guaranteed. The disadvantages of such a system are the need for complete dismantling in case of breakdown and the complexity of repair work. Shut-off valves also differ in the material of manufacture. In most cases, polymers are used for it. The strength and durability of the fittings and the flawless operation of the system depend on the composition of the plastic. Previously, the cost of reinforcement could be used to judge the quality of the material and the accuracy of the design. Currently, the number of manufacturers of these products has increased significantly. New companies that are just beginning to conquer the market produce high-quality products at low cost. And, on the contrary, counterfeits are sometimes found in certified goods. Therefore, unfortunately, low-quality fittings can only be identified during operation.

Metal fittings are distinguished by their high strength and long service life . Bronze or brass alloys are used for its manufacture. These materials are highly resistant to moisture and mechanical stress. Therefore, they retain their functional qualities for several years and are not destroyed by corrosion. Toilet manufacturers install single shut-off valves made of metal only in elite models made in a certain style. Any toilet can be equipped with separate systems.