How does he work

This mechanism must perform two functions - controlling the filling of the container with water and flushing. For this purpose, a rather complex mechanical system was developed, which received the general name of shut-off valves. It is designed to almost completely automate the process. The only thing that is required from a person is to press a key (button). The general design of the drain mechanism fittings consists of the work of two elements - a device for regulating the supply of water to the container and a mechanism for its removal.

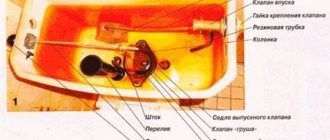

The plumbing float is responsible for performing the first task. Its design consists of a control membrane, which is connected to the float using a system of levers. When filled with water, the float remains on the surface all the time, gradually rising. Having reached a certain level, which you can set yourself, the lever closes the water supply valve.

The next important element is the water removal system. The simplest model consists of a housing in which a valve is placed that opens (closes) the pipe connecting the tank to the bowl.

Advice

To prevent the creation of an emergency situation (overflow), a hose is provided in the side part. It carries excess water into the bowl.

Thus, it can be summarized that any cistern circuit must perform two functions.

- Fill the container with water in a timely manner, the level of which you can set yourself.

- Ensure that water is drained exactly in the volume for which the mechanism was adjusted.

However, every manufacturer is trying to modernize the device. This is the reason for the emergence of mechanisms that differ in their functionality.

Drain valve

From the point of view of the design of the mechanism responsible for flushing, the design of the toilet tank has changed much more radically. We will list only the schemes that have gained the most popularity.

Bell

The bell itself is a massive cast-iron plug with a soft gasket, which was pressed by its mass against the spout seat. This mechanism was used in upper cast iron tanks. (See also the article Sealant for sewer pipes: features.)

How did this scheme work?

- The user pulls a chain attached to one of the arms of the lever.

- The second shoulder raises the bell, opening the way for water.

- After the chain is lowered and the bell is lowered into the saddle, the remaining water is sucked out of the tank through the U-shaped water intake due to the vacuum in the drain pipe. The same water intake serves as an overflow.

The system is extremely fault-tolerant: its maintenance was reduced only to periodic replacement of gaskets. Many samples are still operational.

5 - bell, 2 - water intake pipe (aka overflow).

Corrugation

In this case, the device of the toilet flush cistern in the part responsible for draining is the most primitive. The corrugated plastic pipe bends toward the water surface when the user pulls the top tank rope. After the water begins to drain, until the entire volume is drained, it is again held in an inclined position by the vacuum in the pipe.

Alas, in this case, simplicity did not guarantee reliability. The service life of polyethylene corrugation is from one to five years. A typical fault is a crack at the bend. (See also the article Sewer pipes: features.)

Pear

A drain assembly including a bulb is used in compacts. The principle of its operation is also extremely simple and intuitive: the rod pulls up a rubber bulb, blocking the exit from the tank. The consumption of the entire volume of water is ensured by the buoyancy of the hollow bulb.

This type of drain valve has several modifications:

- The bulb stem can be lifted using a handle passing through the reservoir lid or a side lever.

- The overflow can be a separate pipe or a tube that replaces the stem.

- Finally, an additional float can be used in a mechanism that blocks the lowering of the bulb until the entire volume of water has completely drained.

Typical malfunctions of the mechanism are the loss of elasticity of the bulb (it can be treated by replacing it) and the destruction of the thin copper rod. In the second case, an express repair is possible: the rod is replaced with an aluminum or stainless knitting needle that pierces the pear.

The operation of the mechanism with a pear.

Modern drain valves

The units used in modern imported tanks are a solid block, which is mounted on the outlet pipe of the tank by installing it in grooves and turning it 90 degrees. The design is based on a plastic saddle and an elastic rubber gasket, which is pressed against it by water pressure. The tube in the middle of the ring gasket is used as an overflow.

According to the principle of operation, the design of a toilet cistern with a modern valve differs little from the domestic compact with a bulb; however, several additional features aimed at saving water were not available in the older designs.

- The dual flush system allows you to use only part of the water in the tank when you press one of the buttons.

- Two mechanical sliders allow you to adjust the flush intensity (the height to which the gasket rises above the saddle is adjusted) and water flow in economy mode.

The only operational problem with this type of reinforcement is the loss of elasticity of the gasket. Most often this happens in hard water rich in mineral salts. Replacing the gasket takes no more than a minute.

Modern Cersanit flush valve with dual flush system.

Kinds

The most common is the push-button mechanism. Unlike old lever models, they are more functional and easy to use. The operating principle of push-button devices is quite simple - using a system of levers, water is drained when the button is pressed.

If we talk about a complete classification, we can distinguish the following types.

- Lever. Drainage occurs when the shut-off membrane is raised. The flow of water stops the moment the lever is lowered. Currently, such models are practically not used.

- Button. As the name suggests, water is released by pressing a button. It activates a system of levers that hold the membrane open until a certain water level in the container is reached. It can be single-level (draining the entire volume) or two-level (the design has two buttons, one of which activates a full drain, and the second a partial one.

- Automatically. Installed mainly on expensive models. Drainage is carried out automatically when the corresponding signal is transmitted from the sensors.

The choice of one model or another directly depends on the design of the cistern. Particular attention should be paid to the location of the water supply hose. It can be either side or bottom.

Advice

Manufacturers often provide the opportunity to select a set of shut-off valves with one or another type of water supply connection.

Toilet flush system repair

The toilet flush system is one of the few devices whose reliability practically does not depend on price. Moreover, cheap, simple models often work longer.

However, over time, even these reliable devices fail, and water begins to leak, or, less commonly, does not enter the tank.

The reasons for breakdowns and the need to repair the toilet flush system are different. Of the main ones:

- Deformation of mechanism elements due to aging of plastic.

- Rusting and oxidation of metal parts (if any).

- Limescale. Gradually increasing, it begins to interfere with the operation of parts, reduce the tightness of the junction of plugs and gaskets, and clogs the water supply openings.

- Mechanical failure of a part due to material fatigue or accidental damage during installation, maintenance or adjustment.

Many problems with toilet flushing can be eliminated by cleaning and adjusting the mechanisms.

Often a breakdown occurs in a new or relatively new mechanism. This happens - during installation or adjustment, the rod, lever broke, or the fastener burst.

Alas, it is unlikely that a complete repair of the toilet flush system will be possible. It is best to purchase exactly the same mechanism, replace the broken part, and hide the rest for the future.

It is best to replace a device that has worked for eight years or more with a new one, without going into too much detail about what broke there.

In this case, it makes sense to get involved with repairs if you won’t be able to purchase a new mechanism in the near future, or if you have a similar one at hand.

A leak in the supply tap may be caused by wear of the membrane. Just try turning it over to the other side. Some models (usually lever ones) allow this.

If the mechanism is three to five years old and there are no obvious mechanical breakdowns, it is usually not difficult to fix the problem.

Sometimes it is enough to lower the water supply float, tighten the nuts, and replace the skewed lever.

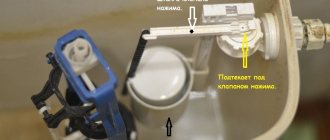

Sometimes it is enough to tighten the nut a little or adjust the float of the toilet flush system to eliminate the leak

If surface adjustment does not help, remove and disassemble the problem unit. We wipe the parts from dirt, carefully clean all parts from lime deposits. We pay special attention to the valves and sockets where they fit.

We clean and check how the lever joints move.

It is advisable to clean and inspect the mechanism at least once every couple of years, no matter how well it works.

Design features from different manufacturers

Why know the features of the drainage mechanism in various models? Without this, it is impossible to fix even a small problem that may be specific to a particular device. In this case, you can do the repair yourself without calling a specialist.

Let's look at the most popular models from various brands.

The simple design of the Cersanit toilet cistern directly affects its reliability. It is made according to the classical scheme - the bulb fixes the position of the water supply shut-off mechanism. The most common problems faced by users are.

- Incorrect water supply valve setting. The result is high fluid consumption.

- Large pear size (for Compact model). Sometimes it gets caught on rough thermal walls, which leads to overflow.

But in general, the products of this company can be described as high quality and reliable.

A special feature of the Keramin toilet cistern is the location of the float. They, like their foreign analogues, are mounted not on a horizontal rocker arm, but on the vertical axis of the valve. This design is more reliable and almost completely protected from possible jamming of the float.

In addition, the location of the safety valve should be noted. It is part of the design of the drain system, which makes it possible to significantly reduce the dimensions of the entire mechanism.

One of the simplest and most reliable models to use are models from Porta. The manufacturer initially strived for simplicity in the functionality of the designs. Most models have a one-button water release option. However, thanks to simple adjustment of the location of the bulb, you can set almost any level of filling the container.

At the same time, it is worth noting the design flaws. It is designed for a small tank volume. Therefore, these shut-off valves are installed mainly in their own products.

Sanita and Colombo toilet cisterns are characterized by similar design features. Despite their apparent simplicity, to repair them you need to know the basic principles and rules for carrying out restoration work.

Options for installing a toilet cistern

There are three key methods for installing a cistern in an apartment or private house:

- Under the ceiling;

- Connection directly to the toilet itself;

- Installation in the wall of the toilet room.

Almost no one installs a drain tank under the ceiling, since for this you will need to buy the appropriate fittings. The key disadvantage of this system will be its not very convenient operation, however, water is both collected and drained under fairly good pressure. Today, such a design is very rare, as it has been replaced by more attractive modern systems.

When the tank is connected directly to the toilet itself, then this technology will have a decent number of positive aspects. In this case, the tank will be in a fairly convenient position - if repair work is necessary, you will not have to think about how to get to this device. It is also very convenient to monitor the tank, see if everything is in order, and so on.

If you plan to install the tank in the wall, then you need to remember that this is a very labor-intensive process. Of course, from an aesthetic point of view, this will be the most profitable option, since a tank of this type will be practically invisible, in addition, with the help of this solution you can seriously save useful space, which is not enough in the sanitary unit.

The device of the outlet valve of a modern toilet cistern