Toilets today have become so commonplace that not everyone thinks about their design. Although the principle of operation is quite primitive, it still arouses interest among many. Let's talk about the design of a toilet flush tank and figure out how to prevent unexpected consequences during operation.

Construction and operation of drain tanks

All flush tanks have a similar design. The only difference is in the water release mechanism.

Structurally, a toilet cistern with a button or two buttons, as well as a flush lever, can be represented as a set of interacting nodes:

- Filling valve. It is responsible for maintaining the water level at a certain level. The operation of the valve is controlled by a hollow float. When the water rises to the desired level, the float closes the water supply channel to the tank;

- Plastic float attached to the filling valve. It works on the principle of a rocker arm, rising when the tank is filled;

- Drain valve with overflow system. Modern versions of tanks involve controlling this valve by pressing a button. With the old-style manual flush control, it is enough to pull the lever or chain to release water into the toilet;

- The overflow is a mandatory component of the tank. It is height adjustable, allowing you to set the maximum water level. When this level is exceeded, water flows through the overflow tube into the sewer without spilling out through its walls.

The basic design elements and the principle of operation of the mechanism are the same for all types of flush tanks, only their execution differs.

A tank with a mechanical drain of water works very simply. Water enters it through the filling valve when the float is lowered. After reaching a strictly defined level, the float shuts off the water supply. The drainage is controlled manually. If the tank is equipped with buttons, then the water is drained after pressing them. In this case, the flush valve partially or completely opens, allowing water to flow into the toilet. The float lowers, opening the filling valve slightly.

The structure of a toilet cistern with two buttons is a little more complicated, but such a cistern can be used more economically. If you press one of the buttons, the water is partially drained. Complete drainage occurs when you press the second button.

More and more often you can find new types of tanks that have a lower connection to the water main. It is advisable to install them if using a side connection is not possible due to lack of space. The main difference between this tank is the presence of a membrane valve. Under the influence of water pressure in the pipeline, the valve opens slightly and lets water inside. As the water rises, the float presses on the piston rod, which gradually closes the diaphragm valve. When the set level is reached, the valve closes completely.

Fittings with bottom water supply and controlled by push button

Adjustment and repair capabilities

During the operation of the toilet, various minor problems arise from time to time. You should not immediately run to the store and buy new filling for the tank, since some problems can be solved in no more than half an hour. In this case, it is not necessary to invite a specialist and pay him money, but just try to do it yourself.

A quick and 100% way to eliminate a leaking toilet cistern

How to adjust the water level in the tank

In devices with a bottom water supply, it is always better to adjust the water level after installing the toilet, since they are all adjusted at the factory to the maximum level, which may turn out to be redundant and uneconomical. To adjust the level in the drain tank, it is enough:

- Drain the water from the tank and also turn off the water supply.

- Unscrew the button.

- Remove the cover.

- Adjust the height of the float using a special screw located at the top of the float mechanism.

Adjusting the water level - Close the tank with a lid and install the button.

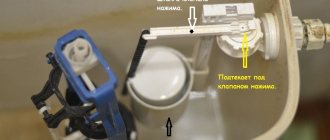

There are cases when, after installing a toilet, water constantly flows from the tank. This indicates that the water level in the tank is high enough and water flows through the overflow system. In this case, it is necessary to reduce the water level by lowering the float using the technology described above.

Setting up the fittings in the cistern

If the float mechanism consists of a curved lever, then the water level is adjusted by bending this lever, which is even simpler. It is important to understand that the lower the float in the tank, the less water it will hold.

By bending the float lever we change the water level

Toilet cistern leaks

Water leaks in the toilet are possible even if the water level is normal, but then you will have to look for other reasons. Water may leak if:

- The sealing rubber of the drain valve has silted up, so it will have to be cleaned. To do this you will have to:

- Turn off the water supply and drain the water from the tank.

- Remove the water drainage mechanism.

- Remove the bleed valve and carefully inspect the gasket. If necessary, it is cleaned or sanded with fine sandpaper.

- Place the mechanism back into the drain tank, turn on the water and test the device. If this does not help, you will have to replace the gasket.

How to fix a water leak from a toilet tank, HOW TO REALLY SAVE SUPER WATER!

- The release mechanism was demolished during operation. This is easy to check; just press the mechanism with your hand. If the water stops flowing, that means it is so. In this case, you can make the glass heavier by adding a little weight to the bottom of the glass.

Adding weight

In any case, you will have to disassemble the mechanism, and then reassemble and check it. If these little tricks do not help, then it is better to buy a new drain mechanism and replace the old one with it. In fact, this is the best option.

Leaking in the toilet drain hole

Water does not fill into the tank

There is also a problem that water does not fill into the tank at all, or it does, but rather slowly. If the water pressure is normal, then the reason is obvious - the filter, tube or valve is clogged. The way out of this situation is quite simple and boils down to cleaning the filter, tube or inlet valve. To do this, you will have to completely remove the water supply mechanism, and then reassemble everything as it was.

You can see how to do this correctly in the video.

What to do if water does not fill into the tank

Repair of a two-button tank

Economical water consumption adds to the popularity of such a plumbing fixture. How to repair a toilet cistern with two buttons? The principle of disassembling such a tank remains the same, as with the one-button version.

Typical failures of a two-button tank:

- Buttons sticking. To install the buttons in place, remove the cover by unscrewing the locking ring near the button. Sometimes the buttons snap back into place if you press them again.

- If the water does not drain, check the integrity of the connecting fittings. Reinstall it or replace it with a piece of copper wire.

- Water flowing through the drain valve indicates that the valve is not positioned correctly relative to the drain hole. If water flows through the overflow neck, adjust the water level by changing the position of the float or the overflow height.

To adjust the float, you just need to raise or lower it a little.

And if you are interested in how to install a shower cabin with your own hands, then we also have material on this topic.

Before purchasing a water filter, we recommend that you read our tips for choosing them.

Varieties of toilets with a cistern according to the type of flush mechanism

The toilet cistern flush device can be operated using a pull or push mechanism. In the first case, the main element is the lever, which is located in the upper part of the body. Water is drained by lifting the handle up. This mechanism has already lost its popularity and is extremely rare in modern products.

Most models are represented by a toilet cistern flush device with a button. Water is drained using a button recessed into the body of the device. The drain valve is opened using a lever system. In turn, the push mechanism can be one-button or two-button. In the first case, there is one button installed on the lid of the toilet tank, which, when pressed, dumps the entire contents of the device into the tank. In dual-mode tanks, there is a button for the toilet tank, which consists of two parts. One half is responsible for dumping half the volume of the tank, the second - for completely emptying it.

Helpful advice! Some modern models are equipped with a stop function button, which, when pressed for the first time, starts draining the water, and when pressed again, closes the drain hole of the tank.

How does the drain mechanism work?

By pressing the release button, the tank system begins to operate. Such a device for drainage equipment is located in connection with its “filling”, located in the container itself. Before the button is pressed, the tank is waiting. It already contains water, which runs up to the set level. Using a special bulb, the liquid is held in the tank. It is made of rubber material, so it always fits quite tightly to the saddle. By pressing the button, a pull is performed, which in turn pushes the bulb away to open the drain. As a result, the seat will not be clogged, liquid will enter the hole in the tank and flow out into the toilet.

Toilet with a button on the cistern lid

After releasing the button located on the tank lid, the bulb does not immediately return to its original position. Otherwise, this would have meant that the drain was short-lived. In the right device, this is the process of slowly lowering the bulb, completely hollow inside. There is only air in it, pushing it out of the saddle.

The lifting force of this component of the system becomes less according to the degree of water collection into the tank. At the end, the pear is completely sucked to the saddle. Installation without a special guide tube would not bring a positive result. The secret here is that various forces act on the rubber shutter, leading it in the direction of minimum resistance. If there was no pipe in the structure, then this rubber element would not be able to return again to the saddle located in the center of the tank.

Types of toilets with a tank depending on location

An unremarkable plumbing product in the form of a toilet cistern is presented in a wide variety of species.

The toilet tank may have a solid body. This monoblock is easy to install. It is enough to install the structure of the flush cistern with the toilet bowl and connect the pipes for supplying and draining water. The product can be floor-standing or hanging. If one of the components of the tank fails, it must be completely replaced, which will lead to disharmony in the design of the monoblock.

The traditional option is represented by a separate toilet cistern, which makes it possible to combine different models of the components of a single system. If you purchase a toilet cistern separately, there are three options for installing the structure. The tank can be attached to the wall, built into it or located on the toilet.

The traditional option is represented by a separate toilet cistern, which makes it possible to combine different models of components of a single system

A wall-hung toilet cistern involves both high and low placement of the element. In the first case, the tank is located at a certain height and is connected to the toilet using a long pipe. This old-fashioned placement is characterized by the creation of optimal pressure and high water flushing speed. However, there is a high level of noise during drainage. The flushing device of the old-style cistern is represented by a lever with a chain located on the side.

Low placement of the cistern is very popular. The element is attached to the wall and connected to the toilet using a short tube. Water is drained from the tank by pressing a button on the device body.

Related article:

How to choose a toilet: main criteria and features of various models

Review of the 5 most popular manufacturers and models. Common breakdowns and ways to fix them.

The compact version is a design where the tank is located on the toilet. Despite the fact that it is similar in appearance to a candy bar, such a tandem consists of two separate elements. There is a special shelf on the toilet on which the tank is installed and then securely fixed to it. The advantages of the design are compact size and ease of maintenance.

Quite common is the corner toilet cistern, which has a triangular or trapezoidal shape, making the structure convenient to place in the corner of the room if it is small.

There is also a hanging version of the product with a flush cistern built into the wall.

The built-in toilet cistern (in the wall) is hidden in a special closed niche. Only a button for draining water is exposed outside, through the hole in which preventive inspection and repair of the device is carried out. Choosing a hidden cistern for the toilet contributes to the aesthetic design of the bathroom interior. In this case, the toilet will be moved close to the wall, which will make the room more spacious and tidy. There is also a hanging version of the product with a cistern built into the wall.

Internal organization

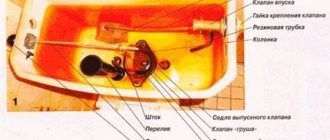

The toilet cistern consists of two simple systems: collecting water and draining it. To troubleshoot possible problems, you need to understand how everything works and works. First, let's look at what parts the old-style toilet cistern consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of this type of tank are very simple. The water supply system is an inlet valve with a float mechanism, the drainage system is a lever and a bulb with a drain valve inside. There is also an overflow tube - it drains excess water from the tank, bypassing the drain hole.

Old design cistern design

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is shown in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens/closes the water supply.

When filling the tank, the float is in the lower position. Its lever does not press on the piston and it is pressed out by water pressure, opening the outlet to the pipe. The water is gradually filling up. As the water level rises, the float rises. Gradually it presses the piston, cutting off the water supply.

The device of the float mechanism in the toilet tank

The system is simple and quite effective; the filling level of the tank can be changed by bending the lever slightly. The disadvantage of this system is the noticeable noise when filling.

Now let's look at how draining water in a tank works. In this embodiment, the drain hole is blocked by the drain valve bulb. There is a chain attached to the bulb, which is connected to the drain lever. By pressing the lever, we lift the pear, the water drains into the hole. When the level drops, the float moves down, opening the water supply. This is how this type of cistern works.

Modern models with lever flush

There is less noise when filling toilet tanks with bottom water supply. This is a more modern version of the device described above. Here the tap/inlet valve is hidden inside the tank - in a tube (in the photo there is a gray tube to which the float is connected).

Drain tank device with water supply from below

The operating mechanism is the same - the float is lowered - the valve is open, water flows. The tank filled, the float rose, and the valve shut off the water. The drain system remains almost unchanged in this version - the same valve that rises when the lever is pressed. The water overflow system has also remained almost unchanged - it is also a tube, but it is led into the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

Models of toilet cisterns with a button have similar water inlet fittings (some with side water supply, some from the bottom) and a different type of drain fitting.

Tank device with push-button drain

The system shown in the photo is most often found in domestically produced toilets. It is inexpensive and quite reliable. The design of imported units is different. They basically have a bottom water supply and another drain and overflow device (pictured below).

Imported fittings for the cistern

There are different such systems:

- with one button, water is drained while the button is pressed;

- with one button, draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The working mechanism here is slightly different, although the principle remains the same. In this fitting, when you press the button, the glass, blocking the drain, rises, while the stand remains motionless. In short, this is all the difference. The drain is adjusted using a rotary nut or a special lever.

Accessories

The general list of everything you need looks like this:

- tank;

- drain mechanism and float valve for filling with water. In expensive plumbing fixtures, these elements are made of brass - they are the most durable. Cheap models use plastic parts. A filter is installed in the inlet valve, designed to supply water from below. Sometimes it gets clogged and then water flows into the tank slowly, with a characteristic whistle. The filter needs to be unscrewed and washed. The push-button flush mechanism comes complete with a single or double push-button screwed into the push-button assembly;

- gasket installed between the tank and the toilet;

- bolts for attaching the tank to the toilet (“compact”) or installation (wall-hung);

- gaskets for these bolts;

- flexible connection for connecting the tank to the water supply;

- ball valve It is recommended to install it on a branch to the tank, so that when repairing the latter you do not have to turn off the water in the entire apartment.

It is advisable to purchase the entire set from one manufacturer. The parts in such kits fit together perfectly and the mechanisms are easily adjusted.

Toilet cistern design

Today, the construction products market includes a wide variety of flush cisterns; their differences lie in the source material, the working arrangement of the parts, price and quality.

The principle of operation of all such structures is approximately the same, only the mechanism is different, which can be:

Toilet bull with one flush button

- with one flush button;

- with a pair of flush buttons;

- with a device that has two modes.

Relatively recently, a mechanism appeared on sale that included two buttons. This system can reduce water consumption. Using one button, all the liquid flows out from the drain tank; using another button, only a part will drain. The flushing procedure itself also looks different:

- Water enters the toilet directly from the flush cistern; here the water moves in one direction.

- During flushing, water constantly flows in different directions. This drain is more efficient, but it produces a lot of noise.

In order not to make a mistake in choosing such a device, and in the future to easily carry out assembly and repairs, it is worth knowing its design. The mechanism of operation of flush cisterns is simple: its work begins with collecting the required amount of water and discharging it into the sewer through the toilet.

To some extent, the design resembles a conventional water seal, which includes a seal, levers and a float. By independently pressing the lever or button on the lid, water flows out, while performing the most important tasks - eliminating waste into the sewer.

Toilet cistern design

There are visible structural elements, these are:

The invisible part of the structure includes:

- stub;

- float valve;

- drain fittings.

Optimal sizes of toilets with a tank

The dimensions of the toilet with a tank (in terms of optimality) are selected based on the dimensions of the room. For a large room, long standard models are suitable, and for a small room it is best to choose compact options. These toilets with cast shelf are 340 mm wide, 605 mm long and 800 mm high. Products with a separate tank are characterized by dimensions of 460x360x815 mm. Corner toilets have the following dimensions: width – 340-370 mm, depth – 720-790 mm, height with tank – 815 mm, seat height – 370-430 mm.

Monoblocks are presented in a single design, which includes a toilet and a cistern. The width of the product can reach 360-375 mm, depth - 685-700 mm, height - 390-775 mm.

The depth of the toilet with a tank is selected based on the need to maintain a distance of at least 60 cm between the device and the front door. Otherwise, it will be uncomfortable to sit on such a product due to the inability to position the knees properly when sitting.

The smallest version of the tank has a width of 275 mm

The height of the device above the floor level is selected based on the person’s height. It should be comfortable to sit on the toilet with relaxed leg muscles. For a tall person, it is better to choose hanging systems with installations that can be adjusted in height.

Important! The smallest version of the tank has a width of 275 mm.

The volume of the drain tank can be 4-13 liters. Imported devices are designed for 4-6 liters. Dual-mode tanks have a capacity of 3 and 6 liters. Standard products that are hung on the wall or installed on the toilet have the following dimensions: width - 150-200 mm, length - 300-360 mm, height with lid - 350-400 mm.

Equipment installation

It is not difficult to buy shut-off valves at any plumbing store, but it would be better to install the branded components included in the kit. Thus, there is a greater likelihood of matching all components.

To install the cistern yourself, you need the following tools:

- wrenches: adjustable and open-end;

- bendable hose;

- screwdriver;

- plumbing system;

- gaskets of the required size;

- fuma made of rubber.

The instructions for installing such equipment include several stages. Initially, you should install the lower part of the drain assembly in the tank, the main thing is to make a tight fit to the outlet hole. Install a rubber gasket between the bottom of the container and the base. Then install the tank on the toilet. A thick rubberized ring should be placed between them. This will prevent surfaces from touching. Using bolts, you should screw the flush and flush structure to the toilet.

If this is a drain tank device with a button with a bottom water supply, then before installing the structure, the elements that will supply the liquid should be correctly installed. In this system, rubber gaskets should be firmly secured. They will help avoid leakage. In a structure placed on top, these elements will not be needed, since they are above the water level. After fixing the tank, you can install such units. The same method is used for these types of installations. A tube is threaded into the hole in the tank and secured on both sides with nuts.

The next step will be to attach a bendable hose to the riser fitting and attach a water tap, allowing, if necessary, to carry out repairs and shut off the flow of water. Typically, hoses have nut-spacer elements in their design, which ensure fastening strength. However, craftsmen most often build in a fuma for greater reliability. After connecting the tank to the water supply system, the float should be adjusted. The liquid level should be 15 cm below the edge of the tank.

At the last stage of installation, you will need to install the mechanism. The top fittings should be placed in the hole of the cover and secured with decorative elements covering the hole.

Installing and replacing the insides of the tank

As a rule, problems with the operation of the drain tank can be solved in two ways: the system can be adjusted or replaced completely. In both cases, you need to know how this is done, since such skills will definitely come in handy sooner or later.

To replace the device completely, you will first have to remove it from the tank, after which a working element is mounted in its place.

Do-it-yourself replacement and adjustment of toilet cistern fittings (flush)

Removing the reservoir cap

To get to the damaged element, you need to remove the tank cap, which is not always so easy if you don’t know how it is attached to the tank. It’s especially unclear when the tank has a button. To remove the cover, you will have to press the button and hold it until the ring around the button is unscrewed.

Removing the reservoir cap with a button

If you cannot unscrew it with your fingers, then by pressing the button, you should carefully examine the inner rim of the ring, since there should be 2 holes located opposite each other. To turn this ring a little, you can use a tool, for example, a screwdriver, which must be inserted into one of the holes. After twisting a little with a screwdriver, the ring can be easily unscrewed with your fingers. Having thus unscrewed the push-button device, it is removed and, after this, the lid is easily removed from the tank.

How to remove the lid from a toilet barrel. Repairing leaks

Removing the tank

To completely replace the old cistern fittings, it is preferable to remove it from the toilet bowl. First of all, you should shut off the water supply by closing the inlet valve, after which, using a wrench, unscrew the water supply hose.

If the water is connected from below

After this, they begin to remove the tank from the toilet bowl, but before doing this, you need to drain the water from the tank completely. If you look from below, you can see the bolts tightened with nuts. These nuts will have to be unscrewed. If they cannot be unscrewed by hand, and some designs use special wing nuts, then wrenches are used. Before removing the tank, you can put a rag under it, since there is some water in the tank, but it will remain and it will definitely spill.

Removing the tank from the toilet

After the nuts are unscrewed, you can remove the tank. This is exactly the moment when you can replace the gasket that is placed between the toilet bowl and the tank. If this is not done, sooner or later you will have to remove the tank again. In this case, you need to carefully inspect the gasket. It is possible that it is of better quality than new - this also happens.

Unscrew the nut holding the mechanism

At the bottom of the tank, where the drain hole is located, there is a large plastic nut with which the water drainage mechanism is attached to the tank: it will also have to be unscrewed, but we should not forget that the nut is plastic and large loads can damage it.

After unscrewing the nut, the drain mechanism can be easily removed from the tank.

Removed drain mechanism

Using almost the same scheme, you can remove the water supply mechanism from the tank, regardless of whether it is located below or on the side.

Water supply mechanism fastening nut

Removed water supply mechanism

Having freed the tank from the fittings, you can begin to clean it, since over the years of work, dirt, sand, and also metal particles in the form of rust accumulate at the bottom of the tank. New fittings can only be installed in a clean tank, otherwise dirt particles may cause a leak to appear after assembling the tank, which is undesirable, since everything will have to start all over again.

Replacing the cistern fittings

The process of installing new elements of the tank interior is carried out in the reverse order. First of all, the water drainage mechanism is secured using a plastic nut, which comes complete with the mechanism. At the same time, it is undesirable not to forget to put a gasket.

Sealing gasket

It is better to tighten the plastic nut first by hand, after which you can tighten it with a wrench, but this must be done very carefully: excessive load on the nut will lead to its breakage.

Be careful with the plastic nut

Sealing process

Once all the functional insides of the cistern are in place, it is time to install the cistern onto the toilet bowl, but before that you need to install the sealing gasket. It is better to clean the installation site from dust and dirt, since various particles often accumulate in this place that can interfere with the normal operation of the junction of the tank and the toilet.

Rubber gasket between the tank and the toilet

Before installation, mounting bolts with gaskets are installed inside the tank into the hole. The tank is installed in its place, after which the nuts and washers are attached.

Tightening the mounting bolts

Before tightening the nuts, the tank is leveled. After this, the nuts are tightened, evenly on both sides, so that the tank does not warp, otherwise it will leak.

Inlet Valve Installation

Since there is no extra space in the tank, the inlet valve with the system is installed last. Be sure to check the installation of the gasket.

Inlet Valve Installation

The next step is to connect the water hose. When connecting the hose, do not overtighten the nut, since the threaded pipe is made of plastic and excess load can break the thread.

Screw on the water supply hose

By turning on the water, the connection is checked for leakage. If a drop appears, the connection can be slightly tightened with a wrench. If you cannot get rid of the droplet, you can replace the gasket. This does not always help, although there are not many such cases. In this case, we can assume that the defective pipe will then have to be filed with the selling organization.

Installing a toilet flush cistern

Basic systems

The operation of any tank is based on the functioning of the water intake and drainage systems. The intake occurs due to the operation of the intake system, which regulates the progressive filling. The inlet fittings, regardless of the type of drainage equipment, are of the same type and consist of a float that allows you to adjust the intensity of filling the system with water.

In the process of draining water, other fittings are used to control this process. This design is variable. Certain positions of the outlet valves make it possible to use dual-mode and emergency drainage.

With one button

You can see a diagram of a toilet cistern with a button in this illustration:

A plastic or metal float regulates the opening process of the ball valve. which facilitates the flow of water into the tank. The volume of incoming water is controlled by a diaphragm, which is equipped with a special lever device that regulates the pressure of the water jet.

The drainage is regulated by a siphon. the location of which is the central part. To secure the siphon to the outlet system, a special gasket is used - a “saddle”. A drain button is fixed on top of the entire structure.

A standard siphon can be represented by a detachable design, which allows the cleaning process to be carried out only on the upper part. and the lower part is simply washed.

With two buttons

The invisible elements of the two-button system are represented by a plug, a float valve and drain fittings.

The visible part of the structure includes a lid and buttons. The device of the flush tank with two buttons is characterized by a high level of efficiency. Water consumption is reduced due to the ability to provide a choice of minimal drainage or completely empty the volume.

Ignorant installation causes two buttons to work as one, with the same volume of drainage. A correctly installed mechanism is characterized by a small drain of 2-4 liters, and a large drain requires about 6-8 liters of water.

The difference from the design of a toilet cistern with one button lies solely in the design of the outlet fittings.

It is impractical to install such fittings on small devices. If replacement is necessary, any hydraulic system of suitable size can be used.

Operating principle of the drain mechanism

The operation of this mechanism begins by pressing a button, which is connected to the internal elements of the drainage system. Up to this point, the tank is already filled with water to the regulated level and the entire volume is held by a rubber bulb. This material ensures a fairly tight fit to the saddle. Pressing the button causes a pull that pushes the bulb away. which opens the drain hole.

After returning the button to its original position, the hollow and air-filled bulb does not immediately return to its place. As it fills with water, the bulb becomes heavier, lowers and fits tightly onto the saddle. However, for the full functioning of the pear, a special pipe is important, which regulates the action of various forces on this rubber element.

After selecting and installing a toilet, certain questions may arise, such as: why water does not flow into the toilet tank or how to fix a leak in the toilet tank. Read the answers to these questions in the following articles.

Find out how to repair a toilet flush cistern with a button in this material.

Classification of tanks

As mentioned above, different models of tanks may have some structural differences. Based on this, we will then get acquainted with their most common types.

Tanks are classified into several groups.

First of all, they can be conditionally divided according to the placement of the tank or button:

- Lateral - in most cases, it is used for wall-hung toilet cisterns, which are located at a certain height. In this case, in order to drain the water, you need to pull the chain. The drainage device, in most cases, is implemented in the form of a rising pear.

- Top - a button or lever is located at the top, in the center of the lid. The drain fittings in similar tanks are more complex.

In addition, containers differ in the material from which they are made.

The following types of products are currently available:

- Porcelain - the most expensive models are made from this material, so they are seen relatively rarely.

- Earthenware is currently the most common option. They are mounted on the toilet shelf. Faience containers can have a wide variety of designs.

- Plastic - these containers are built into the wall and have a flat shape. On the outside, they differ from classic tanks because they resemble more of a canister, but their operating principle is the same. In addition, there are hanging plastic tanks of the Soviet example; lately they have been seen less and less.

Let us emphasize that in some apartments you can also see cast iron tanks, which are already a rarity.

What's the result?

As you can see, in the design of a modern car, increased demands are placed on the engine cooling system and its correct operation. For this reason, for efficient operation, a special tank is additionally used in the design.

You also need to know that if the specified expansion tank of the engine cooling system is involved in the circuit, it is highly advisable to fill the system only with antifreeze or antifreeze, and not water

As for breakdowns, if pressure increases in the cooling system or air pockets form, special attention must be paid to the expansion tank cap. Malfunction of the valves in the cap often leads to damage to the pipes, the thermostat fails faster, and the cooling system pump suffers. ), the engine may overheat, etc.

Malfunction of the valves in the cover often leads to damaged pipes, the thermostat fails faster, the cooling system pump (pump) suffers, the engine may overheat, etc.

Possible problems with the toilet cistern and methods for eliminating them

Any mechanism tends to fail after some time. Most often, water flows from the tank into the toilet. This can happen for several reasons. Sometimes the float on the shut-off valve gets knocked down, which leads to an overflow of water after filling a certain level. To fix the problem, you need to adjust the height of the float. If the element has lost its tightness, it must be replaced with a new one.

Sometimes the float on the shut-off valve gets knocked down, which leads to an overflow of water after filling a certain level

If the regulator responsible for the height of the button is displaced, a gap is formed between the water drain valve and the hole in the toilet sink. The problem can be resolved by adjusting the height of the button. Water may flow into the toilet sink as a result of the nut at the base of the overflow tube becoming loose. To do this, it needs to be tightened.

Water leaking into the toilet sink can occur due to a faulty valve on the shut-off valve. You can check this by pressing the lever going to the float. If the water does not stop flowing, the valve is faulty. It will be necessary to replace the shut-off valves.

If water does not fill into the drain tank, this indicates a float stuck in the rod or a clogged valve. In the first case, the float should be adjusted. The second option requires cleaning the valve. If the procedure does not produce positive results, the shut-off valves will need to be replaced.

If there is a decrease in the force of the drain flow when the tank is completely filled, this indicates a clogged drain hole. This problem can occur as a result of a hose that has come off, which is installed to reduce the water level. The problem can be resolved by removing the tank and cleaning it.

If there is a decrease in the force of the drain flow when the tank is completely filled, this indicates a clogged drain hole.

Putting water into a tank: options and their features

The operation of the water supply device is carried out through the installation of special fittings, which can be carried out in two ways: upper and lower.

Option #1: top placement of fittings

The fittings in this version are located in the upper area of the cistern, while the flow of water is organized through a side channel.

The float located on one arm of the lever reaches a certain level, after which the other arm of the lever presses on the rod. The water supply is shut off using a membrane.

This water supply option is characterized by increased noise that accompanies the operation of the device, but this does not prevent domestic manufacturers from supplying their models with similar fittings.

Option #2: bottom location of the fittings

The lower water supply option does not have the disadvantages of the upper method. With the lower position of the fittings responsible for filling the tank, the equipment operates almost silently.

The float moves along a vertical rod and sets the locking membrane in motion using a special rod, which acts as a regulator of the volume of liquid in the tank.

Types of flush tanks according to the type of connection to water and the location of the float, which determines the level of noise emitted during the operation of the plumbing fixture

Features of repair of installation of wall-hung toilets

The installation system, which is an integral part of the wall-mounted toilet, has a number of advantages over standard tanks:

- high quality flushing mechanisms;

- large selection of keyboard buttons;

- installation in any bathrooms, regardless of interior design;

- hidden installation.

Installation systems rarely fail. If any malfunction is detected, it can be easily eliminated through the inspection hatch. In this case, the entire wall behind which the equipment is located does not have to be broken.

Common failures of installation systems:

- If the tank is leaking, look for the cause in the bottom valve.

- If the tank does not fill with water, it means that the filter or supply hose is clogged;

- If the flush tank is constantly filling, then most likely the gaskets have worn out or were installed incorrectly.

- If the drain mechanism does not work, then the disinfectant was selected incorrectly, which is placed in a special compartment in a plastic container.

Main types of drainage equipment designs

They differ in the mechanisms for supplying and flushing liquid. Drainage work is performed by automatic, push-button or lever-type devices. Structurally, the insides of a toilet cistern look like this: a float, through a rod and a valve, controls the inlet, regulating the water supply. Thus, it plays the role of a shut-off valve.

In this case, the liquid level depends on the height of the float, and it is adjusted on the rod by bending it or changing the position on the guide.

Lever mechanisms

They were the main plumbing models of the last century. Their operation was distinguished by the unpretentiousness of the device: the liquid was drained as long as the shut-off valve was held in place through the chain.

Then systems with siphon functioning were introduced, when the valve was closed automatically after drawing water.

But these types of mechanisms are distinguished by increased, unregulated fluid discharge and do not meet modern aesthetic requirements.

Drain button

Current tanks are equipped with push-button drain mechanisms. Basically, the buttons are located inside the lid of the tank for draining, and the mechanisms at the same time hold the locking valve automatically.

Their advantage, in addition to independent functioning, is the convenient setting of liquid supply. And products with two-button fittings for the drain tank drain the water completely or partially, depending on which button is pressed.

Plastic cisterns for wall-hung toilets

For wall-hung (cantilever toilets) tanks, made in the form of a plastic container, are attached to an installation (steel frame), which is hidden behind a plasterboard partition.

This false wall is tiled, and the drain button is placed in a special window. Through this inspection hatch, after dismantling the cover with the button, maintenance and repair of equipment installed in the tank is carried out.

Swiss installation systems produced under the Ceberit brand are especially popular. High-quality fittings, ergonomically located in a plastic container, ensure reliable operation of the wall-hung toilet.

As in floor-standing models, the tanks of mounted plumbing fixtures have drain and fill valves, equipped with devices for adjusting the volume of outflowing and inflowing water.

There is a small pin on the filling valve that is lowered or raised, and with it the float is lowered or raised.

There is a ring on the drain valve, which, by turning it a certain distance, regulates the volume of one-time water output (from 3 to 9 liters).

Models intended for disabled people are equipped with additional remote drain buttons, which are located on the handrails or on the floor.

Compact monoblock toilets: some advantages

In compact models, the flush tank is placed on a gasket and screwed with two bolts to the toilet bowl. manufacturers refined this design and released solid monoblocks onto the market, devoid of many of the negative qualities of their predecessors.

The absence of gaskets and fasteners makes it impossible for them to wear out and break. Monoblocks are easier to clean, since contaminants do not get into hard-to-reach joints of individual parts of plumbing equipment.

The installation of monoblock products and subsequent maintenance are greatly simplified. Manufacturers are constantly developing new forms of monoblocks, offering sophisticated customers beautiful toilets comparable to real works of art.

An elegant monoblock toilet produced by the famous Italian company Laguraty, famous throughout the world for its luxury sanitary ware

Toilet cisterns: useful recommendations for choosing products

For small bathrooms, preference should be given to monoblocks or compact models. An advisable solution is to install a corner toilet with a cistern, which allows you to save additional space in the room.

When decorating a bathroom in a modern style using newfangled finishing materials and accessories, a floor-mounted unit with a wall-hung toilet cistern built into a niche will look most organic.

When choosing a specific model, you should study the structure and quality of all components, the capabilities of the device

To create an original room design, you can combine separate toilet and cistern models, showing a creative approach to organizing a unique environment in the room.

When choosing a specific model, you should study the structure and quality of all components, and the capabilities of the device. The practicality, reliability, uninterrupted operation and durability of the drain element will depend on this. Numerous reviews about models on the Internet will help you make the right decision.

Important! The key to choosing a high-quality and reliable device is its involvement with a well-known brand with a worldwide reputation.

Drain tanks with a double button allow you to reduce water consumption during operation of the device, which is a real result of savings.

The key to choosing a high-quality and reliable device is its involvement with a well-known brand with a worldwide reputation

Are toilet cisterns sold separately: a review of popular models

Flush cisterns are purchased mainly complete with a toilet. In case of failure of individual parts, original components are selected that will have identical dimensions. In this case, there will be no problems with installation.

High-quality earthenware sanitary fittings are offered by the global manufacturer Roca. The company produces a wide range of products. The Roca Victoria model is very popular. The design has an elegant oval configuration with a pleasant white glossy finish. The product is a device with a bottom water supply.

Colombo toilet cisterns are no less in demand. The manufacturer offers earthenware products with an attractive design. The models have smooth lines and are characterized by compact sizes. Among the wide range of products, the Colombo Orhideya double flush toilet cistern deserves attention. The cost of the products is 2.4 thousand rubles.

They are characterized by two modes, involving the release of water in volumes of 3 liters and 6 liters. The drain mechanism is controlled by pressing a double metal button. The toilet tank has dimensions of 185x370x390 mm. The product warranty is 10 years. The price of a toilet tank is 2.7 thousand rubles.

The Roca Victoria model with bottom water supply is very popular

For floor-standing toilets Verona, Keramin and Cesaro, you should choose Keramin Grand porcelain drain systems. The products have a trapezoidal shape, narrowed at the bottom. Such tanks are characterized by high quality manufacturing, reliability and durability of internal fittings. The bowl size is 380x385x170 mm. You can buy the product for 4.5 thousand rubles.

Another interesting model is the Roca Gap toilet cistern. The product has dimensions 365x365x150 mm. The tank is made of white earthenware. It has a rectangular shape with smooth corners. Equipped with a two-mode control that provides flushing water with a volume of 3-4.5 liters. You can buy the product for 7.5 thousand rubles.

The cistern for the Laufen Pro floor-standing toilet with side water supply has a strict and laconic design. The capacity of the container is 4.5 liters. It has a double water release mode - 3 and 4.5 liters. The price of a toilet tank is 8.5 thousand rubles.

The Villeroy&Boch Hommage toilet cistern, made of porcelain, is original in configuration and design. The water supply is on the right side. The product is equipped with a double button for complete drainage and has a volume of 3 liters. The cost of the tank is 10 thousand rubles.

Flush cisterns are purchased mainly complete with a toilet

Popular options for compact toilets with a flush cistern

An interesting and popular model is the Cersanit Best compact toilet with bottom water supply. The product is made of sanitary ware and has an oval configuration. The dimensions of the device are 360x655x815 mm. Tank volume – 5 l. The drainage mechanism is activated by pressing one button. The cost of the product reaches 3.5 thousand rubles.

For compact-type floor-standing toilets, a good solution is Cersanit Olimpia cisterns, which have internal drain fittings. Products are made from high-quality faience. They are distinguished by a rectangular outline with smooth corners. Water is supplied from below. The dimensions of the toilet with a tank are 360x375x170 mm. The drainage mechanism is equipped with a dual mode with water release of 3 and 6 liters. The cost of the product is 3.7 thousand rubles.

The white floor-standing compact toilet Orion made of sanitary ware deserves attention. It has a dual flush mechanism, designed for 3 and 6 liters. The dimensions of the product are 350x635x810 mm. You can buy such a toilet for 4.5 thousand rubles.

The Sanita Luxe Best compact toilet with bottom water supply is in demand among consumers. Product dimensions – 340x640x770 mm. The Sanita toilet tank, like the device itself, is made of sanitary ware. The tank volume is 6 liters. The product is equipped with dual-mode Geberit fittings. The warranty on the device is 5 years. You can buy a toilet with a tank for 6 thousand rubles.

The Sanita Luxe Best compact toilet with bottom water supply is in demand among consumers

Another popular model is the Classic Soft Close compact toilet with dual flush, high-quality Swiss Geberit internal fittings. The dimensions of the device are 345x590x760 mm. You can buy a compact toilet for 7.3 thousand rubles.

The Santek Alcor compact toilet is equipped with a dual-mode Uklad fitting. The product is made of oval-shaped faience. It has a smooth glossy snow-white surface that is easy to clean. The water supply is carried out from below. Product dimensions – 365x765x670 mm. The cost of a toilet with a tank is 7 thousand rubles.