During the operation of any plumbing equipment, certain problems may arise in the system, which you can fix yourself. In this review, we will take a detailed look at the design of the toilet cistern - repairs to this structure can only be carried out if you understand the basic principles of its functioning. If you understand the topic, you can easily fix most problems without involving plumbers.

To an inexperienced person, the design of a toilet cistern may seem complicated, but in fact everything is quite simple and understandable

Device

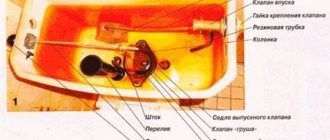

Repairing an old-style toilet cistern with your own hands begins with studying its structure and features. The main difference lies in the fittings, in which the water supply is lateral, and in the design, in which the simplest physical laws are involved.

The main components are presented:

- A filling device, which includes a movable lever with a float and a valve for shutting off the water;

- Drain mechanism.

The design of the most “ancient” drainage devices includes a cast iron bell - a plug with a soft rubber gasket. After pressing the outer lever, the bell rises and the water moves down through the opened hole.

Important! This design is distinguished by great reliability, because the products last for half a century, while repair work only requires periodic replacement of the worn-out gasket.

Later designs are equipped with a rubber or plastic bulb instead of a bell. When the container is released, the float lowers, after which the valve opens, releasing water.

Let's look at the differences between old-style drain systems:

- Unattractive appearance. Previously, external attractiveness was not so important; more attention was paid to the reliability of components and their performance. Therefore, the appearance of old products is not very aesthetic, with a primitive shape and a roughly processed surface.

- Location of the tank. Most often, the location of the container is under the ceiling, and a pipe is intended for the passage of water - a riser. Due to this, the water flow develops a high speed, which leads to high-quality flushing, but at the same time a lot of noise is heard.

- Design features of shut-off valves. Such products are distinguished by a very unique flushing system. It is based on the principle of a rocker arm; to operate, you need to pull a rope or chain. The design is very simple; no instructions are required for assembly.

- High water consumption. Such designs do not use economical drainage modes; the water leaves in full.

- Intake system. Water is supplied only from the side, which makes it impossible to hide the hoses.

Important! In some cases, it is more advisable to replace the tank with a more modern product, for example, if the damage is too extensive.

Features of old systems

The so-called “Soviet” modifications have a number of differences from modern versions; let’s consider the most significant of them:

| Unattractive appearance | Several decades ago, little care was taken about external attractiveness; the main attention was paid to the practical side: the reliability of each unit, its performance. Therefore, old tanks do not look very aesthetically pleasing: primitive shape, rough surface |

| Tank location | In the vast majority of cases, the container is located under the ceiling, and the water flows through a riser pipe. This allows the water flow to gain high speed and provide high-quality flushing, but this is accompanied by noise; compact options can also be found, but they are quite rare |

| Design features of shut-off valves | The flushing system in such products is very unique and is based on the principle of a rocker arm, when you need to pull a chain or rope. The device of the old-style toilet cistern is simple; no assembly instructions are required - everything is clear even to those who see such a system for the first time |

| High water consumption | Previously, no one was worried about the issue of water consumption, so in such designs there are no economical drainage modes; the system always drains the entire volume, which, you see, is not very convenient and impractical |

| Intake system | In all old models, water is supplied exclusively from the side, other options were simply not used, this is both a plus, because everything is unified, and a minus - because the hoses cannot be hidden in any way, and they will always be in sight |

Advice! Sometimes it is much easier to replace the tank with a more modern one than to repair it. The decision is made on a case-by-case basis - if the extent of damage to the elements is large, then repairing them may take too much time and money.

Common breakdowns and repair options

Any, even the most primitive mechanism, can break down over time. How to fix an old style toilet cistern? Even a non-professional can fix most breakdowns; there is nothing complicated about it.

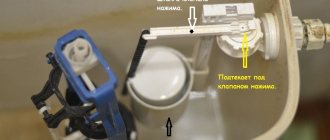

Water flows continuously

In this case, we first check if there is a leak in the filling valve. For this:

- Remove the cover.

- Raise the float lever.

- If the flow of water continues, turn off the tap in front of the tank and drain the water.

- Using a wrench, unscrew the part where the valve and water supply are connected.

- We remove the float lever and the fixing nuts, take out the valve and replace it with a new one.

If the water flow stops after lifting the lever, the problem may be due to:

- The float lever is skewed, causing it to catch on the bushing. As a result, the float fails to float up completely and the valve fails to close. In this case, you need to pull out and straighten the rod.

- Float seal failure. In this case, it remains partially or completely immersed in water, and the valve fails to close.

- The problem is solved by installing a new part. If a necessary part is missing, heated plastic or sealant is used to repair the damage.

Water is constantly leaking

Toilet flush tanks can be repaired even if the water completely leaks out. This sign indicates a violation of the tightness of the drain mechanism, in which water leaks between the bell and the body. This fault may be caused by:

- Corrosion or contamination of the seat surface. Due to deposits, the drain mechanism cannot close tightly. To eliminate the problem, clean the surface with sandpaper.

- The appearance of a gap between the seat and the body. For repairs, use a socket wrench to tighten the fastening nuts.

- The guide bushing falls out of the seat. Due to such a breakdown, the constipation becomes distorted when lowered. In this case, insert the sleeve into the hole of the arc and wrap it with an elastic band.

- Incorrect position of the release lever. The bulb does not completely cover the seat and water flows constantly. To get rid of the problem, bend the lever and lower it below the inlet of the underwater pipe by 2.5 mm. In addition, be sure to check the fasteners that hold the rocker arm and tighten any loose screws.

Important! You will need a short tool to tighten the screws. During the work, be sure to ensure that the vertical plate with four corners does not move out of the recess on the body.

Problems with the supply hose

If damage appears on the supply hose or gaskets at the junction, drops will appear in the places where the hose connects to the body. We carry out repairs in the following sequence:

- Tighten the connecting nut.

- We turn off the water.

- Disconnect the hose.

- We are replacing the gasket.

- We apply a winding to the thread.

- Attach the hose to the tank.

- Tighten the nut.

Loud noise

Even if the flushing mechanism for the toilet is not broken, repairs are carried out. Even if the device seems to be working, it produces a lot of noise.

To solve the problem, you can install a special stabilizing device instead of the part. If water flows into the tank with low pressure, the problem can be solved much easier. The filling valve mechanism includes a tube through which water is released. We install a muffler vertically on it, the lower end of which is lowered into the water at the bottom. To make a muffler we use a flexible hose made of rubber or plastic. After this update, the noise from falling water and the sound of a jumping float will disappear.

Design differences and typical malfunctions

Let's consider how the old versions differed from the modern ones, especially since the difference is fundamental and significantly affects the operation of the system.

Device

To figure out how to repair an old-style toilet cistern, you need to know the main features of its structure and the principles on which the operation of the entire system is based:

- The material used to make the body is earthenware (less often) and cast iron (much more often). The use of a metal container involves corrosion processes on the surface, so the tank must be periodically tinted on the outside and cleaned from the inside, otherwise rust particles may clog some elements, causing breakdown.

- The release lever is located either on the left or in the front, the water supply is most often on the right side . To ensure uninterrupted operation and avoid leaks, it is best to immediately replace the liner - modern flexible options cost little and last a very long time.

- The tank is connected to the toilet by a steel pipe, the length of which can vary . Many developers reduce its length to improve aesthetic appeal; this option looks much better.

- The system works on the principle of a rocker: when you pull the chain, the cast iron bell rises and releases water; when the handle is released, the system closes under its own weight . The water level is controlled by a float connected through a rod to the inlet valve - the system is simple, and therefore reliable and efficient, a minimum of parts ensures its long service life.

Features of repair work

As a rule, the nature of failures in the devices of the group under consideration is typical, so we will consider the most common malfunctions and ways to eliminate them:

- Every few years, the soft rubber gasket installed on the outlet becomes unusable or simply breaks, causing water to constantly flow into the toilet. The solution to the problem is simple: replacing the sealing element, and you can cut it out of rubber yourself to the size of the old worn element.

- The overflow, which is made of cast iron in the shape of a bell, over several decades of operation becomes covered with a layer of rust and other deposits, due to which the flushing efficiency is noticeably reduced.

Tip: The problem is solved quite simply: the element is removed, burned on fire and tapped with a hammer, after which the overflow is installed in place, and it is better to change all the sealing elements at the same time.

- The constant outflow of water through the drainage channel is caused by damage to the float. In this case, finding a replacement can be quite difficult, so the float must be soldered or sealed to restore integrity. Sometimes violations of this kind are caused by the fact that the rod is bent; it can be straightened and the system will work better.

Video material

In reality, it is much easier to repair an old-style cistern than a modern version. The fact is that it is distinguished by a simple system and reliable components included in its design.

Old-style toilet cisterns - features of their design and recommendations for repair work

The old-style toilet cistern has long been discontinued, but, nevertheless, it can be found in houses and apartments throughout the country, which indicates the fairly reliable operation of such systems and their durability.

In this article we will look at the main differences between the old and new options and tell you how to fix the most common breakdowns and malfunctions with your own hands, especially since the work is very simple and does not require the use of special tools and devices.

When did the “shelf” appear in toilets?

The plate toilet, better known as a toilet with a shelf, is integrally connected with the history of the development of sanitary production in the USSR. The predecessors of earthenware products, which were made of concrete in the 30s of the last century, already included this design. However, toilets made of porous material required careful and constant maintenance, which was practically impossible in Soviet communal apartments. They were replaced by more hygienic earthenware products. And in the early 60s, visor-type toilets first appeared in the country. This design differs from the plate design in the absence of a flat platform, and also in the fact that the back wall in such models is sloped. These are the toilets that were installed in Western countries. However, the new product was not widely used in the USSR.

Cleaning the toilet

If repairing the toilet is not the first item in your plans, it would be useful to determine how you can wash the surface of the toilet from mineral deposits, rust and biological waste residues.

The following substances are most effective:

- Cleaning abrasives. When using them, wear gloves to protect your skin from the harmful effects of aggressive chemical elements.

- Alkaline solutions. This is the familiar Domestos and Toilet Duckling. But it is also possible to use simple bleach.

- Acidic household products. The principle of their actions is similar to the past.

- Citric acid and vinegar essence. They wash away old stains on the surface of the toilet bowl well.

Tips for choosing

When choosing a toilet, first of all, you need to inspect the entire room. It is necessary to take into account not only the size of the room, but also its design. In addition, it is worth looking at where all the sewer pipes go. You also need to measure how high the ceilings in the room are. This will determine which toilet model is best to buy: floor-standing or wall-hung. When purchasing, you need to pay attention to the material from which it is made.

The most acceptable, according to experts, are products made of ceramics or porcelain. They are easy and simple to care for.

Particular attention should be paid to whether the toilet has an anti-plex system that protects the room from splashes. In addition, you should choose the right drainage system. It can be either horizontal or circular. In the first case, the water flushes everything on the back of the toilet. In the second case, drainage occurs from three points at once. The second option allows you to better clean the inside surface of the toilet and prevent stagnation of water or the appearance of rust stains.

When purchasing, you must pay attention to the integrity of the product, because even the smallest crack or dent can lead to a split in the structure. Especially if the material from which it is made is faience or ceramics. The choice of toilet depends not only on the preferences of the owners, but also on their income.

If you take into account all the tips for choosing such designs, the toilet can last a long time, regardless of the price.

Using other flush systems

When using the flush valve, the tank is silently filled.

Developments in technology in recent years have meant that the cistern can be replaced with a druckspühler. Druckspühler (translated from German as “press release”) is a mechanism that drains water directly from the water supply system.

It can be installed in several ways: embedded in a wall, hung on a wall, or hidden behind any decorative fence. Inside the device body there are actuators that are responsible for directly draining water into the toilet. The body itself is divided into 2 compartments. When the drain lever is pressed, a difference in water pressure is created in these compartments, and a hole between them opens. It is at the moment of equalization of pressure between the compartments that water is drained into the toilet. When the pressure is finally equalized, the return spring is activated, which closes the valve. The system works in such a way that between pressing the drain lever and closing the valve with a spring, exactly 6 liters of water are drained.

The Druckspühler allows you to save space that would be occupied by a flush tank, while providing greater reliability, since the entire mechanism is made of steel and is very difficult to break or damage. If the mechanism is damaged, it is simply removed and replaced with another (or repaired in a workshop), which takes very little time. In addition, its undeniable advantage is that you do not need to wait until the tank is filled again for the next use. But the use of a dryer also has some disadvantages: it does not have a water supply: if the water is turned off, there will be nothing to wash it off with. In addition, the system functions normally at a pressure in the riser from 1.2 to 5 atm, which is difficult to achieve in Russian conditions. Well, don’t forget that such mechanisms are intended for plumbing systems with high water quality.

Conclusion

Although a toilet with a shelf is a sign of a classic from Soviet times, it continues to be produced today. The catalogs of many well-known brands contain models with a shelf.

For owners of plate-type plumbing fixtures, this means purchasing a convenient design with an “anti-splash” feature at a low price. A branded model at the highest price can be sold for 16.0 thousand rubles.

Manufacturers continue to experiment with bowl shapes to achieve a minimum amount of water at the bottom. All efforts are aimed at combating splashes. But even the Anti-Splash system does not always help. This is what makes manufacturers increasingly return to producing toilets with a shelf.

Sources:

- https://aif.ru/society/healthcare/pochemu_v_sovetskih_unitazah_delali_polochku

- https://home-santehnika.ru/unitazy/s-polochkoj/

- https://www.o-vannoy.ru/unitaz/polochka-v-chashe/

- https://vplate.ru/tualet/santehnika/unitazy/s-polkoj/

- https://vannayaa.ru/unitaz-bide/unitaz-s-polochkoj-v-chashe.html

- 1

Overview of species

All models of toilets with a shelf can be divided into several types according to installation. Each of them is worth considering in more detail.

- Floor models. Such designs are mostly considered classic, and they can also be found in modern bathrooms. Such toilets are chosen because of their ease of installation work, as well as their low cost. Quite often, floor structures are equipped with a small tank that can be easily hidden in any wall or niche.

- Hanging models . When the owners are concerned about the safety of the floor in the bathroom or want to install heated floors in this room, it is best to install suspended structures. The bowl itself is attached to the wall, and the drain tank can be hidden in a specially made niche. Using such toilets, you can significantly save space and also free up space for a shelf or basket.

- Monoblocks. Such models are most often used in large rooms. All of them have an unusual design, which pleases those who want even their bathroom to look perfect and stylish.

Installation of the cistern

The process of installing a cistern begins with the assembly of its parts, which must be placed inside. The instructions from the manufacturer tell you exactly how to do this. At the next stage, it is attached to the toilet itself or to the wall (special installation structure). It depends on its placement. To prevent water from leaking, rubber gaskets are attached. Usually, they are included with the entire device.

This raises the question: how to connect the tank to the toilet? The structure, which has a bottom placement, is attached with two bolts directly to the toilet; special rubber gaskets are placed under their heads in order to prevent mechanical damage to the bowl device or tank container.

Stage 1: preparatory work

Before you remove the old toilet, you will need to prepare your work area. You will need to remove shelves and rugs from the bathroom. In addition, you need to take out all those objects and things that will block the space. After all, if you leave them, then dismantling the old plumbing will be inconvenient. In addition, while performing such work, you can accidentally touch fragile objects, which will eventually break.

After this, bring the following tools and materials to the workplace:

- hammer;

- wrench;

- chisel;

- glasses;

- basin;

- hacksaw for metal;

- scrap;

- pliers;

- latex gloves;

- rags (rags).

Next, you need to turn off the water in the riser, and then drain all the liquid that has accumulated in the tank. After which you can remove the old toilet, that is, move on to the next stage of work.

General information. Types of drain containers

The following types of drainage tank are distinguished. Flush models differ in the type of installation with the toilet bowl and the requirements for installation work.

Types of drains:

1. Compact type drain. The tank is sold as a set, bolted to the shelf of the toilet bowl, and after completion of installation work it forms a single plumbing device. Assembly of this type is considered the simplest and is an economical option.- 2.Autonomous, hinged type of tank. The container is attached to the wall above the bowl, and the toilet is connected to the cistern using a drain pipe leading from the cistern. Flushing is carried out not by pressing a button, but by using a rope or lever.

- 3. Built-in view of the drain tank. This type of cistern was designed specifically for toilets that have a wall-hung bowl. The toilet is built into the wall of the toilet, the flush tank is located behind it on a frame, which is installed behind a false wall, the flush button is placed outside. This plumbing fixture is equipped with a dosed drain.