Without a toilet in the bathroom, it’s hard to call a cottage or apartment comfortable. Agree, this statement is difficult to refute. There are a huge number of models of this plumbing fixture. But they do not differ in the particular complexity of their internal structure; the principle of operation is the same for all modifications.

If there is a breakdown with the water supply, then the flush mechanism for the toilet will most likely have to be repaired - it is the drainage system that most often fails in this plumbing fixture. We are ready to help you quickly deal with this problem.

In this material, we have collected and summarized information about the main types of toilet tanks, breakdowns that may occur, and ways to eliminate them. For clarity, the materials are accompanied by thematic photos and videos.

Design and types of toilet cisterns

The flush cistern is an integral and one of the main elements of the toilet. This is a container with two or three technological holes for supplying/draining water and a lid.

First, water is drawn into this reservoir, and then, at the press of a button, it is discharged into the toilet bowl to flush the sewage down the drain.

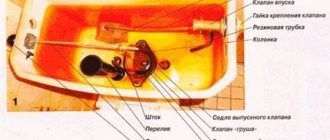

There is nothing particularly interesting or complicated in the design of the toilet flush cistern. There are only a couple of mechanisms inside.

One ensures the supply and shut-off of the supplied water at the moment when it fills the container to the required level, and the second is designed to directly drain the accumulated moisture into the bowl.

Regardless of the design of the toilet, a flush tank must be present in it, since the direct supply of water from the cold water pipeline does not ensure the proper quality and cleanliness of the flush

Based on the material used, flush tanks are divided into three types:

- Ceramic (faience) - reliable and cheap classics.

- Metal - not very aesthetically pleasing in appearance, but a durable option.

- Plastic (polyethylene) - lightweight and easy to install blocks.

According to the method of fastening and location they are:

- low-lying - installed directly on the toilet bowl;

- high-mounted - hung on the wall or located inside it in the installation block.

Separate toilets, in which the tank is separated from the bowl, have a drain pipe for overflowing water. And the higher their storage tank is suspended, the more powerful the water pressure it produces.

Their only drawback is the not very presentable appearance of the tank, located high above the floor. Therefore, most often in domestic toilets you can see models of toilets with tanks placed directly on the edge of the bowl. They are more compact and aesthetically pleasing.

Water supply options

The internal mechanism for supplying water to the toilet flush cistern includes:

- tap (float valve);

- plastic float;

- levers.

Water is supplied to the storage tank through a hole in its body on the right, left or bottom. With the side method, the float is attached to the end of a horizontal lever, which is connected to the valve of the ball valve.

And in the bottom version, the float is connected to a vertical rod located in the supply pipe.

The bottom connection is considered more silent than the side connection - in this case the water does not fall from above, but enters from the side, which eliminates splashing

The basic principle of operation of the mechanism for supplying water to the toilet flush cistern is extremely simple. As a result of the emptying of the storage tank, the float, which floats on the water thanks to the air inside, drops following a decrease in the liquid level.

Once at the bottom, it opens the fitting valve on the water supply, and as the tank fills, it rises again and shuts off the water supply.

Everything in the operation of this mechanism is based on the laws of physics. There are no electronics in its design, which significantly reduces the risk of breakdown. It is possible that there is too little or too much water in the toilet tank.

Then the float only needs to be adjusted so that the filling of the tank corresponds to the required parameters. But if the levers are broken, then the float system will have to be changed.

Types of drain mechanisms

If you need to flush unnecessary things from the toilet, we simply press the button on the tank. Everything else happens by itself. The water release mechanism inside is activated, opening the drain valve.

As a result, the water flow rushes into the bowl and washes everything into the sewer system.

The filling and draining mechanisms are not structurally connected with each other, each of them functions independently, but these devices start/stop in combination simultaneously

The drainage device is activated by:

- by pressing a button;

- pressing the lever;

- pulling the chain (string).

Tanks are available in different shapes and designs. However, most of them are standardized for a volume of 6 or 4 liters and have standard hole sizes for drain valves.

There are a huge number of water drainage mechanisms themselves, different in design. But if the one in the tank breaks, it can be replaced with a new one without any problems.

Our other article contains information about the design of a drainage device - the fittings of a cistern.

The simplest type of drain siphon is a “pear”, shaped like a rubber plunger. Under the weight of water, it is pressed tightly against the drain hole and blocks it.

And when you press the lever, the “pear” rises due to mechanical force and releases water into the toilet bowl.

Then, as the tank fills, it becomes heavier and lowers back onto the seat, again closing the drain hole.

The overflow pipe is always open, its upper edge is above the set water level - if the tank begins to overflow, the liquid simply flows straight into the sewer system

In the event of a breakdown of the water supply device, an overflow is provided in the design of the flush mechanism of the toilet tank. When a certain level is exceeded, the water will flow into this tube and go straight through the bowl into the sewer.

The most common breakdowns of the cistern are discussed in our article: Repairing the toilet cistern with your own hands

Everything is designed in such a way that, by definition, it cannot spill out of the tank. If triggered, such a transfusion will lead to an increase in the readings of the cold water meter, but will avoid a flood.

Structurally, the flush of water in the toilet itself can be horizontal or circular. The first classic option involves supplying water in a continuous stream from one side of the bowl, and the second - forming jets in a circular pattern from its rim.

The horizontal descent is cheaper to implement, but is uneconomical and washes sanitaryware worse. The circular analogue is better in all operational parameters.

However, with a high degree of water hardness, its small holes may become clogged, which will lead to a decrease in the number of jets.

Additional recommendations for choosing a toilet

Having decided on the main parameters for choosing a toilet, you should not forget about secondary, but at the same time important factors.

Firstly, the material from which the toilet is made. The most common are earthenware and porcelain. Both materials are based on clay. Earthenware is not durable: over time, cracks appear in the bowl and the surface becomes stained. Porcelain surfaces are stronger, denser and smoother. Dirt practically does not accumulate on them. You can also select toilets made of ceramics. They are attractive in appearance, but the level of strength and durability leaves much to be desired.

Toilet bowl made of sanitary porcelain

Secondly, the degree of comfort. When choosing, it is recommended to “try on” the toilet and trust your feelings. Staying on the toilet should not be constrained; the abdominal and pelvic muscles should be completely relaxed.

Thirdly, the shape and color of the toilet. These parameters do not in any way affect the functionality of the plumbing fixtures, but they play a very important role when choosing. The market offers many shapes and colors of toilets: from traditional to exclusive and unusual. Here you should be guided only by your own preferences and the general concept of the bathroom.

Plumbing in unusual colors

A person spends a total of about five years of his life in the toilet, so choosing the right toilet is very important. A comfortable toilet with a good flush without splashing will make visiting the toilet not only comfortable, but also hygienic.

Tornado flush system: video

Choosing a toilet: photo

Operating principle of dual-mode drain

Modern models of flush cisterns are equipped with a double flush button. This is a tribute to the fashion for saving water.

Such devices are designed for two operating modes:

- standard – for dumping the entire tank into the bowl (4 or 6 liters);

- half - to pour out only part of the volume (2 or 3 liters).

Such a system is more economical in terms of water consumption. But it is also more capricious in terms of setup and repair. The number of internal elements in it is increased, which means the risk of failure of this device increases.

A two-mode flush tank with a pair of buttons allows you to significantly save water, since in some cases only part of it is used, and not all of it

In addition to the dual option, the button for the dual-mode drain mechanism can be one. In this case, the volume of water released depends on the force of human pressure on the lever.

While the button is pressed, the drain hole remains open, and when released it returns up and at the same time the drain is blocked.

Types of drain mechanisms

A tank for draining water is included in the design of any toilet bowl, and is a container with 2-3 technological holes. Through them, water enters the tank or drains from it. The top of the container is closed with a lid, which increases the decorative effect of the entire device. The process of operating the flush mechanism for a toilet cistern with a button is not very complicated. At the first stage, water enters the container and remains there until the button on the tank is pressed. This occurs mainly through the application of mechanical force, after which a certain volume of water is poured into the bowl. Its flow washes away sewage, removing it into the sewer pipe.

As for the internal structure of the flush tank, there is nothing original or complicated there either. This mechanism consists of a couple of elements. The task of the first of them is to supply and shut off water from a common pipe, which allows you to fill an empty tank with the required amount of liquid. The second device is responsible for pouring the contents of the tank into the bowl after pressing the button.

Adjusting the water level

If water is supplied from the side, then the maximum level in the tank is regulated by changing the length of the spoke. It is at its end that the float is attached. In old and many new models, the role of this lever is performed by a thick brass wire.

You just need to bend it in the middle so that the float moves down or up. The higher it ends up being, the larger the volume of the tank will be filled.

However, now metal is increasingly being replaced with plastic. But it will not be possible to bend the plastic elements at the desired angle; they may simply break.

In this design, the float must be moved along the axis of the plastic pin, thereby increasing or decreasing the lever arm. The farther the float device is from the valve, the more water will flow into the tank.

Image gallery

Photo from

Step 1: Prepare to Adjust the Float Position

Step 2: Adjusting the float position with the nut

Step 3: Checking the operation of the flush device

Step 4: Change the level based on actual results

The float arm in toilet models with bottom water supply is located vertically. Here the water level is much easier to regulate.

The float element simply needs to be moved up/down and fixed at the desired height with the clamps or nuts provided for this purpose.

To simplify the adjustment of the float position, some mechanisms have a threaded connection on the rod or a rotating block to adjust the position of this “displacer”

The main problem when making adjustments is not changing the position of the float, but the need to remove the toilet tank lid. A drain button is attached to it, which in many models is rigidly connected to the drain mechanism.

To avoid breaking anything, this structure should be disassembled extremely carefully. First you need to carefully unscrew the clamping ring of the button. And only after this will it be possible to move the lid without fear.

Have you ever had an unfortunate toilet lid break? You can try to fix it yourself. In this article we looked at how to do this step by step.

If, with the float in the upper position, water still continues to flow into the tank, then the problem lies in the inlet valve. It will have to be disassembled and cleaned or completely replaced

Almost all the working elements of the flush cistern mechanism in the toilet are now made of plastic rather than metal. Because of this, they often break.

Plumbing stores sell both ready-made drain and supply structures, as well as their individual components for repair. In some situations it is cheaper to replace only part of the device, while in others it is easier to replace the entire assembly.

You may also be interested in reading about how to properly disassemble the drain tank so as not to accidentally damage anything.

Installation methods

Another important fact when installing a toilet in your room is the fastening of the plumbing structure. It is this nuance that affects both the design of the toilet room and the possibility of installing utility networks.

There are two types of toilet installation: floor-mounted and wall-hung.

Floor-standing, the most common, does not require much effort for this type of installation. You just need to drill a few holes in the floor, install special bolts, and attach the structure. Moreover, you can place it in any place convenient for you.

If you become the owner of a comfortable and expensive toilet, then you need to “hang” it wisely and with the help of a specialist. They are mounted on a special installation, which, in turn, is mounted on the wall.