What it is?

To find out the answer to the question “What is a profile bender?”, you need to find out what it is for.

This construction specimen is necessary in order to bend a metal profile in a certain direction, which looks like an elongated product in the form of a pipe. What kind of work is performed using a profile bender? This bending tool is designed for profiles that are used in load-bearing structures. Also, the tool in question is very necessary if external or internal finishing work is carried out (for example, for arranging sports fields).

Deformation can be done in the following way.

- Cold deformation. It is carried out in order to minimize the processing cycle and improve performance characteristics.

- Hot deformation is used on alloys that are difficult to form, or to form massive products.

Roll benders have a wide variety and different ways of bending the material, so they are divided into 3 types.

- The press type is different in that in this case the metal blank is fixed using a pressure beam.

- The rotating mechanism has a fixed base and a mechanism that rotates. Suitable for profile pipe.

- The rotary mechanism allows metal to be bent by rolling.

It is rotary profile benders with driven or non-driven rolls that are in greatest demand. This design allows you to work with various materials and carry out complex orders. Roll benders are classified by drive type. For example, an electrical (electromechanical) unit operates on a stationary basis due to its heavy weight and huge dimensions. Used in workshops. A hydraulic product may be mobile, or it may be stationary. Mainly used in industry.

The manual unit is characterized by its low weight, size and price. Its use is possible at home. The devices described above are used to give the desired shape to pipes, channels, beams, etc.

The best hydraulic pipe benders

Hydraulics require minimal human effort to bend pipes. Such tools are easy to operate, convenient to use and are considered the most versatile when working with various materials.

Ridgid 3814E

5

★★★★★ editorial assessment

100% of buyers recommend this product

The model is equipped with a single-circuit hydraulic system with spring return. It allows the owner to control the movement of the piston, allowing for easy and precise pipe bending. A variety of shoe sizes are included, making it easy to work with all popular diameters.

The piston force is 200 kN, the maximum bending angle is 90°. The top plate has a folding design, so that placing and removing the workpiece does not take much time. High-quality seals reliably protect the system from oil leakage.

Advantages:

- high performance;

- robust design;

- long service life;

- powerful engine;

- neat work.

Flaws:

high price.

The Ridgid 3814E is purchased for intensive use. Professional solution for working with pipes with diameters from 3/8″ to 4″.

Super-Ego 1500002308

4.9

★★★★★ editorial assessment

95% of buyers recommend this product

The model with a closed hydraulic system requires no maintenance and is easy to use. The monoblock design with automatic piston return guarantees convenient operation. The robust design is resistant to damage and corrosion.

The maximum force on the rod is 12,000 kg, the pipe diameter is from 1.2 to 3 inches. Small size and weight make the device easy to store and transport.

The hardened piston is treated with chrome plating and has an increased service life. For more precise bending at a given angle, special stops are provided.

Advantages:

- compactness and ease of transportation;

- corrosion resistance;

- high strength;

- great effort.

Flaws:

heavy weight.

Super-Ego is capable of bending pipes at angles up to 90 degrees. It will be useful when installing a gas pipeline, heating system or carrying out repair work.

Stalex HB-60 Premium

4.8

★★★★★ editorial assessment

91% of buyers recommend this product

The base of the pipe bender has special grooves that allow you to fix the structure on a flat surface using fasteners. Pressure quick-release rollers make working with small workpieces easier. Reliable support guarantees stable operation under heavy loads.

The maximum force on the rod is 5000 kilograms, the total weight of the device is 65 kg. The cabinet can also serve as a transport case. There are two handles at the top for easy carrying. The front cover is locked using magnetic and mechanical locks.

Advantages:

- excellent stability on the surface;

- robust design;

- ease of carrying;

- rich equipment;

- ease of use.

Flaws:

large dimensions.

Stalex HB-60 Premium is suitable for bending pipes and rods with a diameter of 15, 20, 25 or 30 millimeters. An excellent solution for occasional use.

Voll V-Bend 2 3.12000

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

The model has a long handle with a relief lining. It does not slip out when wet and ensures comfortable work in any conditions. The body is equipped with many special holes that make it possible to rearrange the side stops to obtain different bending angles.

The maximum stroke of the rod is 250 mm. The robust design is not afraid of heavy loads and has a protective anti-corrosion coating. Reliable supports help to conveniently place the device on a flat surface. The kit includes all the necessary components for quick start of operation.

Advantages:

- ergonomic handle;

- Ease of use;

- durable body;

- rich equipment;

- stable base.

Flaws:

long reconfiguration.

The professional pipe bender Voll V-Bend 2 is recommended for installation and straightening of gas and water supply systems.

The best manual pipe benders

The models are divided into several categories, according to the bending method. This includes models that are used manually by a specialist. Manual models will not allow you to do a large amount of work, unlike electric ones. They are the most affordable in terms of price, but require appropriate skills for bending.

Stayer Master 2350-16

Manually operated model with a lever design. Suitable for bending pipes with a round cross-section. Materials with which the tool interacts: steel, copper, aluminum. It is suitable for most types of pipes, which allows it to be used in any area. The minimum thickness of the pipe being processed is 14 millimeters, while the maximum is limited to 16 millimeters. The bending radius is 95 millimeters. Bends at any angle from 0 to 180 degrees.

Advantages

- Interacts well with metal-plastic;

- Strength;

- Convenience;

- Low price.

Flaws

- Ineffective if not used carefully.

The model is designed for everyday use: it is not suitable for regular professional work. Its low price makes it good for short-term use in small buildings.

Force 653180

Manual pipe bender with a long, comfortable handle. Designed for bending small pipes with a thickness of 6, 8, 10 millimeters. The body is made of a durable metal alloy, which ensures the reliability and durability of the tool when bending any pipes. The tool can withstand heavy loads, which is why it can be used in a professional environment for regular bending of pipes. The latter is carried out at an angle from 0 to 180 degrees. Interacts with all popular materials.

Advantages

- Versatility;

- High strength;

- Convenience;

- Easy bending of thin/medium pipes.

Flaws

- The tool is quite bulky.

A large, powerful model that quickly copes with bending medium-sized pipes made of any materials.

Thanks to its design, the tool is convenient and does not require large amounts of power. The only difficulty will be transporting the device, since it is quite large.

TIM FB1632P

Crossbow-type manual pipe bender for bending metal-polymer and plastic pipes made of non-ferrous metals. It is optimal when bending requires respecting the terrain along the path. Allows you to conveniently bend pipes at any angle, giving them different shapes. The specific structure provides reliable protection against bending/deformation of the pipe. The tool is portable: thanks to its small dimensions, it can be easily carried. Equipped with several interchangeable bends designed to work with pipes of different diameters (from 16 to 32 millimeters).

Advantages

- Compactness;

- High efficiency;

- Convenience;

- Suitable for pipes of different sizes.

Flaws

- High price.

Expensive, but very effective tool for flexible machining of pipe structures made of non-ferrous metals. Suitable for bending complex structures, as it is small in size and easy to use.

My choice

The best choice of model can be made based only on specific needs. But in a specific review, it is best to rely on the advantageous combination of acceptable operating cost, design simplicity and functionality. That's why:

- in the category of vertical models, the repairable and quite powerful Matrix 181335 deserves attention;

- Among the horizontal ones, Rothenberger Robull e is optimal: powerful, convenient and inexpensive to operate;

- At an acceptable operating cost, I highlight the Stalex HB 40 - if something breaks, it can be repaired quickly and inexpensively.

If you think that I am wrong about something, write even sooner. Together we will find the truth :)

The best hydraulic pipe benders

Such a tool has similar design elements, but the drive is carried out as on a jack, which allows you to work with a larger diameter of pipes, an increased wall cross-section and less force on the operator. It is used on construction sites and when laying water communications.

STELS 18115 - for plumbing and heating

This is the best pipe bender for quickly making turns when laying water pipes or heating, since the device comes in a plastic case, convenient for transportation, and is capable of working with parts of various diameters thanks to four adjustment holes in the body for rollers and three shoes included.

Thanks to the hydraulic drive, the master will be able to quickly produce the required number of elbows to create turns in the water supply system.

Pros:

- the cost of 7,500 rubles is acceptable for this category of equipment;

- you can work without securing it to a workbench;

- durable metal frame can withstand heavy loads and does not deform;

- easy change of shoes for different pipe diameters;

- springs on the rod help to quickly return the extended element to its place for installing the next workpiece;

- compact dimensions of the device: 540x530x190 mm;

- on the rod force up to 8 tons;

- suitable for ½, ¾, and inch pipes;

- case included.

Minuses:

- large weight 25 kg;

- there is no bending degree scale;

- The bending angle is only up to 90 degrees.

SWG-2 RENZA 068-1062 - for thick pipes

This is the most popular pipe bender for self-bending thick pipes, since its frame allows you to insert workpieces with a diameter of up to 50 mm into it.

The body has 6 holes for rearranging the rollers, so the giant can bend even a thin ½-inch piece. In addition, the structure has a support tripod on wheels, which is convenient for transportation on a flat floor without additional equipment.

Pros:

- comfortable rubberized handle on the lever;

- quick rearrangement of rollers by removing the locking fingers;

- The included tripod eliminates the need for a workbench;

- high-quality powder coating;

- rod stroke 250 mm;

- 6 shoe attachments included;

- capable of bending workpieces with a diameter of up to 50 mm;

- does not deform the walls;

- high-quality seams on the body.

Minuses:

- cost from 20,900 rubles;

- weight 52 kg;

- The bending angle is limited to 90 degrees.

TOP 3 best lever pipe benders

Lever pipe benders are simple tools that allow you to quickly and accurately bend pipes using physical force. In 2021, three models were recognized as the best in this category.

BISON EXPERT MINI 23526-10

Inexpensive but high-quality pipe bender, which in design and technical characteristics fully meets professional requirements.

The body is made of solid cast alloy, so the tool will not be damaged even with intensive use, although the pipe bender itself remains as light and functional as possible.

Since the device has a lever design, its use will be as comfortable and efficient as possible..

The tool can be safely called universal, because it can be used for bending pipes when installing various utilities, from water supply to heated floors.

There are special notches on the body of the product that allow you to accurately control the bending angle and form bends of different shapes in different planes.

Specifications:

- minimum pipe diameter 6 mm;

- maximum bend angle 180 degrees;

- maximum pipe diameter 10 mm.

pros

- reasonable price with high quality manufacturing of the case;

- allows you to get a clear and neat fold;

- there are notches on the body;

- rubberized lining on the body;

- The simplest design makes it easy to use.

Minuses

- some users complain about manufacturing defects;

- Not suitable for bending pipes made of hard materials.

Kraftool 23502-H9

One of the most convenient and functional pipe benders on the modern market . It costs

more expensive than other similar tools on the market, but the high price is fully justified by the advanced capabilities of the device.

The tool itself is lever-based, so the user will have to make some effort to bend the pipes.

But, since the manufacturer has thought through the design features in detail, using a pipe bender will be as simple as possible.

The main feature of the device is that it is supplied unassembled and consists of handles and a set of bases.

They are designed for pipes of different diameters.

Due to this, by rearranging the bases, the user will be able to accurately and quickly bend pipes of different diameters for the installation of ventilation systems, water supply and other utilities.

Specifications:

- minimum pipe diameter 10 mm;

- weight 4.85 kg;

- maximum bend angle 90 degrees.

pros

- simple lever design facilitates operation;

- suitable for pipes of different diameters;

- Comes with storage case;

- There is a wide selection of nozzles for bending pipes of different diameters;

- reliable mechanical bending mechanism.

Minuses

- costs much more than analogues;

- not always available for sale.

BISON EXPERT 23523-12

Compact, inexpensive, but high-quality pipe bender, which is suitable for both household and semi-professional use.

The product body is made of high-quality steel, which is highly resistant to corrosion and mechanical damage, and does not deform during long-term and intensive use.

For maximum ease of use, the manufacturer has equipped the handles with rubberized pads.

So that the tool can be used with pipes of different diameters, the manufacturer applied special markings to the body.

By adjusting it, the owner will be able to set suitable parameters for bending the pipe in order to adapt it for the installation of a water supply system, sewerage system or other utilities.

Specifications:

- minimum pipe diameter 12 mm;

- maximum bend angle 90 degrees;

- bending radius 43 mm.

pros

- durable metal case;

- there are rubberized linings on the handle;

- suitable for bending pipes of different diameters;

- simple but reliable design;

- Markings are provided on the body.

Minuses

- not suitable for hard materials;

- Often there are factory defects.

Malfunctions and solutions

- Air entering the hydraulic system.

It is easy to determine the malfunction - the handle begins to spring back, and the force developed decreases. To eradicate the problem, tighten the screw as much as possible and remove the axis on which the plunger and handle are attached. Then the first one is removed, and oil is poured into the bushing hole. The elements are assembled in the reverse order, the handle is turned several times to pump up the liquid.

- Broken suction check valve.

Determined by the impossibility of moving the hydraulic cylinder rod. To solve this, the screw is tightened all the way and the handle is raised to the top position. Give it a sharp blow so that it goes down. Perform the operation 2-3 times. If no improvement is noticed, it makes sense to contact a workshop.

- Problems with the electric drive.

Without proper experience, independent repairs are prohibited; again, it is worth visiting specialists.

- Wear of consumables.

Rubber bands, gaskets, oil and other equipment components are replaced with new ones if necessary.

An important aspect of the smooth operation of a hydraulic pipe bender is the presence of good oil in the system. It should be:

- resistant to oxidation (this will ensure long-term operation on this oil without changing it);

- not too thick (otherwise the liquid will not pass through the fine cleaning system);

- thermally stable (so that the liquid retains its properties at extreme operating temperatures);

- hydrolytically stable (that is, if oil is accidentally mixed with water, the latter should not affect its operation).

A hydraulic pipe bender is a useful device for manufacturing processes. If pipe bending is put into production, it is recommended to purchase stationary equipment with an electric drive. If work is carried out periodically, a hand-held compact device is sufficient. In discussions about the article, you can share information about used pipe benders, add to the list of tips on choosing oil and repairs, and also recommend proven device models to your colleagues.

Essential elements

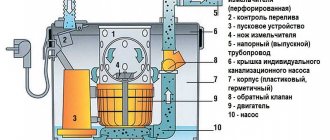

A pipe bender consists of several main parts. They are practically the same in different types of models. Most often, the choice falls on front-facing devices. They consist of the following elements:

- 3 metal shafts;

- axes of rotation;

- drive chain;

- a mechanism that drives the remaining parts of the device;

- metal profiles from which the frame is made.

Often, a pipe bending machine is equipped with polyurethane or wooden rollers. When selecting materials, it is worth assessing the strength of the products that are supposed to be bent. If such requirements are neglected, the main components of the device may not withstand the operating pressure.

The process of bending a workpiece is subject to certain rules that should be taken into account. Basically, pipe benders use the rolling or rolling principle. Such methods provide the safest and most practical way of bending. The risk of breakage or damage to the product in this case is minimal.

When using a manual device, the pipe is inserted between the rollers and then the handle is turned. The use of such a device allows you to obtain the correct bend on the profile pipe.

Using specialized pipe bending tools is the only right choice. This solution will provide the best pipe bending effect. Thanks to the pipe bender, the bent products are not deformed and their structure is not damaged.

There are many advantages of such devices. The main ones include:

- safety of bending metal-plastic products;

- low risk of workpiece destruction;

- the ability to work with almost any pipe;

- bends are obtained without cracks or flattening;

- ease of operation.

Pipe benders are quite convenient to use. They are highly impact resistant - all models are made of metal. Also, when using a pipe bender, you can bend metal-plastic at different angles. Pipe preparation (heating or special treatment) is not required when using such a device. The quality of installation of pipes bent in this way increases noticeably. This is due to the reduction in the number of welding and fastening work when installing pipelines or household networks.

TOP 3 best spring pipe benders

Spring pipe benders, unlike manual ones, have a more thoughtful design and allow you to bend pipes at the desired angle with minimal effort on the part of the user.

BISON 23531-10

The domestically produced spring is designed for bending round pipes with a diameter of no more than 10 mm.

The tool is made of high-quality spring steel, therefore it has increased wear, deformation and mechanical damage. The functionality of the product is slightly limited, since it can only be used to bend soft copper pipes.

Moreover, the tool is suitable even for bending long pipes due to the special shape of the body with a twisted cone.

For additional protection against corrosion, the manufacturer coated the tool with a chrome plated finish.

In addition, the tool boasts a thoughtful shape that prevents pipe deformation at the bend and protects the material from cracks and other mechanical damage.

The tool is compact, so you can easily take it with you to perform construction and installation work on the road.

Specifications:

- weight 0.192 kg;

- pipe diameter 10 mm;

- length 53 cm.

pros

- thoughtful design ensures maximum ease of use;

- low price;

- high quality steel body;

- chrome plated for corrosion protection;

- Suitable for bending long pipes.

Minuses

- bending long pipes requires serious physical effort;

- Only suitable for soft copper pipes.

BISON MASTER 23531-12

Another successful pipe bender model, which is designed for bending pipes manually . For

This will require some physical effort, but the well-thought-out design of the tool makes operation much easier.

According to technical characteristics, the model is designed for bending pipes with a diameter of up to 12 mm.

The product is suitable for both domestic and professional use, but in the latter case the user will have to buy a set of spring pipe benders to work with pipes of different diameters.

The manufacturer has carefully thought through every detail of the product. In particular, the pipe bender body is made of high-quality spring steel, resistant to deformation.

The outside of the product has a chrome coating, which additionally protects the instrument from corrosion..

The body is thought out in detail, and a twisted cone is provided at the place where the pipe is fixed, which facilitates work and prevents deformation and mechanical damage to the pipe during bending.

Specifications:

- length 400 mm;

- maximum pipe diameter 12 mm;

- weight 0.249 kg.

pros

- durable housing made of high-quality spring steel;

- External chrome coating provides reliable protection against corrosion;

- the well-thought-out shape of the case makes it easy to use;

- reasonable price;

- Can be used for bending long pipes.

Minuses

- not suitable for bending pipes made of hard materials;

- Only suitable for pipes of a certain diameter.

BISON 23531-18

A domestically produced spring pipe bender will become an indispensable assistant in the installation of utilities: water supply systems, heating, air conditioning, etc..

In terms of functionality, the product is intended for bending copper pipes: the design of the tool does not allow for working with pipes made of other materials.

At the same time, the user will be able to bend even long pipes with the help of the tool, since the model boasts a special body shape with a twisted cone.

The tool itself is made of high-quality steel, resistant to deformation, and the outer chrome-plated coating protects the product from corrosion, so the pipe bender can be safely used even in a damp environment.

The body of the product is spring-loaded, so bending the pipe at the desired angle will not require serious physical effort, and there will be no cracks or other mechanical damage on the pipe itself.

Specifications:

- length 400 mm;

- pipe diameter 12 mm;

- weight 0.386 kg.

pros

- low price;

- thoughtful design makes it easy to use;

- There is a chrome coating to protect against rust;

- does not take up much space during storage;

- Suitable for home and professional use.

Minuses

- suitable only for working with pipes of a specific diameter;

- There are no notches to control the bending angle.

Overview of species

Those who install various metal structures need to use a profile bender. Now it has become fashionable to install beautiful greenhouses made of metal profiles on your site. They are reliable. Therefore, for greenhouses, canopies (arched), namely for their manufacture, a manual profile bender is quite suitable. It is small and can be installed in any room intended for various construction works.

To bend profiles with tension, you can use a machine that operates on the principle of the PGR-6 machine. This product has a stretching mechanism designed for bending aluminum alloys along contours that are not closed. In a profile bender, the number of rolls plays a major role. The simplest design consists of 2 rolls. Such models are used for very light work.

The number of rolls and versatility determines what type a particular machine can belong to. Some rolling products can rotate rolls only in one direction, while others can rotate rolls in both directions at once. Therefore, in the first case, the machines are not called reversible, but in the second - reversible.

Consider, for example, a three-roll roll forming machine with hydraulic movement of the top roll. In it, the profile is fixed between the rolls. All of them have hydraulic engines and attachments (suitable for any cross-section). The required radius is ensured here using a hydraulic drive. Therefore, these products are in good demand where a machine is needed for the production of simple products.

Using profile benders of different directions, you can make various configurations from metal that differs in radius. They are capable of producing parts of various curvatures with both asymmetrical and symmetrical contours. In more detail, profile benders have the following types.

- Pneumatic profile benders operate using pneumatics.

- There are hydraulic profile benders.

- There are also manual, mechanical and electromechanical profile benders.

By placement method

Profile benders are placed on different flat surfaces. Too large specimens are installed on the floor in a spacious room. Due to their enormous weight, they can only be used in workshops. Such models have an electric drive and operate from the network. Other specimens must be secured using special devices to prevent their involuntary movement. This category of machines is intended for work both on an industrial scale and for individual use. Industrial machines are used for bending where large-scale work takes place. So, there are mobile machines, and there are stationary ones. Each of them has either manual or automatic material feeding.

In most cases, specialists use manual profile bending machines. Some people make them with their own hands. This option is quite affordable. But there are also disadvantages. For example, it is inconvenient to perform several bends on one profile at once. It is also difficult to work with such products due to the heavy load on a person. In addition, the bending time increases and it is impossible to control the bending radius.

By drive type

Roll benders are classified as follows.

An electric profile bender, when compared with a manual one, can operate at a fairly high speed. It is also distinguished by the accuracy of its work. Using such a device, you can bend very strong metal products. It can process any types of profiles, even such as I-beams and round products.

We help with the choice of nibblers, and where are they applicable?

Nibblers are one of the most common and used types of machine equipment, which is used when working with sheet metal of small thickness.

Due to its design and operating principle, with the help of die-cutting […] read more

Tips for choosing equipment

Mistake #3 - incorrectly selected material

If inexpensive, low-quality polypropylene pipes are chosen for installation, even the most skillful installation will not protect home owners from damage. It is best to purchase pipes and fittings from the same reliable supplier, choose a good company, etc. A stingy person pays twice.

Another problem of this kind is trying to connect two high-quality pipes from different manufacturers. The chemical composition of such elements may vary, and therefore such pipes will behave differently when heated. Under such conditions, it is almost impossible to achieve a reliable connection.

A clear result of improper soldering of polypropylene pipes in a section. The use of low-quality material and non-compliance with the time of the “fixation” phase led to deformation of the connection

Excellent pipe benders with hydraulics

In terms of operation, hydraulic pipe benders are much easier. Here you do not have to press the pipe on your own and pull it through the rollers with the strength of your hands. Light pressure with one hand uses fluid pressure to bend the pipe at a variety of angles. The main thing is not to overdo it and not break it. This is especially true for steel pipes, which require careful treatment and break very easily if the pressure on its walls even slightly exceeds the norm.

Hydraulic pipe benders

Each hydraulic pipe bender can be classified into one of two large groups:

- equipped with electric drive;

- manual.

Manual hydraulic pipe benders operate on the principle of a single-stage handle. Such devices contain only 1 valve that regulates the operation of the hydraulic cylinder. The hydraulic pipe bender, powered by electricity, is equipped with a two-stage handle.

Manual devices have fewer capabilities, however, they are quite easy to operate. Electrohydraulic devices are more often used in production. Most of these models have a bending angle limitation - a maximum of 90 degrees. To bend the pipe at a large angle, you will need to purchase additional elements.

Attention! Hydraulic pipe benders of any type allow you to work with many types of products, even thin-walled ones.

Manual devices have to be set in motion with some effort. To bend the pipe, you have to pump up the handle of the mechanism. Electrohydraulic systems are more advanced in this regard. Also, do not forget that when using such a device you will have to pay additionally for electricity consumption.

Advantages and disadvantages of equipment

- A large volume of work that a pipe bender can perform without interruption.

- The ability to select a tool based on the specifics of the job and ensuring convenience (some users need pipes to bend horizontally, while others need a vertical pipe bender).

- The ability to change punches (elements for bending at a certain angle) if you need to achieve greater bending of the workpiece.

- Almost complete absence of deformation of parts when using a hydraulic drive.

- Facilitation of installation of water supply systems by reducing the number of fittings and bends.

- Some pipe benders bend several pieces at once, optimizing production processes.

- Working with a manual or electric pipe bender is not particularly difficult even for a beginner.

- Most stationary hydraulic profile benders are equipped with a frame that protects the worker from injury and prevents the pipe from suddenly slipping out.

- Possibility of repairing some components with your own hands.

The models have few disadvantages, but still not without them. For example, most manual pipe benders only come with one 90-degree bending punch, forcing the user to spend extra money if they need a different angle. The second disadvantage, already related to electrical devices, is high energy consumption. The third is the high cost of stationary models. Fourth is the need to carefully care for the equipment to ensure maximum service life. Now let's talk about common equipment problems.

Types of pipe benders

The main indicator of the classification of machines is the design. Depending on the design features, the following types of machines are distinguished:

- Manual. They work in small enterprises and involve the use of muscular strength during work. Typically, these compact machines are portable, and they are used in the construction industry. Thanks to its mobility, the equipment is used directly on construction sites.

- Hydraulic. Hydraulically driven devices. The design of this equipment is similar to a manual machine, but can be either portable or stationary. These machines mainly differ from manual ones in the presence of a hydraulic booster, which allows processing products with a cross-section of up to 20 mm without serious physical effort.

- Electrical. They are large in size and operate by consuming electricity. When bending, they provide high angle accuracy. An electric industrial pipe bender can also bend products with a large cross-section and thin walls.

Electric pipe bending units are divided into three main types, depending on the degree of automation:

- manual;

- semi-automatic;

- automatic with CNC.

Machines with computerized controls are the most functional. Thanks to CNC, you can program the parameters of the bending angle and radius. These devices are capable of operating in a fully automatic mode, where the processes are controlled by a computer program (in particular, part delivery and mandrel adjustment).

Pipe bending machines for ordinary and profile pipes are different. Manual machines are quite inexpensive, but are much less productive than electric models.

How to choose a pipe bender

- Operating principle

. All pipe benders that are sold on the domestic market can be divided into two groups. Three-roll devices allow you to change the bending radius of the entire pipe. These devices are found in the manufacturing sector. When you need to bend the workpiece only in a limited area, then corner models are suitable. They are most often used in everyday life and in the construction industry. - Type of drive

. Pipe benders are activated in different ways. The simplest device is considered to be a manual pipe bender. To bend the workpiece, the operator will have to apply serious muscular effort. The hydraulic drive increases the force exerted on the pipe. Therefore, such devices are capable of working with thick-walled steel workpieces. The electric drive provides high bending speed; such equipment can be found in large workshops and factory metalworking shops. In everyday life, manual and hydraulic devices are most often used. - Functionality

. Among pipe benders there are both highly specialized and universal models. For craftsmen who are engaged in installation or repair work, devices “tailored” for a specific type of pipe are preferable. In the home workshop or in the public utility sector, universal models are widely used. Thanks to the replaceable bending segments, you can easily bend round and square pipes, as well as rods and strips. - Weight and overall dimensions.

When choosing a pipe bender, you should also take into account parameters such as weight and overall dimensions. The most compact are manual models. It is also possible to transport some hydraulically driven devices. But professional equipment with electrical connection requires the construction of a special foundation on which the base is rigidly mounted.

We have selected 6 of the best pipe benders for our review. You can buy these models in the retail chain of our country. When determining places in the rating, the opinions of experts and consumer reviews were taken into account.

Conclusions and useful video on the topic

The video provides information about the design features of pipe benders and the nuances of working with different models:

It is difficult to clearly determine which type of tool is better: horizontal, vertical, mobile, stationary. The user himself usually selects the configuration of the tool based on the conditions of its use. Meanwhile, among the range of hydraulic pipe benders, universal designs are increasingly appearing. The emergence of such models actually removes the question of choosing according to certain parameters.

If you have experience using hydraulic pipe bending equipment, please share it with our readers. Tell us what model of pipe bender you use, are you satisfied with its performance? Please leave it in the block below the article. There you can ask questions about the topic of the article.

We compare electrohydraulic pipe benders at affordable prices

The advantage of electrohydraulic models of bending machines is that there is no need to use physical effort when working with a tool of this type. As a result, a hydraulic pipe bending machine with an electric drive bends […]

read more

Tips for choosing equipment