If you need to install a toilet cistern, you can do it yourself, the main thing is to follow the instructions.

Very often, toilet cistern fittings fail due to poor-quality tap water. If you still had to face a similar problem with the cistern mechanism, then it is not at all necessary to completely change the toilet; you can simply change the flush cistern. There is no need for professionalism here as such, however, you should familiarize yourself with some of the intricacies of the installation.

Materials of toilet cisterns

To construct flush cisterns, quite a variety of materials are used, which differ in volume and shape. There are three main types of materials for the manufacture of flush tanks. These are ceramics, metal and plastic. Ceramic or earthenware tanks are popular due to their low cost and reliability. Metal tanks, of course, do not look particularly aesthetically pleasing, but they are very durable. Plastic tanks are easy to install and lightweight.

Of course, ceramic products are especially in demand, so the installation of the tank will depend on its configuration.

Work process

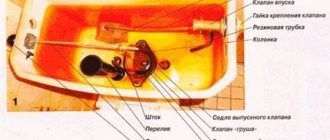

How to attach a compact toilet cistern

Before starting work, we will prepare the installation parts and the necessary tools. Let's assemble the internal fittings of the tank; we will prepare a special rubber gasket connecting the toilet to the flush tank; a flexible hose will be needed to connect the tank to the water pipe, fasteners: nuts, bolts, cone-shaped gaskets, construction lubricant that prevents corrosion.

First, a rubber cuff is applied. The service life increases with careful selection of this gasket; it protects against leakage from under the tank.

Attention! If the gasket is purchased separately, you need to choose the right shape; it is better to purchase a gasket made of high-quality rubber.

The surface of the special protrusion where the tank is attached should not contain any traces of defects. After installation work, the cuff should be in contact with the tank and shelf without gaps. To eliminate possible leaks, the cuffs must be lubricated with silicone sealant. It serves as a guarantee of additional fixation of the rubber gasket during fastening.

The holes on the side of the tank require special attention; they must completely match the holes on the shelf. Before screwing the bolts with an open-end wrench, we put seals on them. If you forget to install gaskets, the plumbing may crack and the container will begin to leak. We run a flexible hose from the tank to the cold water drain. An anti-leak gasket should also be inserted into the washer.

Once the plumbing installation work is completed, we perform a test flush. It is worth paying special attention to the process of filling the tank; if something is not satisfactory, you need to adjust the float device. If the flush tank works properly and there are no leaks, then the job was done correctly.

Types of cisterns

Today, there are several types of drainage systems, and each of them has its own special structure. Depending on the connection between the cistern and the toilet, a distinction is made between joint and separate types of construction.

- With a separate toilet and tank, the tank is attached to the wall and connected to the toilet itself with a special tube. The water drainage mechanism includes a long lever or hanging mechanism. The advantage of the design is the speed of water drainage compared to other designs.

- The most common design is in which the flush cistern is attached directly to the toilet. The advantage of this option is the simple replacement of the insides of the cistern. In particular, replacing the float and the so-called float valve.

- The next view is a complete structure consisting of a toilet bowl and a cistern.

- There is also a type of toilet where the flush cistern is mounted directly into the wall itself. This option is chosen to visually increase the space.

Most attention falls on the “compact” version, in which the flush cistern can be secured with bolts to the back wall of the toilet, or to a special monolithic shelf. However, the best toilets are considered to be those in which one-piece flush cisterns are immediately constructed, in a word, this is a completely integral design.

But those models that are made of two main parts, and a so-called pipe is attached between them, belong to the separate type of drain tanks. The demand for them is falling every day, and besides, toilets without a tank are practically not used at all in plumbing, since their design does not quite meet the necessary criteria.

How to install an autonomous tank

Installing an autonomous water tank on the wall is more difficult than mounting a storage tank on a toilet shelf; it is advisable to do this work together.

The installation process proceeds as follows:

- Two marks are made on the surface of the wall in the places where the container will be attached. You should not lift the autonomous tank high, as it will be inconvenient to use. In addition, it is important to check in advance that the length of the overflow tube is sufficient from the container to the toilet; the two marks made are checked by level so that the container is positioned strictly horizontally;

- in the marked places, holes are drilled with a hammer drill; their diameter must correspond to the diameter of the dowels being inserted;

- a drain fitting is placed inside the storage tank, after which an overflow tube is connected; it is important to connect it through gaskets that seal the equipment;

- the container is secured to the wall using bolts or dowels, which are screwed into the drilled holes;

- the overflow tube is connected to the toilet;

- A flexible water pipe is connected to the autonomous drive through gaskets.

After assembling this equipment and connecting it, testing begins. If a leak occurs, turn off the water supply and repair the leak.

Several basic methods for installing a cistern

It is quite possible to install the cistern yourself without the intervention of a plumber, especially since there are several basic options for this.

- Quite often it is installed directly on the toilet . If there is a need to replace only the drain tank, then in such a situation a special rubber seal is used; it has excellent tightness. If the entire bathroom is being replaced, then you need to install the flush tank on the previously installed toilet, and you can attach it using bolts. The main thing when installing such a tank is not to overtighten the bolts so that cracks do not occur. And use special washers as a layer.

- There is also a way to install a flush cistern above the toilet , in the end you just need to add a drainpipe of a certain size. In general, such fastenings are not often used in plumbing work, because it is believed that this structure does not fully meet external standards.

- built-in drain system will look best . The main advantage is that it is installed in such a way that it is not visible at all, only the drain button for water flow is visible. In addition, there is much more free space, and the appearance of the bathroom itself is more attractive. The built-in cistern has special installation lugs, as well as holes for downspouts. This system is completely hidden in the walls of the bathroom. In the outer space, only one main element remains - the button for draining the water. Where the drain button is installed, the drain system is also repaired.

Construction and adjustment of the compact

When the toilet tank can no longer be repaired, it is replaced. A step-by-step replacement of the toilet tank can be performed by following the following algorithm:

- shut off the flow of cold water;

- disconnect the old tank from the water pipe;

- using an adjustable wrench or wrench, remove the mounting bolts to dismantle the tank;

- clean the container mounting area from traces of rust, dirt and lime;

- install a new tank in accordance with the above recommendations;

- connect the equipment to the water supply;

- adjust the water level;

- install the lid and drain button;

- carry out a test set and drain the water.

- cistern container with lid;

- system for filling water into a container;

- shut-off device or water drainage system;

- control button or lever;

- toilet.

The tank in the compact is installed on a special shelf, which is located behind the bowl. Typically, adjustment of the fittings of such a toilet is carried out after the cistern bowl is installed, but before its lid is installed. Before starting work, it is recommended to carefully study the manufacturer's instructions. Usually there is detailed information about the procedure for performing the work.

Compact toilets are popular because they are convenient and take up little space. The tank of such a device is installed on a shelf directly behind the bowl

The overflow pipe of the device usually indicates the water level that is considered normal for that particular model. You need to find this designation, which is often made in the form of a strip or bead. Usually, if, when filling the tank, the maximum water level is below this mark, poor-quality flushing of sewage is observed.

Read more: How to defrost a refrigerator quickly and correctly, instructions and tips

To change the situation, you need to move the “glass” on the intake valve to a higher position. To do this, loosen the clamps holding this element located under the float. After the required level has been set, you need to check the result of the work, i.e. fill the tank and drain the water.

On the top of the toilet tank inlet valve overflow pipe there is a mark in the form of a dash or collar for adjusting the water level

When installing tank fittings, it should be remembered that all moving parts of the valves must be separated by a distance, at least small. If the valves come into contact during operation, this can disrupt the normal operation of the system, leading to its imbalance and breakdown. It is also unacceptable for the moving elements of the fittings to come into contact with the walls of the tank.

Image gallery

Photo from

If the filling tube is too long, you can simply trim it. If a gap is found in it, you will have to replace it with a new one.

We cut the new filling tube according to the required size. We use a hacksaw for cutting

In place of the broken filling tube we put a new section and fix it

We open the previously shut off water, fill it into the tank and see if the water splashes during the fill. If this does not happen, close the tank with a lid.

Step 1: Inspect the fill tube of the tank fittings

Step 2: Cut out the new filler tube for installation

Step 3: Installing a New Fill Tube

Step 4: Checking the water supply and the operation of the tank

An important stage in installing the tank is installing the lid with a push-button regulator. Before screwing it in, there should be a distance of no more than seven millimeters and no less than three between the cover and this unit. If these conditions are met, the cover will be fastened securely enough.

Before you start screwing the flush button, the instructions recommend making a couple of turns in the opposite direction, i.e. counterclock-wise.

To save water, modern tanks have a double flush button, which allows you to empty only part of the tank if desired.

This will center the thread position. After this, screwing the button assembly is carried out clockwise. You need to rotate it by hand until it stops; additional tools are usually not needed. Upon completion of installation, you should drain the water again to make sure that the button and all fittings are configured correctly and installed correctly.

Compacts are produced with both bottom and side water supply. With fittings designed for bottom water supply, a problem such as clogging of the filter installed at the water supply to the container may arise. After flushing, i.e. During the process of filling the tank, a characteristic, rather loud and unpleasant whistle is heard.

This situation most often indicates that the filter is clogged and needs to be washed. The debris accumulated inside reduces the clearance for water, which enters the tank with high pressure and accompanied by sound effects. In addition, due to this malfunction, the tank fills much more slowly than usual.

There is a filter located under the inlet valve float, a clogged filter that can cause the tank to malfunction. To wash the filter you need to remove it

To correct this plumbing problem, you need to flush this filter. To do this, turn off the water supply to the tank and press the flush button/lever. After this, remove the hose through which water flows to free access to the device. Now the filter just needs to be removed from the intake valve body, washed and installed back. The system is then reassembled in reverse order.

It looks simple in theory, but in reality there can be some complications. For example, you need to unscrew the plastic nut that secures the inlet valve. If this element does not have edges, the task may seem difficult.

You should not use an adjustable wrench in this situation, as excessive force may damage the fastener. It’s not always possible to just do it with your hands, especially if the plastic has become “burnt” as a result of prolonged use.

To ensure that the sediment that forms when low-quality tap water is supplied to the device does not cause a leak due to loose seals and failure of fittings, the tank and devices must be periodically cleaned

Experts recommend using other means; pliers with a large space between the “lips” may be a suitable option. Pliers can also be useful when removing the filter from the housing, since it usually fits tightly and will require additional effort for removal.

Where the quality of tap water remains consistently low (that is, almost everywhere), not only the filter, but also other elements can become clogged. The membrane bushing is at risk, as well as all the holes through which water enters.

If washing only the filter was not effective enough, it makes sense to rinse the entire device and clean all the channels. In this case, you will have to completely dismantle the inlet valve to provide access to the holes.

Unfortunately, washing the filter, and even the entire valve and ducts, does not always help. Low quality intake valves can completely fail within one and a half to two years after the start of operation. In this case, you will have to completely replace the valve with a new model. In such a situation, it is recommended to choose a higher quality filter.

The shut-off and inlet valves of modern toilets are usually provided with detailed instructions, with the help of which these mechanisms are not difficult to assemble, install and adjust

The additional costs will pay off, since there will be several times fewer problems with setup, flushing and repairs. Another way to prolong the operation of the tank fittings and prevent problems: install an additional mechanical filter on the water pipe in front of the toilet or even at the entrance of the system to the apartment.

If the compact has problems with the shut-off valve, i.e. Since water constantly leaks into the toilet, the easiest way to fix the problem is to completely replace the device with a new one, exactly the same. To do this, you need to turn off the water and simply remove the valve from the tank.

The new one is installed in its place, fixing it in the holders of the receiving part. It is recommended to adjust the length of the valve in advance so that there are no problems with installing the flush button.

If it is necessary to replace the old storage tank with a new one, you need to:

- shut off the flow of water into the container by setting the valve to the “closed” position;

- Next, you need to drain the liquid from the bowl;

- if you want to use the old fittings in a new bowl, carefully remove the filling device;

- then you need to unscrew the fastening bolts connecting the container to the toilet seat and remove it;

- remove the drain device by unscrewing the connections attaching the bulb seat to the bowl;

- Before installing a new tank, you need to clean the surface of the toilet seat from rust and mineral/bacteriological deposits.

As can be seen from the above, there is nothing particularly difficult about installing a toilet tank yourself, attaching and adjusting the fittings. These operations are within the power of any person.

Some difficulties may arise only when servicing installed containers, since many operations have to be carried out through a small technological opening in the absence of visual contact.

Connecting water to the cistern

As soon as the installation of the drain tank is completed, you need to move on to the stage of connecting the water supply with a flexible liner. There are two types of water supply connection to the drain tank:

Connection through the bottom of the toilet cistern.

In the first case, water is supplied through the bottom of the cistern. The advantage of this method is the quietness of the water supply. The downside is that it is difficult to repair and install.

Lateral connection of the toilet tank

In the second case, water is supplied through the side wall. In this case, the water supply hose is attached above the water level in the drain tank. The advantage of this method is the ease of operation and repair of fittings. The downside is noise when filling with water. At the same time, maintaining this structure will not be difficult even for a non-specialist.

Checking the operation of the flush system

In order for the drainage system to work correctly, it is important to check all fastenings before doing this and perform the following operations:

- After fixing the tank, a float valve is installed in its inner part along with a water supply using flexible pipes or decorative liners. These hoses come with different threads for connection. They are universal because they have a length from 20 to 180 cm; it makes no difference where the water outlet is located.

- Then the flexible tubes should be connected to the water outlet or to the shut-off valves placed on it.

When connecting devices using decorative liners, it is worth choosing in advance the exact placement of the water socket itself and plumbing structures. According to SNiP, shut-off valves must be located next to the drain tank. This placement makes it easier for water to access the tank. Operation of the toilet flush system - After installation, a test of the functioning of the flushing system is carried out. In turn, the entire structure is checked to see if there are any leaks anywhere. It also checks that the water is functioning properly while filling the cistern.

- The tightness of the device is checked and the liquid level to the overflow pipe is measured. If there are violations, the valve is adjusted, and leaks are removed using a sealed compound. If the system works without breakdowns, then a lid and a button responsible for draining are attached to the tank itself. If this is a top-mounted system, then a decorative coating is installed on the installation systems.

Water supply to the toilet cistern

Water supply can be carried out according to the following options:

- To do this, you can use a special reinforced hose; if you decide to install it, you should distribute the tension correctly, and in no case should you allow it to be excessive. To make the connections better, it is necessary to use a special tow in the work. Thanks to this tow, the threads will be perfectly sealed, and in the future you won’t have to think about water leakage at all.

- As for the second method, here, in order to collect water, they use a rather rigid connecting pipe.

Important: Water is connected to the tank only when it is correctly installed and securely fastened.

You can check this by using a level. Rubber gaskets are installed on almost all threaded connecting tubes, and they must be tightened with simple nuts. It is imperative to take precautions in such a situation, because if you sharply increase the load, cracks may well form. Also, if you tighten the nuts with great impulse, this threatens to break the thread. In this case, repairs cannot be avoided, and you will have to incur extra expenses.

Installation procedure

The specific instructions for attaching the tank to the toilet depend on what type of device you purchased.

The following types of drain containers are available on the modern plumbing equipment market:

- mounted separately from the toilet bowl,

- mounted on a bowl, for which the latter is equipped with a special shelf,

- built into the wall.

Let's consider any option in more detail.

Method 1. Mounted cistern

This method of placement is seen quite rarely and is even less used in private buildings. However, be aware of it.

The toilet tank is fastened as follows:

- A special flush pipe, the diameter of which is 32 mm, is connected to the bottom of the drain tank. There is a special hole for this purpose.

- Then marking is done. The tank is placed against the wall at such a height that the lower end of the pipe is opposite the inlet pipe of the toilet bowl located on the floor. After this, markings are applied to the surface of the wall using a marker or pencil.

- The holes for the brackets are drilled. If the walls of the toilet are cement or tiled, you need to use a hammer drill with a special drill. This will make your work easier and speed up the process, and the resulting hole will be neater.

- Select the correct tool diameter. It must exactly match the dimensions of the dowels or anchor bolts used.

- Then the brackets are screwed to the wall, and a water storage tank is attached to them.

Method 2. Built-in tank

This refers to a structure installed on the shelf of the toilet bowl.

In this case, the flush cistern is attached to the toilet in the following sequence:

- A rubber gasket is installed on the bowl. In most cases, it is already coated with a special adhesive that holds it in place. If this is not true, it is necessary to additionally use a special sealing sanitary gel.

Advice! Coat the gasket on both sides, since one is attached to the toilet shelf, and the other is adjacent to the flush tank. In addition, it is possible to additionally use a special rubber ring that seals the drain hole at the bottom of the container.

- To secure the tank to the toilet bowl, special bolts with cone-shaped rubber gaskets are used. They are inserted into the holes provided for this purpose and screwed in well with nuts from below. Do not use too much force to tighten the nuts. This can lead to breakage of the tank or bowl, since ceramics do not withstand strong external influences well.

Upon completion of installation, the rubber parts provide the most airtight connection, which will not allow leaks after filling the container with water.

- In order to prevent water from leaking out of other holes (for example, for the water supply pipe), it is necessary to use special rubber plugs. Before installation, it is also recommended to lubricate them with gel to obtain the tightest possible connection.

- The next stage is the installation of drain fittings and connection of the water supply. During these operations, it is necessary to ensure that all gaskets, membranes and seals are in place.

It is recommended to wrap polymer tape on the external thread of the inlet pipe to protect against leaks.

- The last stage is testing. It is necessary to unscrew the shut-off valve that cuts off the water supply to the tank and fill the container with water. To adjust the liquid level, a float mounted on a rocker arm or screw is used.

Advice! Plumbing gel takes some time to polymerize. Based on this, it is recommended to carry out testing 1-2 hours after the completion of the installation procedure.

Method 3. Hidden tank

A drainage container hidden in the wall is quite an expensive, but very aesthetic and popular option for arranging a toilet room. In addition to everything else, the hidden placement of the tank allows you to save space in the restroom and protect the structure from accidental damage.

On the outside, the built-in cistern differs from classic models:

- it is made from durable polymers and has fairly thick walls,

- the shape of the hidden tank is more extended upward and to the sides, so that it takes up less space in the wall,

- the shutter button is located not on the cover, but on the front surface of the device,

- For fastening, a special installation is used, which is included in the delivery set.

The work order is as follows:

- A steel frame is installed in a place pre-designated for installation, which will serve to secure both the flush cistern and the toilet itself. When installing it, it is necessary to perfectly maintain the horizontal and vertical, otherwise troubles will arise when you begin to attach additional fittings.

- A tank is installed on the frame and water is supplied to it. For this, it is better to use solid tubes, which provide great reliability. Since after tiling the hidden tank is finished, repairs will be problematic.

- As in previous cases, it is better to connect the supply pipe through a shut-off valve.

- Upon completion of the installation of the tank, the sewage system is installed, the steel frame is sheathed with pages of waterproof plasterboard, which is lined with the selected decorative material.

- The last stage is the installation of a button for the toilet, which controls the flush fittings. It is better to use a separate drain, which allows you to save water from the tap.