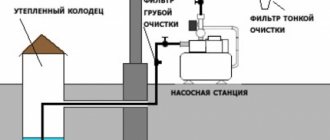

When arranging maximum comfort for living in a country house, a good owner, first of all, thinks about an autonomous water supply system.

But many of them sometimes do not know where to start or, for example, what structural elements a plumbing system should have.

To make this task easier for many owners of country houses, in this article we will talk in detail about what components an autonomous water supply should consist of, and also describe in detail the process of creating a hydraulic tank with your own hands.

- 2 Performed tasks

- 3 How to do it yourself

3.1 What materials are needed

- 3.2 Work order

Tank structure

The design of the hydraulic accumulator is quite simple. It consists of a container. It has a certain volume. There is a membrane or rubber bulb inside this tank. As an addition to the container, measuring instruments are connected, but they are not required.

The main functions are assigned precisely to the membrane. It prevents the mixing of air and liquid, which allows you to create the necessary pressure in the system. A rubber partition divides the container into two compartments. The first of them contains air, the second contains water.

If the amount of water increases, the air compresses. When the tap is opened, it will push liquid out of the container. This is how the pressure is formed when operating a water supply in a private house.

In addition, the considered principle of operation of the hydraulic accumulator allows maintaining uniform pressure and also eliminates water hammer when the pump is operating. This significantly increases the service life of the equipment, reducing the number of breakdowns of the system components. Therefore, installing a storage tank would be the right decision.

What does a hydraulic accumulator consist of?

The hydraulic accumulator has an extremely simple design. This is a sealed steel container divided into two parts. One of them is connected to the heating or water supply system, after which it is filled with water, the other contains air pumped in with excess pressure.

According to their internal structure, hydraulic accumulators are divided into two types:

- Balloon : the water container in such a hydraulic accumulator is a rubber bag, which is often called a bulb or balloon. By means of a flange, its neck is connected to the pipeline system.

- Membrane : in this version, the steel body is divided into two compartments by a flat diaphragm or membrane, which is also made of rubber. The principle is the same: one part is connected to a water supply or heating circuit through an inch pipe, as a result of which it is filled with water; a certain volume of air is pumped into the other.

When the accumulator is filled with water, the membrane or cylinder stretches, as a result of which the pressure in the chamber filled with air increases.

Hydraulic accumulator device

The balloon version of the hydraulic accumulator should be considered more preferable and here's why:

- While in the cylinder, water comes into contact only with its inner surface, so the steel walls of the accumulator remain dry. In membrane tanks, on the contrary, there is contact between the steel body and moisture, which can lead to the development of corrosion.

- The membrane and the cylinder do not have a long service life; after some time this element will need to be replaced. There will be no problems with the bulb; the owner of the tank can easily install a new one on his own. You can replace the membrane yourself only in a few models; in other cases you will have to contact a service center.

General recommendations from experts

Many country property owners have the desire and opportunity to make a hydraulic accumulator for water supply systems with their own hands. To do this, you will need to delve into the issue of water supply installation. Thus, in the city, the pressure in the system is ensured at a level of about 1.5 atm. But for the private sector it will be enough to maintain this indicator around 1 atm. This will help you choose the right equipment in the store or create it yourself.

Experts say that making a storage tank yourself will be quite easy. In terms of its functions, it will in no way be inferior to its purchased varieties.

Hydraulic accumulators for water supply, the price of which today starts from 700 rubles, will cost much less. The more components a home craftsman has in his household, the less he will have to pay for the container. It is necessary to follow all the recommendations of experts in order for the result to be good.

What are the most popular hydraulic accumulators for home water supply systems?

All hydraulic accumulator systems available on the market are approximately equal in their capabilities and functions. The cost of cylinders of equal capacity for branded and regular models can differ by almost two times. What is the difference in the design of hydraulic accumulators?

The main difference, as a rule, is not in the design, but in the materials and technologies used:

- The high-quality metal of the accumulator body with deep anti-corrosion treatment allows the device to be used in water supply systems for at least 15 years;

- High-quality material of the membrane bulb provides a high degree of stretching of the rubber, which means efficient use of the working volume of the accumulator;

- The protective coating allows you to painlessly install the accumulator into the water supply system directly in the caisson;

- The shape of the tank, support legs and fastening make it possible to “squeeze” the tank into almost any chosen place in the caisson.

Important! When buying any model of hydraulic accumulator, it is worth asking the question: where and how can you purchase components and spare parts for the purchased device and how to connect it to the water supply system.

Simple small-sized models of hydraulic accumulators

Often, small-capacity models of hydraulic accumulators are purchased for surface pumps or complete with ready-made pumping stations. The main criterion when choosing is most often small overall dimensions and low price. Such a device will easily fit next to fittings, filters and automation, even in a miniature half-meter hole at the head of a water well. There must always be a filter and a check valve between the pump and the accumulator, otherwise, after switching off, the pressure in the tank will erode water from the pipes of the water supply system into the pump and into the well. Most often these are membrane tanks from 8 to 24 liters.

The cost of a simple Chinese version for a dacha water supply system will be about 1000 rubles. The load on it will be small, so in this case there is no point in buying expensive Italian or German models. For the same money you can buy a good Russian-made option that works well on water supply systems of any complexity. They are more reliable and unpretentious than the Chinese, but in some cases they require manual adjustment of connections when installed in the water supply system.

Home accumulators

Water storage systems have long been used not only for pumps and water supply devices from wells in the country or in a country house. Even in houses and apartments connected to the central water supply system, hydraulic accumulators with a capacity of 20 to 50 liters are successfully used, and for private estates 100 to 120 liters.

Today there is clearly a tendency to abandon the use of small 20-30 liter cylinders in favor of larger tanks of 100 or more liters. This is more profitable in terms of energy and resource savings. A large 100-liter tank has a service life 2-3 times higher than a 30 or even 50 liter cylinder. This parameter is determined mainly by the resource of the elastic membrane-shell, which creates pressure in the water supply system. In a large tank it will work at slightly more than half its capacity.

What can you choose from the hydraulic accumulators available on the market? If you like expensive “sophisticated” products, you can take an interest in water accumulators, “Zilmet” or “Cimm”. But there are practically no guarantees that an expensive system has a branded membrane; you can only trust the certificates from the sellers.

The most interesting of the domestic products is the “Wester Wav-100” hydraulic accumulator, made under Italian license. A cylinder with a capacity of 100 liters will cost less than a 50 liter one produced in Germany. Today, "Wester Wav" is highly rated for the high quality and reliability of metal structures. The membrane on the “Wester Wav” is Italian.

Important! One of the most common causes of failure of hydraulic accumulator systems is normal corrosion affecting the inner surface of the cylinder. Almost any water supply product suffers from this, regardless of the country of production, both branded European water accumulators and cheap Chinese tanks.

How to avoid installing hydraulic accumulators in water supply systems

If desired, you can do without installing a hydraulic accumulator in the water supply system. For example, the developers of modern submersible pumps for wells have long created models with a so-called soft motor start, based on frequency converters. Most often these are very expensive Danish pumps. The overpayment for such a product will be significantly higher than the cost, even for an expensive branded high-capacity hydraulic accumulator. There is no particular gain for the water supply system.

Chinese analogues of rotary pumps with frequency-controlled motors show excellent characteristics, but their service life is several times less than that of Italian or German units.

There are many homemade and semi-homemade electronic control boards designed to smoothly start and control the operation of a pump without a hydraulic accumulator. But such devices are also very expensive, and, in addition, reviews of their successful use in practice are only available for vibration pumps of the “Malysh” type.

Sometimes, instead of a hydraulic accumulator, a regular large-capacity water tank is included in the water supply system, which is installed on a brick platform or even in the attic. This system allows for relatively smooth and shock-free operation of the water supply system. But the pressure in the water supply will be very low, and therefore any water heating devices such as a boiler, washing machine or instantaneous shower water heater will not work. To do this, the container must be raised to a height of 10-12 m above the level of the water supply system.

Any of the listed options cannot become a full-fledged replacement for “hot” hydraulic accumulators, for example, for heating boilers. In the gas boiler circuit through which water or ethylene glycol circulates, a stable pressure of at least 1.5 atm must be maintained. Most often, especially in double-circuit designs, the hot water supply system has a special make-up tap and a sensor that controls the water pressure. The hydraulic accumulator allows you to start and heat water using its own pressure and water supply; without it, at low pressure in the water supply system, the boiler simply will not start.

Homemade version of the hydraulic accumulator

If you really want to, you can make a full-fledged version of a hydraulic accumulator for your home water supply system with your own hands. To make the steel body, they use an old 50-liter gas cylinder for storing propane-butane and a standard rubber casing of a hydraulic accumulator for 30-40 liters of water. The manufacture of a homemade device is carried out in the following sequence:

- A valve is cut out in the upper part of the cylinder, the edges of the cut are carefully aligned;

- If possible, the inner surface is cleaned to bare metal and treated with a phosphate rust converter, after which it is primed and thoroughly dried;

- A counterflange ring made of sheet metal 5-6 mm thick is welded into the cut hole. The edges of the junction of the welded ring and the walls of the cylinder and the inner surface of the seam must be cleaned and polished to a mirror shine. The dimensions of the ring must correspond to the fitting parameters of the accumulator flange for insertion into the system;

- It is better to buy the flange itself and a 24-liter bulb; their cost is just over $20. Before assembly, you need to insert a regular car nipple into the bottom of the cylinder. There are options for tubeless wheels with rubber sheathing and repair copies for older versions of rubber tubes;

- Before assembly, the inside of the cylinder is coated with epoxy varnish and dried for at least a week at a temperature of 20-25°C. The rubber bulb is placed inside and the flange is installed.

After pumping air into the air chamber, you need to check the flange seal for leaks, set the pressure using the pressure gauge, and the homemade hydraulic accumulator for your home water supply system is ready for use. If necessary, a pressure switch can be connected to the cylinder and can be placed in the water supply system.

Necessary materials

Hydraulic accumulators for water supply, the price of which will not hit the family budget, are quite simple to create. To do this, it is necessary to prepare several components of this equipment. First of all, you need a container. It can be plastic or aluminum. Its inner walls should be even and smooth. If this condition is not met, the bulb or membrane will tear when stretched.

The tank volume must be at least 30 liters. But it’s better to choose an even larger capacity. It all depends on the water consumption in a particular house.

Next you will need a pressure switch, as well as any pressure gauge. For fittings, you need to purchase a quarter and tee, as well as a shut-off valve. Typically, ¾-inch reinforcement is used for such purposes. You will also need a half-inch and ball valve.

A regular bicycle inner tube (nipple) will serve as a membrane or bulb. To make all the necessary gaskets, you will need a sheet of rubber, as well as sealant. The fastening elements are nuts and washers.

How to choose tank volume

Knowing the structure of a hydraulic accumulator, you can create this equipment yourself. But before you start, you need to choose the right tank volume. The correct functioning of the water supply of a dacha or country house depends on this. Typically, a container of 30 to 50 liters is suitable for these purposes.

But this amount must be coordinated with the power of the pumping equipment. If the power supply is often turned off (this happens in holiday villages), a larger volume of hydraulic accumulator will be required. Water will fill about 1/3 of the tank.

You should also remember that if a powerful hydraulic pump is installed in the system, a larger tank will be required. This will reduce the number of short-term equipment starts.

However, too large a capacity will not be a good solution. The water inside will stagnate, and its quality will decrease. Therefore, for a summer residence, a 50-liter tank is practically the maximum acceptable option.

What is it and why is it needed

In fact, a hydraulic tank is one of the main components of a private water supply system.

At the same time, you need to understand that its main functions are not the creation of a water reserve, as many people think, but several others. Hydraulic accumulator device

Purpose of the hydraulic accumulator:

- maintaining constant water pressure in the system, protection against surges, during simultaneous operation of several consumers;

- protection of the submersible pump from constant switching on and off, i.e. it turns on only when the pressure in the accumulator drops;

- protection of the water supply system from water hammer when the pump is turned on;

- creating a small water reserve.

The hydraulic accumulator in the water supply system ensures safe and uninterrupted operation of the private water supply.

Instructions for performing the work

The principle of operation of the hydraulic accumulator is quite simple. It's easy to recreate with homemade equipment. To do this, you need to drill holes in the selected container on the bottom, side and lid. A ½-inch tap is installed at the top. It is fixed with washers, installing gaskets and blowing with foam. This will avoid leakage.

When this part of the work is completed and the sealant has dried, you should attach the quarter pipe to the tap. A nipple, a pressure switch and a pressure gauge are attached to this part. A ¾-inch tap is installed at the bottom of the container. A tee is attached to it.

A side hole is provided for a ball valve. The nipple is secured with a plug. It must have an internal thread. Also, all connections must be sealed. This is a tank without a membrane.

First start

After the work has been done, it is necessary to start the pump with a hydraulic accumulator. To do this, several important principles must be observed. First the pump turns on. Then the ball valve is opened on the side surface. Water should flow out of it.

If this condition is met, the tap is closed. Using a conventional bicycle pump, air is pumped into the tank through a previously installed nipple. The required pressure must be created in the container. It is checked using a barometer and ranges from 1 to 1.5 atm.

If the pressure does not meet the requirements, its value is adjusted using a relay. This first trial run is necessary. Once the system has been verified, it can be fully exploited.

Accumulator volume - calculation

When choosing a device, take into account the number of water points. If the house only has a water tap and a shower, then a 24-liter hydraulic accumulator will be sufficient. If there are 3-5 points of analysis, including a shower stall, as a rule, a tank with a volume of 70-100 liters is required. For cottages with several bathrooms, a septic tank, a washing machine and a dishwasher, it is better to use the exact calculation formula:

V = 16.5 x Qmax/a x (Pmin x Pmax/ Pmin-Pmax)*1/Po,

where V is the total volume of the hydraulic accumulator, l; Qmax – maximum value of required water flow, l/min.; a is the number of system starts per hour; Pmin – lower pressure threshold when turning on the pump, bar; Pmax - upper pressure threshold when turning off the pump, bar; Po – initial air pressure in the accumulator, bar.

The lower threshold Pmin for two-story houses is usually 1.5 bar, and the upper threshold Pmax is 3 bar.

So, if Qmax = 40 l/min, a = 15, Pmin = 1.86ap, Pmax = 3.0 6ap, Po = 1.5 bar, a hydraulic accumulator with a volume of 150 l is required.

Prices for hydraulic accumulators are quite affordable - from one to ten thousand rubles, depending on the volume of the tank, the rubber used and the manufacturer

Link on topic: How to choose a pump for your home and garden - pumping equipment

The recommended difference between the lower and upper response thresholds is 1.0-1.5 bar. First you need to determine the minimum pressure value. Let's say the tank is installed in the basement.

You need to calculate the height in meters from the tank to the highest water point, for example a shower on the second floor.

Then add 6 to this number and divide by 10. If the distance to the shower is 7 m, you get (7 + 6)/10 = 1.3 atm.

With less pressure in the accumulator, the water from it will not rise to the second floor. Please note: this value should not be overestimated, otherwise there will simply be no water in the hydraulic tank. The initial air pressure set by manufacturers is usually 1.5 bar. To determine its maximum value, add 1.5 bar to this.

And then it would be useful to compare the obtained value with the pressure characteristics of the pump. It should be 30% below the maximum pressure of the pump used.

Tank type

There are two main types of tank mounting. Its adjustment depends on this. There are vertical and horizontal hydraulic accumulators. The fact is that in the part of the container in which the liquid is located, a small amount of air will accumulate over time. It needs to be bled off from time to time. This will rid the system of unfavorable air pockets.

If the container is vertical, it requires a special nipple. The air in this type of tank accumulates at the top. It will be easier to bleed him off.

The horizontal type of tank differs in this from its vertical counterpart. It's not just the nipple that's required here. A ball valve is required to bleed off excess air. The system also provides for drainage into the sewer.

How to bleed air

When creating a hydraulic accumulator with your own hands, you also need to know the rules of its operation. For small tanks, there is a certain system that allows you to simply remove excess air from the tank.

Some systems require water to be supplied from above. This happens quite rarely. It is better not to set up such a system yourself. For it, according to experts, it will not be necessary to bleed air from the tank. But such a system is complicated by the presence of special filters.

For a homemade small tank, there is a simple procedure for eliminating air. In this case, the power supply is turned off. The mixer tap opens and the tank empties. Then the tap is closed and the pump is turned on again. The container is filled with water. Excess air escapes along with the liquid. This must be done at least once a month.

Conclusion (must read)

A membrane-free hydraulic tank is very simple to manufacture, but there are also significant disadvantages in its design. The main one is that water dissolves oxygen in itself, so we need to frequently service such a hydraulic accumulator so that water hammer does not occur in the system. As the air dissolves, it leaves and makes room for water, so we need to constantly drain excess water and pump in oxygen.

To do this, you need to do the following procedure every 2 days:

- Open side tap

- Drain the water until it stops running

- Close the tap

- Pump air to the desired pressure

From the above, it follows that a membrane-free design is very expensive to maintain. Such a unit can be installed in a bathhouse or in a country house where it is not used for a long time. They arrived, pumped up the pressure, used it, and left. If you need a hydraulic accumulator for a residential building, I recommend buying it from the factory with a membrane. There will be much fewer maintenance problems. If you know any other DIY hydraulic tank diagrams, write about them in the comments.

New tank from old

You can create a new tank from old non-working equipment. Most often, it is the membrane that fails in them. A new bulb for the hydraulic accumulator will solve the issue of creating a new tank.

Special food-grade rubber is used in cold water supply tanks. It is safe to use and does not harm human health. Also, the operating pressure threshold for such products is quite high and can reach 8 Bar. Therefore, before creating a new tank, you need to buy a bulb or membrane with the same characteristics that the previous tank element had.

You can use the same technology that was presented above, but provide the tank with this part. But in this case, the calculations will have to take more time. Therefore, it is more suitable for repairing an old, failed tank.

Rules of operation and repair

Connecting and setting up the accumulator correctly is only half the battle. In order for the device to operate for a long time, it must be operated correctly, as well as periodically perform preventive inspection and maintenance. Instructions require preventive examinations to be carried out twice a year, but practice shows that this is not enough.

The condition of the hydraulic accumulator should be checked every three months. It is recommended to monitor the pressure switch settings at the same frequency in order to correct them if necessary. Incorrect operation of the relay creates additional loads on the entire system, which can also affect the condition of the accumulator.

If during inspection dents or traces of corrosion are found on the device body, these damages must be repaired. It is best to do this as early as possible, otherwise corrosion processes will develop, which can lead to damage to the integrity of the accumulator body.

An important preventive measure is checking the pressure in the hydraulic tank itself using a pressure gauge. If necessary, the required amount of air should be pumped into the device or excess air should be vented. If this does not help and the new pressure gauge readings do not correspond to those expected, it means that either the integrity of the accumulator body is compromised or its membrane is damaged.

If the membrane installed in the accumulator is worn out, you can try to replace it with a new one. To do this, the device will have to be dismantled and disassembled.

Some craftsmen manage to detect and repair areas of damage to the body, but such repairs are not always durable and reliable. The rubber liner or membrane is the weak point of the accumulator. Over time it wears out. You can replace the membrane with a new element at home, but to do this you will have to completely disassemble and reassemble the hydraulic accumulator.

When choosing a suitable location for installing a hydraulic accumulator, you should remember that it must be spacious enough to carry out maintenance of the device

If a home craftsman doubts his abilities in this area or does not have sufficient experience, he can cause even more damage to the device than the previous breakdown. In such a situation, it is better to contact a service center.

Replacing the pear

By creating a hydraulic accumulator with your own hands, you can repair an old tank. This is a fairly simple process. After purchasing a new pear, you can start working. The hydraulic tank must be unscrewed. To do this, unscrew the connection bolts. The old membrane can then be easily removed.

A new bulb is installed in place of the old part. The hydraulic accumulator is assembled in the reverse order. The bolts must be tightened evenly. If you are not careful enough, the membrane may slip and fall inside the flask. In this case, you will have to repeat the procedure again. To prevent this from happening, tighten the bolts lightly at first, and then evenly tighten the fasteners in all places.

Having considered the technique of how to make a hydraulic accumulator with your own hands, every owner of a summer house or country house will be able to create this element of the water supply system. It will extend the operation of all equipment. It will be comfortable to use water.