The problem of waste disposal in a private suburban area has long been solved with the help of an ordinary cesspool, which is a storage tank. The structure has to be constantly pumped out and there is no escape from the unpleasant smell. To solve the problem, it is better to use a more modern independent treatment facility - a cesspool with an overflow. The design is capable of processing large amounts of liquid waste. These are wastewater from shower stalls, dishwashers, washing machines, bathtubs, and appliances used to improve comfort. Therefore, it is necessary to consider the device, operating principle and possible options for an improved sump. This will allow you to avoid the issue of constructing a treatment plant on private territory that is not connected to a centralized sewerage system.

Design and principle of operation of a cesspool with an overflow well

Installation of a treatment plant with an overflow is carried out for the effective disposal of sewage generated as a result of human activity. The degree of processing allows part of the wastewater to be discharged into the soil, onto filtration fields, and used for watering plants.

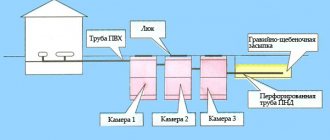

Sump design with overflow well

A drainage pit with an overflow of simple design is a two-chamber treatment facility. A sewer pipe is used to connect the compartments. The first tank is made in the form of a large container with a sealed bottom and walls. This is a receiver where sewage from a private house enters through a polyvinyl chloride sewer pipe with a diameter of 110 mm. It is laid in the ground.

The second container has the same design as a sewer well with a filter bottom. The lower part of the tank is not a monolithic structure. Liquid can leak through it. It is a filter with a minimum thickness of 1 m. Slag, crushed stone, sand, and gravel are used as the filter element.

An overflow well is an absorption structure. The walls of the container can be solid or have holes. The second option allows you to increase the speed of removal of treated sewage.

The two tanks are connected by a PVC sewer pipe located at an angle. It allows sewage to flow naturally from the receiver into the absorption well. The depth of pipe installation is influenced by the climatic conditions of the area. It should be located below the freezing point of the soil. The diameter of the connecting pipeline is usually 50-110 mm, and its length is determined by territorial features.

A ceiling equipped with a hatch is installed above the drainage pit. Both tanks of the treatment plant are covered with lids. Hatches allow you to monitor the operation of the device and carry out repairs. This design also facilitates pumping out sewage.

The treatment plant is equipped with ventilation. The air duct in the form of a pipe is installed above the level of the drains. It must always be above the sewage horizon, regardless of the degree of filling of the tank. Often the ventilation pipe is installed only in the filter well. However, it is recommended to install ventilation in each compartment of a simple wastewater treatment facility.

Operating principle of a sump tank with overflow well

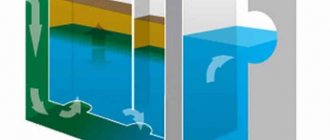

The installation of a cesspool with overflow in a private countryside area, including summer cottages, allows you to process sewage more efficiently and in less time compared to a conventional waste tank. The operating principle of a septic tank in the form of a sump with an overflow well is quite simple. Sewage from the house first enters the first sealed compartment. In it, wastewater accumulates and settles. This is where heavy particles settle. They have the appearance of silty deposits. Solids are periodically removed from the tank. The sediment can be used by the homeowner during composting.

As waste accumulates, the liquid level in the receiving container rises. After reaching the overflow pipe, sewage flows into another tank without a sealed bottom. The settled wastewater enters the second container already partially purified, for example, by bacteriological microorganisms. The post-treatment process of liquid sewage mass is carried out in the absorption well. It passes through a filter layer at the bottom of the tank. It is the placed bulk materials that additionally purify sewage.

Note! On private property, a drainage pit with an overflow well with a sealed bottom can be constructed. In this case, the second tank is also a settling tank. The sewage is re-settled in the container. They can also be cleaned by bacteria, which feed on biowaste and organic matter. If aerobic microorganisms are used, then the treatment plant must be equipped with a ventilation duct or aerator. After this, the wastewater flows into the infiltrator or onto the filtration field.

When organizing a septic tank in the form of a cesspool, grease traps and filter meshes are often installed. The elements are installed on the overflow pipe. They retain some of the dirt when the sewage mass moves between containers.

Design

The design diagram of a septic tank with an overflow is quite large. This installation has several isolated tanks that are connected to each other by overflow pipes.

Advice! Another possible scheme for a septic tank with overflows is one capacious tank, the internal capacity of which is divided into separate compartments by partitions. Overflow pipes are inserted into the partitions.

Ready-made septic tanks with overflow are usually made of plastic. Homemade structures may have tanks:

- made of reinforced concrete (it is possible to construct a monolithic or prefabricated structure; in the latter case, well rings - ready-made reinforced concrete products - are used for installation);

- made of brick;

- From ready-made plastic containers, Eurocubes are most often used.

How does it work?

A two-chamber design is ideal for a small house; its design includes:

- two sealed sedimentation tanks connected to each other by overflow pipes. Mesh filters can be additionally installed in the pipes to retain large debris;

- device for soil filtration - this can be a filter well, filtration fields, etc.

The operating diagram of such a treatment plant:

- used water containing sewage enters the receiving chamber, here a process of gravitational settling occurs, during which substances that are heavier than water settle to the bottom, and light inclusions float to the top;

- During the settling process, the primary purified water remains in the tank. It is there that the overflow pipe is located, through which the clarified liquid enters the second chamber;

- in the second settling tank the settling process is repeated, that is, the liquid settles additionally. This allows it to get rid of even small undissolved inclusions;

- From the second settling tank, the liquid is sent to soil filtration. There it passes through a layer of sand, filtered mechanically and undergoing biological purification;

- sediment at the bottom does not simply accumulate, it undergoes a process of biological decomposition, as a result of which organic matter decomposes to form water, gases (mainly methane) and insoluble sediment, which gradually accumulates at the bottom of settling tanks. About once a year, this sediment must be removed so that it does not have time to compact and reduce the working volume of the chambers;

- To improve the quality of cleaning, a septic tank with an overflow can be supplemented with a biological filter. This is a chamber with a bulk loading (most often, zeolite is used), on which microorganisms settle, which in the process of their life activity decompose organic matter. Since these processes occur in the presence of oxygen, the biological filter must be equipped with a ventilation system.

Advantages and disadvantages of a cesspool with an overflow well

Almost all designs have pros and cons. An overflow septic tank is no exception. The positive and negative aspects of the treatment plant will help you make the right decision regarding the need to construct the structure.

Advantages of a waste overflow pit

The main advantage of a septic tank with an overflow is the less frequent calls for a sewage truck to pump out sewage. Wastewater that has undergone a purification process in a cesspool is often used for technical purposes. They are suitable for watering crops in dachas, washing paths and other structural elements in private areas.

Additional advantages of a waste pit with an overflow well are the following:

- Good performance, since the minimum volume of treatment facilities of this type is 2 m3. The cesspool has a throughput capacity of 0.2 to 0.5 m3 per hour. If necessary, you can always increase the number of containers, which will increase the performance of the septic tank.

- Not bad cleaning efficiency, because the waste treatment process consists of several stages depending on the number of containers. Increasing the number of tanks makes it possible to improve the quality of processing and the safety of wastewater for nature.

- Cost savings during the operation of the structure, since special equipment has to be ordered less frequently due to the same multi-stage sewage treatment. Solid elements of wastewater are filtered out already in the first tank, and the liquid medium moves further. Therefore, the formation of solidified masses and overflow of the treatment plant is eliminated. Moreover, part of the wastewater is absorbed by the soil, and a certain amount is simply dumped into the ground.

- Almost complete absence of unpleasant odor. It will completely disappear if special microorganisms are used to process sewage.

Conventional cesspools make unpleasant popping sounds when overfilled. Designs with overflow do not have this drawback. This allows you not to monitor the amount of waste. You can use water and not worry that the treatment plant will overflow.

Disadvantages of a sewage overflow pit

The disadvantages of a treatment plant with an overflow well include the complexity of installation. The homeowner needs to accurately calculate the angle at which the pipe needs to be laid to and between the tanks. You will also need to calculate the location of the tanks relative to each other. Another disadvantage is the high cost of installation compared to a conventional cesspool, since it is necessary to construct at least 2 independent wells.

Kinds

Septic tanks used for local sewage systems can be divided into two types, differing in the principle of wastewater disposal. This:

- drives;

- installations with an overflow system.

Storage tanks differ little from a traditional drain pit. But, unlike the latter, the drives are completely safe from an environmental point of view, since they are completely sealed. Thus, when using storage tanks, the possibility of sewage getting into the ground is eliminated.

The good thing about drives is that their design is as simple as possible. In essence, it is just a large tank in which wastewater is stored until it is removed. The main disadvantage of using this option for local sewerage is the high operating costs, since as the tank fills, it will need to be cleaned, paying for the services of a sewer.

Advice! The use of storage tanks is economically feasible only in facilities with a relatively small volume of wastewater. For example, at summer cottages. Then the tank can be cleaned once a season, which will not be a big burden on the family budget.

If the water consumption is impressive, then installing septic tanks with overflow would be a more profitable option. Despite the fact that the construction of such an installation will cost more than installing a drive, the costs will quickly be recouped due to low operating costs.

Advice! It is recommended to pump out waste accumulated at the bottom of septic tanks no more than once a year. And in order to further increase the time intervals between pumpings, you can additionally use special biological products - cultures of anaerobic bacteria.

Economical options for septic tanks with overflow

The price of building a treatment plant with an overflow well is affected by the volume of the pit and the type of materials used to equip the structure. However, you can save money if you choose one of the budget options:

- Using tires to build a drainage pit. It will take approximately 8 pieces of products to equip one tank. Typically old tires are used. They can be taken or purchased at a car service station. The work also uses sealant. It is used to seal joints. Concrete is used to fill the bottom. You will also need to buy plastic pipelines and crushed stone to create a drainage layer. Using such materials, it will be possible to build a structure that will last about 10 years.

- The use of bricks for arranging a cesspool. During the construction of a house, building material is often left behind in a suburban area. It can be used to create a drainage hole. A brick structure will last from 30 to 50 years. The service life is affected by the type of material. It is recommended to use red ceramic bricks. However, it is more expensive compared to white blocks, which are also suitable for constructing a drainage pit. The price of installing a wastewater treatment plant is directly affected by the type of brick. The laying of material in the second section of the cesspool can be done with gaps. This will create permeable walls. In this case, it will also be possible to reduce the consumption of bricks during the construction of a wastewater treatment plant.

- Using boards and barrels to create tanks that process sewage from the home. However, such material is short-lived. Therefore, the structure will last no more than 2-3 years. Typically, reservoirs from boards and barrels are installed if temporary sewerage is created. This treatment facility option is the most budget-friendly, because the homeowner will only have to spend a couple of thousand rubles. It must be remembered that it will not be possible to build large-volume containers from boards.

The most common materials for constructing a cesspool are concrete rings. With their help, it will be possible to create a structure with a longer service life. A cesspool made of concrete rings can be built without the involvement of specialists. In this case, it will be possible to reduce the costs of constructing a treatment plant.

Note! There is a more expensive way to build a sealed compartment of a treatment plant with an overflow - using concrete mortar. The composition is poured into a pre-prepared sheathing, reinforced with reinforcement.

Comparative characteristics

The range of septic tanks for collecting and treating sewage is very wide, including price. When choosing, you must first evaluate the conditions of its operation: the availability of free space, the groundwater level on the site, as well as the desired productivity and degree of wastewater treatment.

| Septic tank made of concrete rings | Polyethylene septic tank / container | Polypropylene septic tank | Aeration unit | |

| Manufacturing method | Assembly from ready-made reinforced concrete rings and slabs. | Rotational molding. No seams. | From a monolithic sheet. Welds. | From a monolithic sheet. Welds. |

| Wall thickness | 80-100 mm | ~3-10 mm due to the peculiarities of the technical process | 8-12 mm depending on the volume of the septic tank. | 8-80 mm depending on the volume of the septic tank |

| Tightness | Not guaranteed | Guaranteed | Guaranteed | Guaranteed |

| Power supply | Not required | Not required | To power pumps | To power the pump and compressor |

| Preservation for the winter during long periods of inactivity | Not required | Not required | Required | Required |

| Installation time and complexity | The use of special equipment and waterproofing materials is required. 2-3 days | No special equipment needed. 1 day. | No special equipment needed. 1 day. | No special equipment needed. 1 day. |

| Degree of wastewater treatment | 60% | 70% | 95% | 98% |

| Additional treatment of wastewater with soil | Required | Required | Not required | Not required |

| Service | Regular pumping, washing and re-arrangement of soil tertiary treatment systems is required | Requires periodic pumping and flushing of post-treatment systems with soil | Requires initial loading of biological product and periodic pumping of harmless sludge | Requires periodic cleaning of airlifts and pumping out harmless sludge |

| Septic tank area occupied on the site, m2, taking into account post-treatment | 12.5 m2 (3 rings Ø180cm triangle) | 8 m2 with drainage field | 1 m2 with drainage into a ditch, 3 m2 with a drainage well | 1 m2 with drainage into a ditch, 3 m2 with a drainage well |

| Price | From 30,000 rubles | From 45,000 rubles | From 60,000 rubles | From 70,000 rubles |

Regulatory rules for the construction of a wastewater treatment plant with overflow

The construction of a sump with an overflow well begins with choosing a location for the structure. It is necessary to ensure that special equipment, including a sewer truck, can approach it. The selection of the location is carried out taking into account the distance of the future structure from other objects, since it is necessary to take all measures to prevent contamination of groundwater. The type of soil in the area is also taken into account. If it has high permeability, then the distance to objects increases.

The sewerage structure from the house is installed at a distance of at least 15 m if the site has sandy, gravel, or pebble soil. The distance to a residential building should be at least 10 m when the soil on the territory is sandy loam.

The construction of a treatment plant with an overflow effect is possible only in an area where the soil has good filtration qualities. The construction of an absorption structure is not carried out if the area has rocky or clayey soil.

The construction of a cesspool with an overflow well is carried out from a source of drinking water at a distance of at least 50 m if the soil on a private territory is sandy, and no closer than 30 m when the soil on the site is sandy loam.

The distance between tanks must also be taken into account. The optimal value is 1 m. However, it is possible to create a structure whose compartments are separated by a thick wall. This is where the overflow holes are located. This design of a cesspool with an overflow tank is less efficient.

In order for wastewater to move naturally between tanks, the overflow pipe must be laid with a slope of 150 mm per 1 m. If installed correctly, the treatment facility will operate properly throughout its entire operational life. However, it is still recommended to periodically check the level of sewage in the containers. When installing filters, their performance must be monitored at least once every 30 days.

What are the disadvantages of septic tanks made of concrete rings

- Impossibility of use with high water and high groundwater levels (GWL). Although leading companies allow the installation of septic tanks from rings with a groundwater level no higher than 130 cm from the ground surface, such a septic tank can only be recommended when the groundwater lies deeper than 2 m.

- Relatively high cost of work when installation of rings is possible only with the help of an excavator, crane or manipulator.

- The need to install underground filtration structures. These structures take up space on the site, and quite a large area if the soil is clayey with low water permeability. And if horizontal structures are required - tubular filtration fields, drainage tunnels, etc. Let's take a standard situation: four people permanently live in a house (800 l/day), the soil is light or medium loam, capable of absorbing about 28 l/day from 1 m² of filter surface. If you create a filtration field from drainage pipes, its area will be about 48 m² (4 x 10 m). The septic tank itself will take up about 4-6 m². Not every site has so much space for treatment facilities. And the volume of excavation work for their installation will be very large.

- The complexity of arranging soil filtration structures at high groundwater levels (less than 1 m from the ground surface). In this case, you will have to build drainage tunnels in an embankment up to 120 cm high. For many homeowners, such an embankment is unacceptable.

- A septic tank becomes energy dependent and requires operating costs when water is forcibly removed from it.

As for unpleasant odors from the septic tank, there will be no such problem if ventilation of the sewage system is provided. That is, the air flow through a riser built into the underground filtration structure, and the exhaust through a fan pipe leading to the roof of the house.

Overflow treatment facility with three chambers

When the site has a large area, it is better to build a cesspool, the design of which involves the construction of 3 tanks. All containers of this design are connected by overflow pipes. The compartments of a three-chamber cesspool can be located at a distance of 700 mm from each other. For the construction of such a structure, it is recommended to use concrete rings with a diameter of at least 1 m.

The first two chambers are completely sealed, and the last tank is created with a filter bottom and water-permeable walls. Often, together with a cesspool of three compartments, a filtration field is constructed. It is connected to the treatment plant using drains. They are pipes with holes through which the purified liquid is released.

Drains are allowed to be installed in sedimentary, loose soil with heterogeneous densities. It is best if there are no layers of loam in the soil. Drains are laid below the freezing point of the soil. Pipes with holes must be wrapped in geotextile material and covered with sand mixed with gravel.

How to determine the required volume of a septic tank

The most detailed standards for the construction of septic tanks are prescribed in STO NOSTROY 2.17.176-2015 “Autonomous sewerage systems with septic tanks and underground wastewater filtration structures.” It states that the working volume of the septic tank should be equal to three times the daily inflow with a wastewater flow rate of up to 5 m³ / day. This indicator is based on other standards, in particular, SP 30.13330.2012 “Internal water supply and sewerage of buildings.”

The daily water consumption norm for one person is about 200 liters (SP 30.13330.2012). This means that for a family of five people permanently living in the house, for example, you need a septic tank with a volume of at least 3000 liters (3 m³). For a more accurate calculation, the quantity and type of plumbing equipment with the coefficient of uneven use are always taken into account. The amount of water consumption for various plumbing equipment is indicated in the same SP 30.13330.2012 (Appendix A, Table 1).

One of the advantages of a septic tank made of rings is the ability to easily provide the required volume: due to the number of rings and the number of individual chambers (reservoirs) of the treatment plant connected to each other. According to STO NOSTROY, single-chamber septic tanks are built with a wastewater flow rate of up to 1 m³/day, two-chamber septic tanks - up to 10 m³/day, three-chamber septic tanks - over 10 m³/day. However, several chambers may be required not only when a large working volume of the septic tank is needed. But also, for example, when groundwater does not allow making one deep septic tank. Moreover, the configuration of a structure of several chambers can be any - in a row, a triangle, the letter “G”, etc.

STO NOSTROY also stipulates the permissible dimensions of the septic tank. Its working depth (the distance from the wastewater level to its bottom) should not be more than 2.5 m and less than 1.2 m. Working width - at least 0.75 m, length or diameter (for septic tanks that are round in plan) - not less than 1 m.

Alexey Melnikov

There is often a misconception about septic tanks made of concrete rings: the more chambers, the better the treatment, since there are more stages of mechanical settling of wastewater. It would seem like ironclad logic, but it is wrong. After all, the working physical quantity in a septic tank is gravity. The number of chambers in a concrete septic tank or partitions in a plastic one does not affect this value in any way. Unless there will be more sediment in the first chamber, and this may simplify the process of pumping out the settled sludge. It is no coincidence that STO NOSTROY 2.17.176-2015, which summarizes the vast experience in using treatment facilities, states that for a septic tank volume of up to 3 m³, one chamber is sufficient. What is of fundamental importance during cleaning is not the number of chambers, but the volume of the septic tank and the length of the route of movement of the wastewater. Therefore, it is better, if possible, to use concrete rings with a larger diameter - 1.5-2 m. The larger the rings, the longer the distance from the inlet to the outlet pipe will be, which will improve the hydraulics of the septic tank and increase the efficiency of wastewater treatment.

Features of the design of a two-chamber sewage pit

The cesspool design with two compartments is used in small and medium-sized areas. Construction of the structure begins with marking the territory. At this stage, the configuration of the pits is determined. However, in some cases it is advisable to create one large pit. After installing tanks in it, the space between the tanks is filled with soil.

In the receiving chamber, the bottom is filled with concrete mortar. To make the screed as strong as possible, crushed stone is added to it. The walls of the compartment are constructed directly on the created foundation. If concrete rings are used during the construction of a structure, then the solution is poured inside the structures. It is recommended to coat the sealed container with waterproofing material on the inside.

Concrete rings can be dug into the ground without the use of construction equipment. To do this, a reinforced concrete structure is first installed on the ground surface. Then the soil is removed in an area whose boundaries are the inner space of the ring. Then it is necessary to gradually undermine the soil under the walls of the structure. As a result, the reinforced concrete ring will be lowered into the shaft being created. This method is especially relevant if there is light soil on the site, as it does not allow the walls of the pit to crumble. When using other materials to create a treatment plant, you need to dig a hole with inclined walls. A slight slope will prevent them from collapsing.

When using a plastic tank as a reservoir, it is necessary to fill it gradually while simultaneously filling it with water. This will prevent deformation of the container, which may occur due to soil pressure.

The second chamber is equipped with a waterproof bottom. Then the pipes are laid below the freezing point of the soil. For additional protection of pipelines from freezing, you can use any of the popular heat insulators. It is recommended to install vertical sections at the ends of the overflow pipe. This will allow the treatment plant to function better because it will be impossible for wastewater to flow in the opposite direction if the tanks overflow. When an overflow well is equipped with additional drainage, a pipe is used that is laid in the ground on a bed of crushed stone.

Methane gases are removed from sewage depending on the type of bacteria involved in the operation of the treatment plant. Some microorganisms are always found in wastewater. However, the process of processing sewage can be accelerated if more anaerobic or aerobic bacteria are added to a sealed tank. The first type of microorganisms can live without oxygen, unlike the second type of bacteria. Therefore, it is better to use anaerobic microscopic organisms in a sealed tank.

When a ventilation device is finally installed, then a hole is created in the cover of the treatment plant for a pipe whose diameter is approximately 100 mm. This ventilation duct is closed from above with a conical cap. This will prevent sediment and debris from entering the cesspool.

Types of septic tanks

Choosing a septic tank for a private home is a strategic question. The range of septic tanks for collecting and treating sewage is wide, and when choosing the optimal design of a septic tank, you must first evaluate its operating conditions, the availability of free space, the groundwater level, as well as the desired degree of wastewater treatment.

The main materials for the manufacture of septic tanks are concrete (concrete rings) and plastic: polyethylene and polypropylene. According to the degree of efficiency of wastewater treatment, septic tanks can be divided into:

Aeration units

Complex technical devices with compressors, aerators and airlifts. Purification degree - 98%;

Biological treatment systems

Septic tanks with pumps and biofilter. Purification degree - 95%;

Overflow septic tanks

Non-volatile septic tanks made of concrete rings or plastic. Degree of purification 60 - 70%;

Storage containers

Pumping out untreated wastewater using a sewer truck as it is filled. Purification degree 0%.

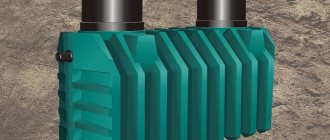

Septic tank made of polypropylene

Septic tank containers, made of durable polypropylene sheets with a thickness of 8-12 mm depending on the volume, are characterized by high resistance to acids and alkalis, zero hydroscopicity and high abrasive resistance. All seam connections are made by extrusion welding with seam quality control. The body of the septic tank made of polypropylene will serve properly for 50 years.

There are cylindrical (round) and square containers on the market. The cylindrical shape of a polypropylene septic tank is optimal for resisting compression by soil, and stiffening ribs and lugs on the base ensure the stability of the structure in the ground.

Video: Biofilter

The high degree of wastewater purification achieved directly inside the housing allows such systems to be called “no pumping” septic tanks.

Septic tank made of polyethylene

Polyethylene septic tanks are made from low-density polyethylene using the rotational molding method, due to which they are immediately seamless. Polyethylene of the LLDPE modification is environmentally friendly and is resistant to aggressive environments and chemical contaminants

It should be noted that during rotational molding, the product may have unequal wall thickness, which can negatively affect the performance properties of the septic tank. In addition, polyethylene has low strength, i.e. In order to avoid damage to the walls of the housing, you must be extremely careful when backfilling the polyethylene septic tank with uncleaned sand.

Polyethylene containers or barrels for sewage

Polyethylene also serves as a construction material for barrels (Eurocubes), which are used for the manufacture of homemade treatment plants.

Septic tank made of polyethylene containers

When living seasonally in a country house and with a small number of users, the owners sometimes simply dig several plastic barrels into the ground into which household waste flows. Sometimes drainage holes are made in barrels or the bottom is cut off altogether to allow wastewater to seep through the ground. Such containers do not have stiffeners and in order to avoid being compressed by the soil, it is necessary to strengthen the walls of the pit with bricks, car tires or concrete.

The storage tank is pumped out as it fills. The disadvantages of such a cleaning system include not only the high costs of frequent sewage disposal and the danger of environmental pollution due to overfilling of the container, but also design imperfections that result in unpleasant odors spreading throughout your area.