Finding the reason

To troubleshoot a water pump, it is important to first find out the cause of the failure. But first of all, it is necessary to determine those conditions without which normal operation of the device is impossible:

- The amount of water that the pump will lift to the top. Reducing its level can affect the pressure.

- Electrical power parameters must correspond to the technical characteristics of the pump. In other words, you need to correctly select the power of the device in accordance with the depth of the well and the calculated water flow.

- Pump serviceability.

- Taps, filters, valves, pipes and other elements of the device must also be in good working order. Failure of at least one component of the system will lead to malfunctions.

Often, tap water in a private home is needed not only for domestic consumption, but also outdoors (for watering the garden, washing the car). Therefore, the cause of the malfunction should be sought in three directions - in the hydraulic system, indoors and outdoors. How to determine the cause? Let's use the elimination method.

First, disconnect the supply hose located in the caisson. If water flows out, it means there is a problem either indoors or in the pipes outside.

If there is no liquid, then the reason may be hidden in the well itself or pump parts. Sometimes this situation happens - the device hums, but there is no water. Then the most likely reasons are:

- Incorrect installation or some parts of the pump that are not quite suitable.

- A decrease in water in the well, as well as surges in the electrical network, can also cause problems with water supply.

- Phase loss during operation of the electric motor.

If until recently the device worked properly without breakdowns, perhaps the reason should be sought in voltage drops in the electrical networks or problems in the water supply of the well. If the system is completely new, then finding the cause will be more difficult.

Drain pump diagnostics

You can repair the drainage pump yourself in situations where the breakdown is not so significant. To do this, you will need to diagnose the operation of the device, identify the malfunction and try to eliminate it. For example, it will not be difficult to replace a worn or broken part, or clean the filters. It is also possible to carry out simple electrical repairs at home - replacing a broken electrical cable or capacitor.

But if a crack appears in the body of the device, the winding of the electric motor burns out, or the valve stops working, it is better to contact a specialized workshop or purchase a new pump.

A break in the power cable can be easily repaired if it breaks near the plug. It will be more difficult to close the gap on submersible models of the drainage pump, in an underwater location. Here, due to the likelihood of a short circuit, you cannot connect the break using simple twisting.

You will need to cut the cord at the fracture site and reattach it to the engine. To do this, you will have to remove the cover and remove the cut off remainder of the cable. Instead, using a tension element, we attach a long cord with a plug, after which we put the cover in place, carefully and thoroughly tighten the fastening bolts.

Most likely cause of failures

If water does not flow from the well and the system is humming, the problem may be related to clogging or mechanical damage to parts of the water supply system. Try to remember if the water quality has changed recently? Has the pressure decreased? If yes, then we can safely assume that the cause of the pump failure was a simple blockage. Small algae, sand, silt - this is what can contaminate the system and cause it to break down.

Clogging is primarily characterized by the appearance of sand and foreign particles in the water flowing from the tap. Then its quantity and pressure gradually decrease until the water stops flowing altogether. Yes, the pumps have protection against so-called “dry” operation, but it may simply not work. And then no water comes from the well, but the motor and all other parts continue to work.

Causes of drainage pump failure

There are many reasons why drainage pumps fail, here are the most common ones:

- Violation of operational standards (the device is constantly under overload, it is not fully immersed);

- The pump is not regularly maintained;

- The pump was not installed correctly;

- Perhaps this is a manufacturing defect.

Before starting repairs, it is necessary to exclude the last of the listed options. If you bought a pump recently, check to see if the warranty period, if any, has yet expired. Because if you try to repair the pump yourself, it will no longer be accepted under warranty service.

To prevent pump breakdown, it is necessary to carry out its maintenance on time. Preventive measures to avoid repairing the float drainage pump, points that need to be paid special attention to:

- The air entering the pump must flow freely through it and out. If air does not flow freely, then there is an air lock somewhere in the pump.

- There should be no visible damage to the piston.

- It is necessary to monitor the distance between the valves and the inlet opening.

Further plan of action

Why does the pump not pump water from the well even after cleaning? The following problems may be the cause:

- Malfunctions in the electrical system.

- Failure of mechanical parts of the pump.

- Pipeline leakage. It is also possible that holes and cracks may appear in the pipes.

- Malfunctions in the operation of pump control units.

To figure out exactly what is broken, we take the pump out of the well and immerse it in a container filled with water. This could be a large basin or barrel. If the motor is running, then there is no fault in the electrical system. If the engine does not start, you need to call a specialist.

Attention! Do not attempt to repair the electrical system of the motor! This should only be done by a professional!

While the engine is running, visually assess whether there are holes or cracks in the pipes and hoses. Remember that even a slight deformation will lead to a drop in pressure. For a more accurate result, close the outlet hole with your hands. Then the pressure inside the pump will increase and you will be able to see even small places where there is a leak.

If any hose is damaged, there is no need to seal it. It's better to buy a new one. The fact is that even after a high-quality repair, the hose will not last long due to its operation under water pressure - the tape will constantly break off, and the glue will be washed off.

Malfunctions of the pumping station, or How to repair the pumping station with your own hands?

No device, no matter how reliable it is, works forever. Alas! This also applies to pumps for water supply systems. Therefore, at the end of the topic about pumping equipment, we will figure out what malfunctions of the pumping station and how to repair the pumping station with your own hands. If you were looking for: water supply pumping station faults, home pumping station faults, water pumping station faults, pumping station pressure switch faults. then this article is still for you. Further I will simply list possible faults and “correct” them.

The pump works but does not pump water

What to do if you find no problems with either the electrical system or the pipes and hoses? Most likely the reason is in the pump itself. Before pumping water from a well, we carry out the following steps:

- First of all, you need to check the filter and check valve. They should either be cleaned or completely replaced. It all depends only on the degree of clogging and wear of the part. Since these components are not that expensive, we recommend replacing them at the first signs of deformation and aging.

- The unit responsible for shutting down the system when the water supply stops may break or burn out. This spare part should not be repaired, but replaced immediately. This will allow you not to worry about the pump stopping supplying water again. At the same time, do not forget to check that the well has adequate water supply. The fact is that this unit can overheat when the water level drops critically.

The pumping station began to hum loudly and the pressure decreased. How to fix?

What could this be and how can I fix it myself?

In most cases, the cause of increased hum and low productivity of the pumping station is the presence of air in the pump volute. Therefore, the first thing to check in this case is the presence of air. The pumping station has a special bolt for bleeding air.

Before turning on the station, it is necessary to unscrew this bolt and fill the pump and the supply pipe, which is lowered into the well, with water through a funnel. You need to fill until no more air bubbles come out. Then remove the funnel, tighten the bolt and start the station.

The second reason may be contamination of the check valve strainer at the end of the suction pipe (the one that goes down into the well). To check this, it is necessary to disconnect the suction pipe from the pumping station and pull it out of the well. Then check the check valve filter and wash it. If you cannot wash it, it is better to replace it with a new one.

Hello everybody! Indeed, there can be a huge number of reasons. Starting from low network voltage and ending with severe clogging or silting of the suction valve.

Let's look at the main reasons:

- Low voltage. Everything is clear here. Check the network voltage; if it is low, you can use a voltage stabilizer.

- Air may be getting into the system. Here you need to check all connections for leaks and redo them. Air ingress can also be attributed to a non-working check valve, which is usually located in front of the station on the suction pipe. There are cases when the valve has a defect or a minor crack (a crack can appear when the valve is over-tightened) or even a very small speck could get into the valve and it will no longer work fully. There are 2 options: if there is a crack or defect, simply replace the valve, and if it is clogged, then remove it, clean it or rinse it, and put it back.

- The strainer valve at the end of the suction pipe is silted or dirty. Everything is simple here too. Disconnect the suction pipe from the station, remove it from the well, clean and rinse the valve; if it cannot be cleaned, then replace it with a new one. And then you put everything back together in reverse order.

These are the main and easiest moments that can happen and which you can easily handle yourself.

Source

A number of other reasons

There are several other reasons why the pump stops pumping water from the well:

- Significant reduction in water level in the well. The main reason for this phenomenon is improper drilling. Often a decrease in water level occurs in the summer, during dry periods. To prevent such situations, it is necessary to contact only trusted well drilling companies, and also use a system of protection against dry work. It would not be superfluous to clean the well using special means.

- A centrifugal pump can pump out water faster than the well can refill. You need to choose the right pump based on your personal needs. In this case, it is better to buy a device with a power slightly higher than needed, because guests may come, or you will need to water the garden with a large amount of water. Don’t forget to save it as wisely as possible - don’t open all the taps in the house at once and don’t pour water in vain.

- Weak pressure. Another problem that arises if you choose the wrong pump. For example, the depth of the well is about 50 meters. And the device is designed for a shaft length of about 30 meters. Of course, he will not be able to raise water to the surface with the required pressure.

- Power outages can negatively affect the operation of all appliances, including the water pump. In this case, it is recommended to buy a voltage stabilizer, or connect the pump to a generator.

- Disconnecting the pipeline. With this option, you can hear the “gurgling” of water. It is necessary to check the water supply system and fix the problem.

- Clogged pipes or system filters. Often occurs during the first test run of the pump and water well. During this time, sand or clay particles may get into the hoses or pipes. The main reason is incorrect or insufficiently high-quality system assembly. It is important to maintain precision and accuracy during installation. To eliminate this problem, the pump can be washed in a container of water after disconnecting the pipeline and check valve.

- If you can clearly hear the sound of a running engine and all possible causes of the problem have been checked, but there is still no water in the house, we recommend removing the pump and taking it to a repair center.

Now you know all the possible reasons why the pump does not pump water from the well. We hope that our tips will help you save on calling a specialist in not very difficult cases.

Common problems

Nature of the failure and cause of its occurrence:

- Doesn't buzz and doesn't work. The drainer is lowered into the water, the float has surfaced and is on the surface, the cable is connected to the circuit, but the engine does not work, there is no vibration. The cause of the breakdown is a discrepancy between the declared motor power and the electrical network to which the device is connected. Carefully read the characteristics of the pump, its power and efficiency. The pump is not lowered deep enough into the water and the float does not work. Remove the device and, lifting the pillow up, turn it back on.

- It works, but doesn't download. The engine is on, but no water comes to the surface. There are several reasons for this. The protective mesh blocking debris and stones at the bottom of the case is clogged. Raise the device and clean the filter. The thick fraction got into the discharge hose and a blockage occurred. If such a breakdown occurs, it may be knocked out of the base of the pump; if this does not happen, you need to disconnect it yourself and wash it. The impeller is broken. Its augers may break or the bearing may collapse; this can be found out by disassembling the pump.

- Vibrates and overheats. The electric motor braid was broken, water got into the engine compartment, and the shaft bearing was destroyed. The unit vibrates and heats up, while the water flows in jerks or stops altogether. We urgently turn off the power to the equipment and pull it to the surface. The cause of the breakdown is hidden inside. For diagnostics it is necessary to disassemble the case. Several impeller blades are broken. The rotation occurs with an eccentric and hits the body on one side.

- Low pressure with a properly running engine is a consequence of a breakdown of the mechanical part of the pump. Impeller or bearing, clogged discharge hose or suction filter. It can be eliminated by simply washing it in clean water or replacing mechanical parts.

- When the unit is connected to the network, the automatic switch is activated. The fuse cuts off the network if a short circuit occurs. Check all electronic parts of the pump. Go through the cable with a tester and find out where the short circuit occurred - replace it. The motor's copper braiding is also at risk if the unit is run dry. The braid can be replaced or a new engine installed only in a repair shop.

- The device works, but turns itself off. Connected to the network and working, pumping water properly. Suddenly it turns off on its own. The reason is a mismatch between the power of the motor and the electrical network. Voltage surges can also affect the smooth operation of the unit. The solution is simple - study the instructions and characteristics of the pump in detail, install a voltage stabilizer.

Tip: to pump out all the liquid completely, the float is tied to a cable in a vertical position and lowered into the water. Adjust the switching on and off of the device by unplugging the plug from the socket.

Recommendations for installation and operation

To reduce the number of problems in the operation of the pumping station, it is important to correctly install the equipment, as well as follow the recommendations for the operation and maintenance of the device. Here are some important points:

- To prevent vacuum compression of the water supply line, it is recommended to use either metal pipes, or sufficiently rigid PVC pipes, or a vacuum-reinforced hose.

- All hoses and pipes should be installed straight, avoiding deformation and twisting.

- All connections must be sealed and sealed, and their condition must be checked regularly during preventive inspections.

- Do not neglect installing a check valve on the water supply hose.

- The pump should be protected from contamination using a filter.

- The depth of immersion of the hose leading to the pump must exactly correspond to the recommendations of specialists.

- The pumping station should be installed on a level and solid base, using rubber gaskets to dampen the effects of vibration during pump operation.

- To prevent the pump from operating without water, it is necessary to install a special circuit breaker.

- In the room where the pumping station is installed, the correct temperature (5-40 degrees) and humidity (no more than 80%) should be maintained.

It is recommended to check the condition of the pumping station at least once every three months. Separately, you should check the readings and settings of the pressure switch.

Another important preventative step is to bleed the air that is released from the water and fills part of the volume of the liner in the hydraulic tank. On large containers there is a separate tap for this. To remove unnecessary air from the membrane of a small tank, you will have to fill it several times in a row and completely drain the water.

Design and operating features

Using a pumping station, you can solve several problems related to water supply:

- organize the automatic supply of water from the source to the water supply system of the house;

- adjust the water pressure in the water supply system, bringing it to an acceptable level;

- protect the water supply system from water hammer;

- create some water reserve in case of problems with water supply.

You can purchase a pumping station ready-made, which will make its installation a little easier, or assemble it yourself, selecting individual elements depending on your own situation.

For example, if a deep well is used as a water source, it makes sense to replace the surface pump with a suitable submersible model.

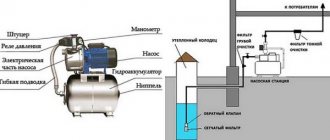

This diagram clearly shows the structure of a conventional pumping station: a hydraulic accumulator connected to a surface pump and a pressure switch

Understanding the principles of operation of a pumping station will help you understand the features of repairing this device. Its central part is a hydraulic tank - a container with a built-in rubber liner. Using a pump, water flows into the membrane part of this container. On the other side of the membrane there is air (sometimes pure nitrogen is supplied to the hydraulic tanks, but this is rare).

This combination creates a certain pressure inside the container. On one side of the tank there is a regular car nipple, through which you can bleed off excess air or pump up the missing one. On the other side there is a pipe installed. The remaining elements of the pumping station and system are connected to it through a special fitting with five outputs: pressure gauge, pressure switch, pump hose, water pipe, etc.

The hydraulic tank is connected to the water supply of the house. When the water is turned on, the tank is emptied and the pressure inside the container decreases. When it reaches the set value, the pump automatically turns on and water flows into the accumulator until it is full and the pressure reaches the set maximum level.

This detailed diagram allows you to understand the design and operating principle of the hydraulic tank. The air pressure in the container should be maintained at about 1.5 atm to prevent damage to the membrane

Switching the pump on and off is controlled by a pressure switch. This is a small device connected to both a hydraulic accumulator and a pump. The presence of such a station has an extremely beneficial effect on both the condition of the water supply system and the operation of the pump. The hydraulic tank serves as a buffer that protects the water supply from sudden water hammer. The pressure switch reduces the number of pump starts and stops to the required minimum, which extends the life of the equipment.

Although there is a small amount of water inside the hydraulic tank at all times, it should not be considered the main place for storing a large supply of water. The larger the volume of the hydraulic tank, the higher its price. If you need to stock up on a significant amount of water, it is better to supplement the system with an inexpensive plastic container of a suitable volume. And a small hydraulic tank will cope quite satisfactorily with protection against water hammer.