A cesspool is the most popular option for arranging a sewer system for a country house or cottage. The comfort of residents directly depends on the quality of functioning of the waste tank. If in summer owners are forced to deal with the problem of unpleasant odor from the cesspool, then in winter a serious problem is the freezing of the sewage system, which leads to its complete unsuitability.

At low temperatures, not the entire cesspool freezes, but only its upper part. This is due to the fact that below there are active microorganisms that live in the ground, wander, and feed on waste. The temperature at the bottom of the pit is slightly higher.

Insulation of a cesspool

Hermetic tanks require special attention. Liquid accumulates inside, there is no air access, so bacteria die in such conditions. If the top of the pit freezes, then over time the bottom will also freeze. Sewage tanks made of concrete rings, slightly elevated above the ground, are also subject to freezing. The part that is not in the ground does not receive soil heat, and therefore freezes much faster than holes that are completely located in the ground.

Installation location

At first glance, it may seem that there will be no problems with the installation location of the cesspool, but this is far from the case. For these structures there are certain rules that must be followed. Firstly, you cannot place a pit near houses, garages, gazebos and other buildings, closer than five meters. If there are wells, springs and other sources of drinking water on the site, then the minimum distance should be thirty meters. All these rules are very important, so the location should be chosen very carefully.

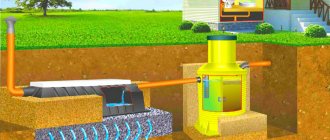

Cesspool design

In order to properly build a sewer system at home, you need to finally decide on the type of structure and installation method. There are two main types of sewer pit designs:

- A cesspool with no bottom.

- A pit with an increased level of tightness.

Despite the abstruse and frightening name, the latter type has a fairly simple and understandable design: a plastic or concrete container, which is subsequently immersed in the ground and buried.

Construction of a cesspool

When buying a house, cottage or plot, it is the arrangement of this sewer system that is practically the first and most important thing, which must be taken with due responsibility and seriousness. It is a well-equipped cesspool that guarantees a high level of comfortable life on the site. Those people who are trying to equip this installation on their own must remember that they cannot do without certain knowledge and skills in the field of construction.

Therefore, if questions or difficulties arise during the installation process, it is best to seek help or advice from a person who is well versed in the construction of just such objects. In addition, official permission from the relevant authorities should be obtained before installation. After this, you can proceed directly to the arrangement. When digging a hole, you should remember that its parameters should be slightly larger than the septic tank that will be installed inside. Septic tanks for cesspools come in the following types:

- Polypropylene.

- Reinforced concrete.

- Brick.

- Plastic.

For self-installation, a septic tank made of plastic is perfect. This type of septic tank interacts very harmoniously and efficiently with concrete rings. The combination of a plastic septic tank with concrete rings provides a cesspool with certain advantages:

- Quite long service life

- High-quality waterproofing

- Corrosion resistance

- Quick installation

- Strength and resistance to stress

Some developers are not suitable for concrete rings as a base for a drainage pit. This comes with the fact that the rings are quite heavy, making them quite difficult to install. In this case, there is an alternative option: a tire cesspool. Rubber tires are much lighter than concrete rings, so installation should not be a problem. They have the same shape and also have almost all the advantages of concrete structures.

As already mentioned, installation of this design is quite quick. It consists of several steps:

- Digging a hole

- Installation of concrete or other rings

- Installation of a septic tank

The diameter, depth, as well as other parameters of the pit and rings are set by the builder himself.

Using a septic tank in winter

The owner of a suburban area who has installed a sewer system using a septic tank is probably waiting for the first frost with some fear. In our region, winters are quite harsh. And the weather in recent years has shown us this. There were times when the temperature dropped below 30 degrees. It is not difficult to understand people who are warily awaiting the onset of cold weather. After all, even builders who install sewer systems do not hide the fact that the septic tank can theoretically freeze. But at the same time, they emphasize that if the project is drawn up correctly and all building codes and regulations are met, the septic tank will fulfill its duty even in the most severe frosts.

The principle of operation of septic tanks

To refute the legend about the freezing of a septic tank, it is enough to remember what its structure is and the principle of its operation. Let us remember that a septic tank is a kind of container in which wastewater from a house is collected. Microorganisms accelerate the process of decomposition of waste water, which, after clarification, is discharged to filtration fields. Often the septic tank is made of plastic, but sometimes it can be made of concrete or metal. As a rule, the structure is located at a depth of two meters underground. If we consider that the temperature at this level, even in severe frosts, cannot drop below five degrees Celsius, then freezing should not threaten the septic tank. In addition, as mentioned above, substances decompose when exposed to a huge number of microorganisms. When processing substances, bacteria produce heat, which means that the septic tank itself is a source of a small amount of heat.

Insulation of septic tanks

But, if the possibility of freezing still exists, there are some tips on how to maintain a septic tank in the winter. To eliminate the slightest possibility of freezing, the septic tank structure and drains can be insulated. If you are afraid that the soil will freeze so much that it will disrupt the operation of your septic tank, you can carry out the insulation yourself, no matter how long ago you installed your sewer system.

There are special insulation materials for this procedure, but if they are not available to you, they can easily be replaced by ordinary polystyrene foam or expanded clay. Insulation of a septic tank is carried out by installing heat-insulating material on the upper surface of the septic tank. Thus, the cold will not be able to penetrate into the sewer system in any way. To further preserve the septic tank and guarantee its trouble-free operation in winter frosts, you can additionally insulate the surface of the pipes through which the drains pass.

Preservation of the septic tank

The installation of septic tanks in country houses and dachas is very popular. Most people live in these houses only during warm seasons. In order not to worry about your site in winter, you can carry out the conservation process even before the onset of the first cold weather. This method prevents the septic tank from freezing.

But conservation of the sewer system also has its own characteristics. The biggest misconception is the idea that it is necessary to completely remove water from the system for conservation. You should not do this, since with the arrival of heat, the accumulated moisture from melted snow can simply push the empty septic tank out of the pit to the surface.

In order for the conservation process to bring only benefits and not even more trouble in the spring, it must be carried out consistently and correctly. First you need to turn off the power to the sewer system. Then the pump and compressor are dismantled. After this, the level of wastewater in the septic tank chamber is reduced. The level is reduced by only a third.

The next step will prevent the septic tank from rising outward. To do this, you need to take regular bottles or any other two-liter containers. Fill them with sand and lower them inside the septic tank. It is enough to put one such bottle of sand in each septic tank. After this, all that remains is to close the lid of the septic tank and insulate it from the outside with any heat-insulating materials.

This procedure allows you to keep the water temperature in the septic tank at least 4 degrees in winter. Bottles with sand are placed in the sewer system in order to protect the walls from water, which expands during the process of thawing the ice crust that can cover the pipes on the outside.

What to do if the septic tank is frozen?

Both ways to protect a septic tank from freezing are quite simple, but there are situations when they don’t help either. For example, if conservation and insulation measures were carried out too late. Or, for some reason, the work to prepare the sewer system for the winter period was not completed. Then the septic tank may freeze. As a result, water from sinks, bathtubs and toilets will not drain, and this problem causes a lot of inconvenience.

What to do in such a situation? The easiest way to restore the functionality of a frozen sewer is to pour hot water into the sink or bathroom. Such a primitive solution will melt the ice in the pipes in front of the septic tank. If hot water is not enough to solve the problem, it is necessary to use special compounds. This can even be a saline solution. This will help to effectively get rid of the ice “clogs” that have appeared and will return your septic tank to functionality.

This happens very rarely, but the septic tank can freeze quite strongly. If neither the first nor the second method helps solve the problem with ice in the sewer, you will have to use extreme measures - install a special heating cable directly in the septic tank chamber. Such a cable will allow you to maintain a constant temperature in the pipes. Thus, throughout the cold season, the drains will not freeze, and the septic tank will work properly all winter.

The cesspool has silted up, what should I do?

A home's sewer system may not always work smoothly. As a result, this building structure may become clogged with silt. In most cases, the reason for this is incorrect pit design. But if such a nuisance happens, there is no need to panic. All that is required is to follow the simple and clear steps exactly:

- Firstly, you need to use the services of a sewage disposal machine, since without it it will not be possible to clean the pits. The path for the vehicle to approach the site of the blockage should be prepared in advance.

- You need to try to soften the solid mass that is inside. To do this, you need to pour as much water as possible and try to pump out as much debris as possible.

- In addition to water, solid elements can be liquefied using chemicals.

- Before adding chemicals to the waste pit, ensure air flow. Chemicals that contain chlorine must not be used.

- After the ball pit has been pumped out, you need to break the compressed sludge into pieces and pull it out of the pit.

As you can see, a clogged drain is a very complex and unpleasant problem, so it must be resolved as soon as possible after its discovery.

Insulation process

Climatic conditions and temperature seriously affect the performance of your home drainage system. In winter, when the temperature is as low as possible, the stable functioning of the sewer system depends on how well the sewer pit has been insulated. It is very important to ensure that it is not exposed to freezing in winter.

To prevent this from happening, you need to know how to insulate a cesspool. The upper half of the structure should be especially carefully sealed and insulated. A large number of bacteria are concentrated in the lower part, which prevent water and other waste from freezing. There are much fewer of these bacteria in the upper part, so frost can damage or stop the operation of the septic tank. Special materials that retain heat can help in this matter. You can insulate with the following materials:

- Foam boards, the thickness of which does not exceed one hundred millimeters.

- A layer of expanded clay up to three hundred millimeters thick.

- Waterproofing with mineral wool.

Do-it-yourself insulation of a drain pit

The stable operation of the sewer system of a private house during the cold season depends on how to insulate its constituent elements. Next, we’ll talk in more detail about how to equip a cesspool so that it does not freeze in winter. Particular attention should be paid to the upper part of the well. Wastewater does not freeze even in the most severe frosts due to the activity of bacteria that cause fermentation. The upper part of the cesspool is less populated by these bacteria, so those elements of the septic tank that are located in the zone of soil freezing and also protrude above the ground require insulation.

You can insulate the drainage pit using the following materials:

- foam boards with a thickness not exceeding 100 mm;

- a layer of expanded clay no more than 300 mm thick;

- mineral wool with waterproofing.

Exhaust from a cesspool

Some time after installing your home waste disposal system, unpleasant odors may come from it. This is due to the fact that a large amount of waste collects in the pit, which is not immediately cleaned up. This problem needs to be dealt with.

To do this, you need to install a special hood in the pit. The hood itself is a pipe of small diameter. Basically, most builders use plastic pipes for this device. It is also fashionable to use metal ones. The diameter of the pipe should not exceed one hundred millimeters.

In order to make a hood, you need to place one end of the pipe inside the cesspool, and bring the other end to the surface. In this position, the pipe must be buried. The principle of operation of the exhaust system is quite simple and understandable: all waste goes into the cesspool, and unpleasant odors come out through a pipe brought to the surface. Odors are removed through the hood due to air circulation in the pipe.

This pipe can be laid a certain distance from the sewer itself. Just like the waste drain system, the exhaust system must be located at a certain distance from places of water supply: water pipes, springs, lakes, ponds, as well as other places where drinking water accumulates.

Cesspools with overflow mechanism

Another deeper septic tank is dug next to the cesspool. Its walls are reinforced with reinforced concrete rings, and the bottom is left earthen. Through holes in the upper rings, the pits are connected by overflow pipes. The pipes should be laid at a distance of at least 500 mm from the soil surface, that is, below the freezing zone. If the region has very severe winters, then this figure can be increased to 800 mm.

A septic tank made of two wells is the optimal solution to the issue of sewerage insulation.

Insulation of a cesspool

A cesspool is the most popular option for arranging a sewer system for a country house or cottage. The comfort of residents directly depends on the quality of functioning of the waste tank. If in summer owners are forced to deal with the problem of unpleasant odor from the cesspool, then in winter a serious problem is the freezing of the sewage system, which leads to its complete unsuitability.

At low temperatures, not the entire cesspool freezes, but only its upper part. This is due to the fact that below there are active microorganisms that live in the ground, wander, and feed on waste. The temperature at the bottom of the pit is slightly higher.

Insulation of a cesspool

Hermetic tanks require special attention. Liquid accumulates inside, there is no air access, so bacteria die in such conditions. If the top of the pit freezes, then over time the bottom will also freeze. Sewage tanks made of concrete rings, slightly elevated above the ground, are also subject to freezing. The part that is not in the ground does not receive soil heat, and therefore freezes much faster than holes that are completely located in the ground.

Why do you need to insulate a cesspool?

Very often, in the process of arranging a sewer system, owners do not understand the role of insulation of the cesspool and miss this point, which then negatively affects the functioning and durability of the structure.

Freezing of the drain tank causes the following problems:

- failure of the sewer system to do its job;

- cesspool overflowing with water;

- spilling sewage onto the site;

- spread of foul odor;

- harm to the environment.

Insulation work is best carried out during the construction of the sewer system. If this has not been done, then thermal insulation can be carried out later, however, you will have to make every effort, and the costs will increase significantly. It is necessary to insulate not only the cesspool itself, but also the drain pipes, because they also freeze at low temperatures.

Insulation work during the construction of the sewer system

You can hear the opinion that the sewer system does not freeze in the cold season due to the fact that hot liquid enters it, which is also in constant movement. But in practice, this hypothesis is not confirmed, and those who did not take care of insulating the cesspool and pipes are faced with troubles.

Welcome to Unipedia

- Articles

- Sewerage

- The sewer system freezes in a private house: problem solving

A suburban autonomous sewer system may fail in the winter, especially when the temperature drops sharply to high levels with a minus sign. Such inconveniences are simply a disaster for permanent residences.

Experts believe that the reasons for this situation were incorrect installation, taking into account weather changes in the region. As the experts say: “A functioning sewer system does not freeze and works without failures all year round.” One cannot but agree with this statement, especially considering the fact that the pipes are inclined and the liquid, the temperature of which is not lower than room temperature, is constantly moving towards the storage tank.

The sad fact is that the freezing that has occurred cannot be eliminated before the arrival of seasonal heat.

Causes of liquid freezing in pipes

- installation error;

- plumbing faults;

- clogged sewer pipes;

- insufficient thermal insulation of pipes;

- incorrectly selected pipe diameter.

An error in installation work includes failure to observe the angle of inclination, which ensures gravity flow of the liquid. The liquid, stopping in the pipe, freezes under the influence of low temperature, layering and clogging of the pipes occurs, regardless of the diameter of the pipe. In addition to this defect, the cause may be the location of the pipes above the freezing level of the ground; even insulation material will not help in cold winters.

A malfunction, in this situation, is considered to be the appearance of a leak, as a result of which cold air penetrates through the air channel into the middle of the sewer system, which causes freezing. The signal may be a decrease in water pressure at the water supply tap, causing the appearance of an ice layer inside the pipes.

Blockages formed in pipes by the accumulation of large-diameter solid particles form stagnant liquid, which gradually takes on a solid form. After which operation becomes impossible due to inoperability.

Ways to solve a frozen problem

If freezing is at an early stage, they noticed the problem in time, did not allow the system to freeze completely, and resorted to the defrosting method. Defrosting, keep in mind that if there is a small area with frozen liquid, defrosting is done by pouring water at boiling point into the drain hole. It is important to take into account the technical characteristics of the installed pipes; if the pipe material cannot withstand sudden changes in temperature, it is better not to carry out such procedures, the pipes may burst, and the damaged section will have to be replaced.

If it is possible to determine the place where the liquid has frozen, the section of the circuit is heated with special tools, a blowtorch, and other devices. For plastic pipes, a steam generator is used; the device generates water vapor, the temperature of which is above 100°C, warms and defrosts the ice inside the pipe.

There is a method of electrical defrosting; for this, terminals and an electric generator are used; if possible, a direct connection to the electrical power supply is used. Under the influence of current, the walls of the pipes heat up, which determines the melting of the ice that formed the blockage.

After the system has been put into operation, preventative measures should be taken to ensure that the problem does not recur. You can flush the system with boiling water once a week.

Technical innovations, such as chemical defrosting agents, are rarely used, for certain reasons. The most basic reasons for abandoning this method is its cost. Such a price and the consequences that cause a decrease in the level of microorganisms in the septic tank are not justified. After such defrosting, you will have to buy additional bacterial mixtures and clean the well shaft.

There are biologically pure preparations, they are not cheap, interaction with water causes heat, which melts the ice.

The convenient method is chosen independently. To do this, you should determine and take into account:

- determine the location of the ice plug;

- the size of the resulting plug;

- geometry of the sewer system;

- method of laying pipes.

Whatever the solution to the problem, an initially competently created sewage system with all the provided nuances is the best option.

Correct installation

Improperly performed work is a huge disadvantage; the problem will repeat itself until you decide to take drastic measures to eliminate the initial defects.

With the arrival of warmer weather, it is worth thinking about work that will prevent such a situation in the future; the use of sewerage will be without problems all year round.

It is better to carry out this work with the help of specialists, or with their participation. Some of the work that does not require qualifications is performed independently to save money. These types include land works.

After the sewerage piping system has been excavated, it is necessary to determine whether the angle of inclination is correct. If not, excavation work continues to obtain the correct parameters.

It’s better not to stop there, especially if the region is located in the north of the country. The system can be heated using a special electric cable that is installed on the surface of the pipe. Work on additional thermal insulation with the participation of a heating cable proceeds as follows:

- it is necessary to measure the required cable footage;

- purchasing a cable;

- purchasing insulating material;

- adhesive tape is required.

The length of the cable is determined taking into account the location with the connection to the electrical power circuit. The cable is cut into pieces convenient for installation, and the same procedure is done with the insulating material. After preparation, we move on to the process of implementing thermal insulation. The cable is attached to the bottom of the pipe using adhesive tape along the entire length of the pipeline with a connection at the break points. The next stage is winding with heat-insulating material, which is firmly fixed.

There are many nuances in such work, for example, the choice of cable. The technical characteristics of cable and wire products are varied; heat transfer depends on the material, number of cores, windings, and other factors. Cables with high heat transfer are covered with special foil before insulation; it helps direct heat to the body of the pipe itself, without damaging the coating of the heat-insulating material.

Cable heating technologies have many types. Spiral winding is considered a popular type; foil and building insulation material create an ideal combination. The spiral winding warms the entire pipe, the consumption of electrical energy is insignificant, given the resulting useful coefficient.

Such winter heating systems for sewer pipes are additionally equipped with temperature sensors that monitor the ambient temperature and the temperature of the pipe body in order to maintain an ideal balance and save energy. In addition to the sensor, a relay is installed that disconnects the power circuit after receiving a signal from the sensor that the maximum heating temperature of the pipeline system has been reached.

You can regulate it yourself, calculating the time to reach a certain temperature, according to the technical capabilities of the selected cable product.

This insulation method is the most effective today. Regions with warm winters do not need such high-quality insulation; it is enough to lower the pipes to a depth below the freezing line, additionally making the thermal winding of the pipes with building materials specially designed for this.

Septic tank freezing

Unfortunately, it's not just the pipes that freeze. Freezing of the septic tank is a problem of no less importance. The main reasons are:

- drainage;

- distance.

Due to drainage, septic tank freezing occurs more often. A malfunction in the removal of water causes the tank to gradually fill, after which the immovable sewage solidifies.

A large distance from the drainage point, the water cools down during the long journey and enters the septic tank in a semi-frozen state, which causes further icing.

According to the standards by which a septic tank is installed, such incidents are excluded if such a problem occurs, it is clearly violated, and the rules of construction installation are instituted.

Defrost the septic tank using means that can be lowered into the tank. For example, an incandescent lamp for heating. The method is very long, the energy costs are high, and it will hit your pocket. The hot water method is much more efficient and economical than electric heating with a lamp.

Quicklime is used if it is a cesspool; for a septic tank this method will be disastrous, especially if it contains rubber elements.

Learn from the mistakes of others, do not neglect the advice of people who have experience in similar situations. The best way to avoid a problem is to prevent it from happening.

The sewer system freezes in a private house

Frozen water supply

Insulating the septic tank for the winter

Options for warming up communications

Sewage system in a private house

Thermal insulation materials

It’s good if it is possible to equip a cesspool and lay sewer pipes below the freezing level of the soil. Otherwise, you will have to look for a solution on how to insulate a cesspool in a private house using thermal insulation materials. Most often in this case they are used:

- basalt;

- asbestos;

- polyurethane foam;

- mineral wool;

- fiberglass;

- polystyrene

Thermal insulation material must be resistant to aggressive chemicals and microorganisms. It must retain its thermal insulation qualities even after getting wet, and also have a high level of adhesion to metal and plastic.

The construction market offers a wide range of materials for insulating cesspools. The choice will depend on the severity of winter, the nature of the soil, and the financial capabilities of the owner.

Thermal insulation methods

First, let's consider whether it is necessary to insulate sewer pipes in a private house. Freezing of drains in the circuit is one of the possible malfunctions, which eliminates the possibility of using plumbing equipment. The reasons for this phenomenon may be:

- untimely cleaning of pipes and removal of blockages;

- design of a system with a large number of turns and insufficient slope towards the waste collection point;

- non-compliance with the level of penetration of the sewer circuit into the ground.

Another reason can be considered the erroneous belief that the canal is periodically heated by warm wastewater. However, such an assumption may be relevant only for regions with a warm and mild climate. In northern latitudes, thermal insulation of external circuits is a necessary measure. Let's look at the main ways to insulate a sewer pipe.

Deepening the line

Here the main parameter is the depth of soil freezing. Pipes with a diameter of 100-110 mm must be laid 30 cm below this level. To do this, a trench is formed, the bottom of which is compacted at a slope from the house within 10-12 degrees.

Laying a sewer channel in a trench Source makler.md

This solution is simple, but has its drawbacks:

- it may be necessary to deepen more than 1.5 meters (labor-intensive);

- excavation work takes a lot of time and effort from the worker (affects wages);

- it is difficult to maintain the required slope, especially for a long pipeline (a 10-meter channel needs to be lowered by about 1.5 meters at the septic tank);

- above the level of soil freezing there are many elements of the system that are still subject to insulation (wells, collectors, the area where the circuit exits the house);

- Isolated sections of the sewer system are more difficult to check for serviceability and repair.

However, despite the disadvantages, deepening below the freezing soil is an effective solution. This way the pipes are protected from natural phenomena and human factors, which reduces the likelihood of emergency situations on the way to the septic tank. This approach also allows you to localize and reduce the area that needs insulation. This is a cost-effective solution.

Providing heating

An electrical cable is used here, which emits a certain amount of heat when connected to the network.

Insulation of a pipe with a heating cable Source yandex.net

See also: Catalog of companies that specialize in water supply, sewerage and related work

Installation involves wrapping the pipe with wire or pulling it inside the main line. The number of threads and the pitch between turns depends on the heater power; higher heat transfer means shorter distance and, accordingly, cable length. The elements are fixed with aluminum tape (the plastic is completely wrapped in foil before attaching the wire). The entire structure is covered with insulation.

Experts say that this solution is relevant for regions with frosts below -15 degrees Celsius. It also allows you to limit the deepening of the sewer system to 0.5 m. You can turn on the heating of the pipes as needed, that is, it is not necessary to constantly maintain one or another temperature. This is especially true for a property where residence is periodic.

There are two cable options. Conventional or resistive heats the line along its entire length with the same heat transfer. Self-regulating is more expensive, but quickly pays for itself due to work in areas with lower temperatures. The economic benefit here is lower energy consumption.

Self-regulating heating cable Source kanaliza.ru

Thermal insulation

This assumes the choice of insulation for outdoor use. The main thing is compliance with installation technologies. This is justified by the fact that the thermal insulation material may also need protection.

It is worth noting that the effect of insulating compounds is not aimed at warming the circuit, but at reducing the level of heat loss. Both above-ground elements of the pipe structure and those laid in the ground need this. In this case, heating the circuits with waste water works. Therefore, the event is held for sewerage, which is used constantly.

Ground channels that need to be insulated Source moikolodets.ru

How to insulate a cesspool

Most often, polystyrene is used to insulate cesspools. This is a material with excellent thermal insulation characteristics, it is resistant to microorganisms that live in the soil, and is not afraid of moisture and aggressive chemicals. In addition, polystyrene is a budget material.

Polystyrene for insulating a cesspool

Note! To make it more convenient to work, polystyrene is produced in the form of slabs and half-rings of different diameters and thicknesses, which greatly facilitates the thermal insulation of cesspools and sewer pipes.

With the help of polystyrene, you can quickly and efficiently solve the problem of how to insulate a cesspool. Thermal insulation is carried out in several stages.

- A trench should be dug around the cesspool, the depth of which should be at least 150 cm.

- Then the thermal insulation material is placed in the trench and secured using a tongue-and-groove mechanism.

- We dig a trench.

- We insulate the sewer cover using polystyrene boards.

Insulation of the drain pit using polystyrene

One of the most common technologies in the field of thermal insulation of a wide variety of objects is polystyrene insulation. This method is also suitable for a cesspool. It is especially convenient that today polystyrene can be purchased not only in the form of flat slabs, but also in the form of a “shell” - half rings. In addition, you can always choose the required thickness and diameter.

Insulation begins with surrounding the cesspool with a trench at least 1.5 meters deep. Then pre-prepared polystyrene half-rings are installed in this trench. The insulation is attached to the walls of the well using a tongue and groove mechanism, after which the trench is buried. The pit cover must also be carefully insulated.

A significant advantage of this method of insulation is that if you need to clean or repair the drainage pit, the polystyrene “shell” can be easily dismantled and, upon completion of all work, returned to its place.

How to insulate a cesspool in a private house?

A sewer system in the courtyard of a private house is a must, especially in cases where there is no central sewer system. The correct operation of the cesspool will depend on how you insulate the cesspool for the winter.

Are you wondering why you need to insulate your cesspool? The fact is that the upper part of the soil often freezes. The water in the pit is populated with bacteria that cause fermentation, so freezing does not occur. The upper part of the pit does not contain these bacteria, so these upper elements of the septic tank freeze, which disrupts the operation of the entire system.

Defrosting with current

When studying information about defrosting a cesspool, you can often come across the method of using electric current . It is effective, but at the same time quite complex and requires maximum caution from you.

Another problem with this technique is that it will only help when the drain pipe is frozen or a thin layer of ice has formed on the surface.

The safest thing is to purchase a special cable for defrosting pipes. It couldn't be easier to use. It is enough to simply wrap the drain pipe of the cesspool and plug the cable into the electrical network.

Considering that the dimensions of the drain pipe are usually quite impressive, defrosting using a cable will take a lot of your time. First of all, we will get rid of the problem in the pipe, and then we need to wait until the entire body of the pit warms up evenly and only then the ice crust subsides. The main thing is to ensure that the pipe does not overheat. This is especially dangerous for plastic products.

If you do not have a special cable, as well as the opportunity to purchase it, you will have to resort to improvised means. Just remember that this method is already more dangerous and requires you to have at least minimal knowledge of electricity.

You will need an iron pin and copper wires with a cross-section of 2 kW, as well as a small hook. The wire must be long enough. Carefully peel off the protective layer from both sides, so that the edge is enough to firmly wrap the pin and hook.

Then the pin is lowered into the hole and poured into the layer of ice. If you have a defrosted pipe and there is no way to immediately penetrate the container, you will have to first wrap the wire around the pipe and defrost it.

To turn on our primitive defrosting system, just throw a hook with a copper wire over the “phase”. Don't forget to wear special protective gloves before doing this. On average, the pit will defrost for 15–20 hours.

All this time you need to check how the process is going, because the method is still imperfect and quite dangerous .

Effective insulation of a cesspool in winter

How to insulate a cesspool in a private house? This question is asked by many people who have encountered this problem for the first time. After all, you need to insulate all its components, and not just the cesspool. The ideal option, of course, is to lay the sewer system pipes below the freezing level. But the problem is that this can be initially missed when constructing a sewer system. Therefore, we can say that this option is not suitable for everyone.

Undoubtedly, the pipeline can also be insulated, but there are many points that may not allow this to be done. For example, pipes may freeze at the entrance to the house or be located in parts of the building that are not heated. In such cases, an electric heater with a power of 10 W would be an excellent idea. The pipes are wrapped with the cable of this heater and the device is connected to electricity. This way we will warm up not only the pipe, but the water that flows in it. Believe me, this method will completely eliminate freezing of the cesspool.

But again, it should be noted that not everyone can afford this method. Firstly, you need to purchase the heater itself, and secondly, constant heating of the pipes draws a lot of electricity, which becomes more expensive every day. Therefore, let's look at other options for insulating a sewer pit:

- Plates made of durable foam plastic, which are 10 cm thick;

- Thermal insulating wool (mineral) with waterproofing;

- Polystyrene – has excellent thermal insulation;

- A layer of expanded clay, not exceeding 30 cm thick.

Let's talk more specifically about the more commonly used method of insulation - polystyrene.

Insulation of a septic tank

The water in the pit does not freeze because fermentation processes raise the temperature. But cooling the liquid on the surface inhibits the activity of bacteria that clean sewage. Therefore, it is still recommended to insulate . At least half the depth of soil freezing in the region.

The insulation can be expanded clay , which is covered with a layer 25-40 PSB-25 foam boards with a thickness of 5 to 10 centimeters.

Expanded polystyrene has good thermal insulation properties. Here is our material about it - technical characteristics of PSB S 35 thermal insulation.

Pit insulation with polystyrene

A cesspool in winter requires special attention, everyone has already understood this. To insulate it, experienced specialists most often use a material such as polystyrene. It is the cheapest option for insulation, and besides, it is not afraid of getting wet and is resistant to bacteria that live in the soil.

It is necessary to draw your attention to the fact that this material began to be produced not only in layers, but also in half rings, moreover, of different sizes and diameters. This greatly simplified the work of insulating the cesspool. What are the stages of insulation:

- No less than 1.5 meters deep, we need to dig a trench around our hole.

- We place the polystyrene half rings in the trench and bury it.

- We insulate the top of the sewer using layers of polystyrene.

Please note that in addition to the fact that this method is easy to do yourself, saving not only on material, there is another advantage - ease of dismantling. This means that if you need to repair or clean the cesspool, the polystyrene half-rings can be easily removed and then placed back.

Stages of insulation

For work on digging a trench, laying and insulating external sewerage, you will need:

- Bayonet and shovel shovels;

- Cord, pegs, building level;

- Scotch tape, silicone sealant;

- Sewer pipes;

- Insulation.

Installation and insulation of the sewer pipeline is carried out as follows:

- Using pegs and a cord, mark the area for the trench. The fewer twists and turns, the better.

- A ditch is being dug. With a standard pipe cross-section of 110 mm and the width should be 60 cm. The depth of the ditch is selected depending on the region of residence, the condition of the soil and the thickness of the insulation. To the selected size you need to add another 10 cm for a shock-absorbing layer of sand. You also need to take into account that the slope of the main should be 2 - 3° in the direction from the house to the drainage pit, that is, 2 - 3 cm for every meter of pipe.

- While digging a trench, you may stumble upon the roots of nearby trees. They must be left intact to preserve the vegetation.

- Sand is poured into a layer of 10–15 cm at the bottom of the ditch, moistened and compacted thoroughly.

- The pipes are lowered into the trench and connected to each other through sockets or using connecting elements. To make the connection airtight, sealing cuffs and silicone are used. If the pipeline is long, inspection wells are installed every 12 m.

- After laying the entire line, insulation is put on the pipes and loosely fixed with tape or metal clamps. It is important that the heat-insulating material is tightly secured to the pipe and does not move to the side.

- The pipes with insulation are covered with sand on top, compacted only on the sides of the communications. It is not sealed over the pipes so as not to damage the insulation.

- The remaining depressions are filled with soil, and it is placed in a mound, taking into account further shrinkage of the soil.

It is important! When using bulk insulation, you need to choose the middle fraction. In this case, thermal insulation will be most effective.

Fighting siltation

The most common cause of malfunction of the cesspool system is siltation of the sewage pit. This is a completely natural and inevitable process. Signs of siltation at the bottom of the waste tank:

- The pit began to fill with waste faster. During siltation, a certain part of the bottom is covered with solid and mixed sediments, which affects the volume of runoff. Accordingly, it does not fulfill its functions of collecting a certain amount of waste and overflows;

Example of siltation

- Unpleasant smell. It is believed that the characteristic aroma always comes from the sewer, but this is not so. If the cesspool is properly equipped (it has a ventilation outlet and a sealed lid), then there should be no such problems. the stench accompanies the process of siltation;

- Precipitation is visible to the naked eye. Rare cleaning, pouring all possible waste into the pit (including soap residue from a shower or household appliances) causes the formation of growths on the walls and bottom. This, as well as natural siltation, negatively affects functionality, reducing the volume of drainage.

You can get rid of sludge with your own hands or by calling specialists. The easiest way is to drain the cesspool by pouring the wastewater into another place, clean it and complete the maintenance by filling it with clean water. This method is very easy to implement and, when done correctly, gives very tangible results.

Photo: cleaning a plastic tank with vacuum cleaners

Elimination of unpleasant odor

The stench accompanies almost all street toilets and cesspools. If ventilation is connected, the unpleasant odor spreads less throughout the area, but does not disappear. To combat this nuisance, you must first clear the drain of sludge, which is the main cause of the stench, and then carry out preventive work.

- Good reviews about microbiological means for cleaning wastewater tanks. They not only effectively combat sludge and solid parts, but also completely eliminate odor. This option is not suitable for cleaning pits with soapy or chlorinated wastewater;

Microbiological odor control agent

Video on the topic: