The principle of measuring wastewater flow in an open channel.

Fluid flow (Q) measurement in a pipeline or channel cannot be performed directly.

To calculate it, the formula Q=Ṽ*A is used, where A is the cross-sectional area of the flow, and Ṽ is its average speed. In this case, the main and difficult task is the correct determination of the average speed Ṽ, since the cross-sectional area A is determined based on the shape of the channel (which can be taken from construction documentation, or measured when creating a metering unit) and the flow level, the measurement of which can be carried out in various ways and , as a rule, does not pose a problem.

Lever-pendulum water meters

This water volume meter is used to measure the amount of wastewater discharged for metering in closed and open canals. The basis for determining the amount of liquid waste using this meter is taking into account 2 main parameters - the liquid level and the average flow rate.

The mechanism of action is based on the operation of a lever-float device, which shows changes in the level of water flow. The wastewater metering unit shows the amount of pure liquid and water with the presence of impurities.

Selecting the type of flow meter for a wastewater metering unit.

To determine the applicability of the above systems in certain conditions, we will consider their main advantages and disadvantages.

(1) Radar non-contact waste flow meters

The main advantage: simplicity and ease of installation and maintenance, which are determined by the fact that the non-contact sensor is located above the surface of the water and does not come into contact with the drain. The device measures the speed of surface runoff, which is a significant advantage compared to just a level gauge.

However, the low distribution of these systems today both in Europe and in Russia, as well as a sufficient number of negative reviews, suggests that they also have disadvantages. The main disadvantage is the very high error in flow measurement, reaching up to 30% and even 50%. The large error is determined by the strong dependence of this measurement method on the state of the flow surface (from waves and ripples), as well as the lack of an unambiguous connection between the measured speed on the surface and the average speed, which determines the volumetric flow rate of the liquid. It is recommended to use radar flow meters only in cases where it is completely impossible to install more accurate (submersible) devices - Doppler or cross-correlation. In addition, radar flow meters are quite expensive today, and their use at commercial water metering sites with low flow rates is impractical.

(2) Flow meters for gravity channels based on level meters

In addition to the above-described disadvantages inherent in radar non-contact systems, when using level meters to determine flow, the problem of a complete lack of information about the flow rate is added.

Such devices can operate relatively adequately in the absence of backups. But guaranteeing the absence of backups is very problematic. If they are not even present at the time of installation of the equipment, they may appear unpredictably over time. Any incipient blockage or foreign object in the channel leads to the appearance of backwater. If a pipe from an enterprise discharges wastewater into the city sewer, and the collector operates in high-fill mode, backwater also occurs. In the presence of backwater, the error of this measurement method can reach hundreds of percent. If the water in the collector is stationary and the level remains high due to backwater, the error tends to infinity.

In addition, the use of ultrasonic level meters is impossible in the presence of foam, steam, fog, intense precipitation, large waves, etc.

The undoubted advantage of flow measurement systems based on level gauges is their low cost, as well as ease of installation and maintenance. It is recommended to use this method either for technological (non-commercial) needs, or for commercial metering on pipes and channels with low flow rates, when even a large instrument error does not lead to large financial losses.

(3) Doppler wastewater flowmeters

Submersible Doppler flow meters measure the speed of particles in a flow based on the Doppler effect (measuring the difference in frequencies of the emitted ultrasonic signal and the signal reflected from the moving particle).

The problem is that particles move at different speeds in different layers of the flow. Closer to the bottom or walls, particles move slower, closer to the surface - faster, on the surface again slower. The distribution of velocities depends on many factors, including the size and nature of bottom sediments, the roughness of the walls, the nature, speed and level of the flow, etc.

| Normal diagram of velocity distribution by flow levels | Velocity plot at the beginning of the rain | Velocity diagram for large bottom sediments |

Doppler sensors are unable to determine at what level the particles they measure are moving at. The average speed in this case is determined as the product of the measured speed and the calibration factor “K”.

Ṽ=Viz*K

In this case, the calibration coefficient is usually selected from tables depending on the material of the walls of the pipeline or channel, the time since the start of operation of the channel, etc. In this case, an essential assumption is already used. Or the coefficient is determined during the calibration process during installation. But, in this case, it must be borne in mind that the actual dependence of the average speed on the measured one is a nonlinear function of the speed and level, i.e. calibration performed with one hydraulic characteristics will not be correct with other characteristics. In addition, the readings of Doppler flow meters are strongly influenced by the level of pollution of the runoff (the number of suspended particles per unit volume). The Doppler measurement method provides significantly more accurate results than the use of level meters or non-contact radar flow meters, but its error in some cases can be 20-25%, with strict compliance with all the requirements of the operating manual (which is confirmed by a number of comparative tests). However, in some cases, depending on the specific hydraulic conditions, Doppler flow meters can provide good accuracy (2-5%).

(4) The use of electromagnetic and ultrasonic flow meters when converting free flow into pressure flow.

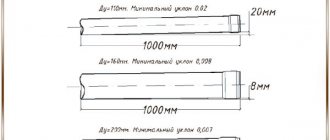

Converting the non-pressure operating mode of a pipeline to pressure mode is a fairly simple and beautiful solution for small-diameter pipes.

After installing a section of pipe bent upward in the well of a free-flow pipeline, the pipeline is completely filled and switches to pressure mode. Measuring flow in a pressure pipeline is a simpler and more mature task. This can be done with both ultrasonic sensors and electromagnetic flow meters, the error of which can be 0.5-1.0%. However, in some cases, with dirty drainage, blockages can form in the place where the pipe bends upward - as a result, the error due to deposits increases (in proportion to the growth of deposits) and after some time the unit becomes inoperable. Daily cleaning of the pipe at the metering point is unlikely to be acceptable to the user. In addition, this method is difficult to implement and quite expensive in large diameter pipes. It is usually used in pipes with a diameter of less than 300 mm.

(5) Cross-correlation metering devices

The cross-correlation method was developed and patented by Nivus GmbH in 2000. This method is sometimes confused with the Doppler method, although it is not directly related to it. The cross-correlation method does not analyze the change in signal frequency when reflected from moving particles, but compares ultrasonic photographs obtained with a frequency of 500 to 2000 units per second.

Based on comparisons of these ultrasonic photographs, the movement of particles in each layer of the flow per unit time is determined, i.e. the speed of movement of all layers of the flow is determined. In this way, the average velocity is accurately calculated from the obtained direct velocity measurements across the flow layers. In this case, neither preliminary calibration nor taking into account the wall roughness by entering tabular (theoretical) coefficients is required.

(6) Time-pulse flowmeters

This type of flowmeter is intended primarily for measurements in relatively clean flows, since the accuracy of their readings strongly depends on the homogeneity of the medium. This type of device is often used to measure the flow of clean drinking water or at water intakes. In terms of wastewater, they are usually used in the discharge channels of cooling circuits of industrial enterprises, as well as for purified water at the outlet of treatment facilities. Their advantage is the ability to measure very wide channels - up to 100 meters or more. Time-pulse flowmeters are produced with mortise or clamp-on sensors for pressure pipes, and for free-flow pipes - in the form of pipe or wedge-shaped sensors, or hemispheres.

Electromagnetic devices

These are flow meters with minimal electrical conductivity, which are used to determine the volume of water (wastewater) in 2 directions. Their work is based on the interaction of an artificially created electromagnetic field with a moving fluid flow. In this case, the liquid must be electrically conductive. The electromotive force, which is directly proportional to the flow speed, is converted into a digital signal. These are the counter indicators.

Operating principle of an electromagnetic wastewater meter

This type of flowmeter is widely used in industry. The main advantages are the absence of vibrations and pressure losses, ease of installation and maintenance, and ease of control. High reliability and stability of measurements allow you to take the most accurate readings on sewer water flow.

Installation of submersible sensors for wastewater metering devices

If everything is quite clear with the installation of non-contact level sensors and radar flow meters (ease of installation is their main advantage, to the detriment of measurement accuracy), then the installation of submersible sensors often requires special technical solutions. In gravity pipes with a diameter of 200-800 mm, Doppler and cross-correlation sensors are installed, as a rule, on a spacer mounting ring, which ensures minimal installation time with reliable fixation.

In pipes with a diameter of over 800 mm, a plate with a sensor is attached to the pipeline wall. When installing in particularly dirty water, such as industrial or sewerage, you need to carefully monitor the laying and fixation of the cable, especially in the lower part of the pipe. In addition to the fact that a poorly fixed cable leads to the accumulation of hair, dirt and rags on it (with the possibility of subsequent clogging or tearing of the entire structure by the flow), it can dangle under the influence of the flow and fray when rubbing against the fastening structure. When attaching metal plates to the wall of a large-diameter pipe with screws, even the shape of the head of the fixing screws and many other technological details are of great importance.

A serious problem is the installation of submersible sensors in deep flows, especially when the flow speed is high and it is impossible to temporarily stop the flow. For this purpose, diving work or work at a minimum flow level (at night, etc.) can be used. However, there are also special technical solutions that make it possible not only to lower sensors into a deep stream, but also to remove them from there without the help of divers for verification and maintenance. The figures below show options for mounting sensors on metal structures that can be lowered into and removed from the channel.

In addition, sensors can be installed upside down on floats. This not only makes it easier to install sensors in deep channels, but also makes it possible to make accurate calculations with variable bottom sediments (in cases where bottom sediments depend on the amount of precipitation, for example), since the ultrasonic level sensor built into the sensor will measure the flow level from the surface to the actual bottom surface with sediments.

We can also mention the additional capabilities of cross-correlation flowmeters for measuring wide flows. This type of flowmeter allows you to connect several velocity sensors to the computer, located at the bottom of the channel, or at the bottom and on the walls of the channel and, due to this, obtain a velocity diagram not only along the flow depth, but also along the width. This ensures high measurement accuracy in wide channels.

Vortex devices

The principle of measuring indicators using a vortex flow meter is based on measuring the frequency of pressure oscillations. In general, these are universal instruments suitable for measuring the flow of liquids and gases. The exception is pipes with small and large diameters, as well as environments with a wide range of temperature differences and high pressure.

Vortex flow meter

Among the vortex devices for measuring wastewater flow parameters, there are several manufacturers that have proven themselves to be the most reliable and professional. These include devices of domestic brands Vzlet, Irvis, Emis and other companies.

Now let's look at the advantages and disadvantages of this type of water meters.

| Advantages | Flaws |

| Accuracy of measurements. Stability of readings. Easy to use and reliable. Lack of sensitivity to pollution. Operation of the device in a wide range of conditions, including temperature, pressure, pipe diameter. Suitable for any liquid medium. No moving elements. | Sensitivity to interference that may be produced by pumps and other units (sound, vibration, noise). Pressure loss up to 45 kPa. Inability to operate at low flow rates. Not suitable for pipes with a diameter less than 150 mm and more than 300 mm. |

Vortex flowmeters are averaged versions of measuring devices in terms of technical parameters, designed for industrial-scale liquid flow rates. They operate in conditions up to 500 C and 30 MPa. This is one of the most suitable types of water meter for large enterprises.

Possible problems when using wastewater meters with submersible sensors

The most serious problem when using submersible sensors is the possibility of them losing their functionality as a result of contamination when working in a dirty sewer, or destruction due to the presence of rolling stones and other heavy objects in the flow. At the same time, Vodokanals of Russia take this problem especially seriously, because they consider sewer pipes in our country to be the dirtiest. But it is not so. Immersion sensors are used all over the world, not only in well-maintained pipes in Germany and Switzerland, but also in India and other countries where sewage systems are no cleaner than domestic ones.

The ultrasonic sensors used are specially designed for difficult working conditions and do not lose their functionality when silting occurs, since wet sludge transmits ultrasound well.

When covering the sensors with a layer of rags or material that is opaque to ultrasound, flow meters from leading manufacturers do not give incorrect readings, but signal an error and the need for cleaning. To reduce the likelihood of clogging, the sensors are usually installed not at the bottom (not at 6 o'clock), but with some offset (for example, at 4 o'clock or 5 o'clock).

Installation on a small elevation (on a special stand) and a number of other methods are also used to minimize problems caused by dirt.

To protect against rolling stones and other solid objects that can break the sensor body, specially shaped metal protection is used.

Another problematic task is measurement in flows that have a low level at some points in time. This results in water not covering the sensor and preventing speed measurements. The possibility of converting a free-flow flow into a pressure flow through the use of a pipe bent upward has already been described above. Small dams can also be used to raise the level. In this case, the flow remains free-flowing, but the level rises.

Possible reasons for inaccurate measurements

Sometimes the sewer meter gives questionable data. From the owner's point of view, his testimony may appear excessively high. The main reasons for data distortion are:

- liquid back-up in the pipe;

- the appearance of blockages.

First of all, you need to inspect and clean the collector. Sometimes the cause of data distortion is layers of dirt on the device body. Backwaters occur due to the following reasons:

- the appearance of obstacles ahead along the fluid;

- presence of debris and objects in the liquid;

- negative pipe slope;

- Incorrect insertion of the collector into the main line.

Sometimes the cause of inaccuracies is a change in pipe diameter. It is caused by siltation, the causes of which are:

- slope too small;

- the presence of sand and small particles in the water;

- destruction of the pipe walls, as a result of which soil and water enter it.

Silted areas must be identified and cleared. This will allow you to restore the calculated cross-section of the pipes and ensure the accuracy of the meter readings.

Review of the most popular models and manufacturers.

Among the flow meters certified and used in Russia, the following manufacturers can be noted: Cross-correlation devices are supplied by Nivus GmbH.

Doppler flowmeters are supplied by several foreign and a number of domestic companies; among foreign ones we can mention Nivus (OCM-F), ISCO, ADS, Hydreka (Mainstream); Domestic and Dnepr do not yet particularly recommend purchasing their Doppler flow meters, while to measure flow in open channels they recommend installing more conventional level meters from their production.

Radar non-contact flow meters with the function of measuring surface runoff velocity are offered by Nivus (OFR), FlowTronic (RavenEye), Hach (Flo-Dar). ISCO offers a non-contact laser flow meter.

Devices for converting gravity flow to pressure flow are offered by Nivus (Profiler), Flow-Tronic (Sewer Mag) and the domestic manufacturer Enrima (Stockmer). Time-pulse flowmeters for channels are offered by Nivus, Accusonic and Seba Hydrometrie.

Among the level gauges with a flow measurement function, the most popular manufacturers are Signur (Echo-R), Vzlet (RSL), Dnepr and many others. You can pay attention to the completely autonomous SonicSens level meters, which operate on batteries for three to five years and transmit information about the level and flow rate via GSM wireless communication channels.

Prices

Sewage flow meters can be purchased both in large specialized stores and in online stores.

Cost of sewer meters from different companies:

- “RSL Takeoff” - 74 thousand rubles.

- “Dnepr 7.01.11-1” - 44 thousand rubles.

- “ECHO-R-02” (ultrasonic) - 45 thousand rubles.

- AKRON-01 (ultrasonic, portable) - 41 thousand rubles.

You must choose a certified product, otherwise you will not be able to register the meter.

Flow meters are in demand. They are used in sewerage systems that operate in a non-pressure manner.

Prices for flow meters for wastewater.

Cross-correlation wastewater meters are the most accurate, reliable and stable flow meters available on the market today. But their price is higher than that of Doppler flow meters and, especially, level meters. If you are dealing with a small pipe, with a small flow, and if the annual water payments for this metering unit are significantly lower than the cost of a high-quality flow meter, then it may be more profitable for you to use a cheaper (albeit less accurate) system - a level meter or Doppler. At the same time, it is interesting that Nivus keeps quite reasonable prices for Doppler wastewater flowmeters, lower than most import suppliers, due to the fact that Nivus places the main emphasis on the most reliable cross-correlation systems. As for high-flow channels, the cross-correlation method is currently the best for them.

Today there is a fairly large selection of wastewater metering devices that differ in price and quality. And if you are faced with the task of buying a meter for non-pressure industrial, household or storm sewerage, or pipes and channels for water intake and spillway, then you can choose your own option for each application. At the same time, it is better to entrust the installation of wastewater metering units to specialists, since the accuracy of the readings and the duration of their operation largely depend on the correct installation of the devices.

- Sewage meter

Why and in what cases is it needed?

When calculating the volume of wastewater, its quantity is equated to cubic meters of water consumed. Theoretically, it is believed that as much liquid enters the house, so much goes out .

But this is a very conditional calculation. And in relation to private households connected to the central sewerage system, this is fundamentally wrong.

The water is used for watering the garden, washing cars and other needs, and does not end up in the drainage system.

Metering devices will allow you to pay for the real, rather than theoretical, volume of wastewater. Savings when installing a metering device reaches 500 liters per week .

This is a preliminary estimate; in reality, this figure is much higher. Owners of autonomous sewer systems that are not connected to public lines do not need to install meters. Apartment owners in apartment buildings do not have the opportunity to install wastewater flow meters, since there is simply nowhere to install them.

Therefore, at present, only common house metering devices are beginning to be installed.

Installation Features

Installation diagram example

To obtain the most accurate readings, you should follow the rules for installing meters.

- The legislation allows the installation of devices only on long, straight sections of pipelines.

- Installation of the device in non-pressure pipelines must be carried out in low-lying areas. In this case, they do not place a flow meter at the bottom of the pipeline if its effluents are discharged from a height at this point and first enter the atmosphere.

When installing a meter on a free-flow gravity sewer, it is important to remember that the fullness of the pipe and the flow rate here are constantly changing.

Possible errors in calculations

There are often cases when the installed mechanism shows several times less or more amount of water being discharged than is supplied to the facility. A priori this cannot be. Therefore, it is worth looking for the reasons for the inaccuracies.

- Incorrect location of the flow meter in the manifold - its installation without taking into account third-party taps into the main line. The equipment is located after the location of another outlet for discharging wastewater into the general network.

- Destruction in the pipeline in front of the flow meter location. As a result, groundwater enters the collector unit, which increases the volume of waste.

- Incorrect determination of the water balance for the facility. For example, a master can only calculate the ratio of incoming cold water and wastewater generation. But they also include DHW resources.

- Malfunctions in the operation of the equipment itself (sensors, levers, blades, coils).

To avoid serious errors in the readings of the meter, its installation must be carried out in strict compliance with the above rules.

Ultrasonic meters

Ultrasonic

high-precision instruments designed to measure the amount of liquid sewage. Measurements are made using area-velocity sensors, which are easily installed in the collector. They are used in open channels, gravity systems, non-pressure pipelines, and in the industrial field for commercial accounting. When equipment is equipped with hydrostatic sensors, in addition to monitoring discharge volumes, the filling of the sewer network is monitored.

Installation is carried out inside the pipeline or channels without additional construction work.

The operation of ultrasonic sensors is based on measuring the difference in the travel time of ultrasonic vibration pulses in the direction of fluid flow and against it. Sensors (piezoelectric transducers) are installed at the measuring section, which initiate the excitation of these pulses.

Operating principle of an ultrasonic meter

The ultrasonic sensor is installed at an angle relative to the flow cross-section. Velocity can be measured using one or two beams of ultrasonic vibrations. The sensors work alternately, first as an emitter, then as a receiver. The movement of the fluid causes a change in the time of complete propagation of signals along and against the flow. Based on the received signals, the speed and volume of wastewater in the pipeline is determined.

The advantages of devices of this type lie in their versatility, the ability to be installed in pipelines of any geometry with a diameter of up to 9 m. Measurements take place in any direction of flow. The construction of additional wells or measuring chambers is not required to install the device.

The disadvantages of the devices include the need to constantly clean the sensors. The heterogeneity of the effluent, the presence of bubbles, and suspended matter reduce the reliability of the indicators. The measurement error reaches 5%.

How to choose a waste meter

When choosing a meter, you need to take into account the characteristics of drains and pipes, the type of drainage system

Basic criteria for purchasing a flow meter:

- maximum temperature indicators of wastewater;

- type of measured liquids (clean or dirty water);

- waste flow range for a specific device model;

- cross-section of a pipe or channel;

- the material from which the highway is made;

- maximum permissible operating pressure in the manifold;

- possibility to narrow the pipe.

Experts also advise listening to the following recommendations:

- It is better to install electromagnetic or ultrasonic meters for wastewater. For clean water - lever-pendulum.

- When installing an ultrasonic device, a long straight section of the pipeline is required. You need to remember this when purchasing equipment.

- It is advisable to abandon the ultrasonic meter with overhead sensors. They are less demanding to install, but at the same time they are characterized by low accuracy of readings.

- For pressure systems, it is better to choose electromagnetic meters.

Using these recommendations, the technician can purchase and install the optimal flow meter for his conditions.