Types of toilet valves

The inlet valve (also known as filler, filling or filling) serves to supply water and stop filling when it reaches the limiter. The outlet valve (aka drain) takes on the functions of flushing water, adjusting the volume and flow rate.

Each inlet valve for a toilet cistern must have a shut-off device to shut off the water. The design of some fill valves for toilets with bottom connections includes a check valve that prevents water from the tank from entering the water supply system when the water supply is turned off.

All inlet and outlet valves for the toilet, in turn, are divided into different types, according to material and design features. Since sanitary fittings are constantly being improved, models with completely new characteristics appear, the information and classification below should be considered approximate.

Valves classification

By material

Inlet and drain valves are made from the following materials:

- entirely made of plastic;

- mainly made of plastic with individual elements made of steel or brass (fitting thread, rocker arm and other parts).

In terms of reliability, modern models for flush tanks with plastic threads, supplied to the market by well-known manufacturers, are not inferior to metal ones.

Gaskets and membranes are made of rubber or silicone; the latter look preferable because they do not lose elasticity.

By location

The following installation options for toilet filler valves are possible:

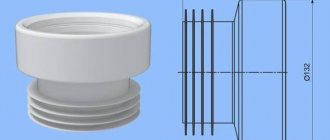

- with bottom water supply – attached to the bottom of the cistern;

- with side connection – attached to the side wall of the tank;

- 2 in 1 – the valve has a removable fitting attached from the bottom or side; it can be attached to the bottom and side wall.

By type of design

Types of toilet fill valves:

- with a side connection and a conventional float on a long metal rocker, the design is familiar from Soviet toilets; with valves of a later time, the filling goes through a tube to reduce noise;

- with a bottom water supply and a float on a long rocker, is a modernized version of the previous model, rare;

- with a side connection and a vertical stand along which the float moves;

- with bottom water supply and vertical stand for float;

- the previous version, supplemented with a check valve.

Features of toilet hoses

Toilet liner

The water supply to the toilet is selected based on the plumbing model. Manufacturers offer options for tanks that differ in size, installation methods and connection to the water supply.

Types of eyeliners

The type of toilet line depends on the size of the toilet, the distance of the water supply pipes, and the type of tank:

- Rigid - tube made of stainless steel, brass, copper. The service life reaches 20 years. The absence of adapters makes installation of the system simple. When purchasing, the type of thread is taken into account.

- Flexible - reinforced hose, bellows tube. Service life from 1 year. Convenient to install in any location of plumbing fixtures.

A rigid product is used infrequently. Mostly in old houses. In new buildings they are connected using flexible hoses.

Popular lines of flexible tubing are made from rubber. Bellows products are made of stainless steel. Resistance to temperature changes, flexibility, and wear resistance make them in demand in the plumbing market.

Parts manufactured using foreign technologies are durable. Products from the German brand Hydraflex are durable and functional. Products of the Italian company PARIGI have good technical qualities. Also, the Turkish plumbing company AYVAZ produces reliable pipes and fittings.

Types of float valves

Float valves for toilets are divided according to the type of locking mechanism into the following types:

- piston;

- membrane

In a piston device, a floating float, when rising, presses on a piston moving towards the flow of water until it rests against the saddle. Piston locking mechanisms are already outdated; they do not have any unique design features.

The disadvantages of such devices include noise during filling and the constant sound of falling drops due to the loss of tight pressure to the inlet over time.

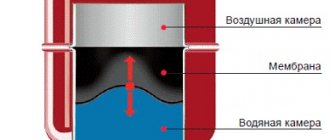

The membrane locking mechanism is activated by the action of the pusher on the rubber or silicone membrane. Among the advantages of membrane devices are fast water collection, less noise, and constant flow intensity. Disadvantage: good constant water pressure is required.

Modern diaphragm valves

Most modern inlet valves for the flush tank are diaphragm devices. After draining, the membrane with the pusher moves away under the pressure of the incoming flow, allowing water to flow into the tank.

Comparison of both types and their disadvantages

Which locking device for the toilet cistern should you prefer - with top or bottom connection? The first design has been in use for a long time. Its advantages are ease of installation and maintenance. The following are considered disadvantages:

- Increased noise when filling the tank .

Typically a soft polymer filling tube is used to reduce noise. But over time, it can fall off the pipe, leading to increased noise in the water intake. In addition, a disconnected filler tube may well get between the bulb and the drain hole, preventing it from closing and leading to a constant leakage (and therefore inflow) of water. - When using a design with a rod valve that gradually blocks the flow of water into the tank, filling to the maximum level can occur within several minutes , which is not always convenient, especially when installed in the toilet of a public office building.

- Another nuisance characteristic of fittings with a top connection and a horizontal arrangement of the control element is its displacement or detachment from the rod during operation , which will require intervention in the system.

The operation of a toilet, the tank of which is connected to the water supply system from below, also has some nuances:

- Inconvenient installation and repair . The lower connection, although more aesthetically pleasing, is less conspicuous, but leads to cramped conditions when installing it and repairing the toilet cistern.

- The membrane valve requires high quality water used , that is, the connection to the system must be made after the water filter. Otherwise, the valve will often become clogged, stopping the flow of liquid into the tank.

- At the connection point of the fittings, water leakage is possible , which occurs due to insufficiently reliable fastening of the fixing nut or a violation of the properties of the rubber gasket.

A common “disease” of any type of locking mechanism is a violation of the tightness of the float, which will lead to its flooding, therefore, water will constantly flow into the tank and go into the sewer through the safety overflow tube.

Therefore, it is better to give preference to foam modifications. To summarize, we can say: if all installation rules are followed and a water filter is used, fittings with a bottom connection type are more reliable in operation and comfortable , creating a minimum of noise when filling the tank. But, on the other hand, designs with top connections are cheaper and easier to repair yourself.

Working principle of drain and fill valve

The general scheme of operation of plumbing fittings for a flush tank includes three stages: automatic water supply – overflow protection – draining.

The actuation mechanism of the fill valve is as follows:

- When water is collected after flushing, the float gradually floats up and moves the lever, which actuates the pusher or piston of the locking device.

- When the maximum filling level of the drain tank is reached, which is regulated by setting the float, the inlet hole is closed.

- The water supply to the toilet cistern stops.

The principle of operation of the drainage device is simple - when you operate a lever, button or handle pull, the rod closing the drain hole rises and the water is drained.

Another function of the flush mechanism is to protect against overfilling of the cistern in the event of improper adjustment of the toilet inlet valve or failure of the shut-off device. For this purpose, the drain valve design provides a special overflow pipe.

The upper end of the pipe is below the edge of the tank, and the lower end is aimed at the drain hole. When the water level in the tank exceeds the upper section of the pipe, excess liquid is drained into the toilet. In some models, the overflow pipe is mounted separately from the rest of the drainage device, but the safety drain mechanism is the same.

When installing and adjusting plumbing fixtures, the upper section of the overflow pipe is installed so that it is located on the same level with the upper plane of the float and at least 10 mm below the hole for the side supply, as well as the air inlet holes, if any.

Reinforcement selection criteria

Replacement of toilet fittings is required when malfunctions in the operation of the system are detected. In order for a new device to serve for a long time, when choosing, you should be guided by the following aspects:

- the fittings can be made of plastic or brass. Brass products can last longer than plastic ones;

Types of reinforcement depending on the material used for manufacturing

- If you purchase plastic bottom or side fittings for a toilet, then you need to check the quality of the components. Plastic components must be smooth, free from burrs and deformation;

- It is more advisable to purchase plastic fittings made of polypropylene or low-density polyethylene. Such devices are considered the most reliable;

- The gaskets used for assembly should be as soft to the touch as possible. If you slightly stretch the sealing element, then no cracks should be visible on it. This aspect indicates the quality of the gaskets and the correctness of their manufacture. All gaskets must be of the correct shape;

Sealing elements for fittings

- The fastening elements of the fittings can be made of plastic or bronze. Metal fasteners are more durable during installation. There should be at least two gaskets on the fasteners;

Set of elements for fastening fittings

- the movement of the float valve must be smooth. Sudden jumps or jamming are not allowed;

- the prefabricated structure must be durable. All elements must be securely fastened to each other. If a separate component part has free movement, the valve will quickly fail.

If, when choosing fittings for the cistern, one or more of the above conditions are not met, then it is more advisable to select another set.

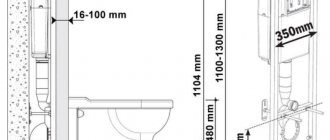

Installation of valves for a toilet with bottom supply

The list of components and parts of the valve device for a toilet cistern with a bottom connection includes:

- float;

- craving;

- rocker arm;

- rocker axis;

- float stand;

- stand extension;

- return element;

- pusher;

- membrane;

- two-piece body with nozzle and thread;

- filter;

- conical gasket;

- swashplate;

- nut for fitting.

The extension is used to extend the float stand when installing a filler valve with a bottom connection, if the toilet tank is very high and it is necessary to raise the filling level. The return element changes the movement of the incoming water flow from top to bottom, thereby reducing noise.

The mechanism of some models, mounted in a drain tank with a bottom connection, is equipped, in addition to a shut-off valve, with a check valve. This additional unit prevents the contents from being discharged back into the water supply when the water supply is temporarily interrupted.

How does a drain tank with a side water supply work?

The design of a toilet cistern with a side flush is simple; once you understand its design, you can carry out repairs or replace the necessary spare parts yourself. It is closed with a lid, on top of which there is a flush button. To look inside, you must first remove the button and then the cover. This must be done very carefully, because all plumbing products are quite fragile.

Toilet and flush tank

Please note that the lid for the tank is sold only as a set; purchasing it separately will be very problematic! Therefore, if damaged, you will have to buy and install a new tank again, if not a new toilet.

This tank design has five holes. Two of them are necessary for water to be supplied to the container. There is also a water inlet system here, which consists of special fittings with a diaphragm valve. The principle of operation is quite simple - when the tank is emptied, the fittings activate the corresponding mechanisms, and the liquid begins to fill again. The design also includes a float, which is designed to regulate the level of water accumulation.

You know how much water you need to flush the entire contents of the toilet bowl. In order to achieve this level in the tank, simply set the float to the correct position. If you lower it down, there will be less water, but if, on the contrary, up, the amount of liquid will increase. The service life of all mechanisms directly depends on the quality of water, so water filters should be used. This will increase the lifespan of your cistern.

When installing the tank and toilet, do not forget to use rubber gaskets that will ensure the tightness of all connections. In the hole located on the side of the cistern there is a plug, which serves more of a decorative function. The advantage of this design is that the location of the filling fittings and plug can be replaced without much difficulty.

The holes located on the bottom of the tank are designed for attaching it to the toilet bowl. This happens, most often, with the help of metal bolts, which ensure the reliability of the structure. In addition to bolts, it is imperative to install them on washers and special cone-shaped gaskets, which are made of rubber.

Insert bolts with washers and spacers into the corresponding holes on the tank and on the bowl shelf, use a screwdriver and a wrench to do this. In the center of the drain container, in its lower part, there is another hole, the main purpose of which is to accommodate a system for draining water.

All fittings are attached to the tank using a union nut made of plastic. At this stage, it is also necessary to use sealing gaskets that will ensure the tightness of the connection. When you press the button, the water drains and the entire contents of the toilet bowl are flushed down the drain. This is how a toilet with a side flush is designed; knowing its design, you can repair it if necessary.

Maintenance of drain and inlet fittings

Water in domestic engineering networks often contains mechanical impurities (rust, sand, salt deposits), so many malfunctions occur due to clogged plumbing fixtures. For this reason, the vast majority of valve maintenance activities involve cleaning.

When servicing and carrying out preventive maintenance, special attention is paid to the filter, membrane, inlet nozzle of the filler valve, locking ring or bulb, and drain hole. It should be borne in mind that the filter is usually installed in Russian-made models; it is not always found in samples from foreign suppliers.

Another part of the problems is related to improper filling of the tank and leaks. The basis for eliminating these shortcomings is the connection and adjustment of components, the serviceability and tight pressure of the gaskets, and the tightening of the nuts to the end.

How to choose fittings for a toilet cistern

The main requirement for tank fittings is a long service life without repairs. When buying a toilet, you should look into the tank or ask the sales consultant to show the fittings separately.

Basic recommendations when buying a toilet

Experts advise adhering to the following rules:

- Do not choose complex mechanisms. They are more likely to malfunction and are not easy to repair. The design should be simple and extremely understandable.

- It is better to choose designs with fixation of the float and valve for dosing the liquid supply to the side wall. The lower supply is a weak point; leaks most often occur here.

- Choosing an exclusive fitting option is not a very good decision. A standard design is easier to repair; if necessary, it can simply be replaced.

- The quality of plastic parts is of great importance. The material must have sufficient strength, resistance to temperature fluctuations, and mechanical loads.

- You should pay attention to the brand. It happens that inexpensive models from an unknown manufacturer are defective.

Having chosen the compact version of the cistern, you should be prepared for the fact that difficulties may arise with replacing the fittings. Often imported membranes are not designed for water with aggressive impurities, which in real conditions leads to rapid wear.

Selection by design of drain fittings

Different models have different design of drain fittings. There are push-button options for complete drainage; some models are equipped with two drainage modes and a special function that allows you to interrupt the drainage of water.

A dual-mode button is an analogue of a key. In one of the positions it releases the liquid completely, in the other - only part. The interrupt function allows you to both block the drain and unblock it.

Reinforcement material

Most fittings are made of polymer materials. The properties of their constituent components determine the durability and quality of operation of the mechanism.

Metal reinforcement is the most durable and resistant to mechanical stress. Manufacturers use a one-piece version of such fittings exclusively in elite models. A separate system can be found in any toilet.

In modern models of flush cisterns, the durability of the fittings mainly depends on the service life of the rubber elements and on the influence of water of different hardness on them. Replacing these parts allows the valve to be used in the future.

Repair of toilet fittings

It is not uncommon for a cistern to break down. In this case, it is not necessary to call a plumber; after studying the principle of operation of the fittings, you can fix the malfunctions yourself.

Basic faults

The most common possible defects are:

- high water consumption;

- leak;

- weak drain;

- production of gaskets.

Insufficient drainage may occur as a result of obstruction of the drainage channel.

A leak can be explained by the addition of water through an overflow or wear of the float. In case of overflow, the fittings are set to moderate water consumption. To do this, bend the lever or adjust the fastening screw. In the second case, the float is made heavier by adding metal hangers or replacing it with a new one.

Troubleshooting an inlet valve

In this unit, a violation of the quality of locking is most often observed. This happens due to the activation of an elastic cuff or rubber stopper. For repairs, the exhaust valve must be removed. Before this, turn off the tap and drain the water from the tank. Next, unscrew the drain button, remove the cover, unscrew the union nut, through which the valve is attached to the bushing.

The valve has a small rocker arm on the reverse side; it is connected to a float lever or rod. This is where the problem with any type of valve lies. To troubleshoot the problem, take the following steps:

- The drive lever is disengaged from this rocker arm.

- The rocker itself is removed. Typically, it is secured to the valve body with a pair of pins.

- Check the condition of the plug pressed into a plastic cup located on the opposite side of the rocker. It is taken out and turned to the water supply spout with the flat side. If this has already been done, the cork is cut, resulting in two even ends. The halves are folded and pressed back into the glass.

Diaphragm-type valves lose their tightness when the rubber disc is deformed, which may also be caused by insufficient float pressure on the valve. In this case, adjust the glass, placing it lower. There is another option - a foam cube is connected to the float from below. When these actions do not give the desired result, the membrane is changed.

Troubleshooting a button

Jamming, unsatisfactory movement, or complete disobedience to the influence may occur in this node. In older models, the button worked by acting on the rack. The latter transmitted movement to a gear on which a long lever was attached. At the end of the lever there is a chain, through which the membrane is lifted. The problem was resolved by tightening the chain more tightly. The teeth on the rack could also work together. To eliminate the malfunction, it was turned with its back side.

Modern drain valves are equipped with a lever mechanism, which is more reliable. The only possible thing is that it is not centered correctly. To avoid this, the threads on the drain valve body are positioned exactly along the central axis of the hole. If this condition is violated, the upper thrust plate of the microlift is shifted in the desired direction.

The cause of such a problem is failure of water to enter the tank, debris in the valve section in the narrowest place. In this case, the tank should be emptied, and the valve, together with the float and lever, should be unscrewed. Then, using a needle, clear the narrow passage through which the liquid enters the tank.

The remaining debris is washed by first opening the valve of the inlet pipe. If water flows freely, the valve is closed and all elements are installed in place.

If you need to replace any part of the fittings, it is better to take the unusable element to the store. In this case, you can purchase a part completely identical to the broken one.