Recently we had a little trouble - the ball valve installed on the inlet to the heating tank jammed. We called a plumber, who repaired everything, and then gave valuable advice on how to resuscitate this part if the same thing happens to it again. To be honest, his recommendation already once helped us avoid calling a specialist and unnecessary waste of money.

A simple solution to the problem

We all know that after a certain time the taps begin to jam. It is enough not to turn the handle for 7-8 months, and problems will already arise. Salts dissolved in water become sour, and the parts of the water tap become rusty.

What do they usually do in such a situation? That's right, turn the valve with pliers. It seems that the more force you apply, the faster the faucet will give way. No. In practice, the handle most often breaks off. The last time I managed to completely tear off the tap. Therefore, when the next jam occurred, I decided to consult a plumber I knew. This is what he advised me:

To resuscitate a soggy faucet, you need to remove the handle. Under it there is a clamping nut that compresses the seal. It is necessary to loosen it a little and twist the rod in different directions (work it out).

Technique for restoring shut-off valve functionality

When planning to restore the functionality of a ball valve, you should ensure not only the availability of the necessary tools, but also good lighting.

When restoring the operation of the faucet, you should first unscrew the self-locking nut (in some cases you should simply unscrew the screw that holds the rotary handle). All this can be easily done using a size 8 or 10 spanner wrench, and an open-end wrench also helps in this matter (everything initially depends on the crane model).

Kuban resorts announced they expect a full recovery of tourist flows

Data does not indicate a new disease: what is known about “Disease X”

To prevent things from falling: the woman added a useful and stylish detail to the narrow shelves

Next, you need to carefully remove the faucet handle. This, as a rule, is not easy, only after its gradual rocking, accomplished by alternating pressure on one or the other side of the structure. In this case, it is important not to knock on it - this will lead to the integrity of the flags and their breakage.

Now you should select the most suitable key, and then try to turn it, alternately changing the direction: first you can try to do it clockwise, and then counterclockwise. When carrying out the described actions, it is important to monitor their amplitude - it should be low, because with great effort there is always a risk of breaking the rod or tearing off the edges.

As soon as movement is noticed, the amplitude of the movements and their scope can be increased. When performing this work, it is very important to ensure that one of your hands holds the head on the rod, and the other turns it.

Coronavirus will not retreat: Alexander Vasiliev on when quarantine will end

Fragrant chocolate cake with cream and soft sponge cake without butter

Second title - KdF-Wagen: Volkswagen celebrates 75 years of Beetle production

As soon as the rod moves as freely as possible, at this point you can put on the handle, and then secure it with a screw (or nut). Now you should continue the rocking process until the water supply is completely blocked.

How to twist and what to twist - detailed instructions

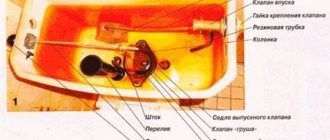

For those who are unfamiliar with the design of a ball valve, I suggest studying the drawing:

As can be seen in the diagram, a ball valve is an extremely simple design. The shutter ball blocks the flow of water, blocking the cross section. The rotation of the ball occurs due to the torsion of the rod, which is inserted into the groove. Nuts, bushings and seals prevent water leakage.

Thus, it becomes clear that the pen is the “tip of the iceberg”. Acidification occurs inside the structure. You need to disassemble it a little in order to act directly on the jammed elements. But it is important not to overdo it.

What to do if the tap is jammed (how to open or close):

- The first step is to remove the handle. Unscrew the fastening nut and remove the handle (butterfly) from the rod.

- We try to twist the rod with pliers. No need to use brute force. We twist it a little in different directions.

- If the rod does not fit, look for the clamping nut. In the picture it is number 3. We loosen it a little, literally half a turn, no more.

- After this, the oil seal will straighten a little, and water may begin to leak. It's not scary.

- We wrap the pliers around the rod again and slightly twist it in different directions.

- After a certain time it will begin to give in. I spent about 3 minutes developing it.

- Tighten the clamping nut back the same half turn. Screw on the handle.

- The tap can now be opened or closed. It will work as it should.

We recommend: Find out how to effectively clean a pipe using folk remedies

It’s worth warning right away: if the ball edge is cheap, Chinese (made of silumin, with a thin jacket), then attempts to develop it will lead to a flood. It will simply burst, and a stream of water will rush in all directions. It's not very pleasant, especially if it's a stream of hot water.

Instructions on how to open a jammed tap

There are no options that 100% guarantee the resuscitation of jammed taps. But you can try.

We invite you to try the most effective and proven way to turn the handle when you urgently need to shut off the flow of water:

- Try to design the valve by hand. Perform the operation with one hand as carefully as possible so as not to break the delicate mechanism. We strongly do not recommend using pliers or twisting the butterfly handle using excessive physical force;

- If you are unable to loosen the tap, unscrew the euro nut using a wrench (6 mm) or an adjustable wrench;

- Remove the pressure sleeve and butterfly valve, slightly loosening the part from side to side;

- Develop the rod using an adjustable wrench, being careful not to make sudden movements until you can turn the ball.

At the final stage, install the mechanism in the desired position, place the butterfly in its original place and do not forget to tighten the nut. If the ball valve is severely worn out and it is not possible to revive it, it is better to replace the device with a higher quality and reliable analogue. As practice shows, brass products from trusted brands do not jam even after decades.

If your water faucet is stuck, contact our plumbers! Call the phone number or leave a request on the website.

Lubricant to make the task easier

In case the parts are stuck tightly and do not want to turn, lubricant will come in handy. You need to lubricate the clamping nut with it and wait a couple of minutes. It is best to use special silicone grease for these purposes. If it is not there, you can use VD-40.

At the end I will add: before starting to “reanimate” the tap, it is better to turn off the water, if possible. When designing a crane, there is always a risk that it will permanently break. Personally, I do not recommend dealing with old, completely rusted taps, or with cheap Chinese ones. It is better to replace them immediately.

Why the ball valve does not turn and what to do in such a situation

Let's look at the problems one by one. Firstly, why is this happening. Secondly, what to do in such a situation. Thirdly, what to pay attention to in the future.

Why is this happening

A feature of the operation of a ball valve is that it must always be open or completely closed. It is not designed to regulate fluid flow.

Sectional view of ball valve

There are cases when the shutdown device is not fully open, or remains in the closed position for a long time. Then the entire ball or part of it has constant contact with water.

Over time, this leads to its damage due to the formation of salt deposits. Overlapping becomes impossible or difficult to achieve.

It often happens that the tap is left in the open position for a long time. Then the exit of the ball, when turning to the “closed” position, may encounter resistance from the same salt deposits.

They form on the inner surface of the product. This will also make it difficult to shut off the flow of water and lead to a situation where the ball valve does not turn.

Therefore, in order for it to work normally, it is necessary to periodically turn the handle - open/close. This will prevent the accumulation of harmful deposits. The surface of the ball will be cleaned and the disconnect device will perform its function normally.

Such actions must be performed at least once every three months. Do this even if there are no problems with the water supply.

Choosing a quality ball valve

If you are still not satisfied with the performance of the ball valve, you can purchase a new product. When choosing, pay attention to one simple rule: the more expensive the faucet, the better it is. Saving a few rubles can cost you. Good quality taps are produced in Germany and Italy, but, unfortunately, the domestic market is overflowing with Chinese products, which are made in a clumsy manner.

When purchasing a ball valve, pay attention to the pipe threads and their diameter. Metal pipes usually have diameters of half an inch, an inch and three-quarters of an inch, while plastic pipes have diameters of 16, 20, 26 and 32 millimeters. If you don’t know what diameter and thread the pipes in your home are, check this point with a specialist. We hope that with this knowledge you will be able to choose the right ball valve that will serve you for a long time.

Subject:

- Repair

- Adviсe

Where to start disassembling the crane?

As in the case of a worm valve, the water is also turned off before removing the ball valve. To avoid losing small parts, plug the drain hole in the sink with a plug. How to unscrew the faucet handle? First, use a screwdriver or other sharp object to remove the two-color plug. It is located below the handle. Then you will see a hole in the form of a narrow strip. There is a screw inside that needs to be unscrewed with a screwdriver. When repairing some models of ball valves, at this stage you cannot do without a hexagon.

After completing these steps, pull the handle up and remove it. It is possible that you will have to make an effort, since the handle is usually set very tightly.

The right approach and expert advice

First, let me emphasize that this article will consider household valves and other water supply control systems, which in most cases are used in an apartment or private house. Products that are used on a gas cylinder belong to a slightly different category. But some of the recommendations below may be useful for them as well.

Disassembly procedure

- For example, it is best to consider the design that is used in the kitchen . The fact is that it has more parts and in most cases is fixed using special fasteners. It can only be compared to a bathroom sink faucet, which is very similar in design.

- First of all, craftsmen advise removing the handles on the taps . To do this, on some models you will need to remove the decorative plugs, and on other systems you will need to remove the pin and remove the handle.

- Most of the manuals explaining how to unscrew a rusty faucet at the next stage advise using a special tool or wrapping it in rags . The fact is that if it comes off or accidentally hits the structure, it can cause important damage that spoils the appearance.

- Craftsmen who say that I can’t unscrew the valve axlebox are first advised to choose the right tool and try with the valve open . At the same time, there is no need to allow distortions or displacements. The tool must be firmly fixed to the surface of the part.

- The installation instructions recommend removing the faucet in the next step . But its chrome-plated nuts must be unscrewed extremely carefully so as not to damage the coating.

- The mixer itself is removed only after the water supply pipes have been disconnected from the system . Along with this, it is necessary to unscrew the fixing bolt or nut that holds the pressure plate. This must be done very carefully, because the price of the sink is quite high, and there is a high chance of accidentally damaging it during this work.

Advice! If the gasket on the axle box is being replaced, the part must be unscrewed very carefully so as not to loosen the mixer itself. In another case, you will need to change the rubber seal on the sink.

Problematic points

Most of the manuals explaining how to unscrew a stuck faucet are confident that such a problem can be solved quite simply and with the right approach it can be eliminated in a couple of minutes. To do this, it is enough to treat the joints with a special compound, and if necessary, it is poured into the cavity of the structure itself.

While it is impossible to remove the axle box if it is stuck, in most cases they look at the material of its manufacture. Along with this, if this part is made of simple metal, like the sink faucet itself, then experts advise making a complete replacement of the entire structure, because, most likely, this part cannot be unscrewed due to rust.

It is worth using different compounds on an axle box or tap, if it is stuck, only in those cases when it is impossible to mechanically unscrew the product. Along with this, if this happens systematically, then you need to think about the quality of the water used and buy a filter.

Advice! Various oils, acidic compounds and alkaline solutions are excellent for removing scale, but their effectiveness is highly questionable, especially if the density of the blockage is quite large.

Expert advice

- If the work is done with your own hands, then it is best to first familiarize yourself with the design of a specific crane model. In most cases, it is outlined in detail in the management that comes with it.

- It’s worth preparing all the necessary tools in advance, because similar work may require additional keys, screwdrivers, etc.

- It is worth emphasizing that virtually all designs of such products are of the same type, despite the fact that they can have a lot of differences. Based on this, the question of how to unscrew a dark tap in a gas boiler can also be attributed to this situation and similar control can be applied.

Types of taps

Ball valves are classified according to various parameters.

Depending on the application, there are shut-off valves, three-way valves and mixers.

Shut-off valves are installed in the pipeline gap and serve to shut off or regulate the pressure.

Three-way valves are used in heating systems; they are designed to redirect the flow of water to different circuits in order to maintain a given coolant temperature. Such designs are also used in water treatment and filtration installations. Faucets are household equipment: they are installed in kitchens and bathrooms to obtain a flow of water at the required temperature and pressure.

Based on the clearance of the ball window in relation to the cross-section of the pipeline, a distinction is made between full-bore and reduced-bore valves. The cross-section of the window of the former is equal to the cross-section of the pipeline, so their valve does not provide additional hydraulic resistance to the flow.

The cross-section of the outlet window of reduced taps is 1-2 standard sizes smaller than the cross-section of the pipe. Such devices allow you to quickly shut off the flow without the risk of water hammer.

According to the method of connecting the main pipe, there are threaded, nipple, welded and flanged valves. The threaded inlet and outlet pipes have internal or external threads. This is the most popular type of connection for household systems, as it allows for quick and convenient installation.

Nipple structures are connected to flexible hoses. They are used in garden plumbing and temporary schemes.

Welded tap pipes are sections of metal or plastic pipes. Their welded connection to the pipeline ensures high strength, tightness and durability of the systems, but creates considerable difficulties when repairing and replacing components.

Flanged valves are equipped with flanged pipes that are bolted to the corresponding elements on the pipes.

According to the design of the body, as mentioned above, ball valves are divided into solid and collapsible. All-welded or cast housings are durable and sealed, but are not suitable for repair.

Parts of dismountable units are connected by threads or bolts; such cranes can be easily disassembled for maintenance and repair.

Broken tap

Too sudden a movement resulted in the handle of the faucet moving, but the ball standing still. We disassemble the faucet - the ball simply split.

In most cases, if the faucet is reinforced or has a thick casing, this operation will revive the faucet, which will continue to work for a long time. How long such an operation can take - it all depends on the degree of jamming. It can take up to 10 minutes - as a rule, it does not happen more. If a drop of water leaks out, it’s okay, it’s just a loosened rod. Let's tighten the nut, the fluoroplastic gasket will compress - and everything will be fine.

In order to make sure that the valve is closed 100%, put the butterfly back and make sure that it touches the ball valve all the way.

If this does not happen, move the tap further.

We tighten this nut - oil seal:

After tightening the seal, wipe the faucet dry with a paper napkin or toilet paper and check for leaks. After this, put on the handle and tighten the nut until the end, making sure that the butterfly touches the stops when opening and closing.

If your faucet does not have an oil seal, perform the same operation without the nut. If there is a leak, the tap will have to be replaced. Ball valves only leak in this position:

If the faucet is completely open or completely closed, it will not flow. We revived the crane and it works well.

Water tap

Sometimes the concepts of faucet and valve are confused. A valve is a valve controlled manually or through an electric (rarely hydraulic or pneumatic) drive, which is installed in a section of a pipe and serves to shut it off. Theorists call a faucet the final consumer device for water collection. Simply put, the faucet is installed above the sink, bathtub or shower stall. On one side it is connected to the water supply pipes, on the other side - to the spout (spout) or shower head. In the middle there is a mechanism that regulates the water supply. A device that allows you to mix hot and cold water to obtain the required temperature is called a mixer. It contains either two separate taps or a single integrated one.

General structure and basic operating principle of ball valves

The body of a valve with a ball mechanism consists of a chamber, inlet and outlet pipes (often one of them is cast together with the chamber).

The chamber is equipped with a valve seat - it is a gasket made most often of metal (stainless steel), less often of rubber or fluoroplastic. In the center of the chamber there is a ball with a through hole, mounted on a vertical axis (rod), around which it can rotate.

Shut-off ball valves have one hole, regulating, mixing and redirecting valves have several.

All designs with a ball mechanism operate according to the following principle. When closed, the ball covers the valve seat, so the flow of medium is completely cut off. As the ball rotates on its axis, the through window begins to align with the lumen of the pipe, and water (gas) passes through the valve. When turning by 90, complete alignment occurs - the flow becomes maximum.

In a shut-off valve, a vertical rod is rigidly fixed in supports above and below a ball, which rotates in only one plane. There is an O-ring on the stem as it passes through the body.