Choosing an installation location

Pumping stations are installed near a water source - a well or a well - in a specially equipped pit - a caisson. The second option is in a utility room in the house. The third is on a shelf in the well (this number will not work with a well), and the fourth is in the underground.

This is what the pumping station looks like

How to Determine Suction Depth

When choosing a location, they are primarily guided by the technical characteristics - the maximum suction depth of the pump (from where the pump can lift water). The thing is that the maximum lifting depth of pumping stations is 8-9 meters.

Suction depth - the distance from the water surface to the pump. The supply pipeline can be lowered to any depth; it will pump water from the level of the water surface.

Wells often have a greater depth than 8-9 meters. In this case, you will have to use other equipment - a submersible pump or a pumping station with an ejector. In this case, water can be supplied from 20-30 meters, which is usually sufficient. The disadvantage of this solution is expensive equipment.

Suction depth is a characteristic that determines the installation method

If you are just a meter short of being able to install conventional equipment, you can install the station in a well or above a well. In the well, a shelf is attached to the wall; in the case of a well, the pit is deepened.

When making calculations, do not forget that the water level “floats” - in summer it usually drops. If your suction depth is on the verge, there may simply be no water during this period. Later, when the level rises, water supply will be restored.

Security Considerations

Another point that must be taken into account is the safety of the equipment. If you plan to install a pumping station near a permanent residence, there are fewer problems - you can choose any option, even in a small shed. There is only one condition - it should not freeze in winter.

Installation of a pumping station in a boiler room

If this is a dacha where people do not live permanently, the matter is more complicated - you need to arrange a room that does not catch the eye. The safest way to install a pumping station is in the house. Although they can take it away in this case too.

The second place where you can install a pumping station is a buried camouflaged caisson.

Installation diagram of a pumping station in a well

The third is on a shelf in the well. Only in this case there is no need to make a traditional well house. You need a steel lid that can be locked with a reliable lock (weld hinges to the ring, make slits in the lid on which to hang the locks). Although, a good cover may also be hidden under the house. Only the design needs to be thought out so that it does not interfere.

Convenience and operating conditions

Installing a pumping station in the house is good for everyone, except that the equipment is noisy during operation. If there is a separate room with good sound insulation and this is possible according to the technical characteristics, no problem. Often a similar room is made in the basement or on the ground floor. If there is no basement, you can make a box in the underground. Access to it is through the hatch. In addition to sound insulation, this box must also have good thermal insulation - the operating temperature range starts from +5°C.

To reduce the noise level, the station can be placed on thick rubber to dampen vibration (created by the cooling fan). In this case, it is even possible to install it in the house, but the sound will certainly still be there.

Caisson made of concrete rings

If you choose to install a pumping station in a caisson, it should also be insulated and also waterproof. Usually, ready-made reinforced concrete containers are used for these purposes, but a caisson can be made from concrete rings (like a well). Place the ring with the bottom down, and the ring with the lid on top. Another option is to build it out of brick and fill the floor with concrete. But this method is suitable for dry areas - the groundwater level should be one meter below the depth of the caisson.

The depth of the caisson is such that the equipment is installed below the freezing level. Insulation foam polystyrene. Better - extruded. Then at the same time you also get waterproofing.

For a caisson made of concrete rings, it is convenient to use a shell (if you find a suitable diameter). But you can also slab polystyrene foam, cut into strips and glue it. For rectangular pits and structures, slabs are suitable that can be glued to the walls using bitumen mastic. Coat the wall, apply insulation, you can additionally secure it with a pair of nails/dowels.

Design and principle of operation ↑

Let's try to figure out what this equipment consists of. Mostly the main “figures” in such installations are one or several ejector-type pumps (working, backup), or, in easy-to-understand terms, self-priming. They capture and lift water from ten meters deep.

In addition to these, the system also includes a steel pressure tank - a closed container divided into two cavities by a membrane, one of which is for water, and the other is filled with air under high pressure.

The volumes of hydraulic accumulators can vary from 20 to 80 liters.

SAV installation diagram

There's a power outage in your area, but you need water? Do not despair - a water supply pumping station can function for some time without “recharge”. How is this done? Elementary. The liquid pumped into the tank, due to the air pressure in the corresponding cavity, is transported into the pipeline. It simply cannot flow back into the pump - the check valve acts as a powerful barrier. As you can already understand, no electricity is required at all. That is why the membrane tank is called a hydraulic accumulator.

Typical design of a pumping station, operating principle of a sewer system

The design of the pumping station implies the presence of an automation unit with pressure sensors, a pump fuse against running dry (idling), and protection against engine overheating.

The operating principle of the pumping station is as follows:

- water flow into the membrane tank;

- when the pressure in the tank reaches a certain value, the pump turns off (a special relay controls the process);

- the system goes into “standby”;

- when the tap is opened, water starts flowing from the tank;

- after the “expiration” of a certain amount of liquid, the pressure in the tank drops to a predetermined value;

- the pump starts working again.

The pumped liquid cools the station. If the engine does overheat, the automation will de-energize the pump.

Connecting the pumping station

Selecting equipment and installation location is only half the battle. You also need to correctly connect everything into the system - the water source, the station and the consumers. The exact connection diagram of the pumping station depends on the selected location. But in any case there is:

- A suction pipeline that is lowered into a well or well. He goes to the pumping station.

- The station itself.

- Pipeline going to consumers.

All this is true, only the strapping patterns will change depending on the circumstances. Let's look at the most common cases.

Water supply from a well for permanent residence

If the station is installed in a house or in a caisson somewhere on the way to the house, the connection diagram is the same. A filter (most often a regular mesh filter) is installed on the supply pipeline lowered into a well or borehole, a check valve is installed after it, and then the pipe goes. Why a filter is understandable - for protection against mechanical impurities. A check valve is needed so that when the pump is turned off, water does not flow back under its own weight. Then the pump will turn on less often (it will last longer).

Installation diagram of a pumping station in a house

The pipe is led out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into a trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay polystyrene foam sheets on top, and then cover it with sand, and then with soil).

Option of passage not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the passage place is also insulated); in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as to remove/introduce the pipeline through the walls, and also that when a leak occurs, it is difficult to localize the damage. To minimize the chances of a leak, take proven quality pipes and lay a whole piece without joints. If there is a connection, it is advisable to make an inspection well.

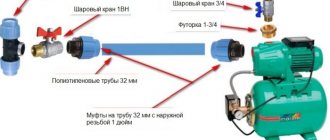

Detailed diagram of the piping of the pumping station when connected to a well or borehole

There is also a way to reduce the volume of excavation work: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the groundwater level is high on the site.

There is another important point - the well cover must be insulated, as well as the outside rings to the freezing depth. It’s just that the section of the pipeline from the water surface to the outlet into the wall should not freeze. This is why insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system during a centralized water supply. In this case, a water pipe is connected to the station input (also through a filter and check valve), and the output goes to consumers.

Connection diagram of the pumping station to the water supply system

It is advisable to install a shut-off valve (ball valve) at the entrance so that, if necessary, you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - so that, if necessary, cut off consumers and not drain water from the pipes.

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Is it just that the pipeline comes out at the place where the casing ends. A caisson pit is usually installed here, and a pumping station can also be installed here.

Installation of a pumping station: connection diagram to a well

As in all previous schemes, a filter and check valve are installed at the end of the pipe. At the inlet you can install a filler tap through a tee. You will need it the first time you start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed at the dacha, it’s okay; the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

Pump

A pump is needed to lift water from a well. Depending on the location, it can be submersible (located in the well at the level of groundwater passage) or surface (located on the surface, drawing water from the well through hoses or pipes).

According to the principle of operation, the pumping device can be centrifugal or vibration, membrane or screw. Most pumps for wells, both deep and surface, require power from the electrical network.

Start-up of the pumping station

In order to put the pumping station into operation, it and the supply pipeline must be completely filled with water. For this purpose, there is a special filler hole in the housing. Pour water into it until it comes out. We screw the plug into place, open the tap at the outlet to the consumers and start the station. At first, the water comes with air - air pockets that formed when filling the pumping station come out. When water flows in a smooth stream without air, your system has entered operating mode and you can operate it.

If you have added water, but the station still does not start - the water does not pump or flows in jerks - you need to figure it out. There are several possible reasons:

- there is no check valve on the suction pipeline lowered into the source, or it does not work;

- somewhere on the pipe there is a leaky connection through which air leaks;

- The resistance of the pipeline is too high - a pipe of a larger diameter or with smoother walls is needed (in the case of a metal pipe);

- The water level is too low, there is not enough power.

To prevent damage to the equipment itself, you can start it by lowering a short supply pipeline into some kind of container (water tank). If everything works, check the line, suction depth and check valve.

Advantages of the pumping unit ↑

An automatic pumping station is capable of maintaining the pressure that is necessary for a full, stable supply of a home or site with the most important liquid, at a level that is by no means worse than in a classic city water supply.

A household self-service system can function for some time without power supply. It is quite light in weight. Even one person can carry out the installation process, and the connection itself will take just a few minutes. It, unlike storage systems that are usually mounted in the attic, can be placed in any place that is appropriate, in your opinion. Which is also quite a significant advantage, isn’t it?

Equipment wear is minimal, since the pump does not work constantly: it turns on periodically (as needed). In a word, the pumping station, without false exaggeration, can serve you well for many years. The main thing is to approach the installation process at all stages responsibly and carefully. Finally get rid of rattling buckets and fussing with washbasins!