Having your own artificial pond is an incomparable pleasure from swimming and an opportunity to cool off on a hot summer day. However, even a small hydraulic structure requires significant maintenance. The cost of filtering devices in specialized stores is quite high, but you simply cannot do without them. Therefore, many people think about how to make a sand filter for a pool with their own hands, so as not to overpay and at the same time achieve high efficiency.

Is such equipment necessary?

Of course, those who have very small stationary or inflatable structures do not have to deal with the issue of water filtration. After use (bathing), it is simply used for household needs and watering cultivated plants on a personal plot. When necessary, the container is refilled - and no problems. However, this is only relevant for small tanks.

Despite this, even a small artificial reservoir can cause certain difficulties for its owners. After draining the liquid, the surface should be washed, only then fill the mini-pool again. Maintenance is a rather labor-intensive process, and in the summer you want to freshen up more than once a day. What can we say about children who are ready to splash in an artificial pond around the clock?

Without proper care, water quickly becomes polluted. Harmful microorganisms and bacteria multiply in it. After some time, a distinct unpleasant odor and green color appear. Swimming in such conditions is unsafe.

In addition to contaminants entering the aquatic environment due to human use, standing liquid becomes a haven for:

- dust particles;

- leaves and grass;

- bird waste products;

- pollen of plant origin.

The presence of these unwanted elements is eliminated using special nets and water vacuum cleaners. However, complete cleaning is not possible with these devices. Most of the substances entering the water dissolve or remain in it in the form of suspensions. That is why it is necessary to clean not only the surface and sediment, but also the liquid layer itself.

Pros and cons of a homemade device

Advantages of homemade devices:

a self-made system costs 2-3 times less than a ready-made store-bought filter;- the installation effectively copes with dirt and debris with a fraction of 20 to 30 microns;

- improvised means and tools are used for production;

- Frequent replacement of consumables is not required (less than once every 2-3 years).

Disadvantages of homemade structures:

- do not provide complete disinfection of water;

- do not remove small debris (less than 20 microns);

- require effort and time to manufacture;

- the need for tools and skills to work with them: to create structures from metal containers you will need a welding machine and the ability to use it, and for plastic and polypropylene containers you need a soldering iron and a set of fittings.

How do sand-based filtration media work?

The sand filter system includes five main elements:

- a tank with a neck that can be tightly closed with a lid;

- a small piece of pipe for supplying liquid;

- drainage pipe;

- sand filler;

- a grid with a narrow cell for drainage.

The tank itself is made of stainless material (for example, plastic). Drainage cylinder made of stainless steel mesh. A water outlet tube is connected to it. The size of the cell holes should be smaller than grains of sand. Quartz or glass sand is usually used as a filter base.

Understanding the diagram of how a sand filter for a pool works, it is easy to notice that this device is extremely simple. It can be constructed from ordinary plastic barrels. A reliable lid and neck are already available; all that remains is to attach the pipe sections and assemble a drainage compartment from a suitable mesh.

Main types of “pool” filters

Three types of filter units can be used to purify pool water:

- sandy;

- diatoms;

- cartridge

Unit #1 - sand filter

Sand filter systems are the most inexpensive and easiest way to keep a small private pool clean and tidy. The sand filter consists of a reservoir, a pressure gauge and a six-position valve. The filter medium is quartz sand of several fractions, which is capable of retaining particles with a diameter of approximately 20 microns. This is enough to keep the water relatively clean.

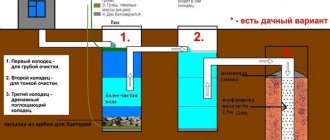

The hemisphere in the diagram is a coarse water filter. It is needed to prevent sand from getting into the pool from a barrel of water. Its role can be played by a container wrapped in nylon fabric.

Through a skimmer or overflow tank, water flows through a pipe into the filter unit. Under pressure, it passes through quartz sand, which traps various dirt particles, after which it flows back into the pool through nozzles. The filter mass can consist only of sand, of several layers of “sand-gravel” or “sand-gravel-carbon-anthracite”. The last two fillers purify water much better. If you use glass sand instead of quartz, then a complete replacement of the filter material will be needed not after three years, but after five to six years.

Naturally, after some time the filter becomes clogged, and the pressure gauge shows that the operating pressure is exceeded. The filter is cleaned by backwashing approximately every seven to ten days, after which the unit can continue normal operation. If the site has its own water source, then such frequent cleaning will not affect the budget in any way. But if we are talking about a pool in the city, then the meter will wind up several additional cubic meters per month.

The design of a sand filter for a pool is so simple that many craftsmen prefer to assemble them themselves, adjusting them according to their own needs.

Unit #2 - installation with diatomaceous filler

A filter based on diatomaceous earth is considered the most reliable and most expensive. It allows you to remove suspended particles with a diameter of up to 1 micron from water. This soil contains silicon dioxide, which gives some healing properties to the water, which is usually called silica.

The diatomaceous earth filter is the most expensive of all three, but it is the one that allows you to not only purify the water, but also gives it some healing properties. So you can both harden and get healthier

Diatomaceous earth itself is a sedimentary rock formed by the fossilization of diatom shells. It has a yellow-brown or gray color. If necessary, the filter layer is cleaned by backwashing. If a complete replacement of the diatomaceous earth mixture is required, you should remember that it belongs to the category “Hazardous Waste” and requires special disposal.

Unit #3 - cartridge filter system

The third type of filtration systems for swimming pools are cartridge filters. The cleaning element - the cartridge - consists of several layers of special paper and polyester, on which particles up to 5-10 microns in size are deposited.

It is recommended to periodically clean the cartridge with special septic tanks that will kill all pathogenic bacteria. To simply remove dirt deposits from the filter element, you can rinse it under running water

Depending on the brand and model, the container contains from one to four cylindrical cartridges. If they become clogged, manufacturers recommend replacing them. However, customer experience shows that you can extend the life of the cartridge for some time if you wash it with water from a hose under low pressure or with a cleaning solution of a suitable brand.

How does it function

Please note that the structure body is not completely filled with filler. There should be space between the sand base and the throat. During operation of the device, it is filled with contaminated liquid from an artificial reservoir. Water is supplied using a pump. The aqueous medium penetrates from top to bottom through a dense layer of sand, thereby getting rid of polluting particles, and is supplied back, already purified. As long as the pumping system is active, circulation does not stop.

It is easy to determine the pressure during operation of the supercharger using a pressure gauge. Data varies depending on the location of the fluid pumping mechanism:

- If it is placed in front of the treatment unit on a section of the water supply pipe, a water volume is pumped into the tank.

- When the pump is installed in the drainage part of the system, H2O is sucked out of the tank. Vacuum is applied.

During the cleaning process, the sand filtration device becomes dirty. For the purpose of washing, a liquid medium is supplied in the opposite direction. Clean water flows into the container from below, and contaminated water coming out from above is drained.

Variety of species

The following types of pool pumps exist:

- volume;

- dynamic;

- Filter;

- Thermals.

Let us consider in more detail the technical characteristics of each type of pumping equipment for artificial storage.

Positive displacement pumps

Switching the suction pump (click to enlarge)

This type of pump is also called self-priming equipment, i.e. The principle of operation of the pump is to suck water from the pool.

Positive displacement pumps have the following characteristics:

- the device is located above the water level in the pool;

- Dirty water is supplied from the pump to the treatment units, and then back to the tank;

- it can be supplemented with a depth filter.

Expert advice: The operating instructions for suction pumps indicate that they should be installed above the water level. But the higher you raise the pump, the higher the load and the more energy is consumed. Therefore, it is recommended to lower the pressure equipment into specially equipped basements next to the pool.

Thus, suction pumps perform the following tasks:

- a basin of water;

- facilitate the operation of filter devices;

- organize the work of countercurrents;

- to maintain the effectiveness of air massage systems.

Dynamic pumps

Dynamic image of the pump

Pumps of this type are also called circulation pumps or centrifugal pumps. They differ in the following properties and characteristics:

- the equipment is immersed directly in water at a certain depth;

- Water circulation is carried out through vortex or blade elements;

- The design of the pump allows a sufficient amount of ozone to be introduced into the aquatic environment;

- This type of pump can be used to create wells or bubbles on the surface of the pool.

When choosing a submersible centrifugal pump for your pool, pay attention to its characteristics, such as the strength of the water pressure and the direction of water flow.

Filter pumps

Pool water purification (click to enlarge)

The name of this pool pump system itself indicates that these devices are designed to purify water for a long time.

The operating principle of filter pumps consists of three sequential actions:

- The device passes clogged water through special coarse separators;

- then the water flow passes through a special filter unit;

- After cleaning, the water returns to the pool bowl.

There are usually three filter systems for this type of pump:

- A pool sand filter is a container of sand through which water flows for microscopic cleaning;

- The main element of the cartridge filter is a propylene membrane that separates sediment from water;

- The diamond cleaning system consists of several cartridges, the main element of which is mineral particles.

Tip: A cartridge water purification system is the optimal filter for swimming pools.

The main function of pool heat pumps is to heat the water. So you can swim in the pool during the cold season.

Wiring diagram for a sand filter for a pool

If you want to make a water purification device yourself, you will need a blueprint for it. As a basis, you should take one of the most suitable ones based on your own capabilities and the expected volumes of liquid to be filtered.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Ratings of the best models

To obtain a high degree of purification of pool water, when choosing a filter unit, it is recommended to pay attention to the products of companies that occupy a leading position in the market. Among the models that make up the top list of pool filters, there are models that differ in volume and design. But to evaluate quality and performance, we selected models that have been at the top of consumer preference lists for several seasons.

Krystal Clear Intex 26644

A model of a popular brand of a manufacturer of household frame pools. The advantage of this model is its high performance in a small size. The declared productivity of 4.5 m3 is quite enough to clean pools with a volume of up to 25 m3. Connection to a standard pool is carried out using proprietary 38 mm hoses. The model has the ability to work in one of 6 modes. For ease of use, the model has a timer and pressure gauge. Krystal Clear Intex 26644 can be filled with both quartz and glass sand with a fraction of 0.4-0.8 mm. For a standard load you need 12 kg of regular sand, for glass - 8 kg.

The manufacturer's instructions say that one refill is enough for 3-5 years of operation.

However, in order for the filter to cope with its task perfectly, it is recommended to change the sand every 2-3 seasons.

The design is made on a platform. The body is made of impact-resistant polyethylene. The installation is compact in size and conveniently connected to the standard connectors of Intex pools. The instructions, in addition to the description, also have a disk with a film - instructions for connecting and servicing the installation.

Bestway 58495

The most compact pool filter model. The productivity is 3.4 m3 of water per hour. A 6-position valve is built into the polypropylene tank. The timer ensures automatic switching on and off of the unit. The built-in pressure gauge allows you to control the pressure inside the container.

A special feature of the model is the presence of a built-in ChemConnect dispenser. The device allows you to automatically add disinfecting chemicals to filtered water. The design includes an additional filter to capture undissolved particles. This function ensures long-term protection of the pump from damage.

Connections for connecting 3.8 cm hoses make the filter universal for connection to most popular models of frame pools. The volume of sand for filling into the filter housing is 9 kg.

Aquaviva FSF350

One of the largest filters for home pools. To load you will need 20 kg of quartz sand with a grain size of 0.5-1 mm. The tank of the filter unit is made of fiberglass. The housing material is not afraid of ultraviolet radiation; it can be installed outdoors.

The system has standard connection types using 50 mm hoses. The productivity is 4.3 m3 of water per hour. The housing can withstand pressure up to 2.5 bar.

Compared to other models, Aquaviva FSF350 operates at a water temperature of +43 degrees.

The system has a modular design. The filter housing and pump are installed on a common platform. The manufacturer recommends using the unit for pools with a volume of 15-18 m3.

Hayward powerline Top

This is the most famous and high-quality filter for home pools. This model provides water filtration with a capacity of 5 to 14 m3 per hour. This variation in performance is due to the fact that the pump for this filter is selected depending on the volume of the pool. The recommended bowl volume for the Hayward powerline Top is 25 m3. The design is equipped with a standard 6 position valve and pressure gauge. The body is made of impact-resistant polypropylene and can withstand a pressure of 2 bar.

To operate the filter, you will need 25 kg of quartz sand with a fraction of 0.4-0.8 kg. All Hayward powerline Top models are connected using 38 mm hoses.

Features of choosing a device

Filter media are usually sold without filler. Therefore, sand must be purchased separately. When choosing a model, rely on volumetric characteristics. This value indicates how powerful the unit in front of you is. Accordingly, how well it copes with cleaning the aquatic environment. The larger the size of the artificial reservoir, the higher the power indicators should be.

When purchasing a device, be sure to consult with a specialist consultant. Pay special attention to the manufacturer. Thus, Voda Otechestva is one of the best manufacturers of water treatment equipment. Our company's products have long proven themselves to be the best on the market.

When selecting a device, take into account the features of the fasteners and the location of the font. Sand-based treatment systems are not mounted directly on the container due to their impressive mass. They are usually installed next to the tank.

It is equally important to choose the filler itself correctly. It is sold packaged in bags and is completely ready for use. The least expensive option would be quartz material. True, it won't last long. It is much more profitable to purchase a glass mixture with a long cleaning life. You can also opt for a combined form with an admixture of gravel or other additions.

Design features and varieties

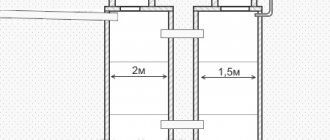

The basis of the sand filter is a sealed housing. In the classic layout of a sand filter, the housing has two outlets - at the top and at the bottom. Hoses for supplying contaminated water and discharging purified water are connected to these holes. The body does not have to be collapsible; it is enough to have a lid at the top for storing quartz sand. This design option corresponds to the classic layout - when water is supplied under low pressure, and the filter element itself cleans from mechanical impurities.

Today, for home pools with a volume of up to 25 m3, filters and filtration stations are used that have a slightly different design.

The first difference from the classic sand filter design of a water purification installation is the presence of a pump in the design. The pump included in the installation allows for high performance of the device by creating additional pressure in the system.

The modular layout, when both the pump and the filter have individual housings and are placed on the same platform, is considered the simplest and most effective.

At the same time, manufacturers also offer an integrated installation scheme - when the filter and pump are installed in one housing. The third no less popular scheme is a filter in a separate housing, to which you can connect any pump, even a regular centrifugal garden pump.

In addition to the layout, modern filtration systems have other design features:

- multi-position valve;

- pressure gauge;

- dispenser for adding chemicals to water;

- on timer;

The design of the filter element housing has an additional filter, which ensures sand retention in the main filter. The second filter is usually installed in front of the pump; it protects the pump from large debris particles entering its cavity.

The housing of the sand filter and pump is made of high-quality plastic, which provides reliable protection of the electric motor from moisture penetration. The filter housing itself is capable of withstanding pressure up to 4.0 bar.

The connection between the filter, pump and pool bowl is made using special hoses or tubes. Here the design provides not only for the usual connection using standard adapters and fittings, but also for the installation of taps and valves for washing sand and discharging contaminated water into the sewer.

Making a sand filter for a pool with your own hands: instructions

To make a filter unit with your own hands, you need to perform a series of sequential actions. Each step is of great importance, the implementation of which must be approached with maximum responsibility.

How does it work

The operation of the filtration device is based on the mechanical extraction of suspensions from the liquid (organic particles and mineral substances). In this case, water passes through the sand base from top to bottom.

The structure body is not completely filled with sand. When closed, a tightly closed area is formed above the surface of the cleaning material, into which H2O is supplied from the reservoir. Passing through the sand mixture, it is filtered. Pollutants are retained by grains of sand. It is important to understand that the filler should be quite fine. The filtered aqueous solution fills the bottom drainage section, from which it is then fed through the drainage system back into the container.

Selecting a connection method

There are three methods to connect a filtration device:

- By installing a filter in front of the sand tank. The liquid is directed through the sand base under pressure.

- The pumping system is installed after the filter unit, which provides a vacuum vacuum in a tightly closed tank. The liquid medium is drawn into the purifier.

- The purified H2O is pumped by a supercharger installed after the purification device. But from the pool it enters the sand structure by gravity.

Cleaning agents are produced on an industrial scale according to the first scheme. They are usually equipped with special pressure gauges.

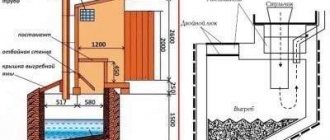

Preparing the body

To do this, you will need to select a suitable container, which can subsequently be sealed with a lid. For example, an expansion tank housing should be used. First, you will have to remove the membrane from it and paint it on the inside to prevent corrosion. A polypropylene barrel is also perfect. Such specimens are easy to find in any summer cottage.

When deciding to install a homemade sand filter for a pool, you can start from the approximate drawings according to the second and third diagrams. You just have to do some additional work with the tightness of the structure, since liquid pumping in these options is carried out by suction. If air gets into the system, it will not function fully.

Insertion of fittings and internal elements

In order for contaminated liquid to be supplied to the filtration device, and clean liquid to be pumped out in a timely manner, connecting pipes must be cut into the walls of the housing. The joining area is first thoroughly treated with a sealing solution.

A coarse filter device is subsequently attached to the embedded section of the tube. In order to make a simple water intake drainage, a plastic product with specially made holes is used. It is covered with suitable garden material. Alternatively, you can simply buy a ready-made cylinder cartridge used for purifying drinking liquid.

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

On one side, the cylinder is blocked with a plug, and on the other, a fitting is installed. After this, a pipe connecting the structure with the fitting is attached and placed at the bottom of the cleaning device.

Filter element

The optimal solution is to use special quartz sand. Sand grains measuring 0.4-0.8 mm ideally retain dirt. This filler does not need to be prepared or disinfected beforehand. To fill a tank for a medium-sized pool of about 40 cubic meters, you will have to purchase a couple of 25 kg bags.

Installation of parts for unit operation

Of the elements necessary for proper functioning, the following must be installed:

- Pressure gauge. A device that can be used to monitor blood pressure readings.

- Security group. Can be installed instead of the above device. Available in the form of a manifold with a meter, an air vent and a safety valve.

- Air vent. A section of narrow pipe with a tap.

Piping of the treatment system

Manufacturers make sand filtration media with built-in six-position valves. When installing it yourself, use the appropriate shut-off valves and fittings. The main thing is that in the end the filter works for washing and cleaning.

An overly powerful pumping system is not the best solution. A power of 150-300 W will be quite enough. The capacity should be selected based on the condition that the contents of the tank should be replaced within 6 hours (no longer).

Pool connection

At this stage, it is necessary to connect the drainage and water supply hoses to the fittings using clamps. If there are nozzles installed in the walls of an artificial reservoir, you can connect to them.

In order for water to circulate well, the points of intake of dirty liquid and removal of purified liquid must be placed as far as possible from each other. It is worth installing a coarse filter device in front of the pump so that the system is not damaged due to the ingress of large contaminants. If the tank is to be gravity fed, the top of the tank should be below the surface of the water in the bathing tank.

Filling the device with sand and then starting it up

When understanding the features of pool filtration according to the instructions, it is important to remember that the structure should not be completely filled with sand. Free space at the top will be required for incoming H2O. When filling the sand base, it is necessary to periodically wet it for greater density. It is strictly forbidden to turn on the device “dry”.

The initial start of the system is considered a trial start. If problems or leaks are found, they must be repaired. Keep in mind that to carry out repair work, you need to drain all the liquid in the cleaning device.

Working principle of a sand filter

The design of the device is really not complicated. The outer casing, which is hermetically sealed, contains a filler - quartz sand and free space in the upper part.

Sand filter device

Water enters the housing under pressure and fills the upper part of the housing. Then, under the pressure of the pump and the force of gravity, it passes through the sand, leaving particles of dirt and debris in it.

After some time, you will have to clean the sand. To do this, simply turn the pump in the opposite direction. Water from the bottom up cleans the sand and takes away all the accumulated dirt. The liquid is then sent down the drain.

In the final stage, the purified water passes through a mesh, through which sand cannot pass, and is taken back into the common tank.

Required materials and tools

All you may need when making a filter device yourself is:

- soldering iron, suitable for polymers;

- hacksaw;

- strong scissors;

- drill;

- pliers;

- sealant.

But first you need to acquire the following list of items:

- suitable container with a wide neck;

- well-closing lid;

- pipe sections, clamps, hoses;

- sand base as filler;

- water intake device;

- drainage pipe;

- pumping system, valve.

The design and principle of operation of a filter for a pool of this type

The standard package includes:

- A sealed housing in the shape of a tank or barrel with two openings for water supply and drainage and built-in diffusers for uniform distribution of water.

- Skimmer for sucking water from the surface of the pool with nets for collecting particularly large debris.

- A pump that provides a sufficient speed of water circulation and directs it into the filtration tank.

- Multi-position control valve for switching modes.

- Pressure gauge for monitoring the water pressure in the filter container and monitoring the degree of contamination of the filler.

- Connecting hoses and auxiliary elements (pallets, stands, fasteners).

Cleaning is carried out according to the following scheme: after turning on the pump, the contaminated water taken through the skimmer is directed into the container with sand, passes from top to bottom, leaving debris there, and returns back.

As impurities settle in the sand, more and more pressure is required for the passage of water inside; at a critical value, the arrow on the pressure gauge indicator goes into the red zone. This serves as a signal to switch the device to backwash mode; after it has passed, the position of the valve changes and the filter returns to operation.

This principle of operation is implemented in all sand filters, the only difference between the models is:

- In the body material. The walls of filtration tanks can be made from inexpensive plastic or polypropylene, or from heavy-duty polyamide, thermoplastic or fiberglass.

- Throughput (performance), in turn determined by the filter diameter, filler volume and pump power.

- Different ways to connect the valve. Filters with side connections take up less space, while filters with top connections are considered more reliable and easier to maintain.

- Number of control valve positions. When planning maximum process automation, it is worth buying a model with a six-position valve. For simpler models, the valve manually switches between 4 modes.

The operating principle of a sand filter is discussed in this article.

Advantages and disadvantages of a DIY pool pump with a sand filter

There are indeed many advantages to such filtration units. Among the advantages of sand devices, one cannot fail to note:

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

- simplicity of design and operation;

- ability to retain organic and mineral contaminants well;

- the ability to assemble a device from scrap materials.

The disadvantages include:

- effective against contaminants larger than 20 microns;

- impressive weight and dimensions of the system;

- difficulties during transportation.

Sand filter for the pool: instructions for use

Anyone who wants to organize their own hydraulic structure for swimming will have to think in advance about methods of maintaining it. Purification of the liquid must occur constantly. As a last resort, short-term interruptions (switching off) of purification devices are allowed if there is, in principle, no even minor contamination in the H2O, which does not happen often. You can turn off filtering devices no more than 2 times a day for 5-6 hours maximum.

Washing the sand base

The frequency of sand washing directly depends on the degree of its contamination, the intensity of use of the artificial reservoir and the volume of chemicals used. According to the recommendations, the sand mass should be washed at least once every 7-10 days. In this case, with regard to the pressure type design, pressure will be of great importance. Within normal limits it is 0.8 bar. If the indicator rises to 1-1.3, cleaning is required.

Replacing material

Over time, the filter part of the device becomes so clogged that it simply cannot be washed. All that remains is to throw away such sand and replace it with new one. If you purchased a quartz mixture as a filler, you won’t have to think about the need to purchase the next batch for 3 years or even more.

Features of use

The process of operating a cleaning device involves following a number of mandatory requirements:

- when switching the unit to another operating mode, be sure to turn off the pumping system;

- the sand layer is removed from the walls of the artificial reservoir by at least 1 m;

- for uninterrupted operation of the pump, it is provided with a constant flow of air;

- Any operations with the filtration device are performed in the off state.

Selection rules

To choose the right pump for your pool, you need to consider a number of important factors:

- Optimal pump performance should depend on the amount of water in the pool;

- The pump should be selected according to its functions (pumps, filters, etc.);

- When choosing a pump, you need to pay attention to the filtration system of the purchased pump;

- You need to know what additional functions the pump unit performs;

- The manufacturer of the purchased equipment is also important.

To ensure your pool pump runs successfully for a long period of time, always follow the instructions below:

- The pumping system must always be filled with water;

- Pumping equipment should not freeze in winter;

- The pump should not operate continuously for more than four hours.

We hope all of the information above will help you choose the right pump for your pool.

To install your pool pump, please read the following video instructions:

Page 4

Swimming pools, regardless of their size, require heating at any time of the year. For this purpose, various devices are used to maintain temperature.

A pool heat pump is the ideal solution to this problem. This is a special converter that allows you to most efficiently generate thermal energy for heating water without polluting the environment.