Tinplate is a unique material that is resistant to corrosion, sufficient strength with unique softness. It does not come into contact with food, therefore it is widely used in the food industry as packaging.

Despite the emergence of new synthetic materials, plastic and titanium, which are also resistant to corrosion, the production of tinned steel throughout the world has not decreased. This metal with exceptional properties will be discussed.

What is tinplate?

Tinplate is sheet metal of the finest parameters. Depending on the thickness, three grades are distinguished: the thinnest (up to 0.33 mm), medium thickness (up to 0.36 mm) and thick (up to 0.48 mm).

An important function of tinplate is to serve the canning industry. In addition to cans, many household items are made from this metal: jugs, teapots, ladles, etc. Tinned steel is also used to produce pipes, various roofing materials, household goods (buckets, lids), specialized containers for paint and varnish products and petroleum products, etc. Basic properties of tin , which determine the scope of its use - non-oxidation, lightness, ductility, viscosity. Thanks to these qualities, tin plate can be easily stamped.

The basis for tinplate is low-carbon steel, which is produced in an oxygen convector. They are produced mainly by the tape method. In this case, the metal is rolled in the form of a strip, and rolling on hot mills occurs not to the final thickness, but to a size of 1.5 mm. Further rolling takes place on cold mills.

The blank for tin is sutunka - strips of iron up to 13 mm thick. with a width of up to 300 mm. For rolling, the sutunka must have a clean surface, free of scale. Therefore, when rolling, the blank is blown with a stream of steam or water under pressure up to 38 at. To obtain high-quality sheets, the sutunka is etched with acid before rolling. The cut pieces are fed to the ovens.

Sorting of tin

In production, finished products are divided into three categories.

- The first grade includes sheets that do not have defects. Only very minor flaws are allowed.

- The second grade consists of sheets with small black dots, minor bubbles, grains of tin, and small dents.

- The third grade includes sheets that are wrinkled and have bent corners, as well as products contaminated with zinc chloride.

During the sorting process, sheets of tin are set aside, which can be improved by re-etching or tinning.

Differences between domestic and foreign technology

During the manufacturing process, domestically produced material is subjected to single cold rolling. As a result, steel strips of the required thickness are formed and then annealed. The final step is a process that improves the technical properties of the material.

Imported technologies include an additional cold rolling procedure. At this stage, special lubricants are used to reduce the thickness of the sheet by 50%. As a result, the material consumption for the production of food containers is noticeably reduced, and the elasticity and strength of the tin increases.

Manufacturing

Stages of production of tinned steel:

- cutting and etching of husk;

- rolling of rough sheet metal (heating, rolling, cutting the strip, second heating, rolling, cutting half-packages, heating and rolling out packages);

- cutting, cutting and sorting cards;

- first etching and annealing;

- sorting and polishing of annealed sheet metal;

- second annealing and etching;

- tinning.

It is necessary to briefly dwell on the sequence of operations. Stainless steel blanks are first fired and then pickled. And this order is justified. When pickling, oxides formed during rolling are removed from the sheet metal. Annealing gives the metal the necessary softness. If etching is carried out first, the sheets enter the annealing oven wet, which increases the annealing time and also causes defects. If you first anneal and then pickle, the sheets will go into the oven dry, which will improve the quality of the tin.

When etching annealed sheet metal, acid consumption is reduced.

In addition, after annealing, the tin is carefully sorted, which prevents etching of defects.

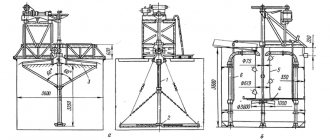

Annealing

After rolling, pallets with tin are covered with special hermetically sealed boxes. Steel boxes with special ribs that retain the coating are treated with clay. The boxes are placed on trolleys and fed into the oven. The annealing process occurs at temperatures of 900–1000 °C for 10–18 hours, depending on the equipment.

To control the annealing process, pyrometers are installed in the openings in the furnace, and flue gas samples are also taken.

After annealing, the pallets are removed from the trolley and placed in a special cooling area. The whole process takes up to 20 hours, but after 8 hours the box is removed for subsequent cooling of the tin in an open form.

8 hours after cooling, the temperature of the tin is about 250 °C, that is, there is absolutely no chance of oxidation.

After annealing, the tin is sorted for the following operations. High-quality material goes to tinning, metal with minor defects is processed into black polished tin, and the low-quality remainder, which cannot be processed, goes to market as black unpolished tin. Under normal conditions, the acceptable ratio of high-quality and defective workpieces is considered to be 75%, 15% and 10%.

Sorting is carried out in sufficient daylight. If conditions do not allow, then quartz or mercury lamps are used during culling, which make it possible to identify the smallest defects.

To avoid contaminating the sheets, the operation is carried out wearing protective gloves.

Etching

After cooling, the sheets of tin are placed vertically in pickling baskets. The sulfuric acid used in the process dissolves the oxides formed on the sheets during rolling. The strength of the treatment solution is 15%. During etching, one basket is swung in acid for 15-20 minutes, the second in water for rinsing, and the third is unloaded and loaded at this time. After etching, the sheets are sorted again.

To completely neutralize the acid after treatment with water, wash in lime milk.

When treated with sulfuric acid, defects appear on sheets of tin. These are bubbles that will clearly be visible after tinning. This is the release of hydrogen, which accumulates in places where there are foreign inclusions or voids. Defects can be avoided either by using high-quality dense metal or by adding special additives during etching.

Drying

Before polishing, the etched sheets are thoroughly dried. This can be done in special machines, or you can pass the tin through very hot water. Of course, the use of mechanisms is preferable: in machines the sheets are not only dried, but also additionally cleaned of dirt.

Polishing

The purpose of the operation is to add gloss to the metal sheet, eliminate minor defects (dents, bumps, etc.), and make it more uniform in thickness. The quality of polishing will determine the cost of subsequent tinning. The better the sheet is polished, the less tin is needed for tinning it.

Attention! High-quality polishing can only be carried out if the premises and machines used are impeccably clean. Therefore, the operation premises must be closed and well lit.

When passing sheets through the rolls of polishing machines, the hardness of the metal increases, the tin becomes brittle and elastic. To give it the same softness, the sheet metal is subjected to white annealing.

White annealing

This process allows you to destroy the work hardening that occurred during polishing, as well as completely remove fatty deposits from the sheets. The operation is identical to the first annealing, but the duration of white annealing will be shorter (maximum 12 hours), and the oven temperature required is a maximum of 750 °C. The need to coat boxes with clay disappears.

White etching

To remove the iron oxide that coated the sheet after annealing, etching is repeated before tinning. The layer of scale that appears after annealing will prevent tinning if it is not removed with acid. The second etching process is identical to the first, except for the concentration of the solution. Since white tin comes in cleaner, one part of acid to ten parts of water is enough to remove scale. But the duration of etching is very important. If you overexpose the sheet, the acid will corrode the polish. If you underexpose it, you will end up with a low-quality half.

Tinning

After etching, the sheets are placed in water and removed immediately before tinning. The operation takes place in hot tin pots, and both sides of the sheet are processed. There are methods of electrolytic tinning, but the quality of the resulting tin will be an order of magnitude lower.

The process itself goes as follows. The tin sheet passes through a layer of zinc chloride (maximum thickness 50 mm). This layer removes excess moisture and remaining oxides. Zinc chloride is hydrochloric acid in which the evolved hydrogen is replaced by zinc.

The metal is then passed through a 300 mm thick layer of tin, which is in a liquid state. The temperature of molten tin is about 300 °C. This temperature must be constantly maintained, since decreasing it makes tinning difficult, and increasing it leads to increased consumption of tin.

The third layer is fatty, usually palm oil.

From the oil bath, the tin goes to the cleaning facility, where the sheets are freed from adhering fats. Typically, during this operation, the leaf is pushed through a cleaning mixture (bran, sawdust and alabaster).

Tinning is the most important process that requires close attention. It is necessary to tin the sheets in such a way as not to spoil the flawless metal. The pickling acid should not get into the tin or zinc chloride layer. Such penetration is fraught with drafts. Overheating of the tin layer gives yellowish tint to the tin, while underheating guarantees sagging. Overheating of the fat layer can cause fat spots. To prevent such defects, it is necessary to install pyrometers in tin baths.

What are the advantages of steel over other materials?

Steel jewelry SL: ring with cubic zirconia;

earrings; bracelet with cubic zirconia (prices via links) Steel does not lose its “new” appearance for a very long time. At the same time, it is much more durable than precious metals, does not oxidize and does not darken over time, and is not afraid of the effects of salt (sea) water, ultraviolet radiation, various acids - the same as orange juice accidentally spilled on a hand with a bracelet or ring. Let us repeat, steel does not cause allergies (strictly speaking, an allergy to gold and silver is our body’s “rejection” of contact with base metals included in jewelry alloys of gold and silver of various grades). It is very difficult to damage steel jewelry - scratch it, get a dent. Finally, the advantage is the price, and also the fact that, despite their low cost, steel products look very, very decent.

On a note! 316L stainless steel, unlike some jewelry alloys, does not contain lead - a metal dangerous to our body

Quality checking

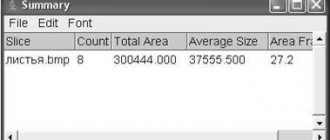

A standard sheet of tin should have a thickness of 0.22-0.4 mm. The first test that the sheet undergoes is bending at a right angle. High-quality tinplate must withstand sixfold bending without mechanical damage or peeling of the coating.

The second test is for softness and viscosity. The metal is checked by pressing the recess with a special apparatus. Any sheet will burst under pressure. The indicator at which mechanical damage occurred is recorded. The norm is considered to be 5.5-6 mm. depth.

Defects and methods for their elimination

The longer and more complex the production process, the greater the likelihood of failures at sites, and the higher the proportion of defective products. Technologists call defects in tinplate defects.

Defects in metal sheets can arise due to the low-quality workpieces used, the low quality of accompanying materials, the technical condition of the machines involved in production, etc.

Only 10% of all tin defects are caused by poor-quality tin, 90% occur during production.

Rolling defects

60% of metal defects occur when rolling rough sheet metal. Main reasons:

- Incorrect temperature conditions in ovens. It is expressed by “ripples” of the leaf cover. Oxygen oxidizes the surface of the hot metal, forming a harder top layer (scale). During rolling, a denser layer is pressed into the metal, forming a defect. Such a defect can be avoided in two ways: to prevent oxidation of the metal or to eliminate scale that has already appeared. To prevent oxide from forming, it is necessary to control the oxygen level in the furnace. To remove the hard layer that has already formed, the bag must be treated with acid.

- Wear of rolling rolls. If the hardened top layer of the roll is damaged, pressure is formed on the tin sheets during rolling, which cannot be removed. The method of dealing with such a defect is periodic quality control of equipment.

- Sticking of sheets. This defect occurs when there is insufficient amount of silicon, carbon and phosphorus in the metal. To prevent a defect, it is necessary to introduce silicon into the sac (in the final analysis, the required level of silicon should be 0.05%). The same problem can occur at high temperatures in the oven or on the rollers. But experiments carried out at factories show that adding silicon in the previously indicated proportion completely eliminates the defect, regardless of the cause of its appearance.

- Plaque on the sheet as a result of sand or clay from the oven. After rolling, these particles leave a significant mark, making the tin unsuitable for tinning. The defect can be prevented only by timely maintenance of furnaces.

- Uneven rolling. According to the standards applied to tinplate, the deviation in metal thickness within one sheet should not exceed 0.03 mm. The uniformity of rolling depends entirely on the machines used, but sheet defects can be caused by incorrect adjustment of the rolls, uneven heating of the roller, low qualification of the rolling operator, etc.

Defects during annealing and tinning

40% of defects occur during annealing and tinning. Main reasons:

- Weak annealing, which can only be detected by mechanical testing. You can fight it if you constantly monitor the quality of the tin. Then it will be clear how long the curd needs to be kept in the oven.

- Appearance of dry edges. The defect occurs when the bundle is not carefully packed before annealing. As a result, the edge comes into contact with air and oxidizes. Sheets with such a defect are unsuitable for tinning.

- The appearance of etching bubbles. To eliminate this defect, chemical additives are used.

- The etching process was not completed. Before tinning, it is enough to carefully sort the material to prevent defects.

- The green color of the sheets occurs when metal sheets are in prolonged contact with air before tinning. The defect is eliminated either by the continuity of the process, when tinning occurs immediately after etching, or by placing the material in water.

- The appearance of black dots on sheets of tinplate. These are places not treated with tin. The danger of such a defect is the rapid formation of rust. The defect is formed when acid gets into tin or zinc chloride. The sheets can be re-etched and tinning.

- The appearance of greasy oil stains, which form when working with old oil or when it is heated too much. It is impossible to eliminate the defect, so it is necessary to install additional measures to control the temperature of the baths.

- Mechanical damage (broken, crumpled sheets, bent corners) is the result of neglect. Tinplate is a very delicate material.

What is steel

Steel is an alloy of iron and carbon. In normal cases, the proportion of carbon ranges from 0.1 to 2.14%. But, given that alloy steels can contain many additional ingredients, today steel means an alloy in which the share of iron is at least 45%.

This video will tell you what steel is and how it is produced:

Concept and features

The main attractive qualities of steel are high strength with the availability of raw materials and a relatively simple production method. It is this combination that puts iron alloys in the position of absolute leader. Today there is simply no area of the national economy where steel does not occupy the position of a structural material.

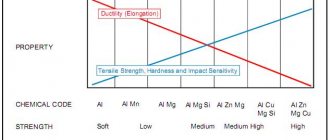

- Iron and carbon are essential components of an alloy. Of these, iron provides ductility and toughness, due to which steel is classified as a deformable, malleable alloy. And carbon is hardness and strength, since hardness is always combined with fragility. The carbon addition is small and even in specialized formulations does not exceed 3.4%.

- In addition, due to the production method, steel always contains some proportion of manganese - up to 1%, and silicon - up to 0.4%. These impurities have little effect on the properties of the composition if they do not exceed the specified norm. For the same reasons, the composition also contains harmful impurities - phosphorus, sulfur, unbound nitrogen and oxygen. During the melting and alloying process, they try to get rid of these ingredients, since they reduce the strength and ductility properties of the alloys.

- Other additives are artificially introduced into the alloy in order to change the quality of the material. Thus, the addition of chromium gives steel heat resistance, and nickel - corrosion resistance and toughness.

- An extremely useful quality of iron alloys is that the change in properties is influenced by very small additions of other substances by weight. This allows you to significantly diversify the quality of the material. In addition, the properties of the alloy are greatly influenced by the method of manufacturing the product itself - cold deformation, hot deformation, quenching, and so on.

Relation to cast iron

Cast iron is closest to steel in properties and composition. Some of the material is made from cast iron. However, in practice, the differences in characteristics are quite noticeable:

- steel is stronger and harder than cast iron;

- Cast iron is actually lighter than steel and has a lower melting point. The massiveness of cast iron products creates a misleading impression, since it is less durable;

- steel is easier to machine due to its low carbon content. It is preferable to cast cast iron;

- cast iron has lower thermal conductivity, that is, products made from it store heat better than steel ones;

- Cast iron cannot be subjected to a procedure such as hardening. And the latter can significantly increase the strength of the material.

Next, we will consider the advantages and disadvantages of steel.

Advantages and disadvantages

It is quite difficult to describe the pros and cons of the material. In practice, we deal with steel products, and from an alloy of various grades, and, therefore, properties. And one of the features of the material is precisely that the method of manufacturing a product from it also affects its properties. The quality of a welded pipe cannot be compared with the characteristics of a cold-rolled steel pipeline.

In general, we can talk about the following advantages of steel:

- high strength and hardness - characteristic of all types;

- a huge variety of properties due to different composition and different processing methods;

- viscosity and elasticity sufficient for use in all areas where resistance to shock, static and dynamic loads in the absence of residual deformation is required;

- ease of machining – welding, cutting, bending;

- very high wear resistance compared to other structural materials and, accordingly, durability;

- the prevalence of raw materials and an economically viable production method, which determines the affordable cost of alloys.

The disadvantages include the following:

- The biggest drawback of the material is its lack of resistance to corrosion. To avoid damage, special types of steel are produced - stainless steel, but their cost is noticeably higher. More often, the problem is solved by coating steel products with a protective layer of metal or polymer;

- the alloy accumulates electricity, which significantly increases electrochemical corrosion. Any large structures - machine bodies, pipelines - require special protection;

- the alloy is not lightweight, steel structures are heavy and significantly make objects heavier;

- The manufacture of steel products is a multi-stage process. Shortcomings and errors at any stage result in a significant reduction in quality.

Next, we will consider the marking and classification of steels by quality, purpose, as well as composition and other characteristics.