How is strength testing performed?

Strength tests for tensile strength are carried out on special test benches. One end of the test sample is fixedly fixed in them, and a drive mount, electromechanical or hydraulic, is attached to the other. This drive creates a smoothly increasing force that acts to break the sample, or to bend or twist it.

Tensile test

The electronic control system records the tensile force and relative elongation, and other types of deformation of the sample.

Types of tensile strength

Tensile strength is one of the main mechanical parameters of steel, as well as any other structural material.

This value is used in strength calculations of parts and structures; based on it, it is decided whether a given material is applicable in a particular area or whether a more durable one needs to be selected.

The following types of tensile strength are distinguished:

- compression - determines the ability of a material to resist the pressure of an external force;

- bending - affects the flexibility of parts;

- torsion - shows how suitable the material is for loaded drive shafts that transmit torque;

- stretching

Types of material strength tests

The scientific name for the parameter used in standards and other official documents is tensile strength.

Chemical properties of steel:

- Heat resistance - the ability not to oxidize at high temperatures, not to form scale.

- Heat resistance - the ability to maintain strength at high temperatures.

- Oxidability - the ability to combine with oxygen. The higher the temperature of the metal, the higher the oxidation. If low carbon steel is exposed to moisture or humid air, it will oxidize, forming iron oxide - rust.

- Corrosion resistance is the ability not to oxidize, not to enter into a chemical reaction with substances that surround the metal.

Tensile strength of steel

Today, steel is still the most used structural material, gradually losing its position to various plastics and composite materials. Its durability, reliability and safety in operation depend on the correct calculation of the strength limits of a metal.

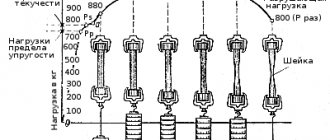

The tensile strength of steel depends on its grade and varies from 300 MPa for ordinary low-carbon structural steel to 900 MPa for special high-alloy grades.

The parameter value is affected by:

- chemical composition of the alloy;

- thermal procedures that help strengthen materials: hardening, tempering, annealing, etc.

Some impurities reduce strength, and they try to get rid of them at the casting and rolling stage, while others, on the contrary, increase it. They are specially added to the alloy composition.

Proof of Yield

In addition to the tensile strength, the related concept of yield strength, denoted σt, is widely used in engineering calculations. It is equal to the amount of tensile strength that must be created in the material in order for the deformation to continue to increase without increasing the load. This state of the material immediately precedes its destruction.

At the microlevel, at such stresses, interatomic bonds in the crystal lattice begin to break, and the specific load on the remaining bonds increases.

General information and characteristics of steels

From the designer’s point of view, the physical and mechanical parameters of steel are of greatest importance for alloys operating under normal conditions. In some cases, when the product is to operate under conditions of extremely high or low temperatures, high pressure, high humidity, or under the influence of aggressive environments, the chemical properties of steel become equally important. Both the physical-mechanical and chemical properties of alloys are largely determined by their chemical composition.

Influence of carbon content on the properties of steels

As the percentage of carbon increases, the plasticity of the substance decreases with a simultaneous increase in strength and hardness. This effect is observed up to approximately 1% share, then a decrease in strength characteristics begins.

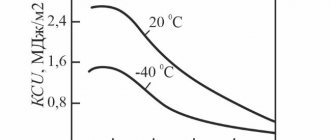

Increasing the proportion of carbon also increases the threshold of cold capacity; this is used to create frost-resistant and cryogenic grades.

The influence of carbon on the mechanical properties of steel

An increase in the C content leads to a deterioration in casting properties and negatively affects the ability of the material to be machined.

Manganese and silicon additives

Mn is contained in most grades of steel. It is used to displace oxygen and sulfur from the melt. Increasing the Mn content to a certain limit (2%) improves machinability parameters such as ductility and weldability. After this limit, further increases in content lead to the formation of cracks during heat treatment.

The influence of silicon on the properties of steels

Si is used as a deoxidizer used in the smelting of steel alloys and determines the type of steel. Quiet high-carbon grades should contain no more than 0.6% silicon. For semi-quiet brands, this limit is even lower - 0.1%.

When producing ferrites, silicon increases their strength parameters without reducing their ductility. This effect persists up to the 0.4% threshold.

The influence of alloying additives on the properties of steel

In combination with Mn or Mo, silicon promotes an increase in hardenability, and together with Cr and Ni increases the corrosion resistance of alloys.

Nitrogen and oxygen in the alloy

These gases, the most common in the earth's atmosphere, have a harmful effect on strength properties. The compounds they form in the form of inclusions in the crystalline structure significantly reduce strength parameters and ductility.

Physical and mechanical properties of steels

Page 1 of 4Next ⇒

General information. Materials used in instrument making. Detachable connections: bayonet (bayonet) connections, clamps. Connections for rotational and translational movements.

General information

The correct choice of materials is one of the most important tasks in the design of instruments and mechanisms, because the accuracy of instrument readings, their weight, insensitivity to changes in temperature, pressure, environmental humidity, etc. depend to a large extent on the properties of the materials used. For example, to reduce the influence of temperature on the sensitive elements of devices, these elements are made either from special alloys (Invar, Elinvar, etc.), or temperature compensators made of bimetals are used (Invar-brass, Invar-steel).

The material for the manufacture of parts is selected taking into account the operating conditions of the parts, the type of production (mass, large-scale, small-scale or single), the cost of the material, the technological process and taking into account the brands of materials used at this enterprise.

When choosing materials, you should remember that non-ferrous metals and their alloys are more expensive than ferrous metals, that the cleanliness of the machined surface depends on both the cutting conditions and the properties of the material, that the friction coefficient of mating parts also depends on the selected materials, which is cheaper in mass and large-scale production use the production of parts of complex designs by injection molding from special alloys or plastics (if increased mechanical properties are not required) rather than by machining on machines, etc.

The following materials are widely used in instrument making:

1. Iron-carbon alloys. 2. Copper alloys. 3. Aluminum alloys. 4. Magnesium alloys. 5. Special alloys. 6. Plastics. 7. Stones and glass.

Materials used in instrument making

Materials used in instrument making include steels, non-ferrous metals and their alloys, plastics, ceramics and many others. The correctly selected material largely determines the quality of the parts and the mechanism as a whole. The choice of part material is carried out on the basis of their physical-mechanical, chemical and technological properties and the compliance of these properties with the operational, technological and economic requirements for the parts.

The operational requirements for the material are determined by the operating conditions of the part in the mechanism. Their implementation is determined by the properties of the material, the main of which are:

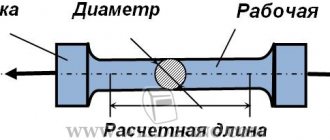

1) strength - the property of a material to resist destruction, as well as irreversible changes in its original shape and size. Strength characteristics are: σв - tensile strength (temporary resistance); σi - bending strength; σ-1 - endurance limit; HB (HRC) - Brinell (or Rockwell) hardness;

2) rigidity, characterized by the elastic modulus E;

3) elasticity, characterized by the yield strength σt;

4) impact strength, the indicator of which is the amount of specific work spent on destruction of the sample;

5) antifriction, characterized by friction coefficient f

;

6) wear resistance - the ability of a material to resist wear, characterized by hardness HRB, HRC or permissible specific pressure p

;

7) corrosion resistance;

material density;

material density;

9) electrical conductivity, thermal conductivity, coefficient of linear expansion, etc.

Technological requirements for the material are aimed at ensuring minimal labor intensity in manufacturing the part. To meet these requirements, the following material properties are taken into account:

1) plasticity - the property of a material to undergo deformation without destruction, which makes it possible to use various methods of pressure treatment in the manufacture of parts;

2) machinability;

3) fusibility and fluidity - properties of the material that ensure the production of parts by casting;

4) heat treatability - the ability of a material to change its properties during heat treatment (hardening, tempering, annealing) and thermochemical treatment (cementation, nitriding, etc.);

5) weldability - the ability of materials to form strong joints when welded.

The economic requirements for materials are determined by the lowest cost of the part, which includes the cost of the material and all production costs for its manufacture. Taking into account these costs, one or another technological process for manufacturing the part is selected. Due to the different costs of preparing production, some technological processes for manufacturing parts (stamping, casting, pressing) are more economically profitable for mass and large-scale production, and for single and small-scale production, it is more profitable to use machined parts.

The properties of materials - their chemical composition and types of metal products (sheets, profiles, calibrated steel, wire, etc.) are regulated by GOSTs.

Physical and mechanical properties of steels

Steels are alloys of iron with carbon and additives of other chemical elements designed to impart certain properties to it. Compared to other materials, steels are characterized by high strength, ductility, good weldability, and good machinability. The properties of most steels can be significantly improved by heat treatment. An important factor is the relatively low cost of steel and a wide range of different types of metal products.

Based on the composition of steel, they are divided into carbon steel and alloy steel. Carbon steels are divided into ordinary quality steels, high-quality structural steels and alloy steels. Alloy steels, in turn, are divided into high-quality, high-quality and especially high-quality.

General purpose carbon steel (GOST 380-71), depending on the type of controlled parameters, is divided into 3 groups:

A - supplied according to mechanical properties (not indicated in the designation);

B - supplied according to chemical composition;

B - supplied according to mechanical properties and chemical composition.

Steels supplied by mechanical properties are designated by the letters St and a number in order of increasing strength. St0 and St6 are most often used . Fasteners, as well as body parts, are made from ordinary quality steels using stamping or welding methods. General purpose carbon steels, as a rule, are not subjected to heat treatment.

Of the mechanical properties of all groups, the tensile strength is normalized - from σв =320 MPa, not less (St0), to σв =600 MPa, not less

(St6), and relative elongation - from 23 to 12%, respectively. In addition, the yield strength σt and, for some categories, impact strength are normalized.

Designation example: St3-3 GOST 380-71 - general purpose carbon steel, supplied only by mechanical properties, steel grade St3, tensile strength and elongation are controlled (category 3).

High-quality structural carbon steel (GOST 1050-74) is provided in grades 05, 08, 10, 15, 20, 25, 30, 35, 40, 45, 50, 58, 60 with a carbon content of 0.06% no more (steel 05 ), up to 0.57-0.65% (steel 60). The brand designation corresponds to the average carbon content in hundredths of a percent. According to the degree of deoxidation, mild steel is produced (not indicated in the designation), semi-calm steel - PS grades 08ps, 10ps, 20ps and boiling steel - grades 05kp, 08kp, 10kp, 15kp, 20kp.

Supplied hot-rolled and calibrated - round, square, hexagonal, in the form of sheets, strips, tapes, wire, as well as round with a special surface finish (silver), without heat treatment (not specified), heat treated (normalized) -T. and cold-worked - N (for calibrated steel and silver).

Depending on the purpose, hot-rolled steel is divided into subgroups:

a - for hot pressure treatment;

b - for cold machining;

c - for cold drawing.

Among the mechanical properties, hardness, yield strength, tensile strength, relative elongation, relative contraction, and for a number of steel grades also impact strength are standardized. For normalized steels, the tensile strength is normalized: from σв = 330 MPa (steel 08) to σв = 690 MPa (steel 60) with a relative elongation from σ = 33% to σ = 10% depending on the steel grade, for work-worked steels (steel 10 …50) σв = 420-670 MPa, σ = 8..6 %.

There are structural low-carbon case-hardened steels (carbon content up to 0.25%), medium and high-carbon steels (carbon content over 0.3%), which can be subjected to heat treatment.

According to the requirements for testing mechanical properties, the following categories of steel are provided:

1- without tensile and impact strength tests (only hardness is standardized);

2- with testing on samples from normalized blanks with a diameter of 25 mm;

3- the same with a sample diameter of up to 100 mm;

4 - the same on quenched and tempered samples;

5 - the same on cold-worked samples (for calibrated steel). If the grade designation in the order does not indicate the steel category,

Category 2 steel supplied.

Example of designation: steel 30-2-a GOST 1050-74 - high-quality carbon steel structural grade 30, 2nd category, subgroup a.

In instrument making, steels of high ductility (08; 08kp; 10; 10kp) are used for lightly loaded, thermally unprocessable and uncemented parts (gaskets, washers, rivets, housings), as well as for parts produced by cold stamping (mainly steel 08; 08kp; and 05kp).

Low-strength steel (15, 15kp, 20, 25) is used to make loaded parts (forks, flanges, bolts, housings), thermally untreated, and also subjected to carburization or cyanidation followed by hardening and tempering (axles, levers, cam shafts, gears, fingers, stars, etc.).

Medium-strength steels (35, 40, 45, 50) are used after normalization, improvement, hardening with low tempering, surface hardening with high-frequency heating for the manufacture of various instrument-making parts (axles, levers, pins, ratchets, stops, keys, gears).

Alloy structural steel (GOST 4543-71) is supplied hot-rolled without heat treatment; heat-treated (annealed or normalized) - T; calibrated with special surface treatment (silver), heat-treated (annealed, tempered, normalized or hardened) - T; hard-worked - N.

To designate high-quality and especially high-quality steels, the letters A or Ш are placed at the end of the mark, respectively.

Depending on the main alloying elements, steel is divided into groups. Including:

chromium - 15X, 30XA, 30XRA, 40X, 50X, etc.,

manganese - 15G, 50G, 10G2..50G2,

chromium-manganese with additions of boron, titanium, vanadium, molybdenum 18ХГ, 18ХГТ, 20ХГР, 25ХГМ, 35ХГФ, etc.,

chrome-molybdenum, chrome-molybdenum-vanadium - 15ХМ, 30Х3МФ, 4ХМФА,

chromium-nickel, chromium-nickel with boron - 20ХН, 20ХНР, 30ХН3А.

In total, about 100 brands have been standardized.

In the stamp, the first numbers are the average carbon content (hundredths of a percent); letters - name of the alloying element: B - tungsten, G - manganese, N - nickel, P - boron, C - silicon, T - titanium, F - vanadium, X - chromium, Yu - aluminum, M - molybdenum. The numbers after the letters indicate

approximate content of alloying element in percentage (if there is no figure - no more than 1.5%).

Alloy steels, like carbon steels, are divided into cemented (up to 0.25% C) and tempered (0.25-0.5% C). The surface hardness and wear resistance of case-hardened parts made of alloy steels remains at the level of those made of carbon steels, but the core properties of such parts are higher. Alloy steels are used for the same purposes as carbon steels, but for more critical large loaded and precise parts and always in heat-treated form.

Corrosion-resistant steels are alloyed with a significant (from 13 to 25%) amount of chromium, and sometimes nickel. Chromium steels (30Х13, 40Х13) are strengthened by heat treatment, chromium-nickel steels (Х18Н10Т, ОХ22Н5Т, etc.) are strengthened only by plastic deformation; they are non-magnetic (GOST 7350 -77).

1Next ⇒

Recommended pages:

Use the site search:

Alloying additives in alloys

These are substances deliberately added to the melt to improve the properties of the alloy and bring its parameters to the required ones. Some of them are added in large quantities (more than a percent), others in very small quantities. I most often use the following alloying additives:

- Chromium. Used to increase hardenability and hardness. Share – 0.8-0.2%.

- Bor. Improves cold brittleness and radiation resistance. Share – 0.003%.

- Titanium. Added to improve the structure of Cr-Mn alloys. Share – 0.1%.

- Molybdenum. Increases strength characteristics and corrosion resistance, reduces fragility. Share – 0.15-0.45%.

- Vanadium. Improves strength parameters and elasticity. Share – 0.1-0.3%.

- Nickel. Promotes an increase in strength characteristics and hardenability, but at the same time leads to an increase in fragility. This effect is compensated by the simultaneous addition of molybdenum.

Metallurgists also use more complex combinations of alloying additives, achieving unique combinations of physical and mechanical properties of steel. The cost of such grades is several times (or even tens of times) higher than the cost of conventional low-carbon steels. They are used for particularly critical structures and assemblies.

Loss of stability at stresses exceeding the proportionality limit. Yasinski's formula

The derivation of Euler's formula is based on the application of the differential equation of an elastic line under the assumption that the material of the rod obeys Hooke's law. Consequently, Euler’s formula is applicable only in the case when the critical stresses do not exceed the proportionality limit, i.e.

Let us determine the critical stresses:

Considering that

where i

min – the smallest of the main radii of gyration of the cross-section

of the rod, we get:

The ratio of the reduced length of the rod to the radius of gyration of the section is called flexibility and is denoted by , i.e.:

Finally we get:

Euler's formula will be applicable until the critical stresses become equal to the limit of proportionality, i.e.

Hence,

Let us determine the limit of applicability of Euler's formula

for rods made of steel St.3, for which the modulus of elasticity is E

= = 2´105 MPa

,

proportionality limit

σ

pc = 200 MPa, yield strength

σ

t = 240 MPa:

Thus, Euler's formula can be used for rods with a slenderness greater than one hundred. Otherwise, Euler's formula cannot be applied.

In a similar way, you can calculate the limit of applicability of Euler’s formula for any other material, knowing the value of its elastic modulus and proportionality limit. For cast iron, Euler's formula is applicable for flexibility > 80, for pine for flexibility > 110.

Let us construct a graph of the dependence of critical stresses on the flexibility of a rod made of steel St.3. If on the ordinate axis (Fig. 12.9) we plot the value of the limit of proportionality ( σпз

==

200 MPa) and draw a straight line from the resulting point parallel to the abscissa axis, then at the intersection with the Euler hyperbola it will give point

K

, the abscissa of which is = 100.

To the left of point K

Euler's hyperbola is shown with a dashed line, since here it gives stress values that are large than the limit of proportionality and the stability of the rod becomes questionable in this region.

It is difficult to solve the problem of stability beyond the proportionality limit theoretically; therefore, empirical formulas are usually used to determine critical stresses. Professor F. S. Yasinsky collected and processed extensive experimental material on longitudinal bending of rods and compiled tables of critical stresses for rods of different flexibility.

Fig. 12.9. Critical stress graph

on the flexibility of the rod

Experiments have shown that short rods with low flexibility (0< < < 40) do not lose stability and collapse from simple compression when the stresses in them reach the yield point, i.e. for them σcr

= =σT

.

For rods of medium flexibility (40 < < 100), Yasinsky proposed an empirical relationship

,

where a

and b

– coefficients depending on physical and mechanical properties

material.

For steel (Art. 3)

:a =

310 MPa,

b

= 1.14 MPa.

For wood (pine): a =

29.3 MPa, b

= 0.194 MPa.

Thus, the graph consists of three parts: the Euler

for rods of high flexibility, an inclined straight line for rods of medium flexibility and a slightly inclined straight line for rods of low flexibility.

Similar graphs can be constructed for other materials.