The evolution of metal roofing

One of the oldest metal roofing materials is seam, which was widely used in pre-revolutionary Russia, and after that in the countries of the Soviet Union. With the development of machine tools, seam roofs were supplemented by roofs made of corrugated sheets profiled from galvanized steel. Metal tiles with a characteristic profile and polymer coating imitating piece ceramic tiles are a Finnish invention. Domestic metallurgical enterprises producing rolled metal products have mastered the technology of painting them, but have not gotten to the point of forming themselves. The first metal tiles appeared in our country in the 90s of the last century - the coated “roll” was produced by the Rautaruukki plant, and its subsidiaries profiled several types of ridges and additional elements. At that time, metal tiles were considered a premium material and a sign of wealth; they were used to cover “epoch-making” cottages made of Italian brick.

At the beginning of the 2000s, Russian metallurgical plants modernized their production, equipping it with powerful (up to two hundred thousand tons per year) lines for the production of galvanized steel coils with polymer coating.

The first national standard for painted coiled steel was issued in 2003 - GOST R 52146-2003 “Cold-rolled and cold-rolled hot-dip galvanized sheet metal with polymer coating from continuous lines. Technical conditions". An improved version, still in effect today, was adopted in 2017. This standard is focused on the raw materials from which not only metal tiles, but also other metal building structures are profiled.

Initially, demand for the new product grew at a high rate, up to 25% per year. As saturation progressed, these figures decreased, but even now more than half a million tons of rolled steel are processed annually into metal tiles and other roofing coverings. Modern collections of metal roofing differ in the type of profile, type of polymer coating and characteristics.

Galvanized roofing sheet - what kind of material is it and what is made from it

The main function of the roof is protective. A roof covering, made, for example, from roofing tin, protects load-bearing structures and interiors from precipitation. Leakage of melt or rain water can damage the structure of a structural element and cause irreparable damage to finishing materials.

Ultimately, this may lead to the need for major repairs, which is associated with large material and labor costs. There are several types of popular roofing materials. One of these is roofing tin.

Technology for the production of metal roofing coverings

Although profiling plays an important role in the production process, the main technical and operational characteristics of a metal roof depend on the parameters of rolled steel.

Irina VanhonenPromotion manager for new types of products in the “Coated rolled products” category

The production of rolled steel at our plant begins with the preparation of iron ore raw materials and coking coal to produce cast iron in blast furnaces. Then steel is made from cast iron and a small amount of scrap metal in converters. This is followed by casting, rolling, galvanizing, and applying a polymer coating. The process ends with testing the product for compliance with the color standard, gloss level, and resistance to mechanical damage.

Based on the results of tests in climatic chambers on polymer-coated steel products, we provide a guarantee. The lifespan ranges from 30 to 50 years, depending on the class of zinc coating and the region of operation. “Steel silk” and “Steel velvet” – up to 30 years, “Steel cashmere” – up to 50 years.

The profiling of rolled products and the production of the final product are carried out by official dealers who produce not only metal tiles with the texture of expensive fabric, but also corrugated roofing and seam roofing. The Severstal technical support service audits the equipment of those who want to become a dealer of the plant to ensure that the quality of profiling meets the requirements.

- No creases along the edge.

- No damage to the polymer coating.

- Availability of separate lines for profiling rolled products with a polymer coating and galvanized rolled products without a protective and decorative layer.

Despite the fact that the manufacturer’s responsibility, in fact, ends at the stage of production of rolled steel, control of suppliers (dealers) is the key to the end consumer receiving high-quality metal roofing.

Metal roofing market

There is a large selection of polymer-coated rolled steel on the market from domestic and foreign manufacturers:

- Severstal;

- Novolipetsk Iron and Steel Works (NLMK);

- Magnitogorsk Iron and Steel Works (MMK);

- Ruukki (SSAB);

- Tata Steel;

- ArcelorMittal et al.

As for the final products, in addition to branded ones, there are also “non-name” metal roofs and outright counterfeits on sale. The 2021 standard is focused on polymer-coated rolled products, from which roofing materials and materials for other household purposes are made, and it does not contain precise technical parameters specifically for roofing coatings. This allows unscrupulous manufacturers to manufacture products from cheaper, non-specialized rolled products. Relatively recently the situation has changed for the better.

Irina VanhonenPromotion manager for new types of products in the “Coated rolled products” category

Now the quality of metal roofing materials is regulated by GOST, developed on the basis of research, scientific institutes, and other industry participants. All of our company’s products, manufactured under roofing brands, meet GOST requirements (and even exceed them) and are comparable in all respects to the products of leading European brands.

The national standard clearly states the main requirements for metal roofs.

- The minimum permissible thickness of the steel base is 0.5 mm (including the protective metal coating, but excluding the polymer coating).

- The minimum class of metal protective coating for rolled steel is 140 (recommended class is 180 and above).

- The minimum thickness of the front polymer coating is 23 microns (taking into account the soil and the maximum thickness deviation of ±2 microns).

- The color of the polymer coating is taken according to the palette of RAL catalogs and other catalogs.

Determining visually, without resorting to complex laboratory methods, whether a metal roof meets these parameters is unrealistic even for a specialist, not to mention consumers. Therefore, information about the manufacturer and basic characteristics of the product is now contained in markings applied to the back of the sheet or panel. Together with a quality certificate (the supplier must have it), this is a guarantee of the authenticity of the material. The mere presence of a certificate, but without markings directly on the metal tiles, corrugated sheets or seams, is a reason to think. A significant proportion of products of dubious quality found on sale is the flip side of the popularity of metal roofing.

Andrey BotkinHead of Roofing Department

Everywhere, the most popular roofing material among consumers is metal tiles. Demand for other metal roofing varies depending on the region of construction. For example, corrugated sheeting is traditionally most often found in the Krasnodar region.

The popularity of metal roofs, both in Europe and here, is due to their high technical and operational characteristics.

- Resistance to all atmospheric factors - metal in polymer is not afraid of either precipitation or wind load.

- Resistance to temperature fluctuations - coatings can withstand both severe Siberian frosts and the scorching sun of the southern regions.

- Fire resistance - the metal does not burn, and to melt it you will need a converter furnace.

- Resistance to mechanical stress - to abrasion or damage both during installation and during operation.

- Decorative – a huge selection of colors, different types of profiles, exquisite textures.

- Availability – optimal price-quality ratio.

Considering that a house is built to last for decades, and the warranty period for a high-quality branded metal roof starts at 30 years, the choice seems obvious. However, the products of little-known manufacturers are attractive to many because of their low cost.

Andrey BotkinHead of Roofing Department

The selling price for metal roofing from different manufacturers can differ by more than two times. But this difference is due not only to the brand, but also to the characteristics of the materials. In the first case, the thickness of the metal base of the metal tile will be 0.5 mm, and in the second - 0.33. Visually, the coatings may even look equally presentable, but the first has a warranty of 30 years, and the second – up to 10 years. In addition, within the framework of the costs of the roof as a whole (rafter system, thermal insulation, membranes, etc.), savings only due to the difference in the price of the finishing layer will be insignificant.

That is, the benefit may turn out to be illusory, but the prospect of re-covering the roof in the foreseeable future is real. Especially if we are not talking about budget material with reduced technical characteristics, but about counterfeit products that do not correspond to the declared parameters at all.

Self-installation

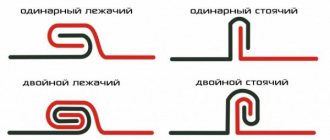

The most economical and common type of laying sheets on the roof can be called seam technology. The basis of this principle consists of the method of connecting elements with curved edges, which form transverse and longitudinal seams (they are called folds).

Transverse seam joints are convenient when the horizontal size of the slope exceeds the classic length of the steel sheet. They come in double and single types and are called horizontal because they have the same direction. They are also recumbent - they are bent towards the sides of the water flow , so that there are no unnecessary barriers to the flow of precipitation.

Longitudinal seam seams should connect the covering elements along the vertical slope (side line of the sheet). They should not be bent so as not to cause stagnation of water on the roof. That's why they were called standing ones. Installation using seam technology involves the use of horizontal standing joints.

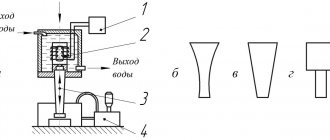

If possible, it is worth eliminating single horizontal connections, which can reduce the roof’s ability to resist atmospheric damage. Standing double folds are the most practical and reliable option. The seams are formed using a wooden screw and hammer or special electromechanical machines.

Description of the specifics of the structure

The main element of the roof is a part assembled from two steel strips with curved edges, which are required for further connection. This piece is called “paintings” and is assembled on the ground. You will need a special workbench that matches the length of the parts of the picture to be joined.

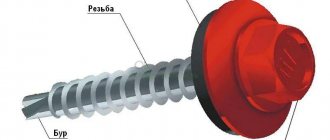

To splice paintings, homemade clamps are required: they are cut from the same sheet of steel, the strips have sides of 3 and 15 centimeters. They are attached every half meter from the vertical seam line. The required amount of fasteners is made in advance from scrap metal sheets. The parts are cut with scissors, since the grinder will leave uneven jagged edges and will also burn out the protective coating.

The assembled paintings with the edges prepared for joining remain to be lifted up.

Rafter system and sheathing

The construction of a rafter system will differ little from the technology for constructing frames for other roofs. It is not necessary to place the rafters very often here, since the material is distinguished by its lightness. But the sheathing beam will need to be installed at intervals of twenty centimeters, because you need to take into account the ability of the metal to bend. Due to this, damage to the coating can be prevented.

The minimum slope of the slopes for a metal roof is 14 degrees, the maximum is 30. If the roof is insulated, then you will need to build a counter-lattice of thin slats on top of the waterproofing in order to form a ventilation gap between the insulating layer or the metal coating. Thanks to such ventilation, there will be an equal temperature on both sides, therefore, condensation will not settle, which can destroy the metal.

The eaves overhang is made of three or four solid boards. The ridge is formed by laying boards on both sides, they converge at a single point.

Assembly of elements and final installation

The assembly of a metal roof fencing must begin with the installation of crutches, which are installed every seventy centimeters along the eaves overhang. First, two crutches are nailed along the edges, a cord is pulled between them for subsequent alignment of other parts.

The paintings are transported by a car lift to a storage area organized above. Along the line of the second picture, clamps are attached every half meter; self-tapping screws are used for this. The clamp is positioned so that the picture laid on top can cover the point of its fixation. After this, the first picture is installed, its side line should coincide with the line of the pediment. The first element is fastened through with self-tapping screws.

Elements of a seam roof must be mounted according to a similar scheme: clamps are installed, then the installation of the next strip, connection with the previous sheet. The fold must be folded together with the fastening strips. Experienced roofers recommend strengthening seams with silicone sealant. And in order to avoid unbending homemade clamps, it is allowed to supplement their location point with a riveting.

And the final steps for installing a metal roof will look like this:

- Upon completion of the splicing, the joints must be sealed with strips of metal and a hammer.

- Then the smaller edge on the ridge is folded over, and the larger ridge edge is placed on top.

- If the galvanized surface does not look very good for aesthetic reasons, then it can first be primed with pigmented drying oil, and then painted in any color you like.

Options for choosing the optimal metal roof

Initially, when metal roofing with a polymer coating was represented only by metal tiles, the choice came down to the type of profile and color; later the texture of the material was added. Today, metal tiles are on sale in several variations, as well as corrugated sheets and seams. The majority of consumers place the durability and presentability of the material at the forefront, which is quite logical - they want the roof to last as long as possible, and beautifully so that it is “pleasant to the eye.” But all high-quality metal roofs now meet these requirements, so other factors should be taken into account when choosing.

- Complexity - the more complex the roof structure, the higher the requirements for the roofing covering both in terms of technical and operational parameters, and in terms of decorativeness. Complex roofs are usually on houses with non-standard architecture and the roof should organically complement it, and not discord. A complex shape means a large number of potentially problematic components in terms of tightness. For the most complex roofs, rebated metal roofing is considered the optimal solution. This is primarily due to the installation features; the rebate is laid without any perforation at all, due to which the coating forms the most airtight contour. Next comes metal tiles, while corrugated sheeting is more suitable for simple, gable or single-pitched roofs (except for roofs with a minimal slope).

- Climate and operating conditions - the more aggressive the environment, the more durable the decorative and protective coating of a metal roof should be. If the house is surrounded by tall trees and the roof is in direct contact with branches, or their fragments will fall on it, the coating should be as resistant to mechanical stress as possible. If the region is characterized by hot summers with scorching sun, resistance to UV radiation is a priority. Polyurethane can provide both, as well as resistance to high humidity on the coast or the smog of industrial agglomerates. Under normal operating conditions, without aggravating factors, polyester will be sufficient.

- Aesthetic preferences - for adherents of the high-tech style and minimalism, both seam and corrugated sheets, with their strict lines, are equally relevant. Whereas connoisseurs of classical architecture would rather prefer the smooth curves of metal tiles.

Metal roofing coverings are as diverse as possible and fully satisfy the needs of consumers in terms of reliability, durability, presentability, and, what is especially important in the current conditions, accessibility. Even with a limited budget, it is possible to choose a decent coating from a reliable manufacturer.

Installation of roofing pictures

When making sheathing for a tin roof, an edged board with a cross section of 50×50 millimeters is used. It should be stuffed perpendicular to the rafters. The sheathing pitch should be 250 millimeters. If the distance between the sheathing boards is greater, then the roofing material may sag, which is not at all desirable.

When making a continuous sheathing, it is necessary to provide a ventilation gap. It should be between the roofing sheet and the sheathing.

Roofing pictures are fixed from left to right. The first row of roofing material is laid with an overlap. Along the eaves overhang the overlap should be 100 millimeters, and along the gable overhang - from 20 to 30 millimeters. The paintings are secured to the sheathing using clamps.

The roof covering is laid in vertical stripes. They are attached from the ridge to the roof overhangs. The strips are connected to each other by means of lying seams, which must be positioned strictly horizontally relative to the roofing ridge. When flattening lying seams, it is advisable to lubricate them with sealant.

Next, the second row is installed. To do this, you first need to place the pictures in the first row. Compared to the first row, the second row will have a smaller edge.

After installing all rows of paintings, you can begin joining along the roof ridge. All excess roofing sheets must be cut off along the ridge using special scissors. To form a standing seam joint, make one side lower and the other higher, after which the edges are folded.

Components of a durable roof

In order for a metal roof to fully use up its intended resource, it is important not only the quality of the roofing itself, but also compliance with the installation technology.

Irina VanhonenPromotion manager for new types of products in the “Coated rolled products” category

The most important condition for the quality and durability of roofing is professional installation, carried out by specialized construction teams.

If (albeit not in the most perfect form) state standards for materials have existed since the beginning of the 2000s, and over the last year a full-fledged GOST for metal roofs was already in effect, the work was more difficult. A separate national GOST for installation was developed with the direct participation of specialists and approved only last year. GOST R 58739-2019 “Roofing works. Installation of roofs with metal roofing. Rules and control of work performance.” Valid from 01/01/2020

Anna MolchanovaDeputy Executive Director of the National Roofing Union

After the entry into force of GOST for the production of metal tiles, an increase in the quality of rolled steel has been observed. The first results of the introduction of a national standard for the installation of metal tiles will appear some time later, at the end of the roofing season (summer-autumn). But today it is a real tool for protecting the interests of both consumers and performers. In addition to the fact that the customer now has the right to demand installation in accordance with GOST, if controversial situations arise, an examination will be carried out on its own basis. If violations are detected, the results of the examination will become the evidence base in legal proceedings against unscrupulous installers. And, on the contrary, compliance with the standard during installation, confirmed by an examination, is an ironclad argument against the customer’s unfounded claims.

Even the best material can be damaged by improper use, metal roofing is no exception. The introduction of GOST standards not only for metal tiles, but also for installation, is an effective way to improve the quality of metal roofing in general.

What is roofing material

The production of galvanized roofing sheets is launched in two versions - in rolls and sheets. The thickness of the sheets varies between 0.5-1 mm. In most cases this is enough to create a durable one.

Reliable, durable roofing covering. Installation of roofing sheets is carried out using the folding method. This is a labor-intensive process that requires specialists to have certain qualifications, experience and knowledge.

In addition, installing a tin roof is an expensive technology, much more expensive than, for example, installing a soft roof. The optimal application option is low-rise construction with a relatively small roofing area.

It is also necessary to incur certain costs for the maintenance of a roof made of galvanized roofing sheet. Periodically clean and paint.

Conclusion

Metal roofing is the key to the durability of the roof and the attractive appearance of the house. But only if you use high-quality roofing, manufactured and installed in accordance with current standards. When choosing the type of metal roof, it is necessary to take into account the roof structure, climatic conditions in the region of residence and the desired service life. Thanks to a large selection of decent coatings in different price segments, you no longer have to skimp on quality.

You can learn more about the rebate, including on the facade, in one of the previous materials. In the construction “series” - about the BarnHouse with a seam roof. The profile topic on the forum has a lot of useful information about the selection and installation of metal roofs. In the video there is a large beautiful frame frame in a picturesque place.

Subscribe to our Telegram channelExclusive posts every week

Types of galvanized roofing

Galvanized steel is often used in private, commercial and industrial housing construction as a roofing material. This coating is distinguished by its affordable price, fairly light weight, long service life, and high reliability.

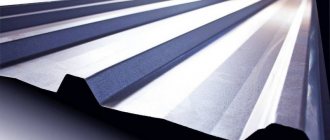

If previously roofers had at their disposal only sheets of rolled steel, which were joined using a seam method to create a sealed layer, now the choice of materials based on this metal is much wider. The most common derivatives of roofing steel are:

- Roofing steel . This material is a roll of rolled galvanized steel, from which roofing pictures of the required size are made. The paintings will be connected to each other using a fold joint, that is, the edges of the large fold are folded over the small one using a sheet bender. This technology allows for a strong, durable coating, in which, if necessary, it is very easy to repair individual panels. In addition, seam joining of sheets reduces material consumption and reduces the number of horizontal seams.

Note! Over time, metal manufacturers are expanding the range of steel roofing coverings. Galvanized iron for the roof can be in the form of bitumen tiles, that is, metal tiles coated with bitumen, or modular metal tiles, that is, sheets with a small cross-section.