The exact technical definition of a gearbox is a device for converting mechanical energy in terms of parameters. It has characteristics of input and output indicators. In practice, the gearbox can not only change the kinetic parameters and levels of energy transfer, but also change the direction of rotation and following of the shafts.

Today, a gearbox is considered in terms of a device that is used to change the shaft rotation speed relative to the drive mechanism. At the same time, the possibility of increasing torque or ensuring an extremely low number of revolutions with very serious efforts can be considered. By design, gearboxes are divided into:

- cylindrical;

- conical and conical-cylindrical;

- worm;

- planetary;

- combined, in which several conversion schemes are used simultaneously.

To understand how suitable a particular type of gearbox is for solving the tasks assigned to it, it is worthwhile to dwell in detail on the features of their operation and conditions of use.

Front and rear gearboxes - what's the difference?

If we consider the elements of both gearboxes in isolation from the overall system, then it will not be possible to determine whether it belongs to the drive. But upon comparative analysis, it turns out that the driven gears of the rear mechanism will be larger. Otherwise, only the configuration of the location of the combined nodes changes. In particular, the rear axle gearbox is located along the longitudinal line of the automobile body together with the gearbox and engine. The cardan shaft is responsible for the flexibility of the coupling. The front-wheel drive system uses ball-type angular velocity reducers. Otherwise, the mechanics of work remain the same.

Application of the mechanism

The purpose of the gearbox is unlimited; most complex machines and units have it in the structure of the mechanism. In heavy industry, worm and cylindrical mechanisms are most often used to transmit force to the tool.

It is also the main component of the mechanism of any car, where several similar elements are used. It is found in the gearbox, driveshaft, gasoline pump, brake system and other components.

Some car owners think that the gearbox and differential have an identical design and perform similar functions. But unlike a gearbox, which changes torque, a differential distributes torque between the axles in a certain proportion, without increasing or decreasing it.

Pressure reducers can be found in gas production. Their use allows you to control pressure and change its direction, be it gas or water pressure. In the oil refining field, a similar mechanism is used in generator sets, various mixers, heating and ventilation systems. Cement plants use planetary models, which are components of conveyor belts that transfer huge amounts of materials. The purpose of wheel gearboxes is to operate belt conveyors.

Almost every production uses devices such as winches and lifts, each of which has a gearbox in its design. Similar mechanisms are found in earthmoving equipment, which is used in construction and industrial quarries.

You can find such models in various household appliances. But most often geared motors are found (in food processors, washing machines, rotary hammers and drills). Rotary hammers use a combination of planetary and geared motors, which allows for optimal performance of translationally rotating elements.

It should be noted that almost every modern complex mechanism cannot do without the use of a gearbox. This element can significantly increase engine performance, transfer force between structural elements and minimize wear of mechanisms. Choosing the appropriate model, timely maintenance and compliance with the standard load will allow you to fully use the gearbox throughout the warranty period, regardless of the scope of its use.

If you find an error, please select a piece of text and press Ctrl+Enter.

To change the torque characteristics, a special mechanism is used, which is called a “gearbox”. This word is derived from the Latin reductor - taking back or returning, which very accurately reflects the principle of operation of this mechanism. At the moment, there are several types of gearboxes that are used in various units to transform and transmit torque from the device’s engine to power consumers.

Read also: Hydraulic press for cable lugs

How is a gearbox different from a differential?

This unit is often confused with a gearbox, which is not entirely correct, although there are good reasons for this. Indeed, both units are part of the same structural system, which is responsible for the transmission and distribution of torque. What is a gearbox in this infrastructure? This is a mechanism that lowers or increases the rotation speed by transmitting movement to the differential. The latter, in turn, does not affect the dynamics of the torque, but only distributes the force between the axles. For this reason, the differential is called an interaxle differential. However, there is also a type of inter-wheel units that can also change the proportions of torque, transmitting it to the wheels when cornering.

Excavator swing gear

The rotation mechanism of an excavator is quite complex, and its main element is the rotation gearbox. With its help, the angular movement of the executive part of the machine occurs.

Excavators have different types of turning mechanisms. The most used is the planetary gearbox. Due to the complex gear scheme, this type of rotary gear has a rather complex design. The device has a ring gear located along the edge.

Using a swing gear on excavators has a number of undeniable advantages. We can offer high-quality equipment that is reliable and has a long service life. Our warehouse is overflowing with a variety of device models, from which you can choose exactly what you need.

Worm gear

A fairly simple and therefore widespread mechanism, the operating principle of which involves the use of a gear with a worm thread in the profile. From an operational point of view, this is the optimal solution for transmitting speed between two axes located perpendicularly. In particular, gearboxes of this type are used in the steering of passenger vehicles. The advantages of worm systems include the ability to produce a high gear ratio (up to several hundred) in one stage. In addition, the worm gearbox is silent, runs smoothly and does not require the use of braking devices, since it activates its own braking mechanism when a certain level of gear ratio is reached.

Helical gearbox: general information

The helical gearbox is the most common type of converter mechanism. It has the main characteristic: the input and output shafts are strictly parallel, but not necessarily coaxial.

The advantages of a helical gearbox include:

- high efficiency, energy losses are minimal;

- does not have self-braking, it is always possible to rotate the output shaft even with little force;

- can transport high power;

- has kinematic accuracy;

- practically do not heat up, without requiring special cooling conditions;

- Products are produced with different gear ratios and conversion stages.

Due to the presence of a large range of products on the market, it is not difficult to select a spur gearbox with the desired gear ratio for use in a particular mechanism.

Features of the combined gearbox

Also in some way a hybrid design, but in this case it combines not an engine with a gearbox, but two different types of torque transmitter. If in the previous case, only one type of transmitter could be implemented based on a gearbox, then in combined installations a cylindrical mechanism is combined with a planetary, bevel or worm gear. There are also no special restrictions on location. This can be either a rear or a front gearbox with a corresponding set of operations and its own specific operation. For example, in a combined-bevel system, as a rule, the wheels are provided with curved teeth in the profile, since this stage will account for the highest angular velocities with a torque of about 60 thousand rpm.

Features of bevel and bevel-helical gearboxes

The operation of bevel and bevel-helical gearboxes has the same features and basic characteristics as cylindrical devices. The main difference is in the shape of the gears inside the housing.

As the name suggests, a bevel gearbox has all gears of a conical shape; a bevel-cylindrical gearbox has elements of both types in its design.

Gearboxes of these classes have their own characteristics:

- capable of changing the direction of the shafts, a bevel gearbox with one conversion stage provides a rotation of 90 degrees;

- the force during gear operation is directed at an angle to the shaft axis. Therefore, bevel and bevel-helical gearboxes must be secured separately to avoid lateral pressure on the drive axis. This may somewhat complicate the design of mechanisms with their participation.

The types of gearboxes under consideration are used only in cases where it is impossible to do without changing the direction of the shaft. These devices are expensive, which is easily explained by the increased complexity of manufacturing gears and the need to guarantee the accuracy of the assembly of the gearbox as a whole.

But otherwise, the devices operate almost silently, products are offered with different gear ratios, they do not require special maintenance, and their service life is very long. The rules for calculating the output shaft speed and torque are the same as for helical gearboxes.

Main characteristics of the gearbox

The most significant technical and operational parameters of the gearbox include the following:

- Gear ratio. Reflects the ratio of the number of gear teeth to the number of gear teeth in the gear. The calculations can also take into account the number of passes to the worm gear and the ratio of the diameter of the larger pulley to the thickness of the smaller pulley in the belt drive.

- Reliability. It does not affect the performance qualities, but expresses the service life of both individual elements and the system as a whole. By the way, changes in structural parameters due to wear can also affect the quality of the main functions of the mechanism, which is also reflected in adjacent units. For example, an axle gearbox may well affect the performance of the axles through a forced reduction in torque.

- Efficiency. Characterizes the performance and efficiency of the device in terms of the quality of energy transmission. To determine efficiency, the ratio of energy used to energy expended is used.

- Protective and insulating qualities. Determined by the IP protection class system. For example, standard mechanisms today are provided with IP 55 housings capable of withstanding temperatures ranging from -15 to 40 °C. The insulation also prevents dust particles, dirt and water from entering the housing.

Blade rotation gearbox

It is a part of the working equipment of a motor grader.

It performs the function of rotating the middle blade to the required angle. From the gearbox, the forces are transmitted to the ring gear, which is located on the turntable. Consists of a housing, shaft, adapters, gears.

The part makes it possible, for example, to efficiently and practically operate equipment for effectively clearing snowy areas in winter.

Heavy equipment cannot do without a blade rotation gearbox, as it allows you to perform many tasks that require a lot of effort from the vehicle. Thus, you can easily loosen the soil, clear the road from snow, level areas for further construction, and move soil from place to place.

Basic structure of the unit

The gearbox housing is usually made of high-strength cast metal with a thermal protective coating. For example, it could be cast iron or steel alloy. If technological requirements set the task of making the structure lighter, then light-alloy housings can also be used. The outer part has fastening units - the so-called legs and ears, thanks to which the unit is securely fixed to the place of operation. Channels are also provided for sealing and sealing to prevent the leakage of technical fluids. But what is a gearbox from the inside? The central part houses the mechanical infrastructure that directly provides power torque to the bridge base. This is a system of driven and driven gears that interact with the shaft. The driven group is usually larger than the leading group, and also has more teeth that move functional units.

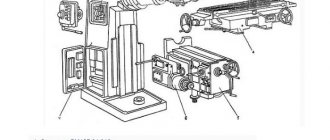

Gearbox device

Types of gearboxes

The purpose of the gearbox is to transmit torque from the drive to the actuator and change the torque and angular speed, including the direction of shaft rotation. In mechanical engineering, worm, cylindrical, bevel, planetary, wave and other types of gearboxes are used. They are used to drive winch drums for freight and passenger elevators or conveyor belts, in worm and gear hoists, for rotating rolls of rolling mills, etc. The main working element of the gearbox is a gear wheel, which meshes with the mating wheel, ensuring the transmission of torque. A spur gearbox, used to transmit torque between parallel shafts, uses a spur gear, the engagement of which can be spur, helical or herringbone. To transmit rotation between perpendicularly located shafts, a worm or bevel gear is used. The worm gearbox uses the so-called. worm gear, consisting of a worm and a worm wheel. The worm can be cylindrical or globoid. The bevel gearbox uses bevel gears with spur or helical gearing, the axes of rotation of which are located at 90° to each other. The most complex, productive and expensive is the planetary gearbox, which is used to transmit rotation between coaxial shafts, where large gear ratios, high performance and compactness are required.

How the gearbox works

Let's consider the purpose and design of the gearbox, the principle of operation using the example of a two-stage helical gearbox.

The main elements of the gearbox are the housing in which the gearbox parts are mounted, a low-speed shaft, designated by the letter T, and a high-speed shaft (B), an intermediate shaft and gears. Since the main purpose of the gearbox is to increase torque due to reduction, i.e. decreasing the angular speed of rotation of the output shaft, then the low-speed shaft is connected to the actuator, and the high-speed shaft is connected to the drive (electric motor, hydraulic motor or internal combustion engine). A gear is mounted on the high-speed shaft, which rotates with the same parameters as the high-speed shaft. This gear engages a larger diameter wheel located at one end of the countershaft. Due to the difference in diameters, the intermediate wheel rotates more slowly, but with more torque. A gear of smaller diameter, but rotating at the same speed and torque, is mounted on the second end of the intermediate shaft.

The small wheel of the intermediate shaft transmits rotation to the gear wheel of the low-speed shaft, which has a larger diameter, so the decrease in rotation speed and increase in torque are repeated. Thus, in such a gearbox there are two gears, which reduce the rotation speed and increase the torque. Each gear has its own gear ratio equal to the ratio of angular velocities or wheel diameters. The gear ratio is the product of the gear ratios of individual pairs of wheels. Thus, we obtain a two-stage gearbox, consisting of two pairs of gears that transmit torque. In this example, we learned how the gearbox works.

Design and operation of a planetary gearbox

Worm, cylindrical and bevel gearboxes have, in general, a similar design - the gears are connected in series and two wheels are always in mesh, with each shaft driven by its own wheel. This ensures simplicity of design and reliability, but leads to an increase in size and weight.

The planetary gearbox uses a different principle of design and operation. A simple planetary gear consists of satellite gears 2, mounted on a carrier 4, rotating around the central sun gear 1, while the support for the satellite gears is a fixed ring gear 3. Rotation is transmitted by several satellites that rotate around the sun gear. As a result, the load on the central wheel is reduced. The gear ratio is determined by the ratio of the angular velocity of the sun gear to the angular velocity of the carrier. Planetary gears can also be multi-stage, where several rows of satellites and sun gears are used, which increases the gear ratio to 1000 or more. Planetary gearboxes are used in drives requiring high speeds, for example drives of transport vehicles, gearboxes, servo drives, etc.

Possible malfunctions and their elimination

| Malfunction | Probable Cause | Remedy |

| 1. Noise during operation of the control unit | The support bearing RP is damaged | Replace bearing |

| 2. Boom torque decreases | Lack of oil in the gearbox | Add transmission fluid to an acceptable level |

| 3. Shocks during column operation | Worm wheel wear | Replace valve RP |

| RP bolts are loose | Tighten the bolts to the optimum torque |

Gearbox maintenance

The CMU turret rotation gearbox is a hydromechanical device that requires lubrication. For this purpose, transmission oil is poured inside. Lubrication helps prevent the accumulation of abrasion products from moving parts (metal shavings) in the hydraulic system of the crane. Scheduled oil changes in the gearbox should be carried out regularly every two years, and also after the first six months after putting the machine into operation. These conditions may differ for cranes from different manufacturers.

In UNIC manipulators, the lubricant level in the rotary gearbox is controlled using an oil dipstick. In other systems, it is possible to have a special viewing window, such as in the DonYang CMU (in the figure).

General recommendations:

- Before adding oil, remove contaminants from equipment surfaces.

- Do not allow foreign matter to enter the transmission oil.

- Make sure that the old oil is completely drained.

Table of approximate maintenance intervals (relevant for UNIC manipulators)

When servicing the CMU, only certified technical fluids recommended by the crane manufacturer should be used. It is prohibited to mix different types of hydraulic and transmission oil to avoid failure of the entire system.

Maintenance, adjustment and monitoring of the technical readiness of the CMU must be carried out in compliance with the requirements of the operating manual and service program developed for a specific machine by its manufacturer.

Crane slewing gear repair

Repair may be required if components are severely worn: bearings, shafts, gears. A common problem is bearing failure. A faulty gearbox usually gives itself away with an atypical hum or crunch, but more often the breakdown goes unnoticed for a long time. Sometimes the manipulator boom works normally, but after a while there is play in the bearings and the column sways. If such situations are detected, it is necessary to troubleshoot the rotary gearbox.

The need for repair and restoration work arises when:

- violation of technological gaps between parts;

- malfunction of the gearbox worm shaft;

- failure of gears and bearings.

Other common causes of breakdowns:

- leakage of seals (oil seals);

- hydraulic motor malfunction;

- water entering the body;

- violation of operating rules;

- wear of the support bearing, accompanied by play of the gear shaft.

Gearbox malfunctions

Most often, gearbox failures, as an integral element of a car transmission, are often associated with the complete exhaustion of the service life of parts that require subsequent replacement. The main reasons contributing to subsequent malfunctions of the rear axle gearbox are: - worn shank seals; — worn shank and differential bearings; — failed differential elements; - worn or broken parts of the main pair. It is simply impossible not to notice the signs of a broken rear axle gearbox. This is an oil leak from the gearbox itself, and a characteristic howling sound that comes from this unit when moving. All this immediately reveals the cause of the breakdown. And if it is quite simple to eliminate a transmission oil leak by installing a new shank oil seal, then the noise that a broken transmission makes is not so easy to eliminate.

First of all, you should check whether the noise disappears when the car coasts. If it disappears, then the cause of the noise is naturally in the main gearbox pair. If the noise and hum do not disappear, then most likely the reason is broken bearings

shank or differential. Why is it so easy to diagnose such serious problems? We answer. While the car is coasting, the elements of the main pair do not come into contact with force, therefore they are not able to in any way influence the appearance of strange noise in the car.

Note that the main pair is often subject to increased wear due to low oil level. When gearbox parts are not sufficiently lubricated, this naturally exposes them to very high frictional and thermal overloads. And the oil level, in turn, drops sharply due to malfunctions in the oil seal, which becomes unsuitable for use if the shank nut is poorly tightened. The next reason leading to replacement of the rear axle gearbox is the increased load on the transmission, which occurs when the machine is used for a long time with heavy overload. Also, do not rule out a defect in parts from the assembly line that are installed on the rear gearbox, the cost of which is prohibitively high.