Wood is a durable and strong material that people have been using for many millennia. Wood manifests itself as an easily processed material, so woodworkers have long used this property in order to give products the required overall dimensions.

With the development of crafts and technology, hand tools for finishing wood have been modified, improved and improved. A modern carpenter, whether a master or an amateur, cannot do without a set of quality tools. There will definitely be a wood rasp there, intended for the initial processing of products.

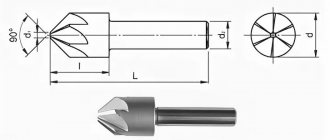

A rasp is a multi-blade cutting tool with a large and sharp notch, used to remove coarse layers of wood, subsequently leveling the surface, filing and giving the required shape to the product.

Legend

All products are assigned alphanumeric codes,

for example, LA2416-100-4, LR12796-2. The letters indicate belonging to a specific group (type) of products, and the numbers indicate the factory article number, dimensions and type of notch.

In the given examples:

LA2416-100-4

(LA – needle file with a round handle, article 2416, full length of the file including handle 100 mm, cut number – 4)

LR12796-2

(LR – groove, article 12796, notch number – 2)

Other examples:

LP1268-4-00

(LP – general purpose precision file, article number 1268, file working length 4 inches, cut number 00)

LP1185-4-2-1.7

(LP – precision general purpose file, article number 1185, length of the working part of the file 4 inches, cut number 2, file thickness 1.7 mm).

Main Dimensions (Measurements)

Length = L

Length = L

What is accepted as parameter L depends on the specific type of tool (file, needle file, riffle, etc.). This can be the full length of the tool or only the length of its working (notched part), or it can be the length of the cylindrical part of the tool. Numerical lengths are indicated in inches or

millimeters or inches and

millimeters (for example, 6'', 150 mm)

Width x thickness = A x B

Width x thickness = A x B

Typically, A is the width or diameter

Typically, B is the thickness of the tool

Dimensions A and B always refer to the widest part of the uncut part of the tool; in the catalog they are indicated in mm. The exception is products of the LO group (scrapers and scrapers).

Swiss file cutting system and their designations Swiss Cut

provides 11 types of notches, ranging from 000 to 8. Notch 000 is the coarsest.

Table of notch numbers

Table 1

Product type

| Notch number | ||||||||||

| Number of cuts (teeth) per 1 cm | ||||||||||

| 000 | 00 | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | |

| Precision files LP series Valtitan files V series Lengths from 100 to 200 mm (4″-8″) | 12 | 16 | 20 | 25 | 31 | 38 | 46 | 56 | 68 | |

| Precision files LP series Valtitan files V series Lengths from 250 to 300 mm (10″-12″) | 9 | 12 | 16 | 20 | 25 | 31 | 38 | 46 | 56 | |

| Precision files "Habilis" LH series Total length 215 mm | 18 | 21 | 25 | 31 | ||||||

| Precision needle files LA series Valtitan needle files V series Lengths from 140 to 200 mm | 20 | 25 | 31 | 38 | 46 | 56 | 68 | 84 | ||

| Precision needle files LE series Lengths from 35 to 55 mm | 20 | 25 | 31 | 38 | 46 | 56 | 68 | 84 | 100 | 116 |

| Precision grooves, double-sided, LR series Length 150 mm | 25 | 38 | 56 | |||||||

| Precision grooves, double-sided, LR series Lengths from 180 to 300 mm | 16 | 25 | 38 | |||||||

| Files series LS Length from 150 to 200 mm (6″-8″) | 12 | 16 | 20 | |||||||

| Files LS series Length 250 mm (10″) | 9 | 12 | 16 |

An example of reading the table: A general purpose precision file, 6 inches long and with a number of cuts (“teeth”) of 31 per 1 cm, has a 2nd cut number.

Table 2 is provided to compare the “Swiss Cut Standard” with the current standards of the Russian Federation*:

*GOST 1465-80 Files. Specifications

GOST 1513-77 Needle files. Technical conditions.

Standard range of file lengths (Switzerland)

: 3” (75 mm), 3.5” (90 mm), 4” (100 mm), 4.5” (115 mm), 5” (125 mm), 7” (175 mm), 8” (200 mm), 10” (250 mm), 12” (300 mm)

Standard range of file lengths (Russia)

: 100, 125, 150, 200, 250, 300, 350, 400, 450 mm

Swiss Cut files also differ significantly from the systems adopted in the USA, Germany and France.

The Vallorb file is not just a file made in Switzerland,

This is a qualitatively different type of file!

Swiss Cut numbers: “Swiss cut”

Notch number.

The cut number is one of the most important characteristics of a file (needle file or riffle). This number depends on the purpose (type) of the file, its length and the number of cuts (“teeth” or notches) per linear centimeter [Z/cm].

The number of cuts (“teeth” or “notches”) is counted in a direction perpendicular to the direction of the cut, as shown in Fig. 1:

So, for example, for a general purpose file 6 inches long and cut number 2, the number of cuts (“teeth”) per 1 linear centimeter [Z/cm] is 31.

Other terms used: Notch pitch. Small step, big step. Notch frequency.

Notch pitch is the distance between adjacent grooves (“teeth”, “notches”). The expressions often used are “small step” or “big step”. The larger the pitch, the coarser the file. Notch frequency – number of notches per 1 cm.

Professional names of files depending on the type (number) of the cut in English and Russian

(purely approximate, no strict correspondence!)

Handle sizes and shapes

The correct size and shape of the handles are important for convenience, high productivity and safety when working with a file. The length of the handle should be approximately 1.5 times longer than the shank. The file shank enters the handle to a depth of 2/3 to 3/4 of its length.

When placing the handle on the file shank, a distance of 10–20 mm is left between the shoulders of the heel and the ends of the handle, which is necessary in order to seat the file into the handle for a more durable fastening.

Handles for files are made from hard wood: birch, maple, beech, ash. The surface of the handles is made smooth and smoothly polished. To prevent the handle from splitting when the file settles and during operation, a steel ring is put on its end. The hole for the file shank is drilled or burned.

When inserting a file, its shank is inserted into the hole of the handle and with the right hand, with vertical strokes, hit the head of the handle on the workbench (Fig. 5, a) or, inserting the shank into the hole of the handle, lightly hit the head of the handle with a hammer (Fig. 5, b). To remove the file, take the handle in your left hand and apply two or three weak blows with a hammer to the upper edge of the ring (Fig. 5, c).

Rice. 5. Attaching and removing the file handle

Kinds

This needle file is manufactured in various designs. All of them can be classified into several main groups depending on the type of notch.

Let's consider each variety separately.

- Single notch. These models are most often used when processing internal corners of non-ferrous metals, but they are often used for other purposes. This type is quite common. The notch itself is presented in the form of small teeth, which are placed in a certain sequence. As a rule, high-carbon steel or special iron alloys are used for its manufacture. In any case, the metal must undergo special heat treatment, which allows the level of hardness to be maximized.

- Cross notch. Such varieties are produced with a special cross design, which must be placed at a certain angle (the main part is at an angle of 65 degrees, the additional part is at an angle of 45 degrees). Such triangular files are most often purchased for deep processing of corners made from cast iron, steel or bronze base.

- Arc, point models of notches. These types of files are used when working with products made from various types of wood. Moreover, they can be used for both roughing and finishing work.

- Stamped notches. These types of triangles can be purchased for processing leather and rubber materials, so they are primarily used in carpentry rather than metalworking.

A special type of triangular tools – diamond-coated models – deserves special attention. Such samples can be produced with various types of notches.

Products with this application are coated with special diamond chips. These triangles are used primarily when processing glass surfaces; they are also often used to work with hardened steel, ceramic objects, and especially hard metal alloys.

Proper use of the rasp

Proper use of a rasp file eliminates the occurrence of defects on the surface of the wood being processed, and also protects the carpenter from injury and damage to the tool. Technological features of the design of the working part of the tool require compliance with certain rules when working with it:

- Products must first be thoroughly cleaned of wood sanding dust and shavings. This can be done using brushes with different bristles softness. This is important for the carpenter to correctly visually assess the degree of required polishing of the product.

- For convenience, a wooden workpiece is often clamped in a vice. This ensures the correct angle of the fixture. For quality work, it is important to maintain a 90° angle between the tool and the arm bent at the elbow.

- During the filing process, a balance of forces applied when pressing with the right and left hands during the working stroke must be maintained. Thus, during the grinding process, the wood will not receive new defects: chips, cuts and burrs.

- Surface treatment is carried out diagonally to the wood fibers. This is due to the peculiarities of the macroscopic structure of wood.

What is it and why do we need it?

A rasp is a cutting tool with a large number of blades. This device may have sharp and large notches. It has found its application in the elimination of rough wood layer with its subsequent leveling, as well as in filing products and giving them a certain shape. This product is found both in garages and in locksmith shops. It is considered universal, as it can be useful for rough and primary work with wood.

The rasp can be used for processing wood, soft and finishing sheet materials. Due to the practicality of use in many technological procedures, this carpentry attribute has gained popularity among craftsmen. Its main purpose is considered to be filing, that is, the elimination of the surface layer from the workpiece in order to subsequently give it the desired shape, size, and roughness. The tool is necessary for quick, high-quality and simple removal of irregularities from any surface.

Despite the fact that filing is considered a labor-intensive process, the use of a high-quality rasp can make the work easier, faster, and also eliminate the formation of defects. The main part of the tool’s design is considered to be metal teeth, which have some resemblance to a grater. The working part of the device is made of steel, and the surface is produced by stamping notches and teeth. The latter are located towards the long side, overlapping each other.

To make the tool easy to use, it has a handle. It is usually made of hard wood or plastic.

Types of files

The industry offers various types of this tool, most of which are universal and can be used with equal success for fine processing of wood and metal. The tools are classified according to the type of cutting part:

- with a single notch;

- with double cross notch;

- for wood with an arc notch;

- with rasp notch;

- stamped file.

Separately, it is worth noting a tool designed for delicate work with miniature parts. A wood file is the same file, but smaller in size, which makes it indispensable for making small crafts from wood and other soft materials. For the same purposes, a type of needle file is used - riffles. Their working part is curved, which significantly facilitates the production of small parts of complex shapes.

All files, regardless of their purpose, are classified according to the cross-section of the working part. The most popular tool is the following profile:

- flat (rectangular);

- square and round section;

- triangular;

- semicircular;

- rhombic.

The shape of the tool, size, depth and type of notch are selected depending on the type of work performed. The rougher the processing, the larger the notch should be and the larger its pitch. From this we can conclude that a home workshop should have not just one file, but a whole set of similar tools with different characteristics.

Purpose

In most cases, product processing is carried out in several stages. The use of such technology allows you to achieve better results, but a larger set of tools is required. Brushed files are used for rough metal processing. Among the features we note the following:

- A hog file is designed to remove metal whose layer is at least 0.25 mm.

- Depending on the specifics of a particular case, the allowance for the layer to be removed with a wormwood file can vary from 0.5 to 1 mm.

The above information indicates that the product is intended for rough surface finishing. After this, finishing sawing is carried out, due to which the required quality is achieved.

That is why experts recommend removing metal exclusively in stages, starting with the use of a hog file.

Marking of files

It is difficult to entrust fine processing of workpieces to machines, but with a set of files, you can cope with this task. The marking of the tool must comply with GOST; it must reflect the main characteristics of the tool:

- Class

– from 1 to 6. - Length

– looks like the number after the Latin letter L. - Type of notch

– from 0 to 5. - Tooth hardness

is double digit after abbreviation HRC. - Type of steel

– U, if the tool is made of carbon alloys, ШХ, if the file is made of alloy steel.

Special types

Sometimes the master faces tasks that are difficult to perform with a conventional tool. In this case, he has to think about buying special types of files that will help him perform operations with metal more efficiently and quickly.

Rasp

Along with metalworking tools, you can grind metal products and other materials using rasps, which have their own notch. Their surface contains fairly large teeth, made in the form of a pyramid, and behind them there are special grooves. The notches are located on the rasp in the form of rows at right angles to the axis. Using rasps, you can grind soft materials - duralumin and aluminum.

For the manufacture of this tool, steel grades U7A and U10A are used. They have a hardness level corresponding to 35−40 HRC. Rasps reach a length of 25−35 cm. Manufacturers offer four types of rasps: round and semicircular, as well as pointed flat and blunt flat. They are used mainly in the manufacture of tin products, as well as in medicine.

Files

Among all manufactured types of tools for processing products, they are the smallest

They are used to perform work where it is important to ensure high processing accuracy. This type of tool is made from steel grades U12 and U12A with a hardness of 54−60 HRC

If we consider needle files according to their cross-sectional shape, they can be divided into the following groups:

- groove and hacksaw;

- diamond shaped;

- oval;

- round and semicircular;

- triangular;

- square;

- flat.

There is no need for a home craftsman to purchase all of the above types of files. He can easily cope with all the tasks that arise in everyday life, having in his arsenal a flat, triangular and round file. It wouldn’t hurt to additionally purchase a set of needle files and a few rasps. This entire set of tools will help you quickly solve any problem related to metal grinding.

What is the difference between a rasp and a file?

Rough processing of parts can be entrusted to a rasp. This type of file is used for rough work; it has the largest notches, which is what makes it stand out. To achieve the best effect in your work, experts advise using a rasp in turn, and then a diamond file. A set of rasps is a good buy; several tools will make the work of a home craftsman much easier. The minimum number of products for working with wood, soft metal, plastic and leather consists of the following types of rasps:

- flat;

- round;

- semicircular.

What is a file?

There are many types of files. This easy-to-use multi-blade tool is known to every craftsman; it can be used to quickly and easily remove the top coating from a workpiece. A variety of materials can be processed with a file; it can easily handle metal, plastic, wood, textolite and others. Using a file, you can gradually and carefully cut off the layers layer by layer, giving the product the required shape, size, or making the surface rough if necessary.

What does a file look like?

A good craftsman should have several files in his arsenal. This tool looks like a metal rod that is attached to a handle. Ease of use and safety in operation depend on it; this is an important element of the file. The handle can be made of wood; a ring is attached to such models to protect the tool from splitting, and it is coated with varnish or paint to prevent the material from rotting. Files with plastic handles are complemented by rubberized inserts for ease of use. The main parts of the file also include:

- shank;

- heel;

- a working part having a face, a toe and an edge.

How does a file work?

You can expand the diameter of the workpiece or shorten any part using a high-quality file. Teeth applied to a metal rod remove parts of the material being processed. A large wood file immediately removes a thick layer of the product; experts advise starting work with a tool with medium teeth, gradually changing files. It is necessary to complete the surface treatment with a product with the smallest notch. With this method of working, the surface will remain smooth and there will be no pronounced grooves on it.

How to use a rasp correctly?

So we found out what a rasp is and what types of devices are available to craftsmen.

Now let's look at the features of proper operation of the tool. When starting work, it is recommended to hold the rasp firmly by the handle. With the other hand you need to press its end to the surface of the material being processed. It is with this positioning of the hands that reliable control over the instrument will be exercised.

When preparing to work with a rasp, the workpiece must be firmly secured in a clamp. Holding the tool with both hands, it is necessary to move its textured part along the workpiece. The rasp must be moved diagonally in relation to the wood fibers. This will make the surface being treated as smooth as possible.

The RADIANT trademark offers various types of files according to their cross-sectional shape

Flat

- pointed blades are used for filing external or internal flat surfaces, as well as sawing splines and grooves.

- blunt-nosed

Semicircular files are used for cutting roundings in corners, grooves of complex profiles, as well as angles less than 60°. The flat side is used for filing surfaces, and the semicircular side is used for sawing concave (semicircular) recesses.

Triangular

Triangular files are used for filing sharp corners both on the outside of the part and in grooves, holes and grooves.

Square

Square files are used for sawing square, rectangular and polygonal holes, as well as for filing narrow flat surfaces.

Rhombic

Diamond files are used for filing the teeth of gears, disks and sprockets, as well as for removing burrs from the teeth of these parts after processing them on machines.

Classification of files according to blade shape

When describing the shape of a canvas, the geometry of the section of the canvas (rectangular, square, round, etc.) and the shape of the canvas in plan are usually mentioned separately. In fact, it should be understood that these two characteristics are interrelated, since both are determined by the purpose of the file. For this reason, for example, square, round and triangular machinist's files always have a tapered tip. They are designed for filing holes and grooves, and their applicability and ease of working with them increases significantly when the same file can be used in two sections: small and large. This is often necessary when machining the same hole or sample. Flat files, on the contrary, have a rectangular (or close to it) shape, since they are intended for filing relatively wide surfaces.

The geometry of the blade section determines the shape of the surface that can be processed using a professional hand tool such as a file. The most commonly used are flat, triangular and round files. They form a kind of universal set that allows you to perform most filing operations. And the use of a square file is absolutely necessary only if you need to “draw” right angles quite accurately.

Flat

Files in cross-section can differ significantly in the shape of the transition from a wide edge to a narrow edge (right angle or rounding) and in the presence of notches on the narrow (side) edges. However, such diversity is typical only for sharpening files. Bench's flat files in cross-section usually have the shape of a regular rectangle, the corners of which are not rounded. These files are available in rectangular and rectangular tapered shapes. The first files are designed for filing relatively large surfaces and usually have a notch on only one narrow edge out of two. The tapered toe of the second files allows you to work in hard-to-reach places.

Flat pointed

A file (also called a groove file) resembles a dagger due to its pointed tip. Primarily, a flat, pointed file is designed for processing narrow grooves. For this purpose, it has a notch on both narrow edges.

Round

Bench files have a tapered tip. Round sharpening files are used only for sharpening saw chains and are usually called files for sharpening saw chains. They have a cylindrical shape, a shank at one end and a free part at the other. Unlike most sharpening files, the cut is double, with a thin chip breaker inclined to the file axis at an angle of 10 - 20°.

Semicircular

Files are produced only for metalworkers. Sometimes such a file is convenient as a universal one, because... combines the properties of flat and, partially, round files.

Rhombic

Files are produced only for sharpening. They are used for sharpening some types of hand saws for wood (primarily garden saws with the so-called “Japanese tooth”). Available with single cut and “Wasa” cut.

Knife-shaped locksmiths

Files are used for cleaning narrow grooves in cutting and stamping tools. Less common are knife-shaped files with the same cross-section, but rectangular in plan.

Knife sharpeners

Files, along with rhombic ones, are used for sharpening wood saws. In shape they practically coincide with knife-shaped metalwork files. Sometimes they are equipped with a notch on the back side, which in this case is made semicircular and is used to form cavities between the teeth of circular and band saws (for effective removal of chips, these cavities must be large enough). However, for this purpose it is better to use round files for sharpening saw chains. Roughing files are a special case of bench files and differ from them only in their cut and, naturally, in their area of application. The wavy shape of the notch prevents the file from being pulled into the stack. Such files are available in lengths from 150 to 350 mm. The vast majority of manufacturers offer only flat-shaped roughing files, but a number of companies that specialize exclusively in the production of files also offer a wider range: triangular, square, round and semicircular files with large milled teeth. In their shape, these files are almost no different from the corresponding metalworker's files.

Making files

Manufacturing consists mainly of the following operations:

- cutting blanks,

- forging the tail and tip of the file,

- annealing,

- editing (straightening),

- turning, or grinding, planes,

- filing for personal and velvet files,

- chamfering,

- hen, or cutting, teeth,

- sock trimming,

- dressing (toe sharpening),

- hardening,

- cleaning,

- tail release,

- lubricant

- package.

File steel

The material for files is carbon steel containing 0.8-1.5% C; 0.10-0.30% Si; 0.25—0.45% MP; <0.04% S and <0.05% P. Carbon steel containing 0.7% C is used for the manufacture of rasps.

Some types, especially velvet and special purpose for working on metal after heat treatment, are made from alloy steel with a chromium additive from 0.3 to 0.7%. The carbon content in steel increases, the smaller the size of the file being produced.

Steel for manufacturing comes in the form of strips of a certain profile and size in accordance with the profile and size. Hardness of steel d.b. not higher than 300 according to Brinell. The first operation - cutting off blanks - is usually carried out on shear presses, and several blanks are cut simultaneously, the number of which depends on the cross-sectional dimensions of the rods being cut.

The next operation is to forge the tip of the file (its end part). This operation is carried out either on a driven spring hammer with a weight of the falling part (shaft) from 15 to 45, depending on the cross-sectional dimensions of the file being forged, or in strikers with grooves corresponding to the cross-section and size of the part being forged. It is more rational to forge flat, triangular and semicircular parts on forging rollers, which gives a smoother surface of the forged part. Heating before forging is carried out in spectacle-type flame furnaces, operating both on oil and coal.

A diagram of testing a number of files on Herbert machines is shown in Fig. 19, it depicts the volume of sawn material as a function of the number of file strokes; Thus, the height of the rise of each individual curve of a given file before it transitions to the horizontal direction (which indicates the final dullness of the file) characterizes the durability of the files, and the tangent of the angle of inclination of the curve to the horizontal axis is proportional to the sharpness.

It should be noted, however, that the test results on the Herbert machine are only comparable to each other when the tested files are under absolutely identical conditions, both in terms of the notch pitch of the pressing weight, and in the sense of the uniform structure and hardness of the test bars.

Types of files for metal

A file is a special cutting tool widely used in various industries. Externally, it is a steel bar of large or medium length with a wooden, plastic or rubberized handle attached to the base. It is necessary to provide the worker with comfort when working with the tool and reduce the risk of occupational injuries.

The body of the file is made of a special grade of steel, which allows the tool to interact with metal objects. The tail part of the steel beam is covered with a special pattern called excision. The nature and type of work performed will depend on the shape and size of the notch.

Processing of metal parts occurs through gradual grinding of layers with a tool until the product is given the required shape. The main thing is that the metal cutting part is selected for its intended purpose.

File shapes

The geometric shape of a metal file determines its scope of application in the production and processing of products:

- flat or flat pointed: processing flat metal parts, as well as smooth surfaces;

- square: necessary for cutting and forming technical holes of various polygonal shapes;

- triangular triangular: using such a metal cutting tool, you can polish, process and clean gaps, grooves and other manufacturing holes;

- semicircular: excellent for various types of processing of curved concave surfaces;

- round: used for sharpening and processing round or oval concave surfaces with a small radius of curvature;

- rhombic: processing of metal parts with teeth;

- hacksaw: a tool for sharpening narrow gaps, holes and other small parts.

Types of files

The type of metal processing tool is determined based on its intended purpose:

- General purpose metal cutters. They are commonly used in plumbing. The tail part is made in the form of two jagged notches, which are superimposed on each other: their length can vary from 1 to 4.5 cm and can be combined with teeth of all sizes.

- Metal cutters for special purposes. They are necessary in the industrial sector, since their main task is to eliminate deviations and adjust small parts, grooves and surfaces of different radii of curvature. This type of tool has many varieties, which are selected based on the nature of the work performed: double-ended, flat, one-time and others.

- Needle files. This group of metal files includes the largest number of types. The ends of steel beams come in all possible geometric shapes, and the beam itself, as a rule, is not very long. Flat, round, hacksaw and all other types of needle files are characterized by the presence of a class 5 notch. Needles are used for processing small metal parts that coarser and more massive metalwork tools cannot handle.

- Rasps. Rasps differ from all other types of files by the particularly long part of the steel bar and large teeth on the tail. There are 3 main types of such tools: metal shoe cutters, hoof cutters and general purpose rasp files. The shape of the instrument is predominantly round and semicircular with an end of varying degrees of sharpness.

Types of notches and their geometry

In order to perform quality work as a metal carver, it is necessary to determine the required type of notch. The structure and size of the teeth are also of great importance when choosing a tool. Steel teeth can be applied to the tail of a steel bar in different ways:

- milling;

- cutting;

- stretching;

- flow;

- cutting.

The most widely used in the field of processing metal products are metal cutters, the teeth of which are made by cutting them on special automated machines. Moreover, the notches themselves can be either double or single.

Double consists of two notches, one of which is the main one, and the second is auxiliary. The notches are located at a special angle relative to each other, which allows sharpening of hard materials (metals and their alloys).

The tooth geometry of files will depend on the number of notches on the body of the steel bar.

What is a file for?

Different types of files perform many functions. For metalworking work, tools with double teeth are suitable, the length of which can be different. Special files are a special type of device that is widely used on an industrial scale; they eliminate major imperfections and adjust large parts with differences in the size of the grooves or differences in the curvature of the surface of the product. To process small parts or work in hard-to-reach places, small files are used - needle files.

What should a set of rasps consist of?

It is worth considering that for high-quality work, a whole set of rasps is required. The classic set is represented by a combination of the following options:

- Flat.

- Round.

- Semicircular.

Classification is also carried out according to the type of notches applied into two classes, only if both are available it is possible to carry out work with high accuracy. The semicircular rasp of the second number has more notches on the surface, which ensures higher efficiency in use.

Most often, a metal rod is made using steel grade U7, in some cases U8 and U10. By increasing the hardness and sharpness of the cutting edge, the degree of engagement with the surface being processed significantly increases at the time of processing.

Only two types of tools are produced abroad: regular and grooved. The teeth of such designs, as a rule, have standard sizes.

Types of rasps

There are quite a large number of different types of such instruments. Classification is carried out according to various criteria, the most important being the type of working part:

- Flat rasps are much more common than other options and are usually included in standard sets. A similar working surface can be used for finishing flat surfaces; the tip can be tapered or straight.

- There is also a semicircular rasp. In most cases, a tool with a similar surface is used for processing semicircular workpieces. The degree of rounding of the main part of the product may vary significantly.

- To work with products that have an unusual shape, versions with a triangular or other complex cross-section are often used. The special shape allows material to be removed from corners and other complex geometries.

There is a roughing rasp with a different working surface, which is made using structural or tool steel. The type of alloy used largely determines the performance characteristics of the product.

How to restore a file at home?

Many novice craftsmen believe that a tool with traces of paint or covered with rust cannot be restored, and they throw it away. Any metal files can be cleaned, sharpened and used for a long time. After work on restoring the metal rod, you can also update the handle; it is recommended to carefully remove the old one if it is cracked and has defects. A new one will last a long time if it is treated with special wood products, varnished or painted.

How to clean a file?

Many craftsmen have encountered a problem when files become covered with rust and cannot be used. You can clean both straight and triangular files, as well as other options, using improvised materials at home.

- Pour hot water into the container where the entire file is placed and clean the surface of the tool with an old toothbrush and dishwashing detergent.

- Drain the soap solution, dry the file, prepare a liquid for cleaning the surface of the tool, consisting of 1 tbsp. hot water and 2 heaped teaspoons of citric acid. Pour the prepared solution into the file and leave it in it for 12 hours.

How to sharpen a file?

Frequent use of a file can cause the tool to become dull. Working with copper, aluminum and stainless steel often causes small metal particles to get stuck between the teeth. A rough file becomes clogged, its surface loses its functions, and its cutting part needs to be sharpened. There are several options that can return the file to its original appearance.

- The chemical method

is fast and effective. Before sharpening, the tool must be cleaned, degreased and dried. The solution into which the file is then placed consists of water (86%), nitric acid (8%) and sulfuric acid (6%). In 10 minutes. After immersion, the instrument must be removed and washed thoroughly. - The electrochemical method

is similar to the previous one. The proportions of the solution in it are slightly different; water (80%), nitric acid (9%) and sulfuric acid (11%) are taken. The file must be dipped into the prepared mixture and a low frequency current must be passed through using aluminum plates. - The mechanical method

of sharpening tools requires a special device - a milling machine. First, the file is fired in a special furnace at a temperature of about 800°C, after which its surface is ground on a machine. Using a chisel, notches are formed on a smooth file. To harden the tool, place it in a solution consisting of water (50 l), salt (2 kg) and hydrochloric acid (1 l). For hardening small instruments, the proportions are reduced. - The sandblasting method

of sharpening files requires the ability to work with special tools. The cutting surface is restored using fine sand, which is passed through a nozzle under pressure. - Folk methods of sharpening

tools are widely used by home craftsmen. Experts recommend using different compounds to restore the working surface of files: citric acid, ferric chloride, vinegar.

Power tool

To increase labor productivity when performing some types of filing work, mechanized tools are used.

There are two types of devices for mechanical filing:

- th type - rotary action, using a flexible shaft or pneumatic and electric machines;

- th type - reciprocating action, using mechanisms that convert rotational motion into rectilinear reciprocating motion.

The devices of the first type are shaped rotating files (Fig. 11) and abrasive wheels.

Rice. 11. Rotating files (boring files)

Filing is greatly facilitated and accelerated by portable pneumatic filing machines, which have replaceable clamping chucks for installing rotating files and abrasive wheels of various shapes and sizes. The exhaust air of the pneumatic drive is directed in the form of a jet onto the surface of the product, thereby removing chips from the processing zone.

Devices of the second type use the drive energy of the flexible shaft of a drill or pneumatic machine. (Fig. 12). The device consists of a housing, inside which the rotational movement of the shaft is converted into a reciprocating movement of the file and has replaceable clamping chucks for installing files of different shapes and sizes.

Rice. 12. Portable pneumatic filing machine with file

The operation of a mechanical file requires some effort, but much less than with manual filing, since the worker here only guides the file and regulates the pressure. The hardest part of the chip removal work is done by the machine. Instead of a file, you can install a hacksaw blade. The exhaust air of the pneumatic drive is directed in the form of a jet onto the surface of the product, thereby removing chips from the processing zone.

Brief characteristics of rasps

As previously noted, each type of rasp is characterized by its own specific properties. The most common version is a flat version, designed for processing concave surfaces. The key features are the following:

- The purpose is for rough processing of wood or various non-ferrous metals.

- Modern versions are equipped with comfortable handles, which are available in two materials. Often a special hole is created for hanging.

- The main working part is made of tool steel, the composition of which eliminates the possibility of severe wear.

The semicircular rasp is very common. It is also often equipped with an ergonomic two-component handle. This ensures the most comfortable conditions for convenient work. This shape of the working part makes it possible to process various round holes and remove unevenness in hard materials. Such tools are often used to perform almost all plumbing jobs.

The created handle is covered with a special coating, which eliminates the possibility of hands slipping. The working part is represented by a combination of a semicircular and flat surface.

A rasp cut is represented by a cutting edge that removes a layer of material from the surface. Do not forget that depending on the intensity of use, it can quickly wear out.

Wood rasp

Despite advances in science and technology, wood is considered one of the most common materials today. Its processing can be carried out using a variety of tools, including a rasp. When considering what a rasp is, we note the following points:

- The most common design has a flat working part with a blunt nose. It is used to remove material from flat and other surfaces.

- The notch is made in large form. This ensures the formation of large chips, which are quite easy to remove from the surface. There is a special groove in front of each tooth, which simplifies the process of removing chips.

- The tool is divided into the main working part and handles. In some cases, the handle can be removed; a variety of materials are used in manufacturing.

In general, we can say that the rasp file is designed for rough work. After its application, finishing and other similar operations are also required. The degree of roughness of the treated surface is very high.