Cutting Rules

To quickly and accurately cut a workpiece, you need to follow several rules. They “work” for most synthetic materials: organic glass, polycarbonate and others. plexiglass at home .

- It is much easier to make a straight or curved cut if the part is heated. To do this, it is warmed up a little before processing. A hair dryer or gas burner is used as a heat source. Important point. In order not to melt the acrylic, it is kept at a distance from the heating device.

- For work, it is best to choose a canvas marked MP.S. This is high strength hardened steel.

- Sawing with any power tool should only be done at low speeds. Otherwise, the acrylic glass will heat up from the blade and melt. The speed for each device is selected individually.

- Do not cut material without eye protection. You must wear a mask or special glasses. During operation, many very sharp small fragments are formed, which fly away from under the cutting unit.

Milling cutting

The edges are processed by milling after previous mechanical operations: drilling, guillotine shearing or shearing. The design of grooves and curved contours is also done by milling. Any milling machines were used as equipment. The cutters are selected as face cutters, single-clone or double-clone, small in diameter.

Engravings, upper or back incisors are used to perform artistic engraving. They can be controlled manually or electronically.

Suitable Tools

There are many options for cutting plexiglass 2 mm and thicker at home. We will analyze in detail the most effective and easily accessible ones.

Hacksaw

In terms of hardness and processing complexity, plexiglass is comparable to beech. It is enough to simply cut it with a hacksaw or, if the amount of work is small, with a homemade cutter made from cutting blade. For processing, choose a blade with frequent small teeth. First, the workpiece is marked and a cutting line is drawn on it. Most often it is straight. Cutting a curved part with a hacksaw is very difficult. It is good to mark with a felt-tip pen or marker. It leaves a clear trace. You can do it differently. Scratch the line with a sharp nail or knife. saw slowly, avoiding excessive heating of the part. To prevent the blade from sticking, it is recommended to periodically water the cutting area with cold water. The cut from the hacksaw is uneven and requires polishing.

Features of the material

Acrylic glass is called plastic. It is obtained by mixing methyl acrylic acid with ether components and their subsequent polymerization. Known under the names acrylic, plexiglass, plexiglass . It is not inferior to glass in transparency, but at the same time has less weight. When heated to 90-100°C, the material becomes plastic. It can be bent and given the desired shape. This property must be taken into account during processing. When heated, it is easy to deform the workpiece.

Acrylic begins to melt at 160°C. During the cutting process, the blade of a power tool heats up and heats up the workpiece. The temperature passes the melting point quite quickly. Plexiglas melts, its particles stick to the cutting unit, which makes work difficult. Therefore, it is advisable to use cooling. So, in production, a stream of cold air is blown or water is supplied. In the home workshop, the latter method is usually used.

Turning

When turning a piece of plexiglass on a lathe, carbide cutters are used for roughing, and the maximum cutting depth of plexiglass should not exceed 6 mm. Fine machining is performed using tool steel cutters. For cooling, drilling emulsions or emulsion oils compatible with organic glass are used.

Rotation. The best way to produce disc-shaped parts is from sheet metal. They are sandwiched in a bag between the machine shank and the cartridge and grounded to the correct size. In a few passes.

Source

Cutting Rules

In order to efficiently cut plexiglass with your own hands at home, experienced craftsmen advise adhering to certain rules (they apply not only to acrylic, but also to plexiglass, as well as cellular polycarbonate).

- It will be much easier to cut a shaped piece to size or saw off an even piece of acrylic glass if, before starting work, you heat the material over a heat source: a gas burner or a hair dryer. This must be done at a considerable distance so as not to melt the material.

- Cutting a piece of plexiglass with a small thickness from 2 mm to 5 mm can be done using an electric jigsaw. With its help, you can not only make a straight cut, but also cut out a circle. To work, you need to take a narrow and thin blade with fine teeth.

- It is easier to cut glass with a blade marked MP. S. Steel for making blades is hardened and has high strength.

- to cut glass at low speed of the cutting blade. You can select the speed for each tool in the process of work in a practical way. During the sawing process, it is important to ensure that the acrylic glass does not begin to melt.

- When cutting organic glass, you should wear safety glasses or a mask. When sawing material, a large amount of small splintered chips are formed, which fly in different directions at high speed.

The greatest difficulties when cutting organic glass at home arise when creating complex curved cuts. The easiest way to solve this problem is to use laser industrial equipment, where automated control allows you to perform all the necessary functions with the highest accuracy and without human intervention. Acrylic is cut manually according to a pre-made template. The easiest way to make such a cut is with a milling cutter. The contours of the resulting workpiece will have jagged edges and roughness, which can be removed by grinding.

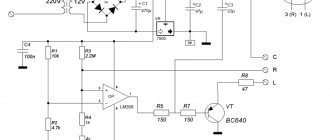

At home, you can speed up the process of cutting organic glass using a hot nichrome wire connected to a voltage source of 24 V. The heated nichrome wire melts the acrylic material through at the desired location of the cut. The edges of the cut are smooth.

It is quite possible to assemble such a device yourself at home, the main thing is to select high-quality nichrome wire with the correct diameter that can withstand heating up to a temperature of 100°C.

How else can you cut plexiglass?

In addition to mechanical methods, thermal methods are also used for cutting plexiglass. This allows you to quickly cut sheets of material of any thickness, as well as obtain workpieces with curved surfaces.

The main tool here is a nichrome thread, which is connected to a transformer with a voltage of 24 V. At the ends of the thread there are handles made of electrically insulating material. When an electric current passes through a nichrome thread, it heats up to 160 0C. This temperature is sufficient to melt acrylic glass. Therefore, when a hot thread comes into contact with plexiglass, it melts, resulting in an even, neat cut, the edges of which do not require additional processing. You can also use a slotted screwdriver instead of nichrome thread.

How and with what to cut plexiglass?

One of the most common synthetic materials used for household and industrial purposes is plexiglass , which is produced by polymerization of methacrylic acid and ether components.

Because of its composition, plexiglass is called acrylic. You can cut it using a special device or improvised means. When cutting plexiglass using a power tool, difficulties often arise due to the fact that the material begins to melt and stick to the cutting blade. Nevertheless, there are still ways that help cut acrylic at home.

Cutting plexiglass on an industrial scale

In production, the most common method is cutting plexiglass with a laser beam. Of course, it is faster and more convenient than other methods. The laser cuts the sheet along a perfectly straight line, the cuts remain slightly rough and require little effort for polishing, and there is virtually no waste. There are a couple of disadvantages to this method - not everyone has acquired a laser machine yet. This is the main disadvantage. And when cutting with a laser, internal stress appears in the material at the level of atoms and molecules - this is the second drawback. It’s just that it is not recommended to connect plexiglass sheets after laser processing with glue - the connection will not be strong.

What to cut with?

Colored and transparent organic glass has certain properties that affect the electric tool at the moment when the material is cut. The fact is that acrylic tends to melt at 160°C. If you need to bend a flat sheet, this can be done after heating it to 100°C. When exposed to the cutting blade of a power tool, the cut site heats up and the molten material sticks to its surface, so cutting off plexiglass is a rather problematic task.

Despite the processing difficulties, acrylic glass has a wide range of applications. To cut the material, thereby giving it the desired size, modern equipment is used in production conditions:

- a CNC laser machine, where the laser, like a knife, cuts the acrylic surface;

- an electric cutter with which you can make holes or a shaped cutout;

- machines equipped with a band saw;

- Disc type electric cutter.

Laser and milling cutting are highly productive and are used in mass production. This equipment is capable of cutting acrylic material with a high degree of precision and accuracy. Laser processing is currently the most widespread; the accuracy of the work is achieved due to the formation of a beam whose thickness is 0.1 mm.

READ What kind of tire can be put on a chainsaw

The cut edges of the material after laser work are absolutely smooth. But the most important thing is that this cutting method does not generate waste.

Cutting acrylic glass mechanically is accompanied by heating of the material, as a result of which it begins to melt, generating significant smoke. To prevent the melting process, the cutting operation must be accompanied by cooling of the acrylic, which is performed using water supply or a flow of cold air.

Home craftsmen often process organic glass on their own, using available tools.

- Hacksaw for metal. The cutting blade is characterized by the presence of small teeth located at a minimum distance from each other. The hacksaw blade is made of durable, hardened steel alloy, so its cutting part becomes dull slowly. Using it makes it possible to obtain an even cut due to an even tangential movement. During work, it is not recommended to saw quickly so that the acrylic does not heat up and undergo plastic deformation. The finished cut will have rough edges that will need to be sanded down with sandpaper.

- Acrylic glass cutter. This device is sold in retail chains and is intended for cutting plexiglass of small thickness - up to 3 mm. To obtain an even cut, a ruler is fixed on the surface of the organic glass, then a cut is made using a cutter in the material (about half its thickness). After this cut, the sheet is broken off along the intended mowing line. The finished cut is uneven, so the workpiece will have to undergo a long grinding process in the future.

How to quickly and easily cut (plexiglas) plexiglass!

- Circular saw. The disc for cutting plexiglass should have small, frequent teeth. If you use a disk with a large pitch between them, then chips and cracks may appear on the material being processed. After obtaining a cut, the workpiece requires finishing grinding.

- Cutter with bearing. This power tool makes high-quality cuts on plexiglass, but the cutting knives quickly become dull and become unusable. When working with a cutter, acrylic quickly heats up, this process is accompanied by strong smoke. To avoid heating the material, use water to cool the working surface.

- Jigsaw. This tool is convenient because it has the ability to regulate the feed speed of the cutting blade. To work with organic glass, special cutting blades are used, which are attached to the jigsaw holder. You can replace such files with a wood blade, the main thing is that the teeth of the blade are frequently spaced and small in size. You need to work at low speeds, otherwise the material will begin to stick to the canvas. After making the cut, the workpiece can be sanded or treated with a flame from a lighter. A jigsaw can make straight or curved cuts.

- Bulgarian. To cut a thick sheet of plexiglass, you can use a blade with three large teeth, which is designed for woodworking. This tool copes well with straight cuts. During operation, acrylic glass does not melt or stick to the disc. It can be used to process acrylic with a thickness of 5–10 mm.

Some home craftsmen use a regular glass cutter to cut organic glass. The results of using the listed tools completely depend on the experience of the master, and in this case no one is immune from the possibility of damaging the material.

In order to cut the acrylic sheet smoothly, it is important to monitor the feed speed of the cutting blade while performing work. It is best to start the cutting process with the lowest possible speed of the power tool. The optimal mode can only be selected experimentally. If during work the acrylic material begins to melt and sticks to the cutting blade, then the work must be stopped, the blade must be cleaned of dirt, and the workpiece being cut must be given time to cool.

When cutting acrylic, it is best to work in a well-ventilated area, since organic glass, when heated, smokes very much and releases chemical components into the environment that are harmful to health.

In order to cut a small piece of organic glass, you can use a slotted screwdriver. The screwdriver is heated over a gas burner and its slotted part is passed along a ruler attached to the workpiece.

Under the influence of the heated section of the screwdriver, a shallow groove will appear in the material. This groove can be deepened even further and then the edge of the glass can be broken off, or you can take a sawing tool and further saw the material in the direction of the groove. After making the cut, the edge of the workpiece will be uneven. It can be leveled by long grinding.

This method takes quite a lot of time, but it prevents the glass from being damaged by the sudden appearance of cracks or chips.

In the next video you will learn how to quickly and easily cut plexiglass.

Features of glass cutting technology

Before cutting glass, you need to properly prepare the material. The glass must be washed from dust and carefully wiped with a dry cloth. If there is debris in the path of the cutting tool, the cutting angle may change, which will not only lead to defects, but may also damage the tool. Completely inconspicuous particles of glass chips or fragments can act as garbage. Even ordinary dust can significantly affect the quality of the cut.

The flat surface to be processed must be placed level and without slopes. In addition to the glass cutter, you need to prepare a marker and a thick ruler for marking the cutting line.

When using a diamond glass cutter, no special effort is required. The tool should be pressed with approximately the same force as a pencil. It can be difficult for new workers to set the correct direction to the cutting element and select the appropriate angle of inclination. To understand the mechanism of operation, you can practice earlier on a sheet of preliminary material. After making a narrow linear cut, you need to figure out what position the glass cutter was in, and use the same principle to do it on a regular sheet. To perform a more ordinary cut, you need to moderately move the tool along the length of the ruler without changing the pressure on the tool and the angle of inclination.

Roller glass cutters must be held perpendicular to the plane of the material. Small linear markings are made on the sides of the sheet with a glass cutter, thanks to which the pressure on these fragile parts can be eased. Otherwise, this will lead to chipping. Then you need to move the ruler away from the markings to the width of the cutting element and create a cut. The work should be done from distant edges; the glass cutter should be brought towards you, pressing its side tightly against the ruler.

The cutting must be done quickly. In such a way that it takes about 2 seconds to walk 1 m. When working with a roller glass cutter, you need to apply more force than when working with diamond tools, but the pressing force should not be changed along the entire length, not counting the edges.

How the instrument is used correctly can be determined by hearing. If there is a steady hissing or crackling sound, it can be said that the work is being done correctly, but if squeaks or squeaks appear, this indicates that something is being done incorrectly. This indicates that the instrument is dull or the pressure is very weak. The presence of small snow-white fragments on the mowing line may indicate overdoing the pressure, so it should be slightly loosened.

High-quality cutting will make it possible to simply break the glass and get smooth edges.

Defective mowing line or very thick glass will need to be tapped on the other side of the sheet. To do this, you need to move the glass to the edge of the working surface in such a way that the linear cut is 5 mm from its edge. Then, using the tool head, you need to tap the mowing line from the top edge of the sheet to the bottom. Due to this, microcracks are formed, which will allow the material being cut to simply break off. You can use the side of a glass cutter or pliers to break off small strips of glass.

The final stage is glass breaking

Thin glass is broken by hand. The piece of glass that has already been cut should be placed on the edge of the table, so that the cutting line is on top and protrudes slightly beyond the edge of the table, and the main part of the glass should lie on the table.

You need to press down on the glass sheet with one hand, and with the other you need to grab the protruding part of the glass and gently press down on the glass with your hand.

If the edge that needs to be broken off is small and it is impossible to break it off with your hands, use pliers.

READ Pneumatic Jack Hammer Device And Work

Understanding the theory of steel cutting allows you to apply this knowledge in practice. In other words, you can take a small piece of glass and practice on it.

After you try glass cutting in practice, you will be more confident in your own abilities in the future. We hope that this information will be useful. We wish you luck and patience!

Pobedite drill

Having a Pobedit drill bit with a non-wearing tip can really help out when you need to cut glass without a glass cutter. The advantage of this method is that you will not need other tools to work. A flat, large table is cleared of crumbs and other debris. A blanket of soft fabric, such as woolen cloth, is laid on top. Then they place the glass, apply a guide ruler and with one movement of the drill towards themselves, cut off the suitable part. It is worth making sure that the cutting tool touches the material with the sharpest side of the tip. Compared to a glass cutter, you need to press harder on the drill. Finally, the edge of the sheet is hung so that the groove made on the surface runs parallel to the tabletop at a distance of 3–5 mm. The master, holding the glass with one hand, breaks off the cut off part with a sharp downward movement. If he doesn’t have enough strength, then from below he taps the cut with a hammer along the cutting line, and then tries again.

When cutting corrugated glass, the side with the rough surface is turned towards the table, and the master works with the smooth one. The same applies to mirrors and glass with patterns.

Cord and kerosene

A wool or cotton rope with a diameter of about 1 mm is soaked in flammable water, for example kerosene. Then the cord is fixed where the cutting line will be and set on fire. Once the rope has completely burned out, cool water is poured onto the surface of the glass. Hearing a click means that the material has cracked due to a sudden temperature change. The method may not work the first time, in which case the actions are repeated again. Fundamentally: the ends of the cord should not hang down, the desktop is protected from fire with a tablecloth made of non-flammable material, the fire extinguisher is located nearby, ready for use.

The indisputable advantage of this method is that it can be used to cut curved surfaces, which is often used when developing unique vases and candlesticks from glass bottles. In certain cases, cutting glass without a glass cutter is not only possible, but also completely justified from a practical point of view.

MK how to cut 10 mm plexiglass. (and thicker) quickly and smoothly.

How to cut plexiglass ? Up to 1 mm. It is enough to make an incision on one side. paper knife. From 1 mm. up to 2.x (2.5 mm) incision on both sides. But 3 mm. You can't cut it with a knife. The cutters are in use. hooks made of hardened steel. In the Foto ; saw blade cutter on top, bottom. from a file.

Plexiglas 10 mm thick. (and more broadly) with such a hook you can, in principle, snatch away. cut 2 mm. on each side and try to break it. But it will be crooked, not beautiful and terribly tiring. What if the thickness is 20 mm? You can cut it . it will be even crooked and no less boring. Therefore, feel free to put the object under the circular saw. Pay attention to the “teeth”.

Feel free to place the plexiglass under the saw and... cut to the required size. It's all about the presentation of the disc. If it's too fast. Such teeth, of course, will smash the plexiglass or leave burrs along the edges, which “is not zer gut.” If it’s too slow. the plexiglass will begin to melt and stick to the disk. Slowly, smoothly, without effort, we feed the saw and get “ochena caracho.”

We rub the saw marks with fine sandpaper. Achtung! The sandpaper sheet should be smooth, i.e. not rolled into a tube, otherwise you will collapse the edges.

The plane very quickly became smooth, but not transparent, but matte. That’s why. three further on the “mikronka” (zero level).

The plane has become almost transparent and if you wipe it with oil, maybe it will come off. But we don’t need “this will do”, do we? We polish on a felt wheel with GOI paste. If someone doesn’t have such a wheel (and you don’t have one), you can simply rub it with a piece of felt or on a piece, and if it’s really bad, then you can do it without the paste. It will just take more time.

This is what happened as a result. The width of the plexiglass is 60 mm. (6 cm). And the book’s lines are clearly visible. It took about 20 minutes to do everything, no more. This takes into account the fact that I am incredibly slow and do everything at a snail’s pace.

READ How to Adjust the Screws on a Chainsaw

Interesting effect (photo without flash). The line was “snatched” from the page and “carried out” by 6 cm. Probably, it can be used somewhere. I just don't know. Where?

Using a hacksaw or other similar tool

In this case, almost any saw can be used; most often this is a hacksaw, jigsaw or other similar tool. With this cutting method, it should be taken into account that plexiglass has poor thermal conductivity and the heat released at the cutting site melts the material itself. The result is often the fusion of the cut after passing through the hacksaw.

To avoid this, water is often used to cool the cutting area.

You can make your work much easier by using a power tool (power saw, jigsaw or grinder). For best cutting quality, the tool should operate at high speeds. How all the work is done is shown here:

Useful tips

There are several tips on how to cut plexiglass without chipping . To achieve a clean cut, leave the acrylic over a gas burner for a while.

Another option: you can use the simplest lighter. True, you will have to spend a lot more time.

You can cut plexiglass using a jigsaw. Use narrow saw blades.

When you purchase them, look for ones that have the MP.S designation on them. These are the most effective devices to solve the problem than cutting off plexiglass.

While working, monitor the speed of the tool. The number of revolutions depends on this. In practice, the speed is selected experimentally. The most important thing is that the plexiglass does not start to melt.

Be sure to wear a protective mask on your face. This will protect you from fragments that will fly at great speed during cutting.

Peculiarities

It is important to consider that the physical properties of the polymer influence the power tool when cutting plexiglass. Because of them, problems often arise on how to cut plexiglass at home.

It begins to melt as soon as the temperature reaches 160 degrees. You can bend it when it reaches only 100 or even 90 degrees. As a result, thick slabs cannot be processed using a simple circular saw. We have to resort to other options.

This material has plenty of pros and cons. The benefits include:

- high light transmittance;

- low thermal conductivity;

- resistance is five times higher than that of glass;

- environmental cleanliness;

- resistance to bacteria, moisture, microorganisms;

- electrical insulating properties.

The bad thing is that acrylic is prone to surface damage, catches fire easily, and microcracks often occur at the bend points.

There are many tools on the market that allow you to make an even cut.

We work with plexiglass at home

If necessary, you can process and cut plexiglass at home. Working with this material is quite simple. In order for you to succeed, you just need to remember some of the features of acrylic, which will help you achieve a good result when cutting.

You can choose one of the proposed tools that will be most convenient for you to work with. So, you may need:

- Hacksaw. The one that is used for working with metal is suitable;

- A circular saw;

- Cutter. You can purchase this tool or make it yourself;

- Jigsaw;

- Filament.

It should be taken into account that plexiglass has a low electrical conductivity

That is why at home, using available tools, you need to act carefully. It is better to cut acrylic with a sharp movement

Therefore, it is necessary to prepare everything in advance and outline the cutting line. There must certainly be water near the workplace. It will be needed to cool the cut. After cutting, you will need to process the cut and remove any existing roughness.

Let's take a closer look at the process of cutting plexiglass at home using the listed tools.

- A fairly simple and inexpensive method is cutting with a hacksaw. The contour will not be smooth. Further process it using sandpaper or a file will do.

- Cutter. To carry out cutting, you will also need a ruler, preferably a metal one. Position it along the intended cutting line. Next, use a cutter to draw a line along the intended line with pressure. Do this 2-3 times. The thickness of the canvas must be cut by 50%. Next, simply break the plexiglass along the cut line. The edge will also be rough and will require processing.

- At home, you can use a thin milling cutter. It is used as an attachment for an electric drill. Be prepared for the fact that smoke will be released during the work, and the acrylic will heat up quickly. To avoid heating and melting of the material at the processing site, use water cooling. In this case, no additional processing is required.

- To obtain shaped contours, you can use a tungsten voltage filament. To build such a tool, you will need a transformer that reduces the voltage of 220V to 24V. Next, attach the thread between two insulators and apply voltage to it. When everything is ready and the thread is heated, cut out the required shape. The heated filament will melt the material.

If you decide to process plexiglass with your own hands, using the tools available in your home or by building some, you can independently cut it into the required elements.

How and with what to cut plexiglass at home

Plexiglas is a common synthetic material. It is produced from an ester of methacrylic acid. In everyday life it is often called acrylic glass, acrylic, plexiglass. It is cut using power tools. But difficulties often arise with this method due to the fact that microscopic particles of organic material stick to the disk. In addition, a power tool may simply not be at hand. how to cut plexiglass using other methods and available means in this article.

Using a hacksaw

Sawing with a hacksaw at home is quite difficult.

First, you need to cut the measuring line with a knife and glue tape along it. This will protect the top layer from damage. Point the tool at an angle of 30 degrees. Carefully move the hacksaw back and forth without pressing hard. To cut laminated chipboard without chipping with a hacksaw at home, choose devices with the finest teeth. In case of damage, the cut area must be passed with a file, directing it from the edge to the center. Finally, rub with sandpaper (fine-grained) and hide the defects under the flexible profile.

How to cut laminated chipboard without chipping at home

Chipboard – chipboard. Used in furniture making and decoration. Affordable price is the main feature. In modern wood production, laminated boards are used. They are made from coniferous and deciduous wood materials. They are durable and easy to process. Improper cutting process can lead to breaks and cracks. To avoid this, you should know what to do to cut laminated chipboard without chipping at home.

Jigsaw

To cut chipboard smoothly with a jigsaw without chipping, you need to choose a device with a minimum tooth size. It is used for small areas of tiles, using smooth movements without pressure at low speed. If you are using a jigsaw for the first time, some cracks may appear on the back of the slab. With further use, the quality of the cut will improve.

Sawing with undercut

The process requires a tire - a thrust ruler. It is secured to the board with clamps. Pruning is carried out according to the markings. The tire is installed along the mowing line, and the cut is made 10 mm deep. The second cut is made through. With this method, there will be no chips on both sides, since the laminate is already cut on the bottom side.

Some elements used in design ideas are cut curvilinearly rather than rectilinearly. In this case, a mixed type of chipboard cutting is used.

Sawing rules

Before sawing , choose a method, as well as accessories and tools.

- scotch;

- masking tape;

- pencil, ruler;

- sandpaper.

- hacksaw;

- milling cutter;

- a circular saw;

- tire;

- jigsaw;

- sawing machine.

- Apply dots to the end part of the chipboard. You need to determine in advance what type of cutting will be done - straight or figured. Their cutting technique is different.

- Connect the dots into a fishing line and stick adhesive tape on top. saw laminated chipboard using adhesive tape. It will reduce cracks when cutting, since the wooden slab is subjected to strong pressure with increasing temperature.

- Cut the board. The accessory is installed at the desired angle to achieve extremely smooth edges. The process should occur smoothly, rhythmically and without strong pressure.

- If necessary, process irregularities and edges with a file and rasp. The edges can be covered with veneer of the appropriate color. This will provide them with protection and will look more beautiful.

To disguise low-quality ends, a decorative finishing method is used - veneering (gluing the sides). Thus, not only the appearance will improve, but also the service life of the product will increase.

Only after placing all the necessary tools on the table can you start cutting.

Circular saw

The tool is a table with a toothed disk for chipboard. Among craftsmen it is called a circular saw. Cuts through wood better than a jigsaw. A good result without chipping is possible by sketching guide lines and securing the circular saw to the board. Chips should not appear where the saw cut into the slab. But the opposite side can be sawed through with fragments.

What can you do with a grinder and where to start?

This tool allows you to confidently cut, grind, clean and polish many well-known materials, such as concrete and tiles, metal and wood, brick and others. In this case, for each specific type of work, a special replaceable nozzle will be required. In some cases, such a tool can be used for other purposes, such as cutting glass with a grinder or sharpening cutting surfaces (knives, drills, etc.).

READ Replacing Husqvarna Chainsaw Starter Cord

This power tool is indispensable in the process of construction or repair work. It is actively used in auto repair shops, utilities, during rescue operations and in other areas of our lives. In other words, angle grinders are widely used in industry and in everyday life.

The work itself as an angle grinder is a high-risk operation. Before you start, it is important to prepare the tool itself. In this case, the choice of nozzle plays a special role. It is important to consider the following points:

- The diameter of the saw blade - the smaller its value, the greater the rotational speed, which means it is able to withstand a greater number of revolutions;

- The working material directly affects the choice of consumables. For example, for metal pipes an abrasive disc, and for concrete. diamond;

- Carefully study the symbols and labeling of such consumables. This will allow you to understand whether this attachment is suitable for the intended job.

Angle grinder discs are actively used in various operations and must be changed for different materials. Moreover, each of them has unique properties and design. This is why it is so important to choose the right consumables for your grinder.

Depending on the purpose they are:

- cutting - for cutting or sawing materials;

- saws – for cutting various wood products;

- roughing – for grinding metal, concrete and wooden workpieces;

- strippers - for removing rust from metal surfaces and eliminating other types of persistent contaminants.

The most common types of cleaning discs include flap wheels. Such tools are suitable for processing materials made of metal, plastic and wood.

- Disconnect the tool from the mains and jam the rotation shaft with the attachment using a special button;

- The lock nut must be unscrewed. To do this, use a key with two protrusions;

- Remove the old disk. After this, a new one can be installed on the mounting flange;

- Screw in and secure the lock nut with a wrench.

Cutting or sawing

Saws are mainly used to perform this operation:

- Disk

- Ribbon.

Circular saws

In industry, acrylic is usually cut with table saws, and in trade. Vertical panels. In mass production, computer-controlled automatic mowers are used. Three process parameters must be linked in the routing:

- Disc diameter;

- Saw rotation speed;

- Acrylic cutting speed.

When cutting thick (more than three millimeters) sheets and blocks, it is necessary to cool the cutting area (for example, using cooling sprays). Although quite often this requirement is ignored for two reasons:

- It is not possible to install a cooling device (due to lack of free space);

- Reluctance to introduce the additional operation of cleaning the workpiece before the next operation (gluing, for example painting).

Band saws

Band saws, which are typically used for metal and wood work, are often used for trimming the edges of molded plexiglass products and contour cutting plexiglass. Due to the use of band saws, the cutting line becomes quite rough, so additional processing is required. Depending on the cutting contour, the saw width is selected in the range of 3.13 mm. Number of teeth. From 3 to 8 pcs. One centimeter of canvas length.

Features of the Dnipro-M angle grinder

Angle grinders produced by Dnipro-M have increased safety measures. By purchasing a branded angle grinder, you can be sure of their quality.

- during prolonged operation, the device's power button is automatically locked;

- elimination of vibration from uneven wear of the disk due to its balancing;

- Automatic engine shutdown during voltage surges or surges;

- engine cooling function;

- almost instantaneous shutdown of the angle grinder in case of jamming of the device;

- dust removal system.

In addition, it would not be amiss to highlight such features of the Dnipro-M angle grinders as: a rubberized handle, which is very conveniently located, additional engine protection through triple varnish coating, as well as the low weight and ergonomic design of each presented model.

Production cutting methods

Plexiglas has become widespread due to its light weight and good flexibility. Today it is used to create greenhouses or gazebos. Over the long-term use of the material, several production processing methods have been developed:

- Laser cutting.

- Milling processing.

- Cutting with a band saw.

- Using a circular saw.

Special milling machines are often used, which are characterized by high productivity and versatility. Their high cost determines that installation is carried out exclusively in mass production.

How to cut tiles, ceramics, granite, tiles

A feature of these materials is a large amount of dust and the possibility of chipping during the cutting process. It is important to approach the preparatory process correctly. If it is impossible to avoid the formation of dust, then minimizing the risk of chipping is quite possible.

To avoid chipping while cutting the tiles, you need to moisten them in water. This step in time reduces the temperature of the material, which is the main cause of destruction. This will also allow you not only to cut the tiles without chips, but also to cut out the necessary fragments. Approximately this principle is used to cut tiles.

There is an alternative way. In this case, you will need to use a stone cutting wheel. The use of such a circle practically eliminates the formation of cracks and chips.

Cutting porcelain stoneware is more difficult, as this material is thicker and stronger. The best solution in this case is to use a stone circle:

- make a contour cut along the contour mowing line. Then again, until the uncut thickness of the product becomes less than the cut thickness;

- move the product to the edge of the table;

- With a sharp, but not strong movement, break the porcelain tile.

Some features of using industrial equipment

All industrial equipment is characterized by the fact that it allows you to automate the process of cutting composite materials. Today, laser cutting is most often used. Among its features, we note the following points:

- The processing accuracy is about 0.005 millimeters. This is achieved by forming a laser beam of 0.1 millimeters.

- All resulting edges are smooth and transparent, and virtually no waste is generated.

Machines with circular and band saws are most widely used. This is due to their relatively low cost. However, such equipment does not allow processing along a complex trajectory.

Laser cutting of plexiglass

During machining, the tool and the material itself can become very hot. Plexiglas is characterized by less resistance to elevated temperatures; when heated, it begins to melt and a large amount of smoke is formed. Air flow or clean water can be used as cooling.

Cut, clean, sand. how to work with an angle grinder correctly

An angle grinder (angle grinder), also known as an angle grinder, is an effective but extremely dangerous tool. Using this unit incorrectly quite often leads to various types of injury, damage and injury, in some cases resulting in death. In most cases, such injuries are caused to themselves by non-professionals who are holding such a tool in their hands for the first time and have only a verbal understanding of its operation. That is why it is of great importance to study safety precautions, operating rules and the use of protection when working with angle grinders.

In order not to get lost among the multitude of “empty” advice and unnecessary recommendations, choose only the right sources of information. You will learn how to use an angle grinder correctly, what protective equipment should be used, and much more just by reading this article.

How to cut metal with a grinder

Cutting metal with a grinder is a rather complex process. Approach it wisely.

Depending on the thickness of the sheet metal, the working circle should be selected. You will also need to choose a rotation speed that is optimal for the job and perform the cut strictly along the drawn lines. Approaching the end of the tile, recess the angle grinder a little so that the cut border does not have a bevel.

You can start the process of cutting corrugated sheets from absolutely any edge. If necessary, the cut can also be started from the middle. The only caveat here concerns thin metal - when cutting it from the reverse side, a torn cut is formed. To avoid injury and to ensure cleanliness, it is recommended to sand such a cut.

Don't know how to cut a pipe with a grinder? Any metal pipe is equivalent to a sheet of metal and does not require additional skills. The whole difference here lies only in the shape of the product itself.

Cutting reinforced concrete can cause some difficulty. Although it's almost the same as cutting metal. A diamond blade is suitable for these purposes. A little advice - start cutting at a depth of about 1 cm. If there are no problems with your angle grinder, continue the operation. The depth of each subsequent cut should be no more than 1.5 cm.

How to break glass correctly

You need to place the sheet on a horizontal surface (for example, a table) so that the marking line rests on the edge of the table top. A huge part of the glass should be held. The area that is planned to be removed must be grasped with your hand by the free edge, preferably in the center, and slightly pressed downwards. If the strip is not wide enough, the glass is removed using pliers, special tongs or wire cutters.

Diamond blade

A grinder equipped with a diamond blade will simply cut a piece of glass sheet. The main difficulty is to guide the saw exactly along the markings. There is no need to plunge the cutter into the material, as in the general case, to separate the desired part, only a narrow groove is required from edge to edge of the sheet. Increased attention should be paid to safety, the highest degree of concentration is required. When working with an angle grinder, glass dust appears, in order to reduce its amount, it is recommended to water the cutting line with water.

How to cut wood, plywood, chipboard

Despite many questions and attempts to cut wood products with a grinder, many experts do not recommend using this tool for such work, but using other tools for these purposes - jigsaws, circular saws, etc. This is explained by the high degree of danger in the process of performing such work.

Among the reasons for increased danger, the most important are:

Cutting plexiglass at home

- There is a possibility that the teeth of the disc will catch a large amount of wood, which will lead to the tool suddenly slipping out of your hands;

- Heating of the disc during the cutting process, which leads to its fragility. In this case, even a slight misalignment causes destruction of the disk, causing its small pieces to fly apart;

- There is a high probability of solder detachment, which can lead to injury to the technician.

Now there is a wide variety of special tools for woodworking. So why risk your own life?

Sources:

https://stroy-podskazka.ru/orgsteklo/kak-rezat/ https://stankotec.ru/raznoe-2/chem-raspilit-orgsteklo-v-domashnix-usloviyax-kak-i-chem-rezat-orgsteklo- v-domashnix-usloviyax.html https://lesoteka.com/obrabotka/kak-raspilit-ldsp-bez-skolov-v-domashnih-usloviyah https://dnipro-m.ua/news/pravilnaya-rabota-bolgarkoy/

Equipment and tools

Plexiglas is processed on the same equipment as wood or metal. A clean cut is obtained when processing the material on high-speed machines.

The only requirement: plexiglass cutting machines and circular saws must be equipped with a hood to quickly remove chips and waste.

Tools made of tool steels, hard alloys and diamonds are used for cutting plexiglass. It is very important to sharpen the cutting edge, since the use of dull, low-quality tools leads to the formation of chips, burrs and stress in the cutting area. For the same reason, do not use a tool that has previously cut metal or wood.