What is a grease trap?

Blockages in sewer systems are a very common problem in country houses with independent sewerage. A common reason for this is improper pipe laying during installation, the discharge of substances that cannot be dissolved, as well as wastewater with too much greasy particles. The last cause of the problem can be solved by installing a grease trap under the sink.

This is a special device that prevents grease from entering sewers and treatment facilities.

It has long been used almost everywhere in restaurants, cafes, bars, small bakeries, pubs, confectionery shops, as well as in industrial enterprises where poultry and meat are processed. But recently it has begun to spread for household needs.

Such small devices are designed for cleaning small amounts of grease and household waste. They are installed under the sink and are able to work with different productivity, different volumes, or as it is called maximum (peak) discharge.

The workshop device can be replaced with several small devices installed under the sinks. Thanks to this, the volume of fat entering the sewer system is reduced.

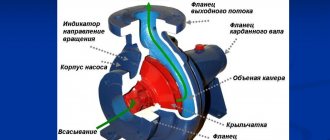

The equipment consists of a housing with inlet and outlet pipes. Inside there is a partition of one compartment, a flow damper and a hole that removes air. A ventilation tube is installed above the surface where fatty waste accumulates.

Currently, there are many types of devices. They are classified depending on the material of manufacture and the method of installation and cleaning.

Popular manufacturers

Many companies specialize in the production of household grease traps, so the consumer always has plenty to choose from. Let's look at the most popular brands:

- Evo Stok is a manufacturer offering grease traps made from durable reinforced plastic. The company's assortment consists of models of low and medium price groups.

- FloTenk is a company that produces primarily round grease traps made from fiberglass reinforced plastic. The brand's products belong to a high price category, so they are not available to all consumers. But for an increased cost, the user receives a device with maximum throughput and an extremely long service life.

Grease trap Fifth element

- The fifth element is a brand that specializes in the production of individual grease traps made of plastic and steel: here you can order a model specifically for the parameters of your kitchen sink. A distinctive feature of the devices is the presence of a removable water flow limiter.

- Wavin Labko is a company that produces high-performance fiberglass grease traps. The brand offers mainly automated models with a sensor that informs about fat levels.

- Vortex is a manufacturer that produces grease traps with a body made of durable reinforced plastic. The company's line includes models for non-standard sewerage systems. A special feature of devices of this brand is the presence of special stiffening ribs on the body, which give the grease trap high resistance to mechanical deformation.

So, now you know what you should first consider when choosing a household grease trap for your kitchen sink. Material of manufacture, performance characteristics, manufacturer and reviews - these are the four main indicators, attention to which will allow you to buy an effective and durable device and forget about extremely unpleasant fatty deposits in kitchen pipes for a long time.

Principle of operation

Wastewater with fat flows into the treatment system, where at the initial stage the suspended particles precipitate, and the fats remain as a film on the surface. The water is then sent to the second stage of purification, where it is separated from the fat. The partition prevents these particles from entering the second compartment. The purified water then goes into the sewer system.

In cafes and canteens, sinks come in cumulative and flow-through types. With the storage type, the dishes are washed in a sink filled with water, after which the plug is removed and the water flows into the drain. A household grease trap under the sink, in this case, is installed based on the volume of the volley discharge being equal to the volume of the sink. For flow-through washers, the calculation is 0.5 m3/h.

Operating parameters

Grease traps differ in the power and performance of the devices. For household devices, the performance indicator varies from 0.1 l/s to 2 l/s. The remaining devices, which have a higher rate, are industrial.

Grease traps can also be distinguished by the method of cleaning the device. It is worth highlighting here:

- Separators with manual cleaning. A person will have to monitor such devices independently. Cleaning occurs using available grease removal products. Such devices most often belong to the class of those installed indoors and having a low throughput.

Manual cleaning of the grease trap

- Separators that are cleaned using pumps or specialized machines. Typically, this type of device uses automatic functions to notify you when maintenance work is required. Industrial grease traps with high performance indicators and outdoor grease traps have similar functions.

Cleaning the grease trap by machine

Types of manufacturing materials

In particular, grease traps for sinks are made from various materials. This:

- stainless steel,

- fiberglass,

- plastic.

The most economical of all types of devices are plastic devices. Therefore, buyers choose this type most of all.

Grease traps for sinks made of fiberglass are mainly purchased for industrial enterprises. Such devices are installed outdoors, since the material is highly resistant to weather changes, as well as to chemical reagents.

The most expensive are, of course, stainless steel appliances. Only the most profitable industrial enterprises afford such grease traps for sinks. But, at the same time, their hygienic properties and service life are the highest.

What determines the need to install the device on a summer cottage?

Look at the photo of grease traps under the sink; the purpose of household equipment is to prevent the penetration of grease and oil into autonomous sewers and cleaning facilities.

Operating principle:

The device first separates liquids from residual fats and oils; due to its principle of operation, the device has received a second name - a separator.

Fat and oils have a different specific gravity compared to water, so they are easily separated from the liquid. Fat particles are collected in a separate sump, and water only goes into the sewer after purification.

Types depending on installation

Devices can be installed in different ways. Based on this property, they can be divided into the following types of devices:

- mounted under the sink,

- installed in another room,

- installed in the basement,

- installed outdoors.

The first three types have no fundamental differences, except that the distance from the place where washing is performed is different.

On the street, mainly devices used for industrial enterprises are installed. They can be made of stainless steel or fiberglass, but not of plastic, since such a coating can be damaged due to weather conditions and interaction with an aggressive environment, namely chemical reagents.

Stainless steel grease traps

As you know, stainless steel has a high cost, which means grease traps made from this material will be expensive. As a rule, large enterprises can afford these treatment facilities. Stainless steel has high anti-corrosion and hygienic properties, as well as mechanical strength. Fiberglass and plastic are inferior in terms of the latter indicator.

The aesthetic appearance of stainless steel separators allows them to be installed indoors without additional camouflage. Since their main parts are removable, they are very easy to maintain. During operation, stainless grease separators are not afraid of temperature changes and liquids with chemical reagents. The tightness of the products prevents the spread of unpleasant odors.

Types by cleaning method

Devices are differentiated depending on how cleaning is carried out. So they are divided into:

- Devices that are cleaned manually . These are the most popular household devices. When cleaning, use cleaning products available on hand. They do not have high throughput.

- Another type of device differs in that special pumps are used for cleaning . The automated functions of the devices are capable of informing themselves that preventive maintenance should be carried out.

It is clear that this type is in demand only in industrial enterprises. They often have outdoor installation.

Types of devices

Before moving on to the question of how to choose a grease trap, it is more logical to first learn about the range of such devices.

Main types

There are industrial and household appliances.

- Industrial grease traps are purchased for installation in large enterprises where the technology involves processing raw materials containing a large percentage of fats or oils.

- Domestic tanks are the “destiny” of houses, apartments, as well as numerous public catering establishments. As a rule, grease traps are installed in bars, restaurants, cafes and canteens.

The operating principle of both structures is the same. Grease traps differ only in size. Both types can be vertical or horizontal, intended for indoors or outdoors. There is one difference: industrial models cannot be cleaned manually due to their large dimensions. In this case, special equipment is used: the set of such devices includes a special pump and a fat level sensor. Vacuum trucks can easily handle large tanks.

Traps and materials for them

There are three suitable options: for the production of grease traps, plastic, fiberglass and stainless steel are used.

Plastic structures

This material is distinguished by its light weight, practicality, and the ability to create the most unusual shapes of structures. If we talk about household grease traps, then plastic models can be considered optimal. Their biggest advantage is the ability to quickly clean.

Advantages of plastic (polypropylene, polyethylene) traps:

- relatively low price of models;

- safety for owners and the environment;

- ease of cleaning: the container is easy to clean with any detergent;

- versatility of the material: it is the basis for many household devices;

- long service life: it is believed that plastic can last 25-30 years.

A wide range of polymer products joins the “army” of advantages: you can choose the volume, shape of the structure, and dimensions of the grease trap. It is possible to make an individual order. A question may arise about the temperature that the polymer material can withstand. The maximum value is 70°. Air temperature - from 5 to 40°.

Fiberglass grease traps

This material is ideal for use in industrial plants with large volumes of liquid to be treated. Fiberglass is able to withstand maximum pressure; it can be installed both indoors and outside buildings, on the street.

Advantages of fiberglass as a fat fighter:

- light weight, but enviable strength, ease of use;

- maximum resistance to chemicals and aggressive environments.

Separately, it is necessary to note the versatility and reliability of the products: after installing fiberglass grease traps anywhere, you will not have to worry about the tank becoming damaged.

Stainless steel traps

If we think about reliability, practicality, convenience and care, then it is difficult to find equal rivals for this material. “Living” evidence are sinks that are made of stainless steel. However, in this case, there is an obstacle for owners of apartments or houses: this is a higher price when compared with the cost of all plastic (composite) models.

For this reason, such steel structures are often purchased for catering establishments. Sometimes they are bought for large private houses. However, owners make decisions about the appropriateness of a particular device based on their own considerations.

Cleaning the Grease Trap

For good equipment operation, it is important not only to install it, but also to properly maintain it. This way, the grease trap under the sink will last much longer.

It is necessary to clean the device depending on the volume of water passing through the kitchen, the capacity of the device, the type of sink itself, and peak discharge. If, for example, it is known that a smaller salvo discharge is used than necessary, then cleaning should be carried out at least once every two to three days with frequent use, or once or twice a month with rare use. In other cases, equipment must be cleaned less frequently, approximately once every six months.

To clean the grease trap under the sink, you need to remove its lid and first put on rubber gloves to remove all the grease and sediment inside. Of course, doing this is completely unpleasant, but it is necessary.

In addition to mechanical cleaning, the so-called neutralization of fats can be used, when special biological products or microorganisms can make a liquid mass from fat deposits on the walls of the device. In this case, it is necessary to choose biological products that can easily tolerate solutions of chemical cleaning agents, hot water, and also destroy bacteria.

When using the product, it is extremely important to store it very carefully so that nothing leaks through the body of the device, because such preparations containing unicellular and multicellular microorganisms are harmful to human health.

Grease trap manufacturers

Today, buying such equipment is not a big problem. It is produced by both foreign and domestic manufacturers. It is impossible to invent anything new in these designs; they are all practically no different from each other. Therefore, it is necessary to focus on the fame and reputation of the brand.

The most famous companies:

- Helyx. This is a Russian manufacturer that produces mainly equipment for industry under this brand.

- Flotenk. A domestic manufacturer that produces industrial and domestic sewage equipment made of fiberglass, the service life of which can reach 50 years.

- Wavin Labko. A manufacturer from Finland offers polyethylene grease traps under the EuroREK Omega brand.

- Evo Stock. A Russian company producing household and industrial grease separators made of polypropylene or reinforced plastic.

- "Fifth Element" is a company that produces inexpensive polypropylene grease traps used for household and industrial purposes.

In conclusion, it must be said that a grease trap is a necessary element in the sewerage system, ensuring sufficient purity of sewage, which is less harmful to the environment than untreated sewage.

Rating of the best grease traps

| Nomination | place | Name of product | price |

| The best grease traps for household use | 1 | Biofor Economy – 40 | 4 900 ₽ |

| 2 | Alta-M-In 0.5-25 | 8 990 ₽ | |

| 3 | Aqua Mini (0.3-20) | 3 515 ₽ | |

| 4 | Onyx 0.5-15 | 7 600 ₽ | |

| The best grease traps for catering units | 1 | Grease Guardian D4 | 366 855 ₽ |

| 2 | PE 1.5-100 “Auto collection” | 39 000 ₽ | |

| 3 | EVO STOCK 1.0-70 10021 | 11 023 ₽ | |

| 4 | Termit 1.0-60 | 6 700 ₽ | |

| 5 | ITERMA CG-05/40N 14780 | 16 200 ₽ |

The best grease traps for catering units

Industrial grease traps demonstrate high performance. They are installed in catering units of canteens, cafes and restaurants. Experts have identified several effective models.

Grease Guardian D4

Rating: 4.9

A highly effective grease trap is the Irish-made Grease Guardian D4. The model is considered to be the only automatic grease trap in the world with a built-in separator. The device demonstrates a record degree of wastewater purification from grease (up to 99%). Separation into fractions is carried out without human intervention around the clock. Thanks to the periodic removal of pieces of food and fat, there is no unpleasant odor in the catering unit. Experts appreciated the high throughput (2.25 l/s) and the stainless steel body, giving the grease trap laurels as a winner.

Owners of catering establishments are pleasantly surprised by the quality of wastewater treatment and the absence of a characteristic odor in the catering unit. The disadvantage of the device is its high price.

Advantages

- automatic operation;

- high degree of purification;

- quality materials;

- excellent performance.

Flaws

- high price.

PE 1.5-100 “Auto collection”

Rating: 4.8

Three points at once (washing baths) in the catering department can be served by a grease trap PE 1.5-100 “Avtosbor”. The productivity of the device is 1.5 cubic meters. m/h, and the maximum water discharge load reaches 100 liters. Experts note the ease and convenience of installation, perfect tightness, and the absence of unpleasant odors. The model is equipped with an “Auto-collection” system, which includes a shaft, a scraper, a gutter and a canister for collecting grease. The container must be cleaned once a month. The versatility of application helped the Russian development take an honorable second place in the review.

Domestic consumers are satisfied with the high efficiency of wastewater treatment, ease of operation and maintenance, and good performance. The downside is that it is not fully automatic.

Advantages

- good performance;

- complete tightness;

- versatility;

- easy installation.

Flaws

- Daily cleaning of the gutter is required.

EVO STOCK 1.0-70 10021

Rating: 4.7

A completely non-volatile device is the grease trap EVO STOK 1.0-70. It is equipped with a one-piece plastic case, inside of which there are 3 sections. Experts liked the simple design; there is a removable tray on the outlet pipe; the lid closes hermetically, preventing the spread of unpleasant odors. The basic package contains all the necessary parts to connect the device to the sewer. The model is inferior to the leaders in productivity (1.0 cubic m/h) and peak discharge volume (70 l).

The strengths of the grease trap, according to users, are its lightness (15 kg) and compactness. The affordable price also looks attractive. The disadvantage of the device is the need for daily cleaning. It is best to do this before starting work.

Advantages

- reasonable price;

- lightness and compactness;

- tightness;

- high-quality separation.

Flaws

- Requires daily cleaning.

Termit 1.0-60

Rating: 4.6

The domestic grease trap Termit 1.0-60 stands out from its competitors at the most attractive price. It is a 3-section plastic container with a sealed lid and pipes. The total salvo discharge is 60 liters, and the model’s productivity reaches 1 cubic meter. m/h. The manufacturer has made the middle section with a narrowed bottom, which makes cleaning easier. Experts advise servicing the device outside to rid the catering unit of an unpleasant odor. The disadvantage of the product is the need to shift the inlet pipe. Because of this, rubber seals quickly fail.

Domestic users like the affordable price, easy installation and operation. Among the shortcomings, the fragility of the sealing elements is noted.

Advantages

- low price;

- simple design;

- easy installation;

- good performance.

Flaws

- Rubber seals wear out quickly.

ITERMA CG-05/40N 14780

Rating: 4.5

The grease trap ITERMA CG-05/40N is considered professional equipment. The body of the product is made of stainless steel, which makes the model reliable and durable. Compact overall dimensions and low weight (9 kg) allow the device to be installed both in catering units of public catering establishments and in private houses and apartments. The grease trap is inferior to the review leaders in such technical parameters as productivity (0.5 cubic m/h) and peak discharge (40 l). Connection to the sewerage and sink is carried out using standard PVC pipes with a diameter of 50 mm.

Owners of cafes and restaurants like the grease trap for its reliability, durability, ease of connection and maintenance. Among the disadvantages, the high price and modest performance are mentioned.

Advantages

- quality materials;

- strength;

- durability;

- easy installation.

Flaws

- high price;

- modest performance.

Operating principle of a grease trap

A grease trap or fat separator works on the principle of separating fat from water through filtration and sedimentation. The word separator itself means separation and the grease trap fully justifies this definition.

The most common method of separating fatty impurities from water is the mechanical method. It is multi-stage and quite simple.

The essence of cleaning is to install several membranes on the water ceiling, which will dampen the flow of wastewater and cool it, trapping fat particles. This is possible in principle, since when the water drains cool, fat is released from the water and floats up.

However, such a simple principle of operation of a mechanical grease trap creates a new problem in cleaning grease traps. Grease traps can be cleaned manually or industrially. It all depends on the type and type of grease traps used.

The best grease traps for household use

Kitchens in apartments and houses produce little wastewater. Therefore, the best option would be to purchase household grease traps. Experts advise paying attention to the following models.

Biofor Economy – 40

Rating: 4.9

The Biofor Economy - 40 model effectively collects fat in apartments, houses and small catering establishments. The device is a solid plastic tank, the internal space of which is divided into several chambers. Large debris collects in the first chamber, fat is retained in the second compartment. Experts note the high-quality separation of wastewater, due to which sewer pipes do not have to be cleaned for a long time. The capacity of the grease trap is 40 liters; up to 0.51 cubic meters can pass through the device in an hour. m of wastewater.

Domestic users are satisfied with the performance, quality of separation, and ease of operation. They have no complaints about the operation of the device. The grease trap wins gold in our review.

Advantages

- compactness;

- good performance;

- high-quality separation;

- ease of maintenance.

Flaws

- not detected.

Alta-M-In 0.5-25

Rating: 4.8

Compact dimensions and low weight (6 kg) are important advantages of the Alta-M-In 0.5-25 grease trap. The container can be installed under a regular sink in a kitchen cabinet. The Russian manufacturer has used innovative wastewater treatment technology, which ensures high treatment efficiency. The body of the model is made of modern polymer materials, the service life is more than 50 years. At the same time, experts appreciated the environmental friendliness of plastic. The grease trap is easy to install and operate; the scope of application of the device is wide (residential buildings, cafes, restaurants, canteens).

Russian consumers liked the quality of workmanship, the efficiency of wastewater treatment, and ease of maintenance. The model receives silver in our review, being inferior in price to the winner.

Advantages

- effective separation;

- compactness and lightness;

- durability;

- environmental friendliness.

Flaws

- high price.

Aqua Mini (0.3-20)

Rating: 4.7

Affordable price and compact dimensions helped the Russian grease trap Aqua Mini (0.3-20) take third place in our review. The model qualitatively separates wastewater into several fractions. Solid sediments collect in one chamber, fats accumulate in another compartment, and clean water comes out of the device. The product weighs only 2.7 kg, although the body is made of durable plastic (wall thickness 8 mm). The advantages of the product, according to experts, include resistance to ultraviolet radiation, tightness and good quality of separation.

So far, the grease trap is rarely found on sale, so there are few real reviews on the Internet. The model deserves praise for its affordable price, ease of installation and ease of maintenance.

Advantages

- lightness and compactness;

- reasonable price;

- ease of installation;

- UV resistance.

Flaws

- rarely found on sale.

Onyx 0.5-15

Rating: 4.7

The grease trap Onix 0.5-15 demonstrates good performance (0.5 cubic m/h). The model is made in the form of a cube with sides measuring 300 mm. The separation of wastewater into fractions in a container occurs based on the principle of gravity, fat collects in the form of a film from above, and clean water seeps out from below. To make the case, the manufacturer used modern heat-resistant polypropylene. The grease trap can operate in a wide temperature range (+5…+70ºС). The device is easy to install and is easy to periodically clean from accumulated fat. Experts pay attention to the manufacturer's 3-year warranty.

Users praise the model for its effective separation and durability. The disadvantages of the product are its cubic shape and high price.

Advantages

- high-quality separation of fractions;

- good performance;

- ease of operation;

- 3 year warranty.

Flaws

- high price;

- cubic shape.

Grease traps installed in the ground

These installations are more common than those installed inside buildings. They can have different capacities - from 1 l/s to 30 l/s, as well as a wide range of incoming pipe connections. They can be installed under the road, or in any free ground. To install an underground grease trap, the following work is required: ground work, concreting and installation itself. Only professionals can install a grease trap correctly for industrial purposes. The main advantage of an industrial grease trap is its high throughput; it can be used in almost all industries. But they also have disadvantages - difficulties in servicing storage tanks. To facilitate this work, special sensors are used to monitor the filling level of containers.

Based on the body material, grease traps are divided into: - plastic; - fiberglass; - made of stainless steel.