The jigsaw came to us from Germany (from German Laubsage). Initially, it was a hand tool with a replaceable saw blade, designed for curved sawing, in a translational motion, of plywood and thin boards and other materials along an internal, closed contour. There were many types of jigsaws. The jigsaw was mainly used in the navy.

Today, a jigsaw is a high-tech hand tool that uses a pneumatic or electric drive. Modern technologies have improved the jigsaw by adding built-in safety features, electronic speed control, vibration and noise dampers. Typically, jigsaws have a touch guard mounted above the base plate to prevent accidental contact with the saw blade.

A jigsaw is a saw with a reciprocating movement of the saw blade (working body). It has a ski to guide the working body when moving along the surface being treated and makes reciprocating movements with a frequency of up to 3000 vibrations per minute.

The jigsaw is ideal for straight, curved and mortise cuts , for cutting circles of various diameters (with a radius of at least 15mm) as well as for rectangular cuts and cuts. It allows you to process any material - wood, stone, plastic, steel sheet, ceramic tile.

Depending on the method of fastening the saw , a jigsaw can be of three types: for saws with a cross-shaped shank, with a smooth shank and with a shank with a hole.

When ", pay attention to its characteristics: if the lowest frequency of saw blade strokes is less than 1000 per minute, then it will not be able to cut plastic, for example. A jigsaw is also characterized by the power of its electric motor . Other parameters that affect productivity depend on power - maximum cutting depth, cutting speed of various materials. Since the jigsaw is held with one hand when working, its weight is important. A jigsaw may have control electronics that ensure a constant set stroke frequency under different loads and cutting different materials.

A modern jigsaw is a very democratic and universal “helper”. With more or less success, this modest worker, created to solve just one task (curvilinear cutting of thin materials), is able to replace:

- router - curved cutting, insertion of simple elements, open joints of the tongue-and-groove type;

- hand saw - cutting and fitting not too massive lumber into place;

- reciprocating saw – fitting mounted lumber near joints, at heights and in other cases where a hand saw is inconvenient;

- angle grinder - cutting not too massive metal workpieces, cutting tin, tiles, cement-based sheet materials;

- circular saw – longitudinal cutting of lumber, plywood, chipboard (including laminated);

- chain saw – cutting wood waste and thin branches/trunks into firewood.

When preparing this article, the Moscow “Tula”, which represents Festool and Protool equipment, served as the material and technical base for us.

Purpose

The above-mentioned “non-core” operations are performed with a jigsaw with a number of restrictions, sometimes quite significant. However, when the listed arsenal is not at hand, such thoughts are hardly appropriate. Let's start talking about methods of use with those jobs for which the tool was originally designed.

In modern construction, sheet materials are very popular: plasterboard, aceite, laminated panels; Often artificial analogues of “lining” are used - panels made of vinyl, MDF or metal. In these cases, voids remain behind the finishing layer, which makes it possible to use a large number of all kinds of built-in elements (lights, switches, sockets, etc.). It is more convenient to place them when the material is already installed. This is where a jigsaw comes in handy - it can be used to carefully and quickly cut holes of any shape.

Kitchen furniture assemblers face similar problems: they often have to cut holes in countertops for sinks, mount socket blocks on decorative panels, and make “passages” for water supply and drainage.

Interior elements and furniture parts also sometimes require rounding, and if a router with a template and/or a band saw can help in mass production, then a home craftsman or a novice craftsman cannot do without a jigsaw. When it comes to work on the road, there is a great temptation to replace the circular saw - in some cases this is successfully accomplished.

When working with a jigsaw, they do not use any templates, mainly relying only on markings. This has its “plus” (less preparatory actions) and its “minus” (higher operator responsibility). However, the most serious danger facing the user is not related to “directional stability”, but to the lateral movement of the canvas from the vertical. For an inexperienced person, this often comes as a surprise: from the top side of the workpiece, the cut goes exactly along the line and it is difficult to find fault with the quality, while from below, instead of a straight line, a “wave” appears or the file goes to one side (typical for circular cuts). Another problem is relevant only in some cases - chips on the front surface of the workpiece. These two problems are solved using similar methods: selecting a file and operating mode. Let's start with the second one.

What is an electric jigsaw used for?

An electric jigsaw is simply irreplaceable for the following types of work:

• Using this material you can cut almost any material - wood, plastic, drywall, tile and, of course, metal sheets.

• It is possible to make holes, both rectangular and round, of any required diameter.

• Any material can be cut “crookedly”, that is, not in straight lines.

I would also like to note that sheet materials are very popular in modern construction - various panels, drywall, etc. In such cases, voids form under the finishing, which are very convenient to use for embedding lamps, switches, and so on. The latter are easier to install if the panels are already installed, and this is where a jigsaw comes to the rescue, which can quickly cut a hole of any size and shape. Similar problems are encountered when assembling furniture, so this tool is necessary there too.

In general, an electric jigsaw is a useful and convenient thing. It can be used without any templates, acting only on the markup. The only trouble that can happen to you when working is the blade moving across from the vertical. If an inexperienced person, then this will come as a surprise to him: everything seems to be perfect from above, but from below the cut is skewed.

Adjustments

Modern jigsaws are usually equipped with three adjustments. The first - tilting the sole - is used extremely rarely, since where the use of a jigsaw is most appropriate, in most cases there is no need for oblique cuts.

The second adjustment - stroke frequency - is needed to adjust to the material. When working on wood, in the vast majority of cases it should be maximum. Only sometimes it is reduced when the canvas is too narrow, prone to overheating, or when it is convenient for the master. When working with ceramics or thick metal, the transition to medium and low speeds is inevitable.

The third setting is responsible for the amplitude of the pendulum stroke of the blade . Once upon a time, the jigsaw rod made strictly vertical movements, and for a long time this suited users. Later, the kinematics of the instrument were modified by adding longitudinal vibrations of small amplitude to the vertical vibrations. As a rule, the support roller and the return spring are responsible for “pumping”. If the mechanism is turned on, the blade will move forward slightly on the up stroke and move back slightly on the down stroke. This contributes to better removal of sawdust from the cutting area and more productive “biting” of the teeth during the working stroke. At first glance, such a modernization does not seem very significant. However, our experiments show that this statement is true only for the case of the thinnest workpieces (plywood, MDF, tin). When cutting thick ones, productivity changes several times. Is it any wonder that at the moment there are almost no models left on the market without a pendulum stroke.

But there is no good without bad. When the blade is tilted forward, it experiences additional loads, which provoke lateral bending and the cutting plane moving away from the vertical. In addition, hard materials (ceramic tiles, thick metal) require a strictly vertical saw stroke. Therefore, we always turn off the “pumping” mode, and in most cases, the amplitude of longitudinal vibrations is adjusted stepwise from zero to maximum. The latter property is often presented as an important virtue, but experience shows that two extreme positions are usually sufficient.

The implementation of pendulum adjustment usually does not affect anything, but not in the case of imported instruments of the lowest price class. They have a defect that leads to a spontaneous transition from the upper positions (fourth and third stages) to the lower ones (third and second). It’s not difficult to check the tool - just turn on the “pumping” to maximum and cut a thick workpiece with decent pressure.

So, how do you set up a jigsaw? First you need to make sure that the sole is perpendicular. It happens that the clamp does not provide rigid fixation of the zero at all or with sufficient accuracy. Then everything depends on the material and the task: wood - maximum stroke frequency, tin - maximum or slightly lower, thick metal - medium or low, ceramics - low or minimum. If high-quality cutting of a massive (10–20 mm) workpiece or laminated board is necessary, as well as when working with ceramics or thick metal, set the pendulum stroke amplitude to zero. If you need to perform a not very important cut, set the pumping amplitude to maximum - this way things will go faster.

However, the adjustments help only partly; the nuances of the jigsaw design and, naturally, the skills of the craftsman are of great importance. For example, it is quite possible to improve the quality of the cut and avoid chips on the front surface if you move the jigsaw not from above, but from below the sheet. This is not so convenient, but it is possible to control the verticality of the saw. In addition, chips will be from the inside out. By the way, it is precisely this way of working that we owe the appearance of the mushroom-shaped handle: it is extremely difficult to act in this way with a “scrape-shaped” jigsaw.

Jigsaw device

Regardless of the manufacturer and cost, the jigsaw must be equipped with a pipe for removing chips, a support platform, a support roller for the saw, a quick-change system for the saw, a rod, a gearbox, a motor and a set of electronics that is responsible for the frequency of the saw’s stroke.

Safety precautions when working with jigsaws

- be sure to wear a respirator and safety glasses;

- clothing should fit close to the body to avoid the possibility of it getting caught in the working mechanism of the jigsaw;

- use a hat that will prevent the jigsaw from coming into contact with your hair;

- Never leave a working tool unattended, even if you only want to step away for a couple of seconds;

- use the jigsaw only for its intended purpose;

- do not slow down the saw with a clamp while the motor is running;

- If the file begins to bend , then it should be replaced immediately. If the replacement does not correct the situation, then you should take the jigsaw to a service center;

- both turning on and unplugging the tool from the outlet must be done only after turning off the engine.

Do not use a jigsaw when:

- the appearance of chips and cracks on the body;

- excessive noise or burning smell from the instrument;

- leakage of lubricant;

Design nuances

The most common jigsaws are designed as follows: the rod inside the gearbox is fixed in guides that provide some freedom of longitudinal movement, and is spring-loaded (tends to take a vertical position). If you pull it from the bottom of the barrel, it will tilt forward. The support roller fork is positioned as low as possible (as geometry allows). The roller gives the structure additional lateral rigidity due to the groove where the file is located. In the “pumping” mode, the fork acquires a reciprocating motion through a pusher and, acting through the roller on the blade, causes pendulum oscillations of the blade-rod system.

The advantage of this design is its simplicity (no adjustments are needed when switching from one saw to another). In the “pumping” mode, such jigsaws provide good cutting quality, since the support roller is pressed against the blade in the best possible way.

There are several disadvantages. First of all, the roller does not guarantee truly high transverse rigidity of the web. Both the fork and the roller are moving parts and therefore have transverse play (by the way, when purchasing a tool, be sure to pay attention to their size). The groove profile is fixed and may not be optimal for webs of different thicknesses and geometries. Finally, a round roller means that the lower point of fixation of the file is at some distance from the surface.

Improving the performance of such jigsaws is a solvable task. The roller and fork require the main attention. First, eliminate all their transverse play by selecting washers and bending the parts. An additional low-lying point for attaching the blade is obtained in two ways. The first is that the jigsaw is fixed on a table equipped with a guide fork (this is not always feasible, because often what is needed is not a machine, but a mobile tool). The second is to manufacture and install an anti-splinter liner that exactly matches the blade being used. It is clear that it is not able to resist wear for a long time - the liner quite quickly loses its ability to support the file in the transverse direction.

Another type of design is not so widespread and is represented on our market by jigsaws from Festool (Germany), Rebir (Latvia), “ Fiolent ” (Ukraine) and “ Diold ” (Russia, Smolensk). Their kinematics are generally similar to those described above, the only difference is in the method of transverse fixation of the canvas. The support roller here is installed in the usual place or on the rod and is responsible only for the longitudinal position of the file. Lateral rigidity is provided by a permanently fixed fork (for Festool and Diold - on the body, for the rest - on the sole). Of course, the Festool design is the leader in all respects: the fork is equipped with carbide tips, its width is precisely adjusted by tightening or loosening just one screw, and the attachment to the body allows you to tilt the sole without disrupting the adjustments. The Diold fork is formed by two steel pins, is not adjustable and needs lubrication. The remaining two tools are inconvenient due to the complexity of precise adjustment, which also gets lost and is required every time the sole is tilted. However, any of these jigsaws, with proper adjustment, can produce high quality cuts. It is possible to achieve this with instruments of the first group only through painstaking modification and preparation for the operation.

Standing apart, for example, are Kress - CST 6286 E and 650 SPS . The peculiarity of their mechanism is that two rod guide bushings are rigidly installed in a part suspended on an axis, the lower part of which serves as a support roller fork. Thus, the rod, blade and roller swing absolutely synchronously. At the same time, the file experiences less load than usual in the mode of “pumping” the blade, because in the other described designs it is the file that transmits vibrations to the rod (spring-loaded and rather inert). The disadvantage of the mechanism is that the relative position of the lock and the roller is fixed, and some webs will be less supported. The main advantage is strength and durability.

in talking in detail about jigsaws without a pendulum stroke - they are practically not on the market. In addition, even the highest quality models of such instruments often cannot claim the title of “Good Buy”. Let's focus on just one of the differences: in some cases, the support roller fork is attached to the body with the same screws as the sole. This is bad because the position of the roller will have to be adjusted every time the plate is adjusted.

What should you pay attention to?

To choose a high-quality and reliable jigsaw, it is important to carefully read the technical specifications and visually inspect each element. Tips on what to look for when purchasing:

- The power of the jigsaw ensures work with dense materials, quality and speed of the saw. For household tasks, 350-450 W is enough; for professional purposes, you should purchase more powerful models;

- The stroke rate affects how intensely the blade will move during sawing. This parameter ranges from 3000 to 3200. Can be adjusted by a smooth or discrete switch;

- The type of power supply ensures autonomy of the device. If you plan to often work outside the workshop, you should pay attention to models with a battery. For indoor sawing, a corded jigsaw is recommended;

- Fastening the file is possible using special bolts or a quick-clamping mechanism. Automatic installation simplifies the replacement of the blade when it is worn out or deformed.

All manufacturers of construction tools, for example, Interskol, produce jigsaws. They are conventionally divided into household and professional. They differ in electric motor power, additional options and functionality. The tool must be selected based on specific tasks.

A jigsaw is an indispensable tool for sawing metal, wood and plastic products. It can be used to make simple, curly and angled cuts. Consists of electrical and mechanical parts. When choosing a model, you need to pay attention to the technical characteristics, ergonomics of the case and additional functionality.

Anti-splinter liner

The best anti-splinter insert is one that exactly matches the thickness and position (depending on the inclination of the slab) of the saw blade. For jigsaws, Festool specially supplies blanks that allow you to produce the perfect version for each blade. The presence of such a detail completely eliminates chipping and for some time increases the resistance of the file to lateral slips.

| 1. Insert the workpiece into the guides |

| 2. Cut out the slot |

| 3. Ready liner |

| 4. Installation is possible at any angle of the file |

Replacing the rod

The procedure for removing a damaged rod and installing a new one is quite trivial and boils down to a banal disassembly of the tool. Depending on the design of the jigsaw, you can access the element by unscrewing the front panel or the side panel, if the first is missing. The faulty rod is removed and a new one is installed in its place. When installing, pay attention to the moving metal parts located on the base of the rod. They must be positioned in such a way that they fit into the grooves of the upper fastening and the metal frame that serves as the base of the rod. The assembled structure must be generously lubricated with a thick lubricant such as litol-24. A more visual demonstration of replacing the rod can be seen in the video below about repairing a fiolent jigsaw with your own hands.

Attaching the file

The key properties of the tool – accuracy and performance – depend on the features given above. Now let's talk about others that affect usability. During operation, you will most likely have to change the blades.

This is not due to their fragility, but to the need to perform different types of operations.

Let's start with a simple case - locks clamped with a key. The most optimal, but, alas, not the most common option is one screw on the side. In such a “chuck”, canvases of almost all thicknesses, and in some cases, types, are reliably fixed, and it’s also simple (there’s only one screw).

In most inexpensive models, the file is pressed by a block with a slot , tightened with two front-mounted screws. The compatibility of such a system is excellent, but with the rest it is worse: for example, unevenly clamped fasteners cause distortion. (Paradoxically, sometimes this turns into an advantage. For example, if the rod is bent or crooked “from birth,” a certain degree of freedom allows you to correct the situation.) For such locks, cases of wedging are not uncommon, when the blade cannot be removed “with a slight movement of the hand.” Impacts with the end of the saw on the workpiece, resulting from careless handling, sometimes lead to the front block breaking into two parts or the threads of the screws being torn off.

The most convenient jigsaws are those with a quick-release fastening system . There is a huge variety of implementation schemes. What distinguishes them from “key cartridges” is the lack of versatility (saw blades with a shank from only one company are suitable) and the presence of some play. In most cases, this is not significant, since there is no shortage of canvases. As for the play, it is usually longitudinal and does not affect the operation of the jigsaw in any way.

Quick-release locks have only one drawback - a limitation on the thickness of the clamped blades. However, if the purchased “consumable” does not “fit”, the situation can be easily corrected by “grinding” the shank with a suitable tool. Clamps similar to those from Festool are much less common. Their advantage is versatility (there are no restrictions on the thickness of the shank). On the other hand, they have lower fixation rigidity (at least with Festool).

For the “Simple power regulator” circuit

To eliminate the malfunction, you will need to rewind the electric motor or replace the faulty part - the stator or rotor. Button malfunction - if the tool motor is malfunctioning, it is possible that the cause of this is the switch. A jigsaw machine makes it much easier to work with shaped parts. It is also impossible to make the bending radius as small as when using a manual sample due to the peculiarities of fastening the file. The engine is started and stopped by the power tool switch, and when it is turned off, the device does not consume current and can remain connected to the network indefinitely. For each model of power tool, manufacturers indicate in the instructions the recommended types of lubricants for the gearbox. If a conductor breakdown is detected in the stator, it must be disconnected from the jigsaw body.

You can also reduce the movement of the file in a perpendicular direction to the movement vector. Moreover, in all types of structures, not only Dewalt and Holzstar, but also other manufacturers can provide sample rotations by degrees. There are a number of signs that you need to pay attention to: the case began to heat up too much during operation; when turning on and further operation, uncharacteristic sounds are heard; commutator brushes spark; the engine cannot be adjusted, other problems are observed.

The operation of the management node is described in detail in [I]. Different models have almost identical bushings. And files, in addition to length, can vary in width from 2 to 10 mm, type of shanks with or without pins, and thickness from 0.6 to 1.25 mm. The culprit was the quick-release fastening of the file. Previously, without such a device, working with manual samples was much more difficult. The homemade structure is attached to the workbench using clamps.

Jigsaw device, application, additional features

It may seem like you can do without it, but then you will have to constantly stop your work and brush away the sawdust by hand. Its width should not exceed 30 cm. The workpiece is mounted on the table, then, under the control of the master, the saw makes the cut. Basic malfunctions of the tool How to determine whether a jigsaw needs repair or preventive measures? Of course, the power of the jigsaw is an important criterion, but this is not the only thing you should pay attention to when purchasing.

Some experts make the hole after installing the frame. Previously, without such a device, working with manual samples was much more difficult.

Stop for 5-10 minutes every half hour. You will need to rewind the rotor winding or replace the part completely. Interturn short circuit - another cause of failure may be the presence of an interturn short circuit. Their mobility is often more expensive than the advanced functionality of this very machine. The optimal power, in our opinion, is in W. R7, C7, VD Design and maintenance of the Phiolent jigsaw, review

Methods for attaching a file

Jigsaw Festool | |

| 1. The lever that releases the file is located on the body, which allows you to replace the blade without removing the protective casing | |

| 2. Pull back the lever. At the same time, the lock opens and the rod moves forward | |

| 3. Insert the blade shank and release the lever | |

| 4. By rotating the adjusting screw, we adjust the blade fixation fork. You can act by monitoring the process visually, or you can tighten the screw to the end and then loosen it slightly | |

Jigsaw Kress |

| 1. Open the protective screen |

| 2. Turn the lever on the rod, insert the blade, release the lever and with a slight force move the blade into the clamp |

| 3. For such locks, the thickness of the installed blades is strictly limited by the size of the slot |

| 4. The thickness of the shank clamped with a caliper is 1.7 mm. It was not possible to install it, but another file (1.5 mm) was mounted without problems |

Jigsaw Protool | |

| The most common and convenient (if you forget about quick-clamping) type of lock is the Protool jigsaw. Remove the casing, loosen the screw, insert the blade and tighten the fasteners. You can use saws with a variety of shanks. | |

Files

Their correct choice is sometimes decisive. They differ in teeth (shape, pitch and setting) and material.

TEETH : to the greatest extent, the quality of the cut depends on the pitch of the teeth and their setting.

- For work that requires a particularly clean saw, without chipping the front surface, blades with reverse teeth are used (they “bite” into the workpiece during the downward stroke).

- Problems of the opposite nature - rough but fast sawing - are solved with the help of a "spreader" with large and widely spaced "cutters".

- Similar files, but without routing, are also productive and will be convenient for thick workpieces - they are less likely to move away from the vertical.

- Blades with variable tooth pitch allow you to combine cutting speed and quality. From above, closer to the front surface of the workpiece, the step is small, and downwards it becomes larger.

- When it comes to thin sheet materials, it is important to consider the following rule of thumb: the pitch of the teeth should be such that at least three are in mesh at the same time. Compliance with it is especially important in the case of metal workpieces.

MATERIAL : homogeneous canvases are well suited for most work, but in special cases non-uniform ones . The most popular of these are bimetallic. They are quite expensive because they are more difficult to manufacture, but they have a number of unique qualities. Their teeth, made of hard metal grades, are capable of cutting not only wood, but also steel, plastics and other materials of increased strength. It is interesting that the supporting strip of bimetallic sheets, on the contrary, is more pliable than usual. This reduces the likelihood of breaking the file (if necessary, it can even be bent, which is very useful in some situations).

For work on ceramics, glass and other similar materials, diamond-coated and carbide-tipped blades . Such files can easily cope with wall tiles, but especially durable types of floor tiles (as well as porcelain tiles) are too tough for them.

Sole

The next subject of description is the soles and their adjustments.

In inexpensive models, the plate is usually stamped from a thin sheet, so it is not too rigid. During the sawing process, when the support area is large, this may not be noticed. But at the very beginning of cutting, when only the front legs are involved, you experience certain inconveniences.

A truly good feel for the tool occurs when working with a jigsaw with a cast sole . The main material is aluminum, but it is a rather soft metal and, of course, is not used in its pure form. Added additives (Mr and Md) give the alloy hardness, but at the same time brittleness, so care must be taken during operation.

to adjust the tilt of the slab , as already mentioned. But this does not mean at all that the level of execution of the mechanism is secondary. If the fastening is done “anyhow”, the selected installation will be lost. In the vast majority of models, the plate is secured with screws. Two or one – it doesn’t matter; it is important that there are additional, precisely made latches in the zero position. Often they are provided for other positions (15, 30 and 45 degrees). In professional-class jigsaws, the plate is screwed to the metal gearbox housing, or less often to the plastic drive casing. The second option is worse (by the way, it is also typical for the vast majority of household models).

At any level of performance of the unit, regardless of the presence of “hard” clamps , before critical work it is necessary to control the position of the slab with a square or a protractor.

| ATTENTION! When the supporting sole is made of thin metal, and especially when its front part does not have a transverse bridge, difficulties arise when starting to cut: depending on the pressure, the jigsaw “plays”. |

The structure of the electrical part of a jigsaw

The electrical part of the jigsaw looks like this:

- Motor stator winding

- Copper winding terminals

- Rotary collector plates

- Rotor

- Brush holder with graphite brush

- Stator (electrical steel core).

As you can see, the tool uses a commutator electric motor, the main elements of which are: stator, rotor, carbon brushes. The stator is made of electrical steel and has a rectangular shape with grooves in which the stator windings are located. There are two stator windings - they are located opposite each other.

The motor rotor is a shaft (located inside the stator) with special grooves in which the so-called armature windings are located. From these windings come leads connected to the collector plates. The collector itself is pressed onto the end of the rotor shaft.

During operation of the electric motor, graphite spring-loaded brushes move along the commutator plates. Thanks to the latter, electrical voltage is supplied to the armature windings. By the way, when repairing any power tool, priority attention is paid to the condition of the brushes.

The last thing to consider about the jigsaw and its electrical part is the button and capacitor. The jigsaw button is a rather complex element in terms of functionality. With its help, voltage is supplied to the engine and the rotation speed of the armature shaft is regulated. The shaft rotation speed is adjusted using a rheostat built into the button. In other words, using the rheostatic button, the user can manually speed up or slow down the movement of the cutting file.

As for the capacitor. The main purpose of this element is to remove residual voltage from the windings after turning off the jigsaw. In addition, the capacitor smoothes out ripples that occur in the electrical network due to the operation of the tool.

We've sorted out the electrical part, let's move on to considering the mechanical component.

Electronics

Another common adjustment is stroke rates . This parameter is set with a wheel located on the body or handle.

Domestic jigsaws have triggers with a function for adjusting the speed . They are good because they allow you not only to set the upper limit (“twist” on the button), but also to approach it smoothly, changing the degree of pressure. The disadvantages of such models are unreliability (the buttons tend to break) and some inaccuracy in the operation of the upper limit limiter, especially at positions close to the minimum. Rare imported jigsaws allow you to adjust the maximum stroke frequency with a wheel on the body and smoothly achieve it by pressing the trigger. They are free from the above disadvantages.

Depending on the level of electronic filling, jigsaws react differently to changes in load. In inexpensive models, the first three to four speeds (out of six to eight possible) do not provide stable operation - the frequency of strokes of the rod strongly depends on the resistance of the material. The first and second positions are often not functional at all.

Instruments of the middle and high price level are much more stable and sometimes difficult to distinguish from models with “ constamatics ”. The latter refers to an electronic regulator equipped with feedback (a sensor that measures engine speed).

Top models sometimes have a starting current limiting system. It makes the start smooth, helping with fine operations and hindering in some other cases (for example, when you need to frequently turn on the tool to do rough work).

Examples of using a jigsaw |

| At the stage of finishing work and in preparation for it, a jigsaw is indispensable |

| To cope with the work shown in the photo, I had to remove the sole and install a slightly curved blade (bimetallic ones bend and do not break) |

| You can cut to any depth (it is not necessary for the blade to go right through the wood). However, it is worth mentioning that in this mode the tool wears out faster |

Types of faults

Prolonged or improper use of the tool can most likely cause it to break. A malfunction of the device occurs as a result of excessive contamination, wear of mechanism parts, or a short circuit of the electric motor. Repair of a jigsaw, depending on the nature of the breakdown, boils down to cleaning and lubricating the elements, or completely replacing them. Below, we will look at the most common types of breakdowns.

Mechanical problems

This category includes contamination, wear, or complete breakdown of mechanism parts.

The engine of the tool is running, but it is not possible to obtain the required cut. There may be several reasons for mechanical breakdowns that require repair of jigsaws. Here are the most typical ones. The jigsaw cuts crookedly

A significant deviation of the fork blade away from the intended line is often associated with the saw attachment mechanism or the rod. The reason for this may be severe contamination of the parts or their wear. To correct the situation, you need to remove the parts, clean them with a rag and put them back together. If the problem persists, the stem or fastener should be replaced.

Severe vibration and noise

Strange noises that are not typical for a running power tool usually come from a faulty gearbox. This may be due to lack of lubrication, contamination or breakage of the gear teeth. To find out the exact cause and its further elimination, it is necessary to remove the side part of the case and visually inspect the mechanism for the presence of the above problems. In case of breakdown, the mechanism should be replaced with a similar one.

The jigsaw hits when cutting

Regular jolts of the tool during operation may be associated with the pendulum mechanism or the rod. The reason for this is mainly damage to parts, and in rare cases, severe contamination. To repair a jigsaw with a similar malfunction, it should be disassembled, the faulty unit should be identified and replaced with a similar one. If there is no obvious damage, all parts should be completely cleaned and lubricated.

Engine malfunctions

Oddly enough, numerous jigsaw breakdowns occur not only on moving parts, elements interacting with each other. Very often, a device stops functioning (partially or completely) due to damaged electronics. To identify such faults, you need a special “multimeter” device that determines the characteristics of the current in the device circuit. It is necessary for a complete diagnosis, although some problems can be identified without it.

The jigsaw does not turn on.

The complete lack of vital activity of the tool is due to the lack of contact between the motor and the network. The reasons for this problem lie in the wiring or the start button. To identify a malfunction, it is necessary to completely inspect, or better yet, ring the instrument cable and internal wiring. The functionality of the button is checked by connecting the wiring directly to the motor. If the tool works when plugged into the network, then the problem lies there. The faulty contact must be replaced.

Doesn't cut under load

At first glance, the working tool is completely unable to cope with once simple tasks and slows down even on materials of small thickness. Significant loss of power is associated with engine damage. The jigsaw anchor, due to a short circuit, does not create a sufficient rotational impulse, creating the illusion of work. Typically, an instrument with such a breakdown sparks and emits a characteristic burning smell. To accurately determine the location of the short circuit, parts of the stator and rotor of the motor are alternately tested with a multimeter. The solution is to replace the damaged part or the entire motor.

Floating speeds and a burning smell

When, during operation, a tool periodically loses its strength, reducing its power and accompanying all this with a burning smell, it is worth paying attention to its wiring. To identify a weak contact, it is necessary to remove the housing cover and visually inspect all wires and their connections for defects. It is better to do this using a multimeter, paying attention to the start button and the motor windings. To restore the integrity of the circuit, the conductors should be replaced or the charred contacts should be cleaned.

Sparking brushes during operation

The abundant formation of sparks that occurs in the commutator area during operation of the tool can be associated not only with a malfunction of the engine, but also with a defect in the graphite brushes. In the modern world, this component is one of the most frequently replaced parts when repairing equipment, so many jigsaws have special grooves for quick and convenient removal. You can make the replacement yourself. It is enough to disconnect the old brushes from the contacts and connect new ones in their place.

Curvilinear cutting

For curved cutting, it is better to use narrow blades. In this case, the radius of the rounding is small, so our file is almost no different from the “standard” one. However, very narrow blades are “contraindicated” - they are less resistant to lateral slip

One way to start the cut is to drill a hole for the file. It is done on the cutting line or to the side of it When working on small radii, it is necessary to navigate by the position of the blade. Keep in mind: guidelines that help with straight cuts (“flies” on the liner or plate), will inevitably be led off courseSometimes you can do without drilling: we rest the tool with the edge of the sole so that the future cut does not intersect the marking lines, and turn on the jigsaw. Carefully tilt it until it touches the workpiece and then increase it angle until a through slot appears. Turn off the jigsaw, wait until the blade stops, remove it and set it to working position Smoothly rounding the cutting line, we reach the marking. Moving along it, we direct the tool, turning it around the axis of the canvas. No lateral forces are allowed; there is practically no need to push the jigsaw forwardSawing table

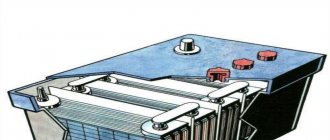

Making a saw table is not difficult. You can buy it for some jigsaws; Universal tables are also sold.

We attach the jigsaw to the underside of the tabletopWe attach the jigsaw to the underside of the tabletopInstalling the tabletop on the frameThe best way to mount a jigsaw is so that the base of the tool is flush with the surface, but below it.To control the tool we use the machine's push-button remote controlIt is more convenient to work on such a machine than with a jigsaw. In addition, the quality increases - it is possible to control the movement of the canvas, and the chips will not be on the front, and on the wrong sideGuide rail

It makes sense to equip a high-quality jigsaw that can cut smoothly with a guide bar. It is quite possible to make it yourself; for some models they are sold complete with a block for installing a jigsaw. Some companies offer universal kits for marking workpieces and sawing along a ruler using different tools.

Having marked the extreme positions, we apply markingsHaving installed the jigsaw in the block, and the last one on the tire, we combine the markings and the “front sight” of the tool at two points, positioning the tireHaving secured the guide, we get to work. Now everything depends on the accuracy of the jigsaw - if the blade moves at a significant angle, the cut will be ruined. However, when working with thin pieces of wood derivatives (plywood, chipboard, MDF 20–30 mm thick) this is unlikely.Additional functionality

Of course, you shouldn’t choose the simplest and cheapest model. The design of the tool is such that for high-quality performance of all work, it is necessary to have certain settings:

- If you work with different materials, then your tool should have a regulator to adjust the cut. After all, wood or metal must be processed not only at different speeds, but also at different angles.

- In order for the work to be as safe as possible, the tool must be equipped with a special plastic protection for the saw.

- For convenience and quality of work, the automatic chip blowing function is important. It may seem like you can do without it, but then you will have to constantly stop your work and brush away the sawdust by hand. This will harm not only the speed of work, but also its quality.

- Availability of regulators for important systems. Simple models do not have them, which is not required of an amateur instrument. But when choosing a high-quality jigsaw that can work with different materials, it is important to be able to adjust the working settings.

- The presence of lighting is no less important. As a rule, even in a well-lit room, shadows will interfere with work. The backlight on the jigsaw solves this problem and makes it possible to carry out work even in poorly lit rooms.

- The presence of a self-cleaning system, because the process of scooping out chips from the device is not the most favorite activity of craftsmen, and it is also not the safest.

When choosing a tool, it is important to pay attention to the presence of a system that allows you to work silently, removes vibration and sounds produced. This is necessary not only for your peace of mind and hearing, but also for quality work.

Rip fence

Almost all jigsaws have mounting holes for a rip fence bar. In some cases (for domestic and inexpensive imported instruments), such a stop is included as standard. Acceptable quality of work with this accessory is achievable only in rare cases and subject to the following requirements:

- the jigsaw must provide resistance to lateral movement of the file when working with this material;

- the supporting plane of the stop must be exactly parallel to the plane of the blade;

- the rigidity of the rod and shoe, as well as the tightness of its fit to the edge of the workpiece, should ensure a straight cut.

What it consists of: additional functions

Modern jigsaws are equipped with a number of additional options. They expand the range of possible work with the tool and simplify the sawing process. The most common functions are:

A high-quality model should have a protective plastic screen that holds sawdust and shavings in one place. In the instructions, additional functions are always listed as a separate item; when choosing a specific model, they are easy to miss - you should carefully inspect the tool itself and check the package contents with the seller.

Important ! Some professional models of jigsaws are equipped with a case for storage and transportation. When purchasing, pay attention to the quality of the latches; they should be made of dense plastic or metal and be pressed tightly against the body.

We saw tin

In order to saw off tin efficiently and easily, it is necessary to securely fasten the workpiece. We lay the sheet on the edge of the workbench or on a hard substrate - the cutting line should be at a minimum distance from the support. We press the workpiece with a block, placing it as close as possible to the saw line, but so that it does not interfere with the free movement of the tool. The mode of “pumping” the blade is zero or first stage, the file is special for metal. If the material is thick (from 2 mm), it would be a good idea to lubricate the area of the upcoming cut with machine oil. The frequency of strokes is lower, the thicker the material (ranging from the upper to medium level).

To improve the quality of the cut (that is, reduce the size of the burrs), we lay the tin between two sheets of hardboard or thin plywood. This method allows you to work at a large distance from the support line, which is necessary for curved cutting.