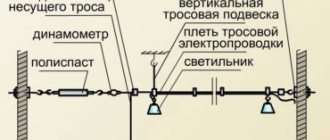

Why is this detail in construction?

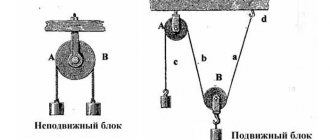

Typically, such devices are used where work is carried out under heavy loads, so only high-strength and high-quality metals are always used for the manufacture of clamps. Manufacturers produce these devices strictly in accordance with standards. The design of the clamps is very simple. They consist of two hex nuts and a steel bow. Professionals recommend installing at least three clamps on one cable; this is enough for safety and reliability of fastening. If the load is higher than the clamps you have chosen can withstand, then you should take a different type of this clamp rather than increase the number.

Only high-quality and high-strength steel is always used for production. This is necessary to ensure a reliable connection at both ends of the elements. For greater reliability and strength, the clamps are often additionally coated with another protective layer. For these purposes, galvanic galvanization is used. The advantage is that with its help the device is provided with maximum resistance to external environmental influences. It also provides excellent protection against corrosion.

Although the design of this device is simple, you still need to read the instructions before use. Any tool or device has its own nuances that must be taken into account in the work. If the steel cable clamp is not installed correctly, the element may simply break. The end of the cable is inserted into the arc and secured inside using a special lock, in this case hex nuts. The nuts are twisted in different directions, and the cable will be between them. When fully twisted, the ends should be tightly pressed together.

Presses for crimping slings

Rope ring slings are durable and easy to use. A VK rope branch with thimbles woven into it is a standard or galvanized piece of rope of a certain length, into the looped end elements of which drop-shaped, round or triangular metal mandrels with an external groove are woven. The design of branch slings also includes:. Home All news Braiding and crimping of rope slings - Behind the scenes. Braiding and crimping of rope slings - Behind the scenes Receive an individual offer.

According to GOST and RD, there are two methods for manufacturing slings from steel rope, which are structurally different from each other: Braiding of rope slings - manual braiding of the ends of the rope; Crimping of slings with a sleeve - sealing the ends by crimping a rope with an aluminum sleeve - tube.

In everyday life this method is called tuning.

Rope loop sling: advantages

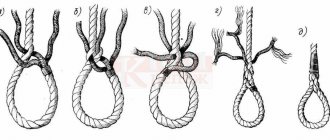

Braiding steel ropes Manually braiding a cable - we weave strands of the loose end of the steel rope between the strands of the unraveled rope.

Crimping of slings - Rope slings crimping method Crimping of slings with a bushing - crimping the ends of steel cables with an aluminum bushing with strands of connected ropes, which are interconnected by the metal of the bushing, forming a homogeneous body in cross-section.

An even cylindrical bushing and a uniform cross-section at the point where the steel sling is compressed means: reliability of sealing the ends of the rope, guarantee of the safety of the sling during loading and unloading operations, absence of burrs on the surface of the bushing - does not injure the slinger’s hands.

Steel cable clamp - classification

Clamps come in different types. They are divided according to purpose, material used and design. You can also formally designate different lengths; the most popular is a cable clamp of 3 mm, 5 mm in diameter, but in special cases sizes up to 40 mm are used. Each species also has different subspecies. Clamps, which are divided according to purpose, are ordinary and reinforced, and according to the material used - steel and copper; an aluminum cable clamp is also popular; a galvanized steel version is used in particularly harsh operating conditions. Clamps, which are divided by design, are flat, arc-shaped, single and double.

Regular clamps are the most common. Typically, they are made from galvanized steel of class 2. In appearance, such clamps resemble closed loops at the base, which have two strong bolts. This type of product is for household use and is not intended for heavy loads. The reinforced version speaks for itself, its design is more thoroughly worked out, the shutter mechanisms are reinforced, and therefore the scope of their application may be more responsible.

Flat types of clamps are often made of high-strength carbon steel. The surface of these devices is galvanized. Their diameter can range from 2 to 40 mm. In shape, such clamps resemble a pair of plates that are connected to each other with a bolt and nut. They are typically used for splicing steel cables or other standing rigging. They are also quite suitable for creating loops at the end of the brace. Professionals recommend installing at least two clamps on one connection.

Flat clamps can also be classified as single or double. The main difference is the number of bolts available. Single clamps are fastened with one bolt, and double clamps are fastened with two bolts. In terms of application, such clamps are not particularly different.

Arc-shaped clamps are made of a cylinder that is bent in an arc, and fastening occurs using two bolts that are located at the ends. Devices of this type are most often used for connecting metal cables, but it is quite possible to use them for making loops. This type of clamps is more industrial; they are designed for heavy loads. A typical standard arc clamp can withstand a load of about 97 kilograms.

Installing crimp lugs on stainless steel cableFast! Qualitatively! Not expensive! Install the lugs on the stainless steel cable

Since September 2010,

the Deel.ru online store has been performing work on installing stainless steel

cable ends on its own professional rolling machine A-3200 (PHU-1). The machine has a certificate from the LLOYD Register.

The following lugs are installed on the stainless steel cable: - All crimp lugs up to and including a 10 mm cable from the Rigging section. — Talrepov with cable ends 8275 8276 4066.

For break-in, a rigid stainless steel cable 1X19 DIN 3053 is recommended since it is usually used for standing rigging. After rolling, the surface of the tip is perfectly flat and smooth, without bumps, holes or wrinkles. The load capacity of the rolled tip at the crimping point is 95-99% of the cable itself. In fact, the tip will be integral with the cable. In addition to good load characteristics, the overall design has an excellent appearance. When performing work, the error in installing tips “to size” along the length is about 1 centimeter at 10 meters

.

Video with the process of installing tips. Filmed in our office and added to our website on April 14, 2011. Stupidly cut out pieces of this original video are sometimes found on other sites - apparently, your imagination doesn’t allow you to film them yourself. No one was given permission to use it.

| Prices for running in (crimping) cable ends purchased from us: Tip for a 3 mm cable - 100 rubles. Tip for cable 4 mm - 150 rub. Tip for cable 5 mm - 200 rub. Tip for cable 6 mm - 250 rub. Tip for cable 7 mm - 300 rub. Tip for cable 8 mm - 600 rub. Tip for cable 10 mm - 800 rub. 1. Prices are indicated for performing single crimps. When completing a complex order that requires the intervention of our specialist to calculate a drawing or for a large number of crimps in a batch, the cost can be increased or decreased by agreement with the manager. 2. Before starting work, a specification is signed with the client: “I agree, the tips, sizes and quantities are correct.” Without it, the work cannot be completed. |

To install lugs on a stainless steel cable, you just need to indicate this in the comments

when placing an order through the cart. It is assumed that you order both the lugs and cable from us, then the store manager will send you a final invoice including the installation labor.

How to send a request for ferrule crimping?

1. Example of ordering the installation of lugs on a stainless steel cable

2. Another example of a drawing for ordering the installation of tips.

3. Example of an order 2014-01-20 from an online store cart

———- Address for delivery ———- 152925 Rybinsk st. Voroshilova ******* ———- Comment on the order ———- install an ear on the cable (# 8378-4-05) (# 8281-4-05) ———- Products ———- DIN 3053 Rigid cable 1X19 A4 5MM Article: #8378-4-05 Price: 108 rub. Quantity: 7 Amount: 756 rub. ———————————————— 8281 Ear for crimping onto cable A4 5MM Article: #8281-4-05 Price: 127 rub. Quantity: 1 Amount: 127 rub. ———————————————— 8406 Collet clamp with A4 5MM thread Article: #8406-4-05 Price: 1236 rub. Quantity: 1 Amount: 1236 rub. ————————————————

4. Order example in PDF file

5. Example ordering with the text

Hello! The following is needed: Cables 1. Stay - 11 meters 75 centimeters (7mm rigid cable 1x19) 2. Top shrouds - 10 meters 77 centimeters (6mm rigid cable 1x19) 2 pcs. 3. Lower front shrouds - 5 meters 42 centimeters (6mm rigid cable 1x19) 2 pcs. 4. Lower rear shrouds 5 meters 54 centimeters (6mm rigid cable 1x19) 2 pcs. 5. Backstay - 10 meters (6mm rigid cable 1x19) Seal all cables with butt-type tips with a hole diameter of 12.5mm. Length of the cable from the centers of the tip.

6. Railing - 40 meters (5mm cable of medium hardness 7x7) without sealing the ends.

7. Shturtros-8 meters (7mm soft cable 7x19) without sealing the ends. 8. Cable for the keel lifting winch 7 meters (7mm soft cable 7x19) without sealing the ends. Can you write how much it will cost me? (preferably by item) Thank you in advance!!!

Specialized and wedge clamps - what are their features?

Many construction jobs cannot be done without a strong clamp. Construction has always been characterized by the presence of a large number of operations. You definitely need to lift something up, pull a load, and in this case it’s building materials; you often have to fix various objects. For such work you need strong spring-loaded clamps. Not only do they allow you to connect the cables, but you can also attach a load to them. Such devices are not very different from standard clamps.

In addition to the usual metal arc, they have a pair of levers that are equipped with movable brackets. This design solution helps ensure a highly durable and durable connection. With its help, you can securely fasten any object to a cable of different thickness. Lately, wedge clamps have become the most popular among specialists. This is an excellent connecting element for copper and aluminum wires, the cross-section of which can range from 35 to 100 square millimeters. Only this type of clamp is good for connecting steel-aluminum devices. Such devices consist of a body and a wedge, which is wear-resistant. Forged cast iron steel is used to make the body, and the wedge itself can be made of bronze or various aluminum alloys.

How to make cable clamps with your own hands?

Cable clamps are used in many industries. There is no industry where they would not find application. But often ordinary household work cannot be done without such a small device. Car owners especially need them. You will need a small diameter metal tube, a couple of metal plates and several bolts and nuts. The metal tube must be bent into an arc. The diameter of the pipe must be such that the cable that is planned to be used can fit into it. The cable must be inserted into the hole in the pipe until the end appears outside.

Then the end must be pulled out of the pipe to a distance of 10-15 cm, then the end of the cable and the cable itself will need to be covered with plates from below and above, and the plates must be tightly connected to each other using strong bolts. This device is well suited for making loops. If you need to connect two cables to each other, then you need to choose a tube with a larger diameter. It must be taken into account that two cables need to be inserted into one hole, but only in different directions. The plates are also selected taking into account the diameter of the cables. Such a clamp will always come in handy in household chores, just keep in mind that it is not suitable for heavy loads, but it is quite possible to try to use it as a tug.

Topic: About cables and guy wires

Backlinks

- Backlink URL

- More about backlinks

- Bookmarks & Share

- Submit a forum topic to Digg!

- Add a forum topic to del.icio.us

- Post to Technorati

- Post on VKontakte

- post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

Theme Options

Well, in general, in my case, we can consider that the tool is “standard.” Everything you listed is present. But I won’t show it, because last time I showed it, five people almost had a heart attack on the forum.

Last edited by RV3MI; 09.23.2018 at 16:57 .

- Share Share this post via

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

Digg

I’ll try to guess the result of breaking your images: – option with clamps. If the cable is not thicker than 6-7mm, the nut survives (it looks like the IO-20 type), the cable will not slip out of the clamps and break. – option with sleeves. In my opinion, this is an unsuccessful crimping option, since without mutual compression of the cables, you get a chain that can break the cable ( steel

) – sleeve

(aluminum

) – cable (

steel

). The friction of the cable on the nut can be ignored. Either the cable will be pulled out of the sleeve or it will be torn in half. About 300-500 kg for a break, I assume, will be enough. Curious to see your result. Good luck in the tests!

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

I came from the factory, where I took a few photos. DIN 3055 rope is the same one that is sold in all Hardware stores. Diameter 4 mm. Insulator IAO-3

Enjoy the photo

the test result is the SAME - with a force of one and a half tons

, the rope breaks.

ps by the way, at the production site where I was today, the guys are professionally engaged in the manufacture of all this lifting equipment. And the ropes there are different, there are even as thick as an arm and ALSO sealed with such a sleeve (though tens of times larger than mine in size). They use exactly the same sleeves as I showed in the photo a couple of messages ago. True, they press them a little differently - from the ends. And if you press “as it should”, then ONE such sleeve is enough - this is in their words.

Miniatures

- Share Share this post via

- Digg

- Del.icio.us

- Technorati

- Post on VKontakte

- Post on Facebook

- Post to MySpace

- Post on Twitter

- Post to LiveJournal

- Post to Google

- Post to Yahoo

- Post to Yandex.Bookmarks

- Post to Links@Mail.Ru

- Reddit!

Maybe it will be useful to someone, as in production we illegally make loops from the cable for tensioning the caterpillar belt of mining excavators - the force on the bucket is 80 tons and the rope is really 39 mm in diameter. We divide the beginning of the cable in half in threes or how many strands in the rope we divide in half, unwind to a certain length and then we make a kind of loop and braid the cable again along the way so that the strands lie evenly, in the end it looks like there are two ends, one is a continuation of the cable, and the second is the end of the cable, but already turned along the continuation of the rope. We do not use this tail We don’t connect it to the main cable, well, if only with an aluminum wire, so as not to interfere. There have never been any cases of this tail being pulled out, the cable actually breaks sometimes. But this already comes from the excavator driver’s ability to operate the machine.

Braiding steel ropes

- Manual cable braiding - we weave strands of the loose end of the steel rope between the strands of the unraveled rope.

Manufacturer of slings - Strop-Arsenal Company produces steel rope slings GOST 25573-82 using the braiding method in accordance with the requirements of GOST and RD 10-33-93:

- for the production of cargo rope slings we use only new steel ropes with a testing certificate from the manufacturer;

- the number of punctures of the rope by strands when braiding slings, as well as braiding ropes onto a thimble, corresponds to the guidelines of GOSGORTEKHNADZOR OF RUSSIA RD 10-33-93 and RD 10-231-98 - (clause 2.4.3)

- the braided section of the rope is tapped manually with a sledgehammer;

- correct braiding of the rope - no protruding ends of the wires

When making slings using the hand-braiding method, we protect the place of the weave so that the slinger does not injure his hands. Just as when braiding a cable onto a thimble, the Strop-Arsenal Company offers 2 ways to isolate the place where the strands are intertwined when braiding a steel cable:

- winding the braided section with soft wire (bandage) - soft steel wire (bandage), tapered, forms a smooth transition from the braided section to the working diameter of the rope.

- sealing the braided area with heat-shrinkable (heat-shrinkable) tube – the heat-shrinkable tube fits tightly around the braided area.

With both methods of sealing the braided area, the sling is easily removed from under the load and DOES NOT INJURY THE SLINGER’S HANDS WITH PROTECTING WIRES.

Method of crimping with an aluminum sleeve made of black rope USK1

The soft core of the rope is cut off in the first case directly at the clamp, in the second - near the thimble, and woven into the hard metal core into the rope with the first strand.

After this, splicing is carried out, the distribution of loose strands between the strands of the main rope and the braid itself are carried out.

According to GOST and RD, there are two methods for manufacturing slings from steel rope, which are structurally different from each other: When making slings using the hand-braiding method, we protect the place of the weave so that the slinger does not injure his hands. Crimping of slings with a bushing is crimping the ends of steel cables with an aluminum bushing with strands of connected ropes, which are interlocked with the metal of the bushing, forming a homogeneous body in cross-section. When producing rope slings using crimping, we use a Unisplice hydraulic press made in the UK as a method for sealing rope ends. Maximum press force tons.

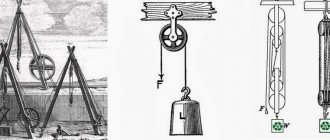

All mechanized devices are based on preliminary unwinding. In mechanized devices, two clamps are installed, one is secured with a loop, the other is the main rope, and rotation is imparted to one of the clamps.

The distance between the clamps is selected from 0.5 to 2.5 m depending on the diameter of the rope and its rigidity. Distribution of loose strands between the strands of the main rope A-E view from the side of the main rope; rice. In the first method of splicing from the gutter, the recess between adjacent strands of the rope passing through the central axis of the thimble, from the side of the loose strands, three strands are counted in the direction of laying, under which an awl is passed.

Crimping of rope slings - new opportunities.

After this, strand 4 is passed from the gutter A-B sequentially after strand 3 in the direction of lay into the gutter B-D and strand 5 into the gutter B-C. koush. Registration Remember?

We're getting the chapter, wait. GOST Cargo rope slings for construction.

Technical specifications with Amendments No. 1, 2. Designation of the technical and technical documentation to which reference is given. Item number, application.

We are pleased to announce that we now have the opportunity to offer you high-quality equipment for the production of cargo slings:. Design and design documentation Designed to expand the functionality of the stand for tensile testing of rope, chain and textile slings. The magnitude of the traction force load is monitored by means of a measuring device, a pressure gauge, in a vibration-resistant version, type DM93, accuracy class 2.5, having a Certificate of the State Standard of Russia on approval of the type of measuring instruments RU. The magnitude of the load created by the hydraulic cylinder is determined by the readings of the pressure gauge, see Sealing the ends of the rope with braiding in accordance with the requirements of the RD with changes.

Appendix 1. Appendix 2. Sling designation. Loading capacity, t. Designation of the rope branch. Permissible load, kN tf.

Sling crimping – Rope slings crimping method

Crimping of slings with a bushing - crimping the ends of steel cables with an aluminum bushing with strands of connected ropes, which are interlocked with the metal of the bushing, forming a homogeneous body in cross-section.

When producing rope slings using crimping, we use a Unisplice 600 hydraulic press made in the UK as a method for sealing rope ends. Maximum press force 600 tons.

The Strop-Arsenal company produces slings from steel rope using the rope crimping method in accordance with GOST 25573-82 and RD 10-33-93:

- For the production of cargo rope slings, we use only new metal ropes with a certificate from the rope manufacturer about their testing

- Aluminum bushings satisfy GOST 25573-82 and RD 10-33-93 - in shape - in design - by grade of aluminum alloys;

Crimping of rope slings

The tag is pressed into an aluminum tube

Sling crimping process

Ready crimping

Uniform crimping of the steel cable at the point of contact with its end over the entire cross-section of the sleeve.

The bushing turns out to be smooth and cylindrical, with no burrs (burrs) - protecting the slinger’s hands.

A smooth cylindrical bushing and a uniform cross-section at the point where the steel sling is compressed is:

- reliability of sealing rope ends

- guarantee of sling safety during loading and unloading operations

- absence of burrs on the surface of the bushing – does not injure the slinger’s hands.

| TAG on slings - braiding method To mark rope slings we use a round a metal tag 2-3 mm thick, which we weave into one strand of rope. It is securely fixed there. Such a tag does not cling to the lifted load and does not fly off when the sling is pulled out from under the load. | TAG on slings - crimping method To mark rope slings we use a round metal tag 2-3 mm thick Using a metal cable, we simultaneously press the tag together with the end of the steel rope into an aluminum sleeve. Thanks to this, the tag is securely fixed to the product. For the convenience of customers, when accepting products and issuing them for work, we indicate the following information on each tag:

You can select, order and purchase rope slings from the Strop-Arsenal Company in the section of the catalog of lifting slings: “ROPE SLANGS” Good to know:Have questions? Ask. We will respond within 15 minutes Strop-Arsenal LLC © 2015-2019. All rights reserved. Production and supply of lifting slings and removable lifting devices in Yekaterinburg, Tyumen and throughout Russia. Working hours: Mon-Fri: 09:00-18:00, Sat-Sun: Closed 620085, Ekaterinburg, st. Titova, 19, letter B, office 418 |

Crimping the cable with aluminum sleeves

Securing the ends of the rope in a crimp sleeve is the most technologically advanced and progressive. The diameter of the fixed ropes when using aluminum bushings is up to 90 mm. The main part of the connection is an oval bushing made of aluminum alloys ADO, AD1, AD31, AMC. The method of pressing in aluminum bushings is not recommended only if the product is used at extremely high temperatures affecting the embedding site (maximum permissible temperature 100◦C).

The end of the rope is passed through an oval sleeve, bent to form a loop and reinserted into the sleeve on the opposite side, after which the connection is crimped in a die so that the sleeve covers the gap formed by the strands. The reliability of this method of sealing depends on the quality of cleaning the rope at the junction, the correct installation of the workpiece in the die and the magnitude of the crimping force. Pressing of aluminum bushings is carried out on presses:

- 100 tons - for ropes with a diameter of 1.5-6 mm

- 300 tons - for ropes with a diameter of 7-16 mm

- 600 tons - for ropes with a diameter of 18-24 mm

- 1000 tons - for ropes with a diameter of 26-44 mm

- 2000 tons - for ropes with a diameter of 50-90 mm

In quasi-statistical tensile testing, slings crimped with an aluminum sleeve can withstand 85% to 100% of the breaking force of the steel rope used. In a tensile fatigue test they withstand - on average - about 60% of the number of tensile cycles of rope clamps. Operating temperatures for aluminum bushings on steel ropes according to GOST with organic cores range between -60ºС and +100ºС. Permissible operating temperatures for aluminum bushings on steel ropes with steel cores range from -60ºС to +150ºС.

When inspecting the bushing and hinge, you should ensure that the dimensions are within specifications. The end connections should then be inspected for any broken wires and any cracks or physical damage in the area around the bushing. During each inspection, it is also necessary to check whether the position of the rope lines at the crimping site has changed. When used in an aggressive external environment (sea water), the bushings are inspected for corrosion damage.