Ceiling height in garage

The convenience of using a garage depends on the size of its internal space.

The room should have enough space for servicing the car, placing various tools, mechanisms and spare parts. Correctly calculated ceiling height in the garage is necessary for the safe operation of the car. SNiP states that the ceiling height in the garage must be at least 2000 mm and does not limit the choice of a higher value. The lower limit may well satisfy any owner of a passenger car whose average height is 1540 mm. But you won’t be able to feel comfortable in such a room.

A garage is not only a place to park a car. It is repaired and serviced here. In garages built into residential buildings, cargo transported in the vehicle is constantly loaded and unloaded. In this case, the trunk must open completely and not touch either the ceiling or the elements of the automatic gate.

When choosing the ceiling height in the garage, it is necessary to take into account the factor of the future. Let's assume that today you are the owner of a car and a sectional garage door. After some time, your financial situation has improved and a decision will be made to replace the passenger car with an SUV, and for ease of entry and exit, it is necessary to replace the sectional gates with automatic ones. The height of the jeep and the space for mounting elements of the new type of door will require sufficient ceiling height in the garage. In order not to spend money on restructuring, it is better to foresee the likely development of events in advance.

Car lifts for service stations and garages

Most often, an American manufacturer is chosen to equip service stations, while good Chinese lifts may be suitable for a personal garage. Due to their safety and reliability, such devices have performed well.

To facilitate repair work, the following devices can be used:

- Four-post lifts. Suitable for major car repairs or wheel alignment work. Used to perform maintenance on cars and trucks. Such devices have one motor and one control panel. Thanks to the cables, the level of lifting of the racks is adjusted, so this design is considered universal.

- A scissor car lift is used at wheel alignment stations or tire shops, since the device is mobile and has a hydraulic drive. A scissor garage lift is useful when performing car body repairs.

- Plunger lifts have a simple design and do not take up much space in the garage since they are mounted into the floor. They are reliable and durable, which distinguishes them from other designs. The cost of such a device is high, so their use has not yet gained much popularity.

The lifting and lowering speed is about one to two minutes. The height of the electromechanical lift is about 2 meters, but can be up to 3.5 meters.

Calculation of garage ceiling height for cars and jeeps

The height is determined by the distance between the floor level and the actual ceiling. When building a garage, the level is considered to be a completely finished version of the floor, with a finishing coating applied to it in the form of a cement-concrete screed or laid on top of decorative tiles.

This calculation is advisory in nature. If desired, the ceiling level can be raised even higher for maximum comfort in using the car in the garage.

The optimal ceiling height in the garage is calculated taking into account the following data:

- Vehicle height

- Distance for safe trunk opening, 500 mm

- Space under the ceiling for placing elements of automatic gates and lighting, 300 mm

- Free headroom, 200 mm

The average passenger car has a height of 1500 mm, and a jeep – 2000 mm.

By adding all the indicators, we get the optimal values for the ceiling height in the garage:

- For a passenger car – 2500 mm

- For a jeep – 3000 mm

Naturally, the ceiling height can be adjusted taking into account the actual height of the car. For example, the ceiling height in a Jeep garage can vary significantly depending on the make and model of the car. The range of height ratings for jeeps, unlike passenger cars, is very large, from 1700 mm to 2500 mm.

Installing a post lift - where to start?

The main task that awaits the owner even before the actual purchase is to determine the optimal location. It is determined based on several factors - the dimensions of the mechanism itself, the required working area (depending on the specifics of the enterprise - for example, more space will be required for trucks and less for cars), as well as the area of the building itself and the availability of free space, not cluttered with anything else. , places.

At the same time, it is important to remember the safety rules, which are specified in detail in the addendum to the technical documentation of the product. For example, installation is allowed only on a flat, stable area, at a distance of at least one meter from walls and other objects

It is not recommended to install the lift under open areas without a canopy, since atmospheric and climatic phenomena can negatively affect its operation.

Thus, the width of the platform on which it is planned to install the lift should be approximately equal to the sum of the distance between its racks and the minimum permissible distance to the wall/walls. The length depends solely on the cars that are planned to be worked with at this enterprise. The standard option – 8-10 meters – is optimal for any passenger cars and many trucks; however, there are no average values in this matter - each decision is unique and depends on certain circumstances.

Lift in the garage

Today, many car enthusiasts give preference to the inspection pit in favor of lifts. There are many advantages of this choice. No need to huddle in a small and often damp recess in the garage floor. The lift provides an excellent overview of all the mechanisms located below the car. Repair and replacement of parts is greatly simplified. When using a lift, especially an overpass type, it becomes possible to place cars in two tiers.

The height of the ceiling with a lift in the garage is calculated without taking into account the raised trunk, but with the introduction of the maximum height of the car with the lift into the formula.

The maximum lifting capacity of a car with a lift is 1900 mm.

You will definitely have to take into account the type of lift. If it is of an overpass type, then the total height of the car is added to the formula. When using a lift with retractable arms, the height between the floor level and the bottom of the car is subtracted, which is approximately 300 mm.

The ceiling height in a garage with a lift is obtained by adding and subtracting the values and is:

- Overpass lift:

- Passenger car – 3900 mm

- SUV – 4400 mm

- Lift with retractable arms:

- Passenger car – 3600 mm

- SUV – 4100 mm

The actual height of the garage ceiling can be calculated by substituting the vehicle's height data into the calculation formula.

Ceiling heights in economy garages

The sectional version of garage doors is the most common. The risk of failure or damage to expensive mechanisms and decorative elements of automatic gates is reduced.

The ceiling height in the garage for sectional doors can be significantly lower, since there is no need to reserve 300 mm under the ceiling for automation mechanisms. From the formulas for calculating the ceiling height of garages, both with and without a lift, it is necessary to subtract these values.

If the economy regime is the most stringent and you have to save on building materials, then the minimum ceiling height in the garage should not be less than 2000 mm.

According to reviews of most car owners, it is still better to add 200 - 300 mm. The resulting standard garage ceiling height of 2200 – 2300 mm will ensure a comfortable location and convenient maintenance of the car.

Increasing the internal space of the garage due to the high ceiling has a beneficial effect on the comfort and ease of use of the technical room for storing a personal car.

Features of the selection and installation of a lift

The choice of a lift for an auto repair shop, garage, or workshop is influenced by the following factors:

- serviced vehicle fleet (types of vehicles, their dimensions, weight);

- types of work that are planned to be performed in this work area;

- available workspace (room area, ceiling height, etc.);

- equipped with energy sources.

Depending on the weight parameters, the lifting capacity of the equipment is selected. Various types of repairs require convenient access to certain machine components, which not every lifting device design can provide. The dimensions of the room, passages, and entrances affect the type and size of the lift, and the presence of electrical and pneumatic networks affects the choice of drive. Many types of lifting devices can be used for both cars and trucks if capacity permits, but much of the equipment is designed with a specific class of vehicle in mind.

The choice of a two-post lift with a mechanical or hydraulic drive has become typical and most popular for a car service center and a small car repair enterprise focusing on passenger cars.

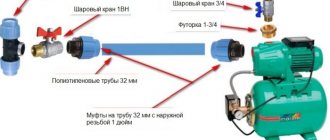

A living example is the well-known model WDK-523/524 from Wiederkraft with a lifting capacity of 4-5 tons in the photo above with a water delivery machine.

The supports for the lifted vehicle in such a device are retractable rotary brackets (legs), placed in pairs on carriages that synchronously move along the guides of two vertical columns (racks). The movement of the carriages is carried out using electromechanical (electric motor plus screw pair) or electrohydraulic (electric motor - pump - hydraulic cylinders) mechanisms.

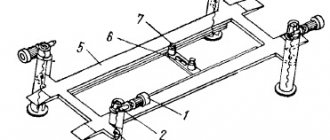

The synchronization of their lifting is usually ensured with the help of rollers and a cable passed through a crossbar connecting the beams from above or below (upper or lower synchronization).

When installing a two-post lift yourself, special attention should be paid to preparing the base. The supporting platforms of the load-bearing racks are attached to the floor using anchor bolts buried in concrete

The relatively small support area and significant longitudinal and lateral loads perceived by the racks are transferred to the base material and bolts. This explains the need for a thick (15-20 cm) layer of durable reinforced concrete.

But even reliable fastening of the racks does not exclude their elastic deformation and deviation from the vertical under load. Therefore, when installing and aligning using levels, they often deliberately create a slight “camber” of the racks relative to each other. The scheme with top synchronization has significantly greater rigidity due to the presence of a traverse connecting the free ends of the racks.

When assembling the lift, you must follow the manufacturer's instructions, the requirements of the drawings, and other technical documentation. This guarantees its reliability and safety. The second important condition for the effective use of stationary equipment is its optimal placement. It is necessary to plan the work area and the space around it in advance. The layout of the lift should provide the best access to the machine components and ease of dismantling and repair. In addition, you need to think about the entry and exit of the car, if necessary, add ramps to pass through the floor elements of the structure or recess the protruding parts to the floor level. And don't forget about the height of the ceiling. Neither the roof of the body nor its parts (hood, trunk door, trunk lid, etc.) should rest against it.

The assembly of the hydraulic system requires special attention. It is necessary to prevent not only dirt, but also dust from getting on the connecting fittings, sealing rings, and cuffs. It is advisable to hire an experienced specialist to install the hydraulic drive. The installation and connection of electrical equipment will also require the participation of a qualified electrician.

Installing a lift in the garage with your own hands

If you want to create a real mini-car repair shop out of an ordinary garage space, you need to install a lift in the garage, in this case you can carry out almost any repair of a passenger car. Installation of the equipment can be done with your own hands, but first choose the lift wisely, because the rush to purchase will turn the equipment into a set of parts.

Homemade lift

At large and medium-sized service stations, lifts are not uncommon. But there are still craftsmen who work in garages, and a small business does not allow the purchase of serious equipment. In this case, you can make a car lift with your own hands. It will be no worse in efficiency and reliability than branded designs. But to manufacture such a system, you must have skills in working with metal and be able to use a welding machine.

Assembling a homemade lift is a very difficult job, requiring the creation of drawings and manufacturing diagrams with different types of drive. As a compromise solution, you can consider purchasing previously used equipment. The cost of such lifts is much lower, while you significantly save time on their installation.

Differences between lift drives

According to the type of drive, the equipment is:

In turn, the types of lifts are graded into:

Electromechanical equipment according to the type of lifting supports is divided into:

- One-two-three-post,

- Multi-post,

- Scissor.

Based on the number of plungers, hydraulic technology can be:

- Single plunger,

- Two-three-plunger,

- Multi-plunger.

For optimal selection and installation of equipment, differences in drives must be taken into account.

Inexpensive lifts include electromechanical equipment, which is characterized by its simple design and ease of maintenance and operation. Among the features of electromechanical technology we highlight:

- Lack of stoppers included

- The need to regularly lubricate working parts,

- The presence of a transmission shaft significantly increases the safety of equipment.

If you want the equipment to operate smoothly and silently, then choose the option with an electro-hydraulic drive. A small overpayment will pay for itself during the operation of the equipment, and the installation of the equipment is practically no different from the installation of other types of equipment. Also, when choosing an electro-hydraulic drive, the speed of work increases, which in some cases is of value to the garage owner.

Note! If your choice falls on a twin-engine garage lift, then choose equipment with a high-quality synchronization program. If the engines are of the highest class, but the software is not very good, then the operation of the equipment will become not only ineffective, but also unsafe!

Difficulties in making a lift

The cost of a finished car lift is high, but a self-made version can damage a person working under it if the design is unreliable. The weight of the car should not exceed more than a ton; if the structure falls on a person, irreversible injuries can occur.

A homemade car lift is made according to prepared drawings, or versions of finished products are used. In the latter case, one has to rely on the author's high computational skills. Incorrect calculation of the base or one of the fastened units can lead to irreversible consequences, at best, damage to the lifted unit.

For a homemade kit, made with your own hands, you will need parts and components, without which assembly is impossible. You can find this type of component in large stores that sell construction equipment. If there are not enough funds for new parts, you need to go to scrap metal collection points and enterprises that write off old parts.

Tips for choosing a garage lift

For an ordinary garage, the best option is to install a one- or two-post electromechanical lift, since such a unit is reliable and has a load capacity sufficient for repairing a passenger car. In addition, this type of equipment is compact (small room height is suitable and there are fewer requirements for the size of the garage box) and does not require special knowledge for maintenance. The small size of this equipment allows it to be installed even in small rooms with a ceiling height of 2 meters.

A higher-class lift is rarely used for private needs; its place is in a car repair shop, not in a garage.

Also be sure to take the height of the room into account. The small height of the garage for a lift simply technically does not allow the installation of powerful equipment, and it is not necessary for a private owner.

When choosing a lift, pay attention to:

- Load capacity,

- Load lifting speed,

- Design features (size, weight and configuration).

Don't want to make a fatal mistake and purchase low-level equipment? Do not trust unknown manufacturers - we advise you to choose NORDBERG and Trommelberg brands.

Recommendations for preparing the base for installing a two-post lift TZ

If you want to create a real mini-car repair shop out of an ordinary garage space, you need to install a lift in the garage, in this case you can carry out almost any repair of a passenger car. Installation of the equipment can be done with your own hands, but first choose the lift wisely, because the rush to purchase will turn the equipment into a set of parts.

For any room - a convenient car lift

You've found a good place for a car service center, found several business partners and are ready to get started. There’s just one problem - it’s impossible to make an inspection hole in the room where your car service center will be located. It’s not scary, because for such cases there are car lifts for car service centers.

All other tools and equipment are acquired over time, but you can’t start a business without a car lift. It is with its help that all preliminary inspections and further repairs of the car are carried out. Today there are many offers of similar devices on the market with different characteristics and prices, and on the Internet you will find many photos and descriptions.

You can choose to purchase a lift that can only be installed by the manufacturer’s service technicians, or look for an option where the device also comes with detailed instructions for do-it-yourself installation, with photos and directions - in this case you can save a lot of money.

Which foundation to choose?

It is important to remember that all these measurements will be useless if you do not first take care of the foundation strength necessary for this very installation. The primary requirements for it are, of course, external integrity, density, the absence of any irregularities or differences, etc.

It is recommended to take this issue as seriously as possible - after all, even if installing a lift on a crooked or cracked foundation is successful, there is no guarantee that everything will not go awry when lifting the first load. So negligence and neglect are almost guaranteed to lead not to additional savings, but, on the contrary, to even greater expenses:

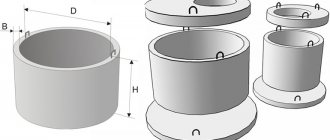

- it is not difficult to avoid this. So, for example, when installing a two-post lift with lower synchronization (in particular, installing a T4 and T4B lift), the optimal foundation thickness is approximately 15-20 cm (or more for working with the largest equipment). The required density is provided by concrete solution M300 and higher;

More on the topic: Characteristics of a platform lift

Foundation for the lift

- however, for devices with top synchronization (S4D, S4D-2), as well as lifts consisting of several individual racks, these measures will be insufficient. In particular, the minimum thickness of the foundation for such mechanisms should be at least 30-35 cm, and the minimum acceptable grade of concrete should be M400. Also, in some cases, it is recommended to additionally strengthen the foundation using metal mounting beams and other reinforcing elements, the required list of which is indicated in the appendix to the technical documentation.

It is prohibited to install lifts (as well as other massive structures) on a recently poured foundation. The optimal time required for compaction and hardening of concrete is about 30 days.

To further strengthen and seal microscopic (and other) holes on its surfaces, polymer and paint coatings, silicone, rubber and ceramic tiles are used, which also contribute to less friction and abrasive wear of the floor.

We recommend to buy

The nuances of installing a lift in the garage

Even the correct choice of a garage lift does not guarantee optimal operation of the equipment, since the equipment requires high-quality installation. First of all, the garage must have a solid foundation.

The area for lifting equipment must have a concrete thickness of 10 cm, plus during concreting, additional reinforcement of the concrete base is carried out. Without reinforcement, the lift will push through the foundation and the equipment will have to be dismantled before refilling the concrete, taking into account the recommendations.

If you are just buying a garage, then immediately check with the seller for information about the thickness of the screed and foundation. The golden rule is that the dimensions of the room and the dimensions of the equipment must be compatible!

From this data, the size, type of drive, height and features of the lifting equipment are selected. If the requirements for the foundation are ignored, you will damage the foundation, disable the equipment and may be injured when working with the lift.

Remember - a garage and complex equipment for auto repair require an appropriate approach; if you do not understand the types of equipment and do not know how to install it correctly, then it is better to spend money on a specialist.

When installing, also consider:

- Minimum paw lowering height,

- Dimensions of equipment and premises.

The lower point of lowering the paws is different for different manufacturers and is in the range of 95-110 mm. At the bottom point, the base should be smooth and strong (read about reinforcement above).

The height of the garage ceiling for the lift should be such that the car can rise to the desired height, while the lift should not freeze halfway through the rise due to the low ceiling in the garage.

If there is a basement in the garage, then it is better to make lower supports in it, which are installed between the base of the basement and the top slab and concreted. This reduces the load on the floor slabs and reduces vibration when equipment operates under the weight of the vehicle.

It is advisable to install the lift on M18 studs with a length of 30 cm. A metal plate with a metal thickness of 3-5 mm is also fixed at the bottom. This option is suitable for a small to medium sized and weight lift. In auto repair shops, in any case, a reinforced foundation is required and the equipment is not installed above the basement, since the floor slabs may not support the weight of the truck even with additional supports.

Post lift

Here the main load is on the vertical stand. The lower part, which provides stability to the system, is usually mounted using anchor bolts into the concrete subfloor. On the side of this structure there is a lifting mechanism - it can be of an electromechanical or electrohydraulic type. You can also see the fastenings on the side. Rack-mounted units can also be produced in a mobile version.

Based on the number of racks, these units are divided into single-post, two- and four-post structures. Let's look at the features of each of them.

The best place to place a lift

Before installing a car lift, you need to correctly select the installation location. The equipment must be installed on a concrete surface, the thickness of which is in the range of 25-40 centimeters.

The surface on which the equipment is mounted must not be uneven. This does not apply to lifts with a frame base, which are installed even on uneven floors.

In addition, when choosing a place, keep in mind that when servicing and repairing a machine on a car lift, it should not touch the ceiling surface when fully raised.

When choosing equipment for a garage space, you must consider the following characteristics:

- Maximum permissible weight. A lift designed for a passenger car will not be able to lift a minibus.

- Vehicle lifting speed.

- Dimensions, weight, configuration. Here, take into account the parameters of the garage space.

Lift prices

How and with what to polish car headlights with your own hands in the garage.

The prices of lifts are influenced by the materials, the permitted weight of the structure, and the manufacturer’s brand. We recommend official representative offices that have warehouses of spare parts and consumables for maintenance. When choosing, it is necessary to take into account the distance between the racks, the lifting height, the clearance between the floor and the feet, and the requirements for the floor covering.

For repairs, the structure can be rented from auto mechanic workshops. The cost of renting equipment is affected by the service life, type of lift (hydraulic or mechanical), etc.

A mid-price car lift will cost 80,000-150,000 rubles. The two-post hydraulic lift S4D-2 AE&T costs more than 130,000 rubles. Designs of two-post lifts of 5 tons are represented by models costing about 170,000 rubles. It is necessary to take into account the cost of delivery of large-sized goods and installation services. Average delivery prices from the warehouse are about 3,000 rubles, for installation services - 8,000-14,000 rubles.

Optimal dimensions and height

Not every garage will be able to install a car lift. For example, if you are the owner of a minibus, which almost touches the ceiling when entering the garage, there is no question of any single/two-post lift. The garage space must have appropriate dimensions.

Next, you can familiarize yourself with the minimum garage dimensions required for a certain type of car. Add to the height of the garage the value of the height to which you plan to raise the car. This way you will determine what minimum height the garage ceiling must have to install a car lift.

For passenger cars

The length of the garage should be three meters greater than the length of the car, and the width should be the same. The optimal height is three meters.

For jeep

The length, width, and height of the garage space for a jeep or other SUV should be eight, five, three meters, respectively.

For minibus

If you own a minibus, the garage should be large. The optimal length is seven and a half meters, width is five meters. The minimum garage height for a minibus is three and a half meters.

If you have a Gazelle cargo truck with an extended platform, the length of the garage space should be ten meters. The minimum height here increases to four meters.

Garage Door Height Principles

The height of the garage door is a very important aspect, because it directly determines which vehicle can easily enter the room. The best option is when the height of the garage and the structure correspond to each other, that is, if they are the same.

The type of garage door plays a significant role. For example, if they are hinged, then large parameters can make work difficult as a result of the impressive weight of the sashes.

Today there are no specific standards for the height of garage doors; it all depends on individual preferences. If you are planning to order a finished design, then you should know that most manufacturers specify the main dimensions of their products.

Mostly people prefer a width of 2-5 and a height of 2-3 meters. If the dimensions of the future structure are planned to be non-standard, then be prepared for the need to make it to order.

Step-by-step installation of a lift with your own hands

Having chosen the right car lift, you do not get a guarantee that it will work properly. For comfortable operation, the device must be installed. The main condition for successful installation is the high reliability of the garage foundation.

Installation of a solid base

The area of the garage in which the car lift will be installed using fastenings must have a thickness of concrete material of at least ten centimeters. In addition, when pouring concrete, the layer of material is additionally reinforced. Without reinforcement, the foundation may be pushed through. In such a situation, it will be necessary to dismantle the car lift and re-fill the foundation.

Calculation of the minimum height of paw lowering

When installing the lift, you need to determine the minimum height for lowering the legs. The plane below should be level. The minimum height to which the arms of the equipment can be lowered depends on the specific model of the device.

However, there is a standard: the maximum height is 11 centimeters, the minimum is 9.5.

Assembly of the structure

The equipment must be positioned according to the length of the machine. On average, the bumper of all cars protrudes about two meters from the center of the lift holders.

At the next stage of installing the car lift, it is necessary to install its frame and fix it. Next, the solution is poured. Before pouring, you need to check whether the frame is symmetrical. After the solution has hardened, you need to tighten the bolted connections. This will allow the frame to be securely fastened.

The bolts are installed in the grooves of the risers. The minimum length of bolts is 22 centimeters. After tightening the bolts, tighten the nuts. Attaching the stands to the frame is carried out in accordance with the instructions supplied with the equipment.

Preliminary height adjustment is necessary for screw car lifts. If the lift operates hydraulically, the cable must be pulled. Then all the chains are installed, and the quality of tightening of bolted connections on the frame floors is checked.

If, when tightening bolted connections, the frame is displaced and the symmetry of the racks is disturbed, metal plates are placed under them. Metal plates are usually supplied with the car lift.

Electrical connection

After assembling the structure, electrical cables are connected and emergency switches are installed. To do this, it is advisable to call an experienced electrician who will carry out the procedures according to the wiring diagram. If you know how to build electrical circuits, you can do it all yourself. Whether the lift drives will work properly depends on how correctly the electrics are connected.

How to make a reliable car lift with your own hands

It is not easy to make a car lift from a jack yourself, and therefore you need to read the instructions in advance.

Calculation of dimensions and creation of a drawing

First you need to decide on the size of the equipment for working with cars.

The choice of car lift dimensions depends on the size of the garage in which it will be used. The average height of the device is three and a half meters, and the width is three meters. Equipment with such dimensions is capable of lifting a vehicle whose weight reaches 3-4 tons.

Required Components and Tools

Having decided on the dimensions of the car lift, you can begin to prepare the necessary tools and materials. To work you will need:

- welding machine for joining iron components;

- drill;

- drill;

- tape measure for measuring the dimensions of device parts.

The materials from which the device is made include:

- bedding corners eight centimeters wide;

- iron plates, the thickness of which should be 1-2 centimeters;

- worm gearbox.

Assembly instructions

At the initial stage of creating a lift, steel corners are installed in the walls of the garage pit. After this, a metal plate is installed on their shelves and attached to the surface. The gearbox is installed on top, after which a key is fixed on the drive shaft.

After installing the gearbox, holes are made on the surface of the plate through which the chain will pass. When the chain is installed, a sprocket is put on the shaft. To install the second chain, the same holes are made on the opposite side of the plate.

Selecting a lift, calculating dimensions and loads

First, choose the type and load capacity of the equipment, then a specific model. For a typical garage, one- or two-post electromechanical lifts are suitable. They are compact, reliable and have a load capacity sufficient to service passenger cars. The maximum dimensions of the equipment being serviced are added to the dimensions of the model. The distance between the lift and walls and other installed equipment must be at least 1 meter. By adding up all the parameters, the width, depth and height of the area are calculated. The minimum values for passenger cars are 4*5*2.3 meters. After determining the size of the area for installation, the maximum load on the foundation is calculated. To do this, the estimated mass of the machine is added to the total mass of the equipment and divided by the area of the site. The result is multiplied by a reserve factor of 1.2. The resulting load value is used to determine the type and thickness of the foundation.

Ceiling height

For some types of lifts with upper posts, the height of the ceilings in the room is critical. In addition, when calculating the dimensions, you need to take into account the position of the machine on the platform. It may hit the ceiling when rising if the height was calculated using average values. As a last resort, they arrange a mechanic’s pit.

Layout diagram

Typically, four-post lifts are placed next to the side walls, diagonally, at an angle of approximately 75 degrees, parallel to each other for easy entry and exit. Two-post models are installed in the center, when necessary, arranged in rows. In small rooms for scissor lifts, niches are sometimes installed in the floor and lowered into these recesses when they are not needed, closing from above. The best option is to place the devices at a sufficient distance from washing and painting areas, paint booths. If the service does not have enough space, equipment for heavy trucks is installed in open areas.

Foundation structure

A concrete foundation with potholes and unevenness that does not correspond to the design load will cause uneven distribution of weight between the racks, skewing and falling of the car. Typically, installation instructions for a lift include minimum requirements for the base. If the concrete does not correspond to them, the screed is removed and a new foundation is poured. The standard requirements are minimum thickness - from 25 cm, concrete grade - from M300, reinforcement is required. For two-post models (lower synchronization) these parameters are 30 cm, M400. Ditch equipment requires the installation of an internal bowl in which the lift will move. In this case, first fill the lower formwork of the base, and then the sidewalls. All work is carried out in one day to avoid cold seams. Installation of equipment begins after the concrete has completely set - 28 days after pouring. If the cars are heavy, extended beams are placed under the lower pillars to strengthen the base and distribute the load evenly.

Floor construction

To make work and cleaning easier, concrete floors are poured with topping. Another coating option is technical porcelain stoneware. Its advantages are strength, easy removal of contaminants, and frost resistance.

How to install a lift yourself?

Before assembly, electricity and (if needed) a pneumatic drive must be supplied. As a rule, the delivery package includes instructions for installing the lift yourself, in accordance with which the installation of the equipment is carried out. According to general rules, assembly takes place in several stages: Marking. The contours of the location of the base and holes are marked on the floor. Drilling for anchors. The depth of the mounting holes should be 4-5 cm less than the thickness of the foundation. After drilling, concrete chips are blown off the surfaces with a pneumatic gun.

Installation of anchors

The anchor bolts are threaded through the holes in the base and the drilled cavities, and then driven in with a hammer. All nuts are tightened using a torque wrench. The work is carried out by checking the level of horizontal and vertical planes. When the installation of the lift with your own hands is completed, it is connected to communications and checked. First, the empty platform is lowered and raised. If the equipment operates smoothly, without extraneous noise or failures, it is tested with variable loads. After successful tests, work with the machines begins. Did you do everything according to the instructions? The installed lift will last for many years. On our website you can select any necessary equipment. If you have any questions about installing a lift yourself, we provide car lift installation services. Contact us, we value every customer.

source

Garage dimensions for comfortable work with lifts

The specific dimensions of the garage space should also be taken into account. When you calculate garage height for a lift, you don't have to take the raised trunk into account.

In this case, the maximum lifting height of the machine with this device is of great importance. Typically this parameter is 190 cm. Take into account the type of lift. If the mechanism extends its legs, you need to subtract the distance between the bottom and the floor level. Usually it is 30 cm.

Minimum paw lowering height

The maximum height for lowering the paws is of great importance. You need to choose a private garage with a lift based on the lowest point. The plane there should be flat. In accordance with accepted standards, the minimum height of lowering the paws is a maximum of 110 mm, a minimum of 95 mm.

Let us note several significant points.

The electromechanical lift must be inspected daily to ensure that the clearance of the safety nut is always checked.

This is extremely important! As soon as the gap is reduced, the mechanism should be repaired immediately. Parts are also lubricated regularly

Lifts with low lamella lowering heights are designed for low-slung vehicles, such as sports models. Lifts are selected depending on the specific type of car. For example, some designs are designed specifically for passenger cars, while others are designed only for trucks. There are lifts for motorcycles. This allows you to work more efficiently and use space efficiently. Experts note that electro-hydraulic type lifts are the most practical. They can also be lowered manually if there are electrical problems.

Interestingly, experienced garage workers very skillfully fit lifts into the garage space: they are installed even in rooms with a height of 2.7 meters. And they work with the lift while sitting on a stool.

How to properly install a lift in a car service center

Every workshop should have at least one car lift. Today, the work of any service station or car service center is unthinkable without it. This lifting equipment allows you to optimize work processes and significantly facilitate vehicle maintenance during diagnostics, repairs, and replacement of spare parts.And if the volume of work is large and the room is divided into several repair areas, then it is better if there are two or three lifts - this will allow you to lift several cars at the same time and not make customers wait. Of course, the technical equipment of a workshop requires certain investments, and you need to be prepared for this.

Moreover, you often have to pay not only for the lift itself, but also for services related to its delivery and installation.

Simple arithmetic. For example, purchasing a mid-price car lift can cost from 80,000 to 150,000 rubles, its delivery from a warehouse can cost up to 3,000 rubles, and installation services can cost from 8,000 to 14,000 rubles. If you take equipment worth 90,000 rubles, you will end up paying more than 100,000 rubles.

Did you know that you can save a lot of money on installing a lift? If you install the lift yourself, you will not have to pay for this service. Knowing the basic rules and some subtleties, you can cope with this matter. So, evaluate your strengths and skills, think about whether you can devote enough time to this. Yes? Then get ready for some serious work. Let's start with planning...

Types of lifts

Before installing a car gearbox lift on a pit in the garage, we study its main varieties in more detail. This will help you figure out what a pit lift can be like.

By drive type

Jacks for lifting cars differ in the type of drive that is installed in them. There are two main models in this classification:

- hydraulic jack;

- devices with manual mechanical drives.

Experts advise using hydraulic models, as they are more efficient. However, it is not easy to make such a device yourself, and that is why many people make manual car lifts.

By type of lifts

Another distinctive feature of car jacks is the type of lift used in them:

- Screw. To install such equipment, use two durable racks in which special screws are installed. They are responsible for raising and lowering the vehicle. The operation of the installed screws is controlled by an electric motor.

- Mini. In the manufacture of such models, hydraulic or mechanical drives are used. A special feature of the equipment is its small size. Therefore, mini-lifts are not used to lift freight vehicles.

Electromechanical Engineering

Some models use different electromechanical technology. Based on this, car lifts are produced:

- Single post. Experienced motorists advise using such models in small garages, as they are compact. They consist of an electric motor, a movable carriage, and a vertical support.

- Scissor. Scissor car lifts can be mobile or stationary. They are equipped with a strong frame for attaching hinges and a compressor device.

By number of plungers

Based on the number of plungers, multi-plunger, double-plunger and single-plunger models are distinguished. In models with several plungers, a special traverse is installed, which is responsible for the efficiency of the equipment.