If necessary, any user can purchase the sawmill he needs, which will help him in cutting wood. Sawmills are very useful equipment that is designed for such purposes. If you need to use a sawmill, then purchasing it is possible, but it also has its disadvantages.

The fact is that

such equipment is very expensive , so it can hit the user’s wallet hard.

Even taking into account all the strengths of such devices, their high price can become a serious obstacle for a potential buyer. Therefore, many choose a more complex option for getting such a sawmill for themselves, but much less expensive, that is, they prefer to make this device with their own hands. The article below contains information about the design of the available sawmill options, as well as instructions for creating a homemade circular sawmill.

Design selection

The design of a circular sawmill is being developed for specific needs. Productivity, log width, even cut along the entire length of the workpiece require certain technical solutions in the assembled equipment. When feeding manually, the plane wave of the resulting board increases. The size of the saw blade and the limits of its displacement relative to the stop pad will determine the maximum size of the wood for sawing.

Main nodes

The components of the future machine must first be correctly positioned on the drawing. The device of any homemade disk sawmill includes:

- frame. Unites all components into a functional whole. At the same time, the distance between parts must allow for safe DIY work, maintenance, cooling, and waste disposal. The main qualities are stability, rigidity;

- engine. The electric three-phase version is selected according to power and number of revolutions. Operating voltage 380 V. If there is no connection to the network, install a gasoline engine with a step-up gearbox;

- cutting unit. Placed horizontally, vertically. Consists of one disk or two (corner). A single saw can be fixed in one specified position or rotated 90° to eliminate reverse idling (cutting an angle);

- supply line. A simple homemade product is limited to a fixed table with manual feed. This type is used for small DIY work with small workpieces. A massive log is fed under the knife on a carriage;

- Remote Control. Performs on/off operations, available control switches (revolutions, feed, indication). It is carried out to a place on the frame that is convenient for work and control of the process.

Despite the fact that manufacturing takes place at home, safety precautions must be observed - cover the rotating parts with a casing, and install a protective sheet of metal on the operator’s side to prevent the disc from flying apart. Woodworking circular sawmills are classified as high-risk equipment.

Two disks

The design of a circular sawmill with two simultaneously operating cutting tools allows the processing productivity to be increased. They are located at right angles to each other. Such homemade devices are more difficult to manufacture.

Each disk is equipped with its own motor and drive. The rotation frequency is selected to be the same.

Types of cuts

The horizontal movement of the angular pairs of the disk with the drive mechanism occurs on a movable carriage. Guides are placed under it. To adjust the relative position of circular saws with your own hands, each pair is equipped with adjustment devices.

The principle of operation of the sawmill

explain how a sawmill works using the example of spools of thread.

This device resembles the rotation of two spools with a thread stretched between them. It is this that acts as a saw, and the distance between the coils will be the optimal size of the log. A DIY sawmill allows you to:

The work of the sawmill is carried out as follows : a log is fixed on the platform, which remains motionless, and at this time the mobile cart starts moving and cuts the tree. The saw must be in a horizontal position.

In order to obtain boards of the required size, the operator initially sets the necessary parameters. The saw blade acts as a saw, and it must be well tensioned.

Drawing and material

Depending on the design, drawings of a circular sawmill of varying complexity are drawn up. In custom development, certain requirements must be taken into account.

- Using log feed on a carriage, the width of the platform is taken equal to the width of the guide rails. This will ensure stability under load. The rail is taken P50, the rollers are selected accordingly;

- on the platform, provide clamps for a tree trunk, convenient, reliable fixation of various sizes of workpieces;

- It is advisable not to combine an electric motor and a saw on a rigid drive. It should be protected by a belt (chain) drive. This will improve the air cooling of the windings and remove them from the zone of intense wood dust formation. Before creating a drawing with your own hands, you need to measure the dimensions of the engine; with the same characteristics, the manufacturer gives its size according to the overall dimensions;

- calculate the working area for a saw Ø 500 – 700 mm;

- The frame, depending on the dimensions of the installation, should be welded or dismountable (moving to a new place of work). Channel No. 4, No. 6 are placed in the main harness. Additional stiffening elements are made from steel corners and pipes (if necessary).

Installation design

To make a sawmill, you need to develop a layout diagram. It determines the position of nodes. Their interaction is considered.

Calculations are needed to determine engine power. For a disk with a diameter of 400 mm or more, 5 kW will be required. With a lower value, sawing performance will be low.

Of course, for a homemade installation you do not need a full set of drawings, but basic sketches will be required. Using them, the master works out the features of the mutual movements of moving elements.

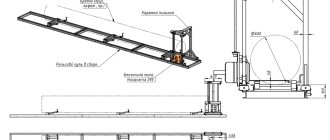

General view of the circular sawmill. The main structural elements are visible - rail track, tool frame, saw head:

Assembly order

The DIY installation process is divided into 3 stages. After each, the dimensions, tolerances, and stroke limits of the moving parts are checked against the working drawing.

- Support frame frame. Welded (bolted) joints are made. They check the quality, diagonals, location of seats, stability.

- Feeding part. In the case of a fixed table, the level is set to a horizontal plane. The coincidence of the longitudinal axis with the supporting frame is recorded. For a moving platform, first place the rails at the same level coaxially with each other and the base. Load the trolley with a check for smooth running and no chafing of the wheel flanges. A small homemade circular sawmill can have a light trolley on bearings and rollers. For them, a guide track is made from a corner for passage forward and backward. On larger models, the principle of moving a carriage with a disk above a log fixedly fixed on the table is used.

Household disc sawmill Astrogan 2

- Cutting organ. The first to be installed is the sawmill shaft with the saw. The support bearing assembly is mounted on the subframe, the axis of rotation and the presence of runout are checked. Then the engine is hung on the mounting slots. The fastening bolt should not be located at the edge of the groove. If a V-belt/chain drive is used, then with repeated revolutions it becomes loose and subsequent tensioning is necessary. When replacing with a new product, the motor is again fed closer to the shaft. Continuous adjustment can be made with spacer bolts on each side. A heavily tensioned belt or chain will overheat when the equipment is in use for long periods of time.

When assembling a corner sawmill with your own hands with a block of disks on a movable carriage, the design distances are controlled along the entire length of the stroke. An unexpected change in saw angles during sawing will lead to damage to raw materials and an accident.

Where to start making?

Any master has a question about how to make a device so that it has certain abilities. It is necessary to develop an installation diagram. It should include a number of main components:

- guides for moving the tool frame (rail track);

- the frame itself on which the instrument is mounted;

- clamp for workpieces (logs);

- auxiliary devices for fixing and moving the tool along the frame.

General view of the design of the simplest circular sawmill: 1 – guides; 2 – tool frame; 3 – saw blade; 4 – V-belt gearbox.

It is necessary to consider what the components of a homemade circular sawmill consist of. Then select the source materials.

Individual approach

Where a high-capacity sawmill is not required, a mini-machine with a sliding feed on a stationary plate is designed.

As the weight and length of the workpiece increases, the table is equipped with freely rotating rollers to facilitate manual pressure.

A universal solution would be a rotary (90°) gearbox for a circular saw. In some cases, the owner prefers to install end clamps to rotate the workpiece around the longitudinal axis.

Moving the tree or saw is a crucial issue in the design of a sawmill.

Essential tips and tricks

Since the sawmill is considered a rather dangerous unit of impressive size, before assembling it with your own hands, you need to carefully consider where it will be used.

Good for this: Such a place should be well ventilated, spacious and have sufficient lighting. A place for this device can also be found on the street, but a canopy must be equipped for it.

If the sawmill has an electric motor , then you need to carefully consider the installation of wiring and installation of the necessary switches and machines. If there is a warehouse for finished boards near the place of work, this greatly simplifies the whole process.

When assembling the unit with your own hands, special attention must be paid to its cutting and moving parts, which are considered the most dangerous elements. In general, safety precautions should be observed when operating the device.

After assembling the sawmill and before starting work, be sure to check all fastenings and components, as well as the stability of the structure. The first start of the device is carried out after following all the necessary recommendations.

Thus, making a sawmill with your own hands is not difficult . These devices come in different types and the process of their assembly is presented in the video. You should also definitely use the drawings so as not to make any mistakes. When operating a sawmill, it is necessary to observe safety precautions, because this is a rather dangerous device.

Source

Owner reviews

Owners of sawmills made from chainsaws note the high efficiency, low cost and ease of installation of the structure. Most reviews about this device are positive.

They talk about the advantages of such an improvised sawmill. Thus, the famous video blogger Maxim Egorov assembled a sawmill from a chainsaw right in the forest. To do this, he used several boards and two roughly processed pine logs. Using the device, he managed to obtain boards in the required quantity, which were intended for the construction of a forest house. Maxim noted the simplicity and efficiency of the design, as well as the ability to quickly transform it back into a chainsaw.

Another video blogger, Mark Didenko, also assembled a similar design. True, he did not use boards for this, but a metal profile. In order for the cart to move smoothly along the base, he attached a gear drive to it, which is driven by rotating the handle. Didenko was also pleased with the assembled device. He noted the low cost of materials as its main advantage - according to the blogger, they cost only 10,000 rubles (not taking into account the cost of the chainsaw itself).

But the author of the blog “Lumberjack” is more critical of the device. He agrees that it can be assembled quickly and cheaply and even tells how he used a homemade one to build his parents' house.

But the blogger also points out two important aspects:

- The saw constantly operates at maximum load, which can lead to engine breakdowns or burnout of the electric motor.

- When using a homemade sawmill there is a very high risk of injury.

Operating principle

Before making the structure yourself, it is necessary to study the operation and features of the configuration of a miniature circular sawmill. It is often used for processing medium and large logs. As a result, timber and boards are formed.

The main element of the design is the power unit, which ensures the rotation of the sawing discs. In addition, to ensure automation of work, the following components are required:

- supply line It can be automatic and motionless. Often the latter solution is preferred because it is more economical to do it yourself;

- cutting unit . May include one or more cutting blades. It can also be transverse and horizontal;

- control block . It is located on top of the cutting unit. Using this device, the master has the opportunity to adjust engine speed, start and deactivate equipment.