Purpose and principle of operation of the grinder

The grinder is actively used in the field of repair and construction, processing of wood, stone and metal, and all due to the fact that almost any material can be subjected to abrasive processing without much difficulty.

As you know, the working element of a grinder is precisely an abrasive wheel, although one type of it is needed for cutting, and a completely different one for grinding.

NOTE:

To work with different materials, wheels with different compositions are used, and they are marked with different colors.

Angle grinders are used for processing steel, alloys, tiles, stone, brick, and concrete.

This list can be continued endlessly.

When using special equipment, you can polish surfaces.

Device

An angle grinder is a simple tool by modern standards. Its main parts:

- frame;

- electric drive;

- gearbox;

- spindle;

- protective casing;

- lever.

The housing is made of durable materials to protect the angle grinder from stress and accidental impacts from the external environment. The body houses buttons and controls.

The drive is powered from a 220 V network, less often from batteries. The rapid rotation creates heat, so a fan is placed nearby.

The gearbox has only one stage. Placed in a separate fenced section filled with lubricant.

The spindle has a thread through which the saw blade or grinding wheel is secured with a washer and nut.

Grinding machine device

The protective casing prevents sparks and particles of the processed material from flying towards the worker.

The handle is made removable. There are threaded holes along the body into which this handle can be screwed and thereby create a convenient option for the worker to hold the grinder.

Device and characteristics

The grinder consists of a cylindrical body, inside of which there is an electric motor, the shaft of which is ultimately located at right angles to the axis of rotation of the working disk, and the coupling is made through a gearbox with a tooth gear.

That’s why an angle grinder is called an angle grinder.

During operation, the tool is held by the body with one hand, and to increase ease of use and accuracy of operations, an additional handle is screwed into the head of the grinder (metal front part with a gearbox).

The grinding disc is mounted on the gearbox shaft, which has a thread, and is tightened with a special nut for angle grinders.

Its peculiarity lies in the presence of four holes around the perimeter for a special tightening wrench.

Which side will press the disk depends on the purpose of the disk itself, since the nut is double-sided.

Also, to fix the disk, use a quick-release nut SDS, which does not require any additional tools to unscrew.

Attention!

During operation, the disk may be destroyed with fragments scattering at high speed.

Also dangerous are sparks and particles of the material being processed, some of which are stopped by the protective casing that covers the disk on the operator’s side.

The grinder is powered by a removable battery or mains power supply. In the latter case, a network cable is used that comes out from the end of the tool.

Material

The main part of the grinder body and the main handle are made of fairly thick impact-resistant plastic.

Magnesium alloy is predominantly used in the production of the gearbox housing.

An angle grinder is often equipped with rubber pads that prevent your hands from slipping.

Dimensions and weight

The sizes of grinders are determined by the maximum diameters of the discs they are designed to work with.

Grinders can be divided into several types based on size:

- Small - on average 270 mm long and 100 mm high, for 115 - 125 mm discs.

- Medium - 350 mm long and 120 - 130 mm high, for 150 - 180 mm discs.

- Large ones - 400 mm long and more than 140 mm high, for 210 - 230 mm discs.

As for the weight of grinders, it ranges from 1.8 to 6-7 kg.

The standard mounting diameter of the disks is 22.2 mm, their thickness is 0.8 - 2 mm, and the outer diameter is 100 - 230 mm.

Engine type and power

Most angle grinders are equipped with universal commutator motors, making the tool relatively cheap.

An alternative is a more modern option - an asynchronous electric motor with control electronics, including, for example, a frequency converter.

These motors are installed mainly on professional-class equipment.

As for the power of the angle grinder motor, this parameter for most models lies in the range of 0.7 - 2.2 kW.

In general, the performance of the tool, as well as the efficiency of working with various materials, depends on power.

So, for example, grinding metal and sawing concrete requires 600 - 900 W, for more complex work - 1 - 1.5 kW.

The more powerful the tool, the more stable it works under load.

Rotational speed

This parameter does not play a special role, because at the factory, for each tool model, the optimal disk rotation speed is selected based on its diameter.

The same number of revolutions of the grinder accelerates the cutting edge of circles of different diameters to different speeds.

This should be remembered, since if the edge speed exceeds 80 m/s, the disk will simply begin to collapse.

For this reason, manufacturers tie the upper threshold of rotation speed to the diameter of the working element.

For a 125 mm tool, the rotation speed limit is 11 thousand rpm, for a 230 mm wheel - about 6.5 thousand rpm, because the larger the diameter of the disk, the greater the linear speed of its edge at the same angular speed, that is just the number of revolutions.

If the rotation speed is too low, the life of the disk and the speed of operation itself suffer significantly.

When in contact with the surface being treated, the speed drops due to the friction of the working element, therefore the presence of a system for maintaining constant speed under load significantly increases the efficiency of work, preventing drawdowns in the performance of the angle grinder.

NOTE:

Some angle grinders have initially low spindle speeds, as they are designed for working with stainless steel.

The fact is that high speed in this case leads to the appearance of tarnished colors with the loss of the material’s properties.

Working time without interruption

The grinder is not intended for continuous operation, since during operation both the electric motor itself and the gearbox heat up, despite the apparent high efficiency of the ventilation holes on the body.

If the tool becomes overheated, turn it off and leave it until it cools down.

It is recommended to use the grinder in the following mode: 15 minutes of operation, and then rest until the body temperature is equal to the ambient temperature.

How to properly disassemble an angle grinder gearbox

When repairing the gearbox of any angle grinder, the most difficult task is removing the gears and pressing out the support bearing.

Disassembling the gearbox begins with removing the gearbox cover pos. 1 and disconnecting the stator housing and freeing the rotor pos. 2. The freed rotor is clamped in a vice and the fastening nut pos. 3 of the drive small gear is unscrewed.

The spindle bearing is pressed into the gearbox cover. To remove the bearing, in some angle grinders you must remove the retaining ring that secures the support bearing and remove the bearing.

The destroyed bearing, pos. 1, in the gearbox housing, pos. 2, is easiest to get out by prying it off with a screwdriver.

In other models, a locking ring secures the gear in the spindle.

The driven large gear is mounted on the spindle in several ways:

- The gear is pressed onto the spindle.

- The gear is secured with a key.

The driving small gear is either screwed onto the shaft along the left-hand thread (in some Sparky models, the thread is right-handed), or is fixed with a key connection and clamped with a nut.

How to remove gears

Grinders up to 1000 W use spur gears, while angle grinders use helical gears.

Gears are attached differently in different angle grinders. The drive gear is mounted on the rotor shaft with a keyed connection or mounted on a thread. The driven gear is secured to the spindle shaft by an interference fit or a keyed connection. Details on how to remove gears and bearings from the shaft.

Gear repair consists of replacing them, and only in pairs.

Long-term and uninterrupted operation of the gearbox depends on the presence of a sufficient amount of lubricant and its timely replacement.

Spindle lock button repair

The spindle lock button is designed to quickly remove the working tool. The button breaks when you press it while the disk is rotating. Repairing an angle grinder involves completely replacing the button.

The button should be pressed only when the grinder is completely stopped.

Security systems

In addition to the above recommendations on how to choose an angle grinder, it is also necessary to take into account whether the grinder is equipped with safety mechanisms. The following options are important:

- number of handles for strong fixation;

- smooth start to prevent the wheel from jumping off during startup and to minimize wear;

- protection against a new start after a stop;

- tool cooling system;

- starting current regulator to reduce the load on the network at startup;

- protective coupling to prevent damage to the disc when it jams;

- stopping mechanism at the moment of jamming;

- safety system to protect the engine from overheating.

GOST

Requirements for test methods and safety for standard disc grinders, including angle versions, are described in GOST R IEC 60745-2-3-2011.

Grinders are also subject to the standards GOST 16519-2006 (vibration), GOST 12.2.030-2000 (system of occupational safety standards), GOST 30805.14.1-2013, GOST 30805.14.2-2013, GOST 30804.3.2-2013, GOST 30804.3. 3-2013.

Round nuts with holes at the end for a special wrench, which are used to clamp the cutting discs of an angle grinder, are manufactured in accordance with GOST 6393-73.

Marking

Each manufacturer labels angle grinders based on their own preferences.

As a rule, the marking indicates the model of the tool, its power and the maximum diameter of the disk used.

Additional functions of the grinder

In order to ensure additional convenience and safe operation, manufacturers equip the tool with various functional and safety automation and mechanics, of which the most common are:

- Soft start – allows you to protect tool components from short-term excessive loads at the time of start-up. This applies not only to the gears of the gearbox, but also to the electrical part of the angle grinder, because at the moment of start, the electric motor experiences current surges. The function will prevent the tool from jerking at the start. This is especially true for large massive grinders.

- Anti-vibration system - designed to dampen vibrations that occur during uneven rotation of large-diameter disks. This function is also called a balancing system.

- Protection against accidental start - is usually implemented by an additional button, pressing which unlocks the start key. Allows you to avoid accidental starting of the tool, thereby increasing the safety of its operation.

- Maintaining constant speed under load - makes it easier to process parts by stabilizing the speed of rotation of the cutting wheel with any change in load in automatic mode.

- Rotation speed adjustment – allows you to select the desired operating mode of the angle grinder for specific tasks, for example, cutting or grinding material.

- Quick-release nut SDS – its presence allows you to remove and install the working element of the angle grinder without using any keys or any additional tools. This nut can be loosened by hand.

Also, modern models are equipped with protection systems against disk “wedge” and secondary start-up.

Types of grinders and their prices

Despite the widespread use of electric angle grinders, there is a tool with a different type of drive, but more on that a little later.

Classic manual grinders are divided into:

Network

The most common option.

Requires connection to a household network to operate.

The advantages include relatively low cost and independence from fuel.

Disadvantages: limitation of the working radius by the length of the wire, which, moreover, can create inconvenience.

You have to constantly monitor the network cable so that it is not accidentally cut by the rotating disk.

The cost starts at 2 thousand rubles.

Rechargeable

They are independent of the presence of a source of electricity, which means they are excellent for working in field conditions.

They require a charged battery, and for continuous operation it is necessary to have two batteries, one of which will be charged while the other is being used on the instrument.

Manufacturers do not make such grinders powerful to save battery, however, their cost is higher, averaging 8 - 15 thousand rubles.

According to the scope of application, grinders can be divided into:

Household

As a rule, low-power models are small in size and not intended for long-term use without interruption.

After 15 minutes of work, they require rest, otherwise the matter may end up overheating.

Their power is in the range of 800 - 1000 W, and they are designed to work in tandem with disks with a diameter of 125 - 150 mm.

The price for the simplest models is 2–4 thousand rubles, high-quality and “sophisticated” ones are 8–12 thousand rubles.

Professional

Designed for continuous long-term operation, they can be operated without overheating for a really long time, but these are heavier models.

Their power can exceed 2.5 kW, and the diameter of compatible disks ranges from 180 mm, sometimes reaching 305 mm.

The tool often has a full range of additional functions that protect both the grinder itself from various damages and the operator.

Such options are sometimes produced with a water supply system to the working area, which expands their capabilities.

Cost from 4 thousand rubles.

According to the number of handles, grinders are divided into:

One-handed

Models with discs with a diameter of up to 125 mm, in which the tool body itself acts as the main handle, and an additional removable handle is fixed in two positions on the sides of the gearbox.

Due to its low weight, you can work with such a tool by grasping the main handle with both hands.

Attention!

For safety reasons, this tool cannot be used with one hand.

By violating safety precautions, you risk the health of yourself and those around you.

Two-handed

With an independent main handle mounted behind the body.

For some models, it can be rotated, which increases the ease of use of the tool in different planes.

The additional handle is fixed in three positions.

In addition to electric ones, there are machines with another type of drive:

Gasoline

A tool that cannot be called a grinder.

These are professional cutters, also known as gas cutters, designed for long-term continuous work in difficult field conditions, they are distinguished by high power, and are able to cut very hard materials without any problems.

Pneumatic

Designed to work under heavy load, do not overheat, require connection to a pneumatic line or compressor, and are characterized by an increased spindle speed.

The tool can be used in places with high humidity, mainly used in the metalworking industry.

The price of such grinders is about 30 thousand rubles.

Choosing an Angle Grinder

When choosing an angle grinder, you should decide for what purpose, where and how often it will be used, as well as what materials it will process. In addition, you should immediately select additional attachments and discs, if required.

This tool will not be used often in an apartment. Basically, a grinder will help you cut ceramic tiles, wire or nails, or peel off paint from a battery or an old set. For home use, it is recommended to purchase a low-power angle grinder with a disc up to 125 mm in diameter and several attachments for certain operations.

The country version of the grinder can be the same in power and performance as the version for the home. It all depends on the hard work of the owner of the summer cottage. If he is interested in cutting stone or rolled metal himself, then it is better to get a more powerful version of an angle grinder (1 kW or more).

Professional use means that grinders are purchased to perform a specific job. As mentioned earlier, powerful grinders with large-diameter disks are excellent at cutting to great depths, but it will be difficult to grind on them. That's why professionals often have multiple tools.

We should also talk about battery-powered angle grinders, which have appeared in stores relatively recently. The design uses a high-capacity battery, but it adds weight to the angle grinder. The diameter of the disks used and the rotation speed are limited. It is necessary to charge the batteries regularly and the cost of such a grinder is much higher than that of conventional ones.

Cordless grinder

The use of such a unit is advisable if there are no electrical networks near the processing object or if you have to pull wires.

Why is an angle grinder called an angle grinder?

The word grinder first appeared in popular slang in the 70s of the last century in the USSR, when Bulgaria began to supply its first tools - angle grinders produced at the Sparky Eltos enterprise in the city of Lovech. It takes a long time to call a tool in everyday life or at work an angle grinder, so people shortened this name to a short and succinct one - an angle grinder, according to the country where the tool was produced. This is how the name angle grinder – grinder – stuck in everyday life.

The word Bulgarian has taken root in colloquial speech since the times of the USSR and is still used in the CIS. So on the Russian-language Internet, the word grinder is used in searches 320,000 times, and the word angle grinder is used only 10,000 times. In Bulgaria at that time, the grinder was called flex, since the capitalists’ first angle grinders were produced by FLEX-Elektrowerkzeuge GmbH. You will be surprised by the spelling of the grinder - angle grinder in the Bulgarian language - ъgloshlayfi (Ъгъл - angle). In English, an angle grinder is written - angle grinder, in German - winkelschleifer.

Pneumatic grinders

The pneumatic angle grinder is capable of operating for a long time without overheating under severe load conditions. They are most widespread in the metalworking industry, but can also be used in repair, construction and other fields of activity.

Grinder in the family of pneumatic tools

Its distinctive feature is the absence of an electrical network cable and the possibility of complete isolation from the compressor or air line. This tool can be used safely in conditions of high humidity. Pneumatic grinders also have a higher spindle speed.

Which grinder should you choose?

As already mentioned, an ordinary household grinder will be sufficient for the home, especially if it is not planned to be used frequently or for any specific work that requires high power and a disk diameter of over 150 mm.

For professional activities, a tool with a power of over 1.5 kW with disks with a diameter of 180 mm or more is required.

In general, in the process of choosing an angle grinder, the following information will be very useful:

- Cord length. Its optimal value is 2 – 3 meters. A shorter length will simply limit freedom of action, but a longer length is not needed, since in any case you will have to use an extension cord at a distance from the outlet.

- Handle position. The ease of use of the tool depends on the number of positions of the additional handle. On the body of the angle grinder gearbox there are holes for its installation, most often in the amount of 3 pieces, which makes it possible to use the grinder for left-handed and right-handed people, as well as at different angles.

NOTE:

There are five-position grinders, where the screw-in handle can have up to five positions.

There are models in which the main handle on the body is switched, where switching occurs by turning along the axis of the tool. Switching the main handle can have 2-3 positions.

- Replacing motor brushes. Graphite brushes wear out over time and require replacement. To avoid having to disassemble the angle grinder or contact service, many manufacturers use a quick replacement system. Such models have two small screw-on caps on the instrument body on opposite sides. To access the brushes you simply need to unscrew them.

- Smooth start – reduces wear on gears, preventing jerking at start-up. The presence of this function will extend the life of the tool. This also includes a starting current limiting system, which reduces the load on the network at start-up.

- Protection against accidental start - an additional button that blocks the start key from inadvertent pressing. Some models have a restart locking system. If the tool is de-energized and then restarted while holding down the start key, it will not start.

- Quick-release nut for grinder. Many modern models of grinders are equipped with it. Allows you to replace the working disk without using additional tools.

- Maintaining constant rpm under load will ensure high productivity when working with materials of different densities. The electronics will independently bring the speed of the cutting wheel to the nominal value, despite the load applied to it. The presence of a manual speed control function will allow you to select the disk rotation speed to suit specific tasks.

- Anti-vibration system - automatically balances the cutting wheel due to a special clutch with balls immersed in oil, which, distributed in the required manner, shift the center of gravity, reducing vibration of the angle grinder.

- The weight of the tool is responsible for the ability to work for a long time without operator fatigue. The weight and size are affected by the power of the grinder. Professionals try to choose a middle ground for themselves in this regard.

Attention!

Beginners are not recommended to buy powerful models without having an idea of the strength of the possible kickback.

An important point when choosing an angle grinder remains the warranty, or rather its duration and conditions.

European manufacturers offer from 3 years of warranty service, and some over 5 years, which hints at the quality of the tool.

Additional functions of the angle grinder

The wide distribution and functionality of such a tool is largely ensured by the presence of various additional systems, functions and capabilities of such equipment.

Starting current limitation

The trouble-free operation and durability of the angle grinder will largely depend on the quality of the current in the electrical network. When the engine is turned on, an abrupt increase in load may be observed, which leads to rapid failure of the electrical equipment in the angle grinder. To prevent this, such equipment is equipped with a starting current limiting system, which ensures longevity and trouble-free operation of professional and household angle grinders.

Maintaining constant disk speed

At the moment of contact between the working disk and the surface being processed, the rotation speed of the tool may decrease, and at the same time, the resulting friction increases the load on the engine. The constant speed control system used is able to compensate for this resistance, ensuring a constant cutting speed. Professional models of grinders are equipped with similar systems, which allows such a tool to be durable, and the angle grinder guarantees the quality of the work performed.

Restart lock

The presence of such a system eliminates the possibility of restarting the grinder's engine, which ensures the safety of using such a power tool. The restart locking system is a mandatory feature for professional and domestic models.

Motor overload protection

When using an angle grinder, its engine may be subject to increased load, which negatively affects the durability of the drive. This system of motor overvoltage protection allows you to eliminate prolonged load on the tool, and you will be completely confident in the durability of the equipment you use.

Dust protection system

Today, angle grinders can have the following technological and design solutions for dust protection:

- Use of closed type bearings.

- The presence of a fine mesh on the ventilation holes.

- Use of cord bands at the rotor and armoring of the starter windings.

- Filling the starter winding with epoxy resin.

The presence of such a dust protection system allows you to extend the life of the tool, without the need to regularly open the angle grinder to clean it of dust.

An angle grinder is a popular power tool today, which is used with equal success by ordinary homeowners, professional finishers and builders.

Safety precautions

As with any other power tool, you should read the instructions before using the angle grinder. Failure to comply with safety regulations can result in death or significant harm to health. The main dangerous factors when working with angle grinders are:

- Possibility of electric shock;

- The possibility of being injured by parts of the processed material flying out from under the grinder circle or parts of the working circle in the event of its destruction;

- Negative effects on the respiratory system, eyesight, and skin of dust released during the operation of an angle grinder.

- “Snack” of the disc in the workpiece, which can lead to the angle grinder jerking and rupture of the disc.

The following safety rules must be observed (the list may not be exhaustive):

- The main thing in the safe use of angle grinders is to anticipate the behavior of the parts of the product being cut at the moment of their separation;

- When working with the machine, it is necessary to take a stable posture and use a protective mask covering the face, as well as clothing, shoes, gloves and a hat to prevent injury from fast-flying particles of the disk and the material being processed, taking into account ricochet from nearby obstacles, and the tool catching clothing and hair;

- The machine cord must be protected from accidental damage; it must not come into contact with hot surfaces, petroleum products, or chemically active substances.

- When replacing the disk, the angle grinder should be disconnected from the network;

Prohibited:

- Use an angle grinder without a standard protective blade guard;

- Work the sparks towards yourself (when a disk ruptures, the fragments fly in the direction of the stream of sparks)

- Bend the power cable closer than 5 cm from the angle grinder body and carry the tool by the cable;

- Handle materials containing asbestos, cement, chalk and abrasives.

- Allow children to enter the car;

- Operate angle grinders under conditions of exposure to drops, in rooms with high humidity, as well as outdoors during rain or snowfall;

- Operate angle grinders in rooms with an explosive or chemically active environment that destroys metals and insulation;

- Use replacement wheels whose warranty period has expired without first testing them for mechanical strength;

- Use saw blades from a circular saw;

- Operate the machine from ladders;

- Work with angle grinders inside boilers, tanks, power supplies;

- Leave the machine connected to the electrical network unattended;

- Pull and twist the cord, subject it to stress;

- Use the machine if there is at least one of the following malfunctions: a damaged plug, a damaged wire or its protective sheath, unclear operation of the switch, sparking under the motor brushes, the appearance of smoke or a smell characteristic of burning insulation, the appearance of noise levels uncharacteristic of normal operation, knocking or vibration, breakdowns or damage to parts of the housing or gearbox, destruction of the replacement wheel (disc).

Operating principle of the tool

To operate the angle grinder, you need to press a button or switch on its body.

Power can be supplied from the mains or from a built-in/removable battery. Basically, the tool is equipped with a commutator motor with high inductive reactance. This achieves a significant reduction in operating currents.

The electric motor shaft spins and drives the gear driving in the gearbox. This, in turn, rotates the driven gear, transmitting voltage to the spindle.

On expensive models, a release clutch is used, which is installed between the gearbox and the engine. Its main function is to prevent kickback in the event of an unexpected disk stop due to jamming. Such a device protects angle grinder components from damage and the operator from possible injuries.

How to disassemble an angle grinder gearbox correctly, video

There are many companies specializing in the production of angle grinders. The basic design principles of angle grinders for all companies are practically the same. However, there are some features that should be taken into account when repairing angle grinders of a certain brand. The experience of such repairs is presented by craftsmen in video formats, it is presented below.

Bosch

An overview of one of the household models of an angle grinder from Bosch is presented in the following video. It disassembles the gearbox, after which a visual inspection of the bevel gear . The presence and condition of the lubricant is determined. It is possible to determine the degree of gear wear. In this case, since the angle grinder is new, you can only make sure that there is one support on the spindle in the form of a plain bearing and a bevel gear - it is spur gear . The author classifies these design features of this Bosch angle grinder model as disadvantages. Indeed, the service life of such an angle grinder and the noise level will not be good .

In the following video, after disassembling the gearbox of another model of a Bosch angle grinder, significant contamination of the lubricant with abrasive particles is observed. Conclusion: the internal cavity of the gearbox should be inspected regularly to avoid early failure of the power tool.

The author suggests replacing expensive lubricant from Bosch with another cheaper and more accessible domestic one. Important: the postulate that there is no such thing as too much lubrication is not acceptable here. A large amount of lubricant will lead to its squeezing out through the seals on the gear housing, for example, through the retainer seal. Therefore, a strictly defined amount of lubricant should be placed in the gearbox.

Hitachi

The following video describes in detail the process of disassembling the gearbox spindle of an angle grinder of one of the Hitachi models. This is caused by replacing a stuck bearing located in the gear housing cover. In order to get to it, you must remove the driven gear pressed onto the shaft. Due to the small distance between the gear and the gearbox cover, the puller jaws are modified by grinding their surface to the required thickness in order to fit into this gap. Important: before pressing out the gear, you must remove the retaining ring that secures it.

DeWalt

A design feature of the angle grinder of one of the DeWalt models is the design of the gearbox housing. The lid here does not have any additional functions other than protection against abrasive particles getting inside. The flange where the bearing unit is located is made as a single unit together with the housing.

Usually, when replacing a structural element (in this case brushes), in most cases the lubricant in the gearbox is replaced. To do this, the DeWalt angle grinder is completely disassembled with the rotor removed, so that it is convenient to rinse and clean the gearbox cavity from old grease.

Another feature of the DeWalt grinder is the design of the driven large gear . A conical insert inside the gear housing prevents operation under overloads. The preload force of the conical insert is adjusted to operate under permissible loads. With increased effort, the gear will slip along the conical surface.

For convenience, when changing oil, the author uses a measuring syringe . Here it is easy to control the amount of lubricant required for refilling.

Makita

The following video shows a preventive inspection of the gearbox of one of the models of Makita angle grinders. After a certain amount of operating time, the grinder was completely disassembled and the rotor was removed . Wear on the teeth of both gears is visually visible, and there are chips. The author, unfortunately, did not analyze the reasons for their appearance. Replacing worn gears with new ones does not guarantee their long-term operation.

Sparky

In the Sparky angle grinder, in the following video, the author shows the reason for the one-sided rotation of the spindle and how to eliminate the defect. A collapsed rotor bearing with a support in the gearbox casing caused its misalignment, which contributed to damage to the aluminum casing in the form of chipped chips. Using pullers and a wooden drift, the author can easily disassemble the gearbox and replace both bearings on the rotor supports.

Lepse

The video shows a very reliable angle grinder from Lepse, which broke down after ten years of use. During disassembly, a defect was discovered that is quite rare . The reason for the breakage of the bolt securing the drive gear remains unclear to the author. Perhaps these are fatigue stresses from periodic loads. The repair method using a drill and sprocket is worthy of attention.

Fiolent

In the following video, disassembling the gearbox helped to identify the cause of the malfunction of the Fiolent angle grinder. After carefully unscrewing the fasteners on the gearbox housing, a large spindle play in the bearing assembly support. Particles of the bearing race confirmed the direction of repair work to replace the collapsed support unit.

Diold

the reason for the increased noise of the Diold grinder in the following video. After disassembling the gearbox, large gaps were discovered in the bearing units . It should be noted that they did not in any way affect the quality of the gear teeth - they are in full working order. That is, if the gears are made of high-quality material in compliance with heat treatment technology, they can work reliably in the most difficult conditions. Using the tools necessary for such repair work, the author shows how to replace defective bearings .

DWT

A jammed spindle in an angle grinder model DWT, which is described in the following video, is repaired using well-established technology . The brushes are disconnected from the rotor so as not to damage them in further repairs, and the gearbox is disassembled . Then the wear of the gears and the play of the bearing units are visually checked.

In this particular case, it was the failed bearing that caused the grinder to malfunction. The video shows how one faulty bearing can lead to a whole train of broken other parts. You should carefully monitor the condition of the bearing units and regularly check for play.

Disc diameter

This criterion is basic. It influences the choice of power and required disk speed. You can find different discs by diameter:

- 115 and 125 mm - used for domestic needs. With their help, you can quite effectively remove rust or old paintwork from parts, perform polishing work, and cut material no more than 50 mm thick;

- 150 mm is an intermediate version of the grinder. 180 mm wheels are often classified as middle class.

- 180 and 230 mm – designed for processing dense and thick products. You can safely cut thick concrete or brick curbs, as well as asphalt pavement. The disk itself will be quite heavy, so when cutting thin products there will be strong vibration, which is inconvenient and unacceptable.

Models and manufacturers

It is quite difficult to navigate correctly and choose the appropriate option in today’s abundance of models. The only thing I can recommend is not to buy cheap Chinese counterfeits.

Domestic grinders (for example, the Interskol company) are slightly inferior in quality to well-known world brands (Bosh, Kress, Metabo, Makita), but at the same time they are much superior to their Chinese counterparts. Therefore, when choosing a particular model, special attention should be paid to proven and well-established companies.

Angle grinder device

Most models of such power tools consist of the following elements:

- A housing that is made of metal, reinforced polymers or plastic.

- An electric motor that receives energy from built-in or external batteries and from a household network.

- Single-stage angular gearbox, which is made of aluminum or magnesium alloys. The presence of such a gearbox allows the grinder to operate at different speeds, which makes it possible to use the tool for working with wood, processing and cutting ceramic tiles, concrete and metal.

- A spindle consisting of a metric thread, a shaft and mounting nuts for the cutting disc.

- A removable handle that can be mounted in different positions, which allows you to conveniently use such a tool.

- A protective casing that allows you to protect a person working with an angle grinder from a sheaf of sparks and chips that appear during operation of the tool.

The operating principle of such angle grinders is extremely simple.

An electric motor drives the spindle through a corresponding gearbox. A cutting disc or any other equipment is mounted on the spindle, which allows processing or cutting of various materials. When purchasing models of grinders for home use, you need to pay attention to the tool’s ability to change the spindle speed, which allows you to use such a tool for working with various materials. But when choosing professional models of angle grinders, you need to pay attention to the presence of a splitting coupling, which is installed between the gearbox and the engine. This clutch eliminates the possibility of kickback, which can occur when the disk jams at high spindle speeds.

The main safety rule: choosing a disc for an angle grinder

When choosing a circle for an angle grinder, you should pay attention to its rotation speed. The higher it is, the smaller the disc diameter will be. The maximum permissible rotation speed is always indicated on its side surface. Under no circumstances should this data be ignored. Let's give one of the real examples.

Do not repeat! The worker did not find a small cutting wheel for an angle grinder with a rotation speed of 16,000 rpm, and, having removed the protective cover, installed a large disc with a maximum of 6,600 rpm. Having tightened the nut, he pressed the start button, as a result of which, naturally, the disk instantly shattered. The result is the absence of two fingers on the left hand, damage to the eye and numerous minor injuries.

Such incidents happen regularly at construction sites. There are several reasons for this. Many “sin” due to the lack of instructions in the workplace, but it must be remembered that safety, first of all, must be ensured for yourself. This means that the worker himself must first of all know the rules and follow them.

What is angle grinder used for and how is it designed?

The angle grinder (angle grinder), or “grinder”, has firmly entered the everyday and industrial life of not only the craftsman, but also the common man who likes to comfortably solve plumbing and carpentry tasks. The popularity of this power tool is due to its simplicity, versatility and multifunctionality of use.

With the help of various additional attachments, the grinder can cut metal, grind various surfaces, and clean them of rust or old paintwork. The angle grinder's arsenal includes such functions as sharpening cutting tools, chipping concrete walls, cutting ceramic tiles or stone.

The device of the grinder

Structurally, the grinder is an electric motor with a power of 500 to 2000 W, which converts the power of electric current into rotational motion. A planetary gearbox, consisting of two main gears with a straight or bevel gear, serves the same purpose. The rotation of the spindle of the working shaft is carried out in direct transmission mode, the speed is determined by the ratio of the number of gear teeth. Some angle grinders are equipped with an electronic engine soft start unit and rotation speed control.

Professional angle grinder with engine speed control

Electric motor type: asynchronous, single-phase. Electromotive force arises when the rotor winding interacts with the magnetic field of the stator, which is fixedly fixed in the housing. Thanks to the angular transmission of torque, the level of safety during operation is significantly increased. If the disk jams in a viscous material, the tool body does not rotate reactively, which prevents possible injury to the operator.

Many have experienced in their own practice the phenomenon of reactivity when operating an electric drill. When a drill bit jams, for example, in hard wood, the body of the device begins to forcefully rotate in the opposite direction, is torn out of the hands and can lead to injury or even disfigurement.

What is an angle grinder and what is it intended for: general information

The name itself suggests that it is intended for grinding corners. However, the work performed by the grinder will depend on the selected and installed disk. For example, it could be a cutting wheel, a grinding wheel, or a special metal brush that allows you to quickly remove rust from a metal surface. But brushes are used extremely rarely. The most common use of an angle grinder is cutting various metals - pipes, sheets, angles or channels.

When working, the grinder should be held very firmly in one position, without tilting to its side.

Cutting is considered the most dangerous job using an angle grinder. To make this job faster, easier and safer, you should choose the right type of tool.

Disk turnover rate

The spindle with the disk mounted on it rotates at a given speed, making a certain number of revolutions per unit of time. In existing models of angle grinders, this parameter can vary within 2800-11000 rpm. The size of the disc determines the required speed limit - for larger circles a smaller number of revolutions is required.

For small diameter discs up to 125 mm, the highest speed parameter is set to 10-11 thousand rpm. For circles with a diameter of 180 mm, the speed limit is 8.5 thousand per minute, and for maximum discs of 230 mm - no more than 6.65 thousand revolutions. If this parameter is not observed, the disc may break off and cause injury to the operator.

The marking of an angle grinder indicates the maximum size of the disc that can be used, for example, a model with a limit of 150 mm can accommodate circles of 115-150 mm. Therefore, it is recommended to buy more universal angle grinders with a speed controller.

A few points to make the right choice

All the tool parameters listed above may have helped you navigate the functional equipment of angle grinders, but did not bring clarity and specificity to the selection process. All grinders are initially similar, and you can evaluate the correctness of your choice only during long-term use of the tool. But, nevertheless, let’s try to specify the selection algorithm:

- We determine the required disk diameter - 125 mm is best for home use.

- Based on the operating mode, we determine the power.

- We determine the need and availability of additional functions.

- We are looking for models, proven brands - in fact, everything we select will suit you, but...

- We look at the convenience of their body and the location of the handles.

- Let's get acquainted with the terms and duration of the warranty.

- Let's choose!

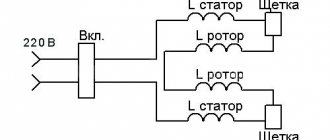

Electrical diagram

Knowing the purpose of the main parts will not give a 100% positive result during repairs.

It is also necessary to understand and understand how the electrical circuit of the angle grinder works and how the electric motor works. The circuit involves two windings, which are connected in series through a power wire to a network with a voltage of 220 V and are not interconnected in the electrical circuit. A mechanically installed switch is connected to the on/off button of the sander. Each of the windings is connected through contacts with graphite brushes. Through brushes, the windings are connected to the rotor commutator. It is also very important that the armature has many windings, but only two windings are connected to graphite brushes, and failure most often occurs due to a break in the electrical circuit. Diagnostics of the electrical circuit of the device is carried out with a special device - a tester. A portable measuring device is used not only in repairing angle grinders, but also for testing other electrical tools and devices.

Proper testing should be done from the input power cable to the elements connected in series. When checking conductivity, the multimeter switch is set to the minimum voltage.

Gasoline cutters

A gasoline cutter is, of course, not an angle grinder and is not intended for home use. But this professional tool allows you to perform some similar operations for separating solid materials, is capable of long-term autonomous operation, and has quite a lot of power.

The petrol cutter is a distant “relative” of the angle grinder along the functional line