Long gone are the days when hay was harvested and turned using a conventional rake. Progress has made the hard work of farming easier, and mowing work has become much easier. Manufacturers of agricultural machinery offer quite effective attachments for hay harvesting. Such equipment is not always affordable for beginning farmers, so many people prefer to make tedder rakes with their own hands.

Application of tedder rakes

After mowing, you should prepare the grass for turning it into hay. This means that it is necessary to form windrows, turn over from time to time, and collect into bales or rolls. Factory or homemade tedder rakes collect the mown grass into windrows and, if necessary, turn them over to dry. To use hay harvesting equipment, walk-behind tractors, mini tractors, tractors and even horses are used. This is much more efficient than working with hand tools. You can perform the following operations:

- raking of mown plant matter;

- tedding the grass;

- windrow wrapping and spreading;

- doubling of arranged rows of rolls.

Do-it-yourself rakes for mini tractors have a number of advantages. The device is more efficient than hand tools, is easily transported to the storage area and takes up little space. Affordable price and no problems purchasing spare parts.

Kinds

All tedders can be divided into several types. For example, rakes differ in the rotation of the working elements when forming transverse and lateral rolls. They are also divided according to the type of working mechanisms:

- wheel-finger, allowing you to make rolls of the required size. This type can only work with dry plant mass and this is perhaps the only drawback. Thanks to the thoughtful design of the rake, tedders of this type are characterized by good performance and are considered the most practical;

- drum or rotary, characterized by structural strength and independent arrangement of raking wheels. They are considered the most expensive models on the agricultural equipment market, but this is justified by their functionality. This type of equipment can not only turn over the mown plant mass, but also form neat windrows from it;

- tooth tedders. Thanks to the design, it is possible to change the angles of inclination of the working elements.

Depending on the type of traction, the equipment can be either tractor or horse. The second type can be used together with a walk-behind tractor. Installation of factory or homemade rakes is possible in three ways:

- trailed (installed on tractors);

- semi-mounted rakes (the most affordable);

- mounted tedders (aggregated with walk-behind tractors and mini tractors).

Rotary tedders are considered the most expensive, so many people prefer to do it themselves, especially since there are no problems with spare parts. They can be purchased in specialized stores or removed from old equipment. Making your own rake is not that difficult; all you need is the desire and experience in handling a plumbing tool.

Features of equipment designs

According to the model type, tedder rakes can be used on tractors, mini tractors and walk-behind tractors. During operation they are operated by one person. According to their technical characteristics, they are classified according to the following parameters:

- By type of traction they are divided into tractor (for tractors) and horse-drawn (for walk-behind tractors);

- according to the method of collecting hay in windrows - transverse and lateral;

- by design (geared, wheel-finger and drum);

- according to the method of attachment to the equipment.

Due to its shape and appearance, the structure is called the “sun” due to the similarity of the rotor tubes to the sun’s rays. There are many models of tedder rakes in factory production, but the most popular are rotary and wheeled.

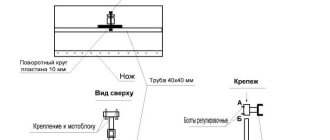

Rake tedder 5 wheels

Rotary rakes are designed in such a way that their basis is one wheel with rotor pipes, on which pin tubes are secured with springs. With the help of these devices, types of work such as tedding and drying grass are carried out. But they are not suitable for windrow collection. The rake is mounted on wheeled tractors and operates using the machine's hydraulic system.

Wheeled tractor tedders are a model consisting of several (4-5) “floating” wheels mounted on a suspension. This type of design makes it possible to work on fields with different terrain. Rotary and wheeled tedders can be used on all types of agricultural machines. Therefore, they often make roller rakes with their own hands.

Interesting. Replacing manual labor using simple rakes with mechanical tedders allows you to increase efficiency tenfold.

How to make a rake on a mini tractor

Making hay harvesting equipment yourself is not difficult. Such equipment is perfect for farmers who own small plots of land and mini tractors. The presented version is designed for use in coupling with mini-equipment and is equipped with 5 raking wheels. Before you make a tractor rake with your own hands, you need to prepare the following materials:

Scheme 1 Scheme 2 Scheme 3 Scheme 4 Scheme 5

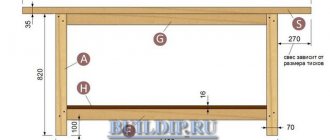

Drawings and approximate dimensions.

- metal pipe (often an old motorcycle frame is used);

- brackets for mounting wheels;

- spring steel wire 4-8 mm thick for raking fingers;

- steel sheets for the manufacture of impeller disks;

- 2 bearings in the hubs for each wheel;

- parts for making a hitch for attaching a do-it-yourself tedder to the power plant.

Mount 1

Raking fingers

Bearing

Mount 2

For hubs, it is best to use hubs from Zhiguli, since they have tapered bearings. This will increase the wear resistance and durability of the chassis. The above figure shows the device. It is necessary to be careful when creating a rotor so that in the event of a possible breakdown it does not cause the failure of the power plant, and also does not cause harm to the health of the person operating the equipment.

The best option when manufacturing a rotor assembly would be to use a rear automobile axle. Properly assembled tedders can greatly facilitate the collection and tedding of dry plant mass, as well as its subsequent baling. Rotary rakes are characterized by gentle handling when harvesting crops such as alfalfa. The use of tedder rakes will minimize losses when harvesting haylage.

Rakes for tractors - varieties, do it yourself

Rakes have always been a necessary hand tool for homeowners. Virtually no land work could be done without their help. They could rake up garbage or mown grass, break clods of earth, and level beds. But their main purpose, then and now, concerns drying and harvesting hay.

With the introduction of technological progress in agriculture, even drying and harvesting hay has ceased to be hard manual labor. With the help of tractor-mounted hay rakes, these labor-intensive processes will no longer take so much time. Let's take a closer look at this type of attachment.

Types of rakes for tractors

Tractor rakes for hay have the same purpose as manual ones - turning over, raking grass, forming windrows of hay. They can be classified according to different parameters - by the type of working mechanism, by the method of fastening and traction, by the method of forming windrows, etc. But still, the main criterion by which tractor rakes differ is by design. There are 3 types of rakes:

Wheel mounted rakes for tractor

This includes the “Sun” type rake, popular among users, which is suitable for mini tractors and heavy implements.

The design allows you to quickly and efficiently turn and rake hay on both sides of the unit. The design provides from 3 to 5 or more tedder impellers.

Also, the advantages of this type of rake for a tractor include:

- ease of use and ease of repair, long service life;

- power and performance;

- The adjustment is hydraulic, the operator can easily and comfortably control the working position of the hitch.

Rotary windrow rake

They operate from the power take-off shaft.

The design is a horizontal disk with metal pipes onto which fingers made of steel rods are attached. Compared to the previous species, they have a slightly limited specialization - collecting hay and forming windrows. Although the hay also moves during the process, air circulation improves. Also, this type of tractor rake is more suitable for fragile types of hay that require careful care (for example, alfalfa).

Belt rake for tractor

More productive and technologically advanced units.

Designed for collecting and turning freshly cut grass and hay. Suitable for tractors with power from 20 HP. s., productivity – about 1.5 ha/hour.

How to make a rake for a tractor?

Making a rake for a tractor with your own hands is not that difficult. A homemade design will differ from the factory one in parameters that are ideally selected for your conditions of use. Before starting production, you should decide on the type of future equipment (wheeled or rotary rakes). First of all, the choice will depend on the type of terrain. Rotary rakes are suitable for flat terrain, as they work at a certain height. On hilly, uneven surfaces it will be easier to work with a wheeled adjustable rake.

You should also acquire drawings, tools and necessary supplies.

Drawing of a wheeled rake of the “Sun” type

To make a wheeled rake of the “Sun” type you will need:

- tools - welding, grinder, wrenches, drill, measuring tools, etc.;

- metal pipes for the frame (you can take a ready-made frame from an old motorcycle);

- wheel brackets;

- wire about 6 mm thick for making raking fingers;

- metal sheets about 4 mm thick for making working disks;

- wheel bearings;

- spare parts for the manufacture of a device for attaching to a tractor.

Advantages

Frame 1 Rake in transport position Frame view from the top Frame and drawbar Rake in working position Rake in transport position view from the front Fastening from the cardan Fastenings Frame 2 Frame 3

The simplicity and strength of the tedder design make it possible to use this type of hay harvesting equipment on almost any soil. The rake teeth and most parts of the unit are made of durable spring steel, thanks to which the rake can work even after being hit by stones. Even self-made mounted tedder rakes on a tractor allow you to efficiently and carefully collect the mown dry plant mass and place it in even hay windrows. The most popular are the “Solnyshko” tedders. This is due to a number of advantages:

- minimal equipment maintenance costs;

- the hinged design ensures a long service life;

- the design has a powerful frame and traction drawbar;

- convenient transfer of equipment to transport or working condition;

- price.

Most farmers claim that thanks to the use of rotary rakes and tedders aggregated with mini-tractors, the loss of dried plant matter during raking is minimized. In addition, the “fingers” on the turner wheels not only beat the hay well, but also turn it over, which improves the ventilation of the windrows and, accordingly, increases the quality of the hay mass.

Types of tedders

The most commonly used type is a hay rake. To harvest it, you need a tool that performs tasks such as raking grass, turning and collecting hay into windrows. These universal tools are turners, which are divided into groups:

- by the nature of manufacturing of the working part;

- by type of traction;

- according to the method of formation of wolves;

- by type of fastening.

By type, such devices for tractors can be divided into two parts:

Tedders Sunshine for a mini tractor

- wheel-mounted (for example, Solnyshko tedder rake);

- rotary.

Wheeled ones usually have 3-5 built-in wheels, located obliquely from each other. This increases overall labor productivity. Using the mounted rake of the tedder increases both the gripping area and the thoroughness of raking the grass, and, accordingly, the speed of work as a whole. A simplified repair of the wheelbase is noted in Solnyshka - tractor tedders and rakes have interchangeable wheels secured by two bearings. The most popular among Solnyshko tedders are the GVK tedder rakes, which allow you to rake windrows on both sides at once and turn hay.

Important How to make a harrow for a walk-behind tractor with your own hands according to the drawing

Among the advantages of the Solnyshko tedders are:

- low level of labor costs for servicing the mechanism;

- mounted tedder rake ensures longer service life;

- have a powerful traction drawbar and frame (more relevant to factory production);

- convenient transfer of the unit to the working or transport position, which is implemented through the hydraulic system by the tractor operator;

- Convenience of adjusting the pressure of the drive wheels.

Tedders for walk-behind tractor

Rotary tedder rake includes horizontally located disks (rotors) that are connected to the engine and rotate under the influence of the PTO. Metal pipes with fingers made of iron rods are attached to the rotors. Like tractor rakes, rotary tedders do their “duties” well, but they also have specialization. Their specific direction is collecting hay into compact windrows.

There are also cross tractor rakes. They belong to the mounted type of turners. Transverse devices are designed for raking freshly cut grass with a wide grip. On average, the grip of such instruments is 12-15 meters. to menu