Due to the peculiarities of their design, groove cutters (also called slotting cutters) are considered multifunctional tools that can be used to form grooves on workpieces of cylindrical and conical configurations. Such technological operations (especially those associated with radial grooving) are characterized by significant loads, which are successfully carried by a cutter of this type, characterized by high structural rigidity. Moreover, groove cutters are successfully used for axial grooving and facing, making them versatile turning tools.

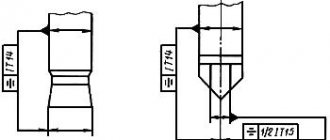

Grooving cutters for internal and external grooves with mechanical fastening of replaceable cutting inserts

It is advisable to use groove turning tools to obtain parts with complex configurations. The versatility of cutters of this type in such cases allows us to minimize the number of tools used and reduce the time for equipment changeover. It is also noteworthy that the use of a groove cutter when performing many technological operations makes it possible to form surfaces with higher quality characteristics than when using a conventional turning tool.

Particularly successful is the use of a groove cutter when creating wide grooves on the surface of workpieces. When performing this technological operation, such a tool demonstrates exceptional durability; wear of its cutting plate occurs evenly even when performing a large number of passes. What is also important is that when using a groove cutter, the chip separation process is well controlled.

Requirements for groove-type cutters, which are produced in a wide variety of standard sizes, are specified by the provisions of GOST 18874-73.

GOST 18885-73 and 18874-73 regarding groove cutters

The contents of GOST 18874-73 “Slotting and parting cutters made of high-speed steel” and GOST 18885-73 “Threaded turning cutters with hard alloy plates” can be found below:

GOST 18874-7

GOST 18885-73

GOST standards for groove cutters

Regulatory documents have been developed for groove cutters of various modifications:

- GOST 18874-73 regulates the standards for cutting and slotting equipment, which specifies the dimensions and design of the tool, which is made of high-speed steel.

- GOST 18885-73 describes the design features of groove cutters for thread production, which are equipped with carbide plates.

- GOST 18884 - 73 - this normative act gives instructions on the size and design of cutting tools for turning, the plates of which are tipped with carbide alloys.

- GOST 28978-91 - the document defines the standard for prefabricated groove cutting tools.

Types of groove cutters

Turning tools for forming grooves include cutters for internal and external machining. Both the first and second can be made entirely of carbide materials or have a replaceable cutting part. Carbide cutters are a fairly expensive tool, so their use must be economically feasible. When performing external work, products with replaceable inserts are usually used; using carbide groove cutters in such cases does not make sense.

The situation is completely different with the processing of internal grooves. Here it is necessary to take into account the diameter of the hole into which the cutter is to be inserted, as well as the rigidity of the tool. The requirements for a cutter to have a minimum size of its holder and sufficient rigidity to perform metal processing are met only by carbide groove tools.

Naturally, when the processing conditions and geometric parameters of the workpiece allow it, it is more advisable to use an inexpensive tool with replaceable inserts to form external and internal grooves.

Damn.1

Damn.1

Table 1

Dimensions, mm

| Cutter section | |

| 4x4 | 4 |

| 6x6 | |

| 8x8 | 6 |

| 10x10 | 8 |

| 12x12 | 10 |

| 16x16 | 12 |

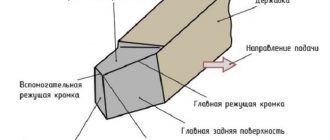

2. Structural elements and geometric parameters of cutting tools are indicated in Figure 2 and Table 2.

Geometry and dimensions of groove type cutters

Since groove-type cutters experience significant load during processing, which determines increased requirements for their rigidity, they are manufactured with soldered carbide plates, the characteristics of which are specified in GOST 2209-82. The requirements for the cutter itself, as stated above, are given in GOST 18874-73.

The main feature of the geometry of groove-type cutters is that the shape of their cutting part must exactly match the shape of the groove that is planned to be obtained with their help. The grooves created on the surface of the workpiece are usually small in width. Accordingly, the cutting part of the tool with which they are formed is also quite narrow, which makes it very vulnerable to mechanical damage. In addition, the working head on each side has a narrowing towards the holder (by 1–2 degrees). Such a narrowing of the sides of the cutting part is necessary in order to reduce their friction against the walls of the groove being formed.

Geometric parameters of the groove cutter

To increase the strength of the cutting head of a groove turning tool, its height is made significantly larger than its width. This also requires a small rake angle and a sharpening of the cutting edge with a small radius (curvilinear). The optimal cutting angles for groove-type cutters are 15–250 (front), 8–120 (rear).

The width of the working part of the groove tool, which, according to the requirements of GOST 18874-73, can vary over a wide range, is selected depending on the width of the groove that needs to be formed on the outer or inner surface of the workpiece.

Selection rules

The first thing you should focus on when choosing a groove turning tool is a drawing of the finished product, which indicates both the dimensions and shape of the grooves, as well as the tolerances for the accuracy of their geometric parameters. Naturally, the choice of cutter and its geometric parameters is influenced by the material from which the workpiece is made.

External groove cutter

When forming grooves on small parts, it is especially important to maintain a low cutting force, which minimizes the distortion that occurs during processing. Compliance with this requirement is ensured by the sharp sharpening of the groove tool, which, however, can lead to its breakage if the carbide plate material and cutting conditions are selected incorrectly - the rotation speed of the workpiece and the feed rate.

When choosing a groove cutter, you should also take into account the shape of its cutting edge, which can be straight and sharpened with a small radius. Naturally, you should not choose a product with a curved sharpening of the cutting edge if the bottom of the groove, according to the provided drawing, should be straight.

Internal groove cutter

Types of cutting tools

The cutting cutter - cockerel - is so named due to the unique geometry after sharpening. For the first time, the cockerel turning cutter was used by I.K. Evseev, the essence of his rationalization proposal was to reduce the width of the chips compared to the width of the cut. The chips will not be able to wedge - the likelihood of destruction of the cutting edge is reduced. The operation is performed faster, no increase in spindle speed is required. When installed with the cutting edge down, the chips fall onto the bed and do not require active operator intervention.

The VK8 cutting cutter is used for processing steel and cast iron; it has increased strength and temperature characteristics and good cutting speed.

VK8 is a hard alloy (tungsten carbide 92%, cobalt 8%) used as a coating for tools cutting stone, metal, granite. GOST 3882-74, developed back in the USSR, regulates the physical and mechanical properties and percentage of components.

Download GOST 3882-74

When choosing a cutting tool for metal, you need to consider a number of factors:

- material to be processed;

- intensity of work;

- specifics of workpiece processing;

- degree of wear of turning equipment.

Tools made of high-speed steel cannot be used to process hardened workpieces and steel with a high viscosity coefficient - the working surfaces will quickly crumble and restoring them will be problematic, and the cost of new ones is high. For working on CNC machines, the best choice would be carbide cutters that can withstand temperature loads well, which will almost always be present in the processing cycle. When working on old, worn-out equipment with large backlashes and runouts, it is better to use prefabricated cutters; they are easier to sharpen and change.

Features of turning using a groove cutter

The cutting modes when using groove-type cutters have some differences from the modes of processing the workpiece with other types of turning tools. Thus, the depth of cut is taken to be a value equal to the width of the groove being formed, and the tool feed per revolution of the part is measured in the direction perpendicular to its axis. The feed rate, depending on the material from which the cutting part of the groove tool is made, is selected in the range of 0.07–0.2 mm/rev, and the cutting speed is 15–180 m/min.

Several types of grooves can be obtained on the surface of the workpiece.

- Narrow grooves, the width of which corresponds to the width of the cutting part of the tool, are made in one pass of the cutter, which is fed manually. Before this, the exact location of the groove is determined on the surface of the part, and then the cutter is placed opposite this place and fed.

- The grooves on the ledges and ends of the part are made according to the same principle; their diameter is set using the transverse feed dial, and their depth is set using the longitudinal movement dial of the caliper.

- Wide grooves are made in several passes according to the following scheme. First, determine the location of the right edge of the groove and place the cutter opposite this location. Using a transverse feed, the cutter is cut into the part to a depth that is 0.5 mm less than the depth of the groove being cut (this allowance is left for finishing). Then, using a longitudinal feed, the groove tool begins to move to the left edge of the groove being cut, the boundary of which has been previously marked. After the rough groove is formed, its bottom is processed cleanly - to the required depth, carrying out the longitudinal feed of the cutter from left to right. In the event that it is necessary to form a groove with a very precise location of its left and right edges, allowances can also be left on them during roughing, which are then removed using the transverse feed of a groove or scoring cutter.

Types of work performed by grooving cutters

Cutting cutter

Main Dimensions

| Height, mm | Width, mm | Length, mm | Marking |

| 12 | 12 | 100 | VK8 |

| 12 | 12 | 100 | T15K6 |

| 12 | 12 | 100 | T5K10 |

| 25 | 16 | 140 | VK8 |

| 25 | 16 | 140 | T15K6 |

| 25 | 16 | 140 | T5K10 |

| 32 | 20 | 170 | VK8 |

| 32 | 20 | 170 | T15K6 |

| 32 | 20 | 170 | T5K10 |

| 40 | 25 | 200 | T15K6 |

| 40 | 25 | 200 | T5K10 |

Geometric parameters of cutting tool

The cutting cutter has its own unique ratio of parameters in the shape of the cutter. It is designed for cutting workpieces as quickly as possible, even if we are talking about a relatively large size. Because of this, the cutter has a large overhang. But often they are made quite thin, which has a bad effect on rigidity. The only way to strengthen it is to change the composition of the plate itself so that it is made of strong materials. Externally, they stand out quite strongly due to their oblong shape.

photo: geometric parameters of cutting tool

Choosing a parting cutter

Cut-off cutters for a lathe can quickly break if chosen incorrectly or used for other purposes. First of all, it is worth noting that for constant use you need to select something made of carbide materials. The VK8 cutting cutter will be cheaper, but it can only be used in cases where the need for these operations arises periodically.

“Advice of professionals! For automatic equipment, only an automatic cutting cutter should be selected.” But there are also several differences among carbide types that help provide better resistance to shock or vibration or resistance to high temperatures. Thus, one of the main principles of choice is what materials will have to be interacted with. It all depends on the characteristics of the material and workpieces with which you will have to work. To improve results, you must follow the correct regimen.

Cutting modes when using a cutting tool

Metal cutting tools should be placed exclusively at right angles to the axis of the part being processed. The cutting edge is set higher, within 0.1-0.2 mm, than the workpiece being processed. If you install the edge cutter lower, then there will be an unprocessed protrusion at the end of the part. The distance from the machined end in the bar to the end of the fastening device should not be greater than the diameter of this same bar.

Taking into account the fact that cutters of this type have low strength, workpieces should be cut using a curved tool with the cutting edge directed downwards. In this case, the spindle should be rotated in the opposite direction. This is especially true when working on old, worn-out machines.

The cutting process should be done as close as possible to the part that is responsible for fastening. When cutting brittle material, indentations may appear on the surface where the cutting occurs. This means that the part broke off during the cutting process. To prevent this from happening, you should not increase the cutting speed, and the process itself should be done very gradually.

Marking

The marking of cutting cutters is based on the material used to make their cutting insert. For example, T15K6 is classified as a hard alloy material in the titanium-tungsten group. The content of titanium carbide reaches 15%, and cobalt – 6%.

Labeling and manufacturers

The description of groove turning tools will be incomplete without mentioning the markings, which determine the composition of the material of their cutting part. For example, the T5K10 cutter is made of a hard alloy of the titanium-tungsten group, which contains 5% titanium carbide and 10% cobalt. The markings of products made from other materials are deciphered in a similar way.

The most famous manufacturers of grooving turning tools are:

- Dnepropetrovsk industrial tools plant (Ukraine);

- (Ukraine);

- Zenitech company (Switzerland);

- Proma company (Czech Republic);

- Itertool company (China).

Marking

The marking describes the main mechanical and physical parameters of the tool. For example, 2130-0255 VK6 GOST 18884-73 says that this is a groove cutter, corresponds to GOST 18884-73, right-handed in version 1, with a cross-section of 25X16 mm and a plate made of VK6 hard alloy. Unlike a conventional cutting cutter according to GOST, the groove cutter is distinguished by the presence of a plate with VK6.

Download GOST 18884-73

The cutting cutter according to GOST 18884-82 has an even more high-strength plate made from VK8 alloy or harder. Such tools can be used in automatic mode. You can select a product with the required parameters using the appropriate reference books.