Features of arranging a cellar for storage

Cellar shelves are made as separate sections installed on the walls of the storage room.

Such designs are easy to install and use. It is customary to choose the width of the rack depending on the volume of installed cans, taking into account a small margin. In order for self-made shelves in the cellar to serve for a long time, you need to make them no more than 70 cm in length, otherwise they will sag. During the production of special shelving and installation of shelves, it is necessary to maintain the ability to access the wall part. This will simplify the process of summer drying and preventive work in the underground area. Before you can make shelves in your jar cellar, you need to make a supporting structure.

First of all, a transverse horizontal frame is made; for this, marks are made on the racks indicating the height of the shelves. The bars are cut to a width of 60 mm and a length equal to the length of the future shelves. The strength of the future structure and the load that the shelves in the cellar will withstand depend on the chosen width. The installation of shelving involves cutting out nests or grooves corresponding to the size of the bars. After this, the structure can be assembled and secured. As shelving, shelves made of wood or plywood are placed on a frame made of bars.

Important! Before arranging and placing shelves in the cellar, all material should be thoroughly treated with an antiseptic solution. Otherwise, rapid rotting of the racks is possible.

Advantages of a rack storage system

- It is not expensive. Unlike cabinets with walls and doors, the rack has a more affordable price with the same capacity.

- It's comfortable. It is easy to place many things on the shelves and adjust the position of the shelves themselves depending on the items stored.

- It's reliable. The shelves can withstand weight loads of up to 100 kg, and when the structure is built up, it can be reinforced with additional racks.

- It's aesthetically pleasing. Instead of things piled in a corner or a pile of boxes, install a shelving unit to keep things organized while keeping the items you need within easy reach.

- It's universal. The design is suitable for storing any items - from file folders to jars with homemade ingredients.

Dimensions. They affect the capacity of the storage system and how much space it will take up. For example, there are models with dimensions 1800x600x1800 mm, 2000x1000x400 mm, 2500x1000x500 mm. Pay attention to the shape - the structure can be extended in width or height.

Number of shelves. The prefabricated rack can be supplied complete with 3 – 4 shelves. Additional ones are purchased separately along with reinforcing elements, if the extension is provided for in the design.

Maximum load per shelf. Can range from 100 to 350 kg. Depending on what items you plan to store, choose the appropriate option.

How to assemble it yourself

To assemble the wooden version yourself, you must first make a design drawing indicating the dimensions. And only then, depending on the purpose of this piece of furniture and the intended design, you can begin to select the appropriate material.

To make the drawing accurate, it is recommended to correctly measure the place where it will stand. If this is a structure for storing canned food or tools, then it is better to give preference to simple and reliable forms. More often it is done to the full height of the wall. While the width of the shelves will depend on its contents. The length of the shelves also depends on what will be stored on them. If these are heavy items and you need to withstand a large load, it should be no more than 0.9 m. Whereas for light items, the length of the shelf can be about 1.5 m.

Material selection

Shelves can be made from a variety of materials, be it metal basement shelving, plastic shelving, or even concrete shelves. The rest of the article will discuss the most popular materials for manufacturing, as well as how to create the required basement microclimate.

Wood

Coniferous wood, kept in good conditions, can last a long time. Since cellars have high humidity, and any type of wood swells easily, after a certain time they can rot and collapse.

If you watch a lot of useful videos about the basement and the necessary materials, you can understand that deciduous tree species will last much longer than others. However, not a single species for making shelves in the basement will last the required time without being treated with special solutions to combat mold and mildew.

Chipboard or plywood

Basement equipment made from this material, unfortunately, will not be able to withstand too much load. The manufacturing features of such shelves come down to the load that they can withstand, so you should use material such as plywood or chipboard sheets only for small containers.

Important! Wood, including chipboard and plywood, are highly hygroscopic and therefore vulnerable to the effects of humidity and dampness in the basement. For this reason, treatment with special liquids is required.

Metallic profile

This design option is the most practical and reliable, despite the fact that the metal is highly susceptible to corrosion. Theoretically, corrosion of each shelf should ultimately lead to its unusability, however, practice shows that this happens for a very long time, so much so that you don’t even have to worry and safely choose a metal corner for mounting racks and shelves made of steel. For durability, the shelves can be treated with some kind of anti-corrosion coating.

Durable plastic

When making shelves in the cellar, some people choose plastic ones instead of wooden ones, which have good accessibility and ease of installation. The low weight and strength of the structure attracts many, but it is important to understand that temperature changes together with excess humidity will ultimately lead to a loss of strength of the material and final unusability.

Concrete

This is a durable and reliable material that allows you to make a structure for a very long time. The downside is the difficulty of working with concrete: you need to calculate everything in detail, since after that it will be impossible to make corrections. Concrete shelves allow you not to think about how much the food and its bones that will be stored on them weigh.

Brick

Brick shelves are made in accordance with all bricklaying standards during house construction. The advantages are durability, strength and an excellent addition to the interior. The only downside of brick is that without special skills it is very difficult to make such a shelf yourself.

Slate

Flat slate is extremely rarely used for making shelves in the basement, but you can cut out the elements necessary for the shelf from it, and then assemble them together as a construction set. The material does not withstand heavy loads, but such shelves can be strengthened by welding strips between the fastening corners across the entire width, maintaining an interval of half a meter.

Advantages of Prefabricated Metal Shelving

The principle of connecting parts on a metal rack

Metal collapsible shelving is used in homes, offices, shops and warehouses.

Their popularity is due to such advantages as:

- Easy to install and dismantle. In order to assemble a metal collapsible rack, you do not need to attract specialists and pay them money. You can do everything yourself, and even in the absence of relevant experience.

- Ability to withstand heavy loads. By itself, metal is difficult to damage or bend. The average load on one shelf is calculated from 90 kilograms.

- Affordable price. Especially considering the fact that all assembly and installation work will be carried out independently. The raw materials for manufacturing are very cheap, as are all the necessary components.

- Durability. Few materials can compare with metal in terms of durability. The only difficulty you should be wary of is direct contact with water, but this can also be avoided if you use special polymer dyes.

- Good aesthetic qualities , especially considering that the design and project will also be developed independently.

Adjustable brackets are installed on the racks of some shelving models. This feature allows you to set the required height distance between the shelves.

When choosing a rack, you need to take into account such product parameters as:

- Dimensions

- Form,

- Number of shelves

- Color and design,

- The metal from which it is made is

- Coverage quality.

The strength of the structure and its ability to withstand heavy weight depends not only on the quality and type of material used, but also on the thickness of the beams, the shape of the pallets and shelves, and the distance between the supporting posts.

Racks must not only withstand the weight of objects placed on them. They must be resistant to chemical and mechanical influences. You can find out what load the rack is designed for by reading the documentation that is always attached to such products.

Advice! It is better to purchase racks with a safety margin. If you are going to store items with a total weight of about 100 kg on the shelves, then the rack should be strong enough to withstand all 125 kg. This will ensure a long service life and help prevent the possibility of shelves collapsing and destruction of the entire structure.

Types of structures

The manufactured structure can be of several types, each of which should be considered separately.

Team

The “constructor” principle works here, that is, the shelves are assembled according to parts. They are easy to install, functional and mobile, but they are not able to withstand heavy weight. The material for such a structure can be anything - wood, plastic, slate or plywood, but most often a metal profile or square pipe is used. The material is cut into pieces of the required length to prepare the shelf parts, namely:

- columns;

- cross jumpers;

- connecting supports;

- slats for shelving.

The resulting parts are attached to each other by welding. They can also be connected using corners, but in this case the structure will already be collapsible (the next type).

Collapsible

These structures resemble prefabricated ones, but differ in that they require the possibility of disassembling and reassembling the racks. For example, they can be disassembled for drying, disinfection and preparation of storage for storing vegetables. The collapsible model can be made from any materials, but plastic is most often used. As a rule, parts are sold unassembled. So, a home craftsman will only need to select a structure of the desired size and shape, and then assemble it in the cellar, securely fastening all the parts together using hinges, corners and bolts. This design will also be durable and reliable.

Monolithic

Such shelves cannot be disassembled and, unlike prefabricated structures, are not mobile, that is, they cannot be rearranged. Most often they are made of brick or concrete. In this case, the entire structure is mounted immediately in the place where it will stand in the future. Collapsible structures are in great demand, since in this case the shelves can be pulled out, washed and disinfected at any time.

Radial

Such racks can be semicircular or rounded. They are most often located in the corner. This is convenient because there is more free space for moving and storing boxes of vegetables.

Options

The most popular material for making shelving is wood. Thick bars will allow you to easily build a strong rack on which all the cans can be conveniently placed. The advantages of this material include accessibility and low cost. Working with such material is quite simple; it is enough to have only basic knowledge. The downside of such racks is their fragility. Due to the impact of moisture on the racks, they deteriorate very quickly and require regular repairs.

Angle steel racks are more durable and reliable. However, this material is subject to corrosion, which cannot be ignored when choosing material for shelves. When making racks from steel angles, you may have to use welding, and this is not always available. The same applies to steel shelves.

Shelves made of multilayer plywood or chipboard. These shelves are suitable for storing small cans. A tub of pickled tomatoes will bend the shelf, and maybe even break it. This material is also afraid of moisture and does not have a long service life.

Concrete shelves are positioned as the most durable and durable. These shelves will last your home for generations. Making such shelves will require a lot of time and physical effort. But the result is worth it.

Another available material is plastic. Shelves made of it are impervious to the microclimate of the room, but have their own disadvantage - they cannot withstand heavy loads.

What tools and materials will be needed

To make shelves for storage in the cellar with your own hands, all you need is a classic carpentry set of tools.

- screwdriver or hammer;

- screws or nails;

- file or saw;

- sandpaper or grinder;

- measuring instruments (ruler, tape measure, pencil or marker for marks);

- soldering iron (for working with metal).

As for materials, this point is individual for each master. The fact is that you can make shelves in the cellar with your own hands from any repair surplus forgotten in the garage. Wood, metal profiles, plastic window sills - to create a storage space you can resort to various tricks. If the owner purchases new materials for the project, then it is necessary to build on preferences, available money and the properties of the source material.

As many experienced craftsmen admit, the most suitable material for a cellar remains plastic and its derivatives. Durable and durable, it is not afraid of moisture and cold. The high cost and rarity of source materials can, however, frighten the owner.

How to make a rope rack with your own hands

These stylish shelving units are easy to make: just attach the shelves to ropes and hang the structure. The only problem is that they are not very stable: if you touch them carelessly, things can fall down. To avoid this, place the shelving away from aisles or additionally attach the bottom shelf to the wall.

What do you need

How to do

Soak thick rope in hot water to straighten it.

Shot: Living to DIY with Rachel Metz / YouTube

Drill four holes in the corners of each board - the rope will pass through them.

Shot: Living to DIY with Rachel Metz / YouTube

Sand the boards with sandpaper.

Shot: Living to DIY with Rachel Metz / YouTube

If desired, paint future shelves.

Shot: Living to DIY with Rachel Metz / YouTube

Lay the thick rope straight and let it dry. Cut into two equal parts. Fold each one in half to make a loop. Secure the loops using thin sisal or jute rope.

Shot: Living to DIY with Rachel Metz / YouTube

Measure equal distances on thick ropes and secure the shelves with knots.

Shot: Living to DIY with Rachel Metz / Youtube

Attach anchor hooks to the ceiling. To do this, drill a place for fastening with a hammer drill. Important: the depth of the hole must match the length of the spacer part of the anchor hook, and the diameter of the drill must match the diameter of the anchor. Hammer the anchor into the hole and tighten the spacer nut. Hang the shelving unit.

Shot: Living to DIY with Rachel Metz / YouTube

What other options are there?

You can diversify the appearance of the rack, for example, by threading ropes through the holes in the shelves crosswise:

How to make it yourself

To save time, you can buy ready-made shelves, but it is much cheaper to make them yourself using wood or metal.

The production technology includes several stages:

- Making supports: for this purpose you can use thick wooden beams, metal pipes or profiles. It is important to consider that the thickness of the column must be at least 7 cm. The number of supports is calculated individually, depending on the desired dimensions of the structure.

- Cross bars (about 4 cm thick) are attached to the posts using self-tapping screws, nails, corners or hardware. Fasteners are chosen based on personal financial capabilities. However, it is recommended to select reliable fittings so that the finished structure can withstand the weight of cans with blanks.

- Attaching the shelves is the final stage of construction. They can be made from wooden planks or sheet metal.

Before final assembly, do not forget to treat all structural elements with compounds against fungus and mold, or anti-corrosion compounds.

When assembling the rack, it is not recommended to install it close to the walls of the cellar. Otherwise, the structure will begin to collapse. When designing and installing racks, supports and other structural elements are calculated, and it is recommended to adhere to the following recommendations:

- Vertical racks are made using timber with a cross-section of at least 100x100 mm, while the use of a round, profile pipe capable of withstanding similar loads is allowed.

- The height of the rack with shelves should be equal to the height of the basement. Even in cases where the shelves are not planned to be placed at full height, it is better to make a full support.

- You need to make marks on the vertical posts where the shelves will be installed. The crossbars themselves are mounted on bars, which are nailed to the racks.

- Grooves are made in the racks where the support bar will be installed - this will increase the strength of the structure.

- Since wood is susceptible to rotting, it is treated with special antiseptics or drying oil, as well as insect repellents.

- To create better conditions and keep the shelves the way they originally looked, it is worth drying them every year in the sun and re-treating them with impregnations.

Metal or combined racks

Metal rack with MDF shelves.

If you have the opportunity and skills to work with welding, then you can make a metal rack for your garage, greenhouse or balcony. In addition, recently a metal shelving unit has become an indispensable piece of furniture in various styles, such as loft, hi-tech, modern.

Suitable material can always be found in the garage or purchased at an affordable price. The frame is made mainly from a corner, the cross-section of which is selected based on the mass of the expected load.

For lighter structures, a perforated galvanized profile is used, which is much easier and more convenient to work with. The instructions for assembling shelving from a profile are understandable to the most ignorant person in this area. The technology for manufacturing a metal structure is similar to assembling a wooden rack, only welding or bolted connections are used instead of self-tapping screws.

Shelves for heavy things are made of sheet metal or boards 40–50 mm thick. Masters of artistic forging and welding fill the side walls of the racks with openwork patterns made of wire or strip, but if this is not possible, then the ends can be covered with the same chipboard or MDF, clapboard, planed board.

A DIY corner rack will cost an order of magnitude cheaper than something ordered or purchased ready-made. In addition, if you show your imagination, you can get an original design product that can become a source of pride for the author.

Concrete shelving

As mentioned above, concrete shelves are the most durable and reliable shelves in the cellar. To make such racks with your own hands, you will need metal rods, reinforced mesh, cement mortar and boards, as well as plywood for formwork.

At the first stage, we install the reinforcement into the wall. To do this, we hammer metal rods into the cellar wall at a distance of 40-50 cm from each other. These rods will serve as the basis for future shelves.

After the reinforcement is installed, we begin the formwork. To do this, we nail the sides of wooden boards onto the plywood, lay a reinforcing mesh on the bottom of the resulting “boat,” after which we fill it all with concrete and wait for it to harden. If the weather is dry and warm, it will take 2 days for complete hardening.

When the concrete hardens, the formwork is removed. We install the newly made shelf on metal rods. This concludes the manufacture of a concrete rack with your own hands.

How to make a wooden shelf with your own hands

It is not always possible to solve the problem of storing things simply by purchasing furniture or equipping a dressing room.

Old apartments could not be imagined without bookshelves. They put small trinkets and watches on them. Now this piece of furniture is somewhat outdated. Moreover, with the development of fashion for modifying housing space, sometimes there is simply nothing to attach them to. Plasterboard floors simply will not withstand this. The solution to this problem is to make a shelving unit. Read also: How to make a toy rack with your own hands

Wooden shelves and racks

Wood is one of the easiest materials to process, but, unfortunately, it also deteriorates easily and quickly.

High humidity is the main enemy of wood; under the influence of damp air, the structure of the wood deteriorates, expands, and accordingly, the product is deformed.

And since the humidity in the cellar is very high, the rotting process occurs even faster. But wooden shelves have a number of advantages:

Easy handling and installation of shelving. A minimum set of tools and minimal skills are required. Even a beginner can handle building a wooden shelving unit.

Cheapness of the material and its availability.

Strength. A wooden structure can withstand significant loads, naturally if the proportions are respected.

Wooden shelves can be easily removed and taken out of the cellar to dry.

The basic rule when working with wood is maintaining proportions. The height of the racks can vary, but usually they are made up to the ceiling.

The supports can be made from wooden blocks 10 cm thick or from metal slats, then you get a prefabricated structure.

Its advantage is that if the wooden elements have deteriorated, they can be replaced with new ones without dismantling the entire structure.

The width of the surfaces should not exceed 70 cm, if more, then deflection and deformation of the structure is possible.

Wooden shelving will last longer if it is periodically impregnated with drying oil and other compounds that allow the structure of the material to be preserved for as long as possible.

How to make a classic shelving unit with solid walls

Classic shelving is reinforced with a solid frame on the outside, and sometimes also with a back wall. This design will withstand heavy loads, such as full shelves of books.

What do you need

How to do

Unfold the plywood sheets and battens onto the following elements.

Let us remind you: if you do not have a circular saw, you can cut the elements to the desired size at a hardware store.

Frame: The Home Depot / YouTube

Mark under the shelves on the side walls. Using a pencil and ruler, place marks at a distance of 8, 36, 72, 108, 144 cm from the bottom edge.

Frame: The Home Depot / YouTube

To install shelves, prepare holes for fasteners. If you don't want the screws to be visible, use a jig and drill holes in the shelves at a sharp angle. If there is no jig, drill through the outer side walls of the rack at right angles along the marking lines from the previous step. In both cases, step back 5 cm from the edges.

Frame: The Home Depot / YouTube

Assemble the outer frame with nails and reinforce the joints with confirmats. Place the shelves along the marking lines and screw the euroscrews into the pre-prepared holes.

Frame: The Home Depot / YouTube

Manufacturing of metal shelving

The undeniable advantage of metal racks is their lightness and compactness. At the same time, they are very durable and wear-resistant. The corrosion resistance of the rack can be easily increased by painting or galvanizing.

Option for making a rack from a perforated metal profile.

If you have no experience with welding, you can easily get by with a hacksaw, screwdriver, screwdriver and tape measure (in this case you will need to purchase a perforated angle). The manufacture of a metal rack begins with calculating its dimensions.

In order not to lose sight of anything, we recommend drawing a sketch of the future shelving on paper. After this, you count how many identical parts you will need, and start sawing them off, cutting them out, etc.

Don’t forget about the saying “Measure twice, cut once,” so be careful in your calculations.

To make a standard rack 2 m high, 1.5 m wide and 40 cm deep, you will need the following parts:

- 4 vertical posts 2 m long.

- 4 pieces of corner for the back and front, the length of which is 1.5 m.

- 4 side crossbars 0.4 m long.

To avoid bevels when cutting, carry out the procedure on a flat surface, laying the pipes horizontally.

After the sections of the required length have been prepared, fitting assembly is carried out. To do this, the main racks (2 m) are laid horizontally, with the rear and front parts of the frame placed between them. If all the pieces are the same length, then you will have no protrusions or gaps between the posts and the frame. If there are still errors, trim the pipes again.

It is recommended that metal racks be secured to walls to prevent them from tipping over. Therefore, the back of the rack is attached to the wall using brackets.

At the first stage of making a rack, the frames are assembled with your own hands. To do this, you will need corner fasteners into which the side and rear/front frames will be installed. The assembled frames are then attached to the vertical posts.

At the final stage, the shelves are installed. They can be cut from chipboard, plywood, steel sheet, metal, etc. They are fastened with self-tapping screws.

A more complex design made of metal profiles. Click to enlarge.

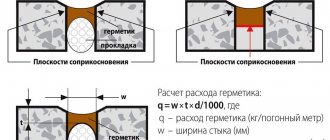

Once the shelving unit is securely attached to the wall with brackets, caulk the mounting points to make it even more durable.

Development of a model for self-production

To begin with, the idea of a rack needs to be depicted in a drawing. To do this, the space allocated for it must be measured and drawn to scale on graph paper. Then the shelves are drawn, tied to the actual size and taking into account what will be stored on the rack.

If heavy items, such as spare parts or tools, will be placed on it, you should not make the shelves too long so that they do not sag over time. Their length should not exceed 1 meter, and they can be additionally reinforced with a metal profile.

If the rack is installed from wall to wall, then you need to decide which design to choose:

- a static option from wall to wall is possible, with shelves fixed directly to the walls. This solution has several disadvantages, and the gain in space is small;

- It’s better to make an autonomous structure, then if necessary it can be moved. In this case, the drawing leaves at least 15 cm of space to the wall, maybe even a little more, so that it can be placed and, if necessary, moved.

Even if light weight items are placed on the shelves, they should not be made longer than 1.5 m, otherwise they will begin to sag.

The rack can be designed as a built-in cabinet or directly in it.

The shelves themselves should not be too deep so that all things can be easily reached. In general, having several rows on shelves very quickly begins to tire, especially when you have to put everything out in order to find what you need. Therefore, the depth of the shelves should not exceed half a meter.

The height of the shelves is also worth thinking about separately. It can be a distance from 30-40 cm to 50-60 cm. This value depends on the dimensions of the things; you need to immediately plan what will stand and where. The height of the shelf should be at least 7-10 cm higher than the tallest item that will be placed on the shelf, then it will be convenient to get it out.

The simplest rack is suitable for a garage or pantry; if the product will be placed in the rooms, you should consider a more elegant design solution - finishing, configuration, and the presence of decorative details.

All calculations should be schematically reflected on a scale grid in compliance with proportions. Then simply measure the dimensions of the components, make an approximate layout of the material and get to work.

Below is a diagram of the assembly of the simplest rack, the main parts of which are support frames and shelves.

Rack made of polypropylene pipe

Polypropylene pipes are a modern material that is actively used in summer cottages. Thanks to its composition, it is not afraid of temperature changes, exposure to moisture, and is also easy to use.

The only difficulty is the possible lack of starting materials and special equipment. However, tools can be rented and materials can be purchased on sale or at stock prices.

Algorithm for creating shelves in the basement for cans from polypropylene pipes:

- Take measurements of future sections. Pipe No. 32 is suitable for production. “Tees” are used as connections for external fasteners, and “crosses” for internal fasteners.

- Fix the required number of pipes.

- Install the structure.

- The final stage is laying the flooring. Any material is suitable here - plastic, plywood, wood, etc. It is noteworthy that polypropylene is organically combined with PVC window sills.

Pipe sections last for many years, and their production takes 2-3 hours. At the same time, the design is not afraid of flooding and is easy to maintain. To reduce the financial burden, order material from recycled materials.

Preparing tools

To complete the work you will need the following tools:

- construction pencil (a regular one with a soft lead will do);

- tape measure (preferably with millimeters, or at least with half-centimeter marks);

- jigsaw;

- drill (drills with a diameter slightly smaller than the diameter of the screws and a drill with a diameter slightly larger than the screw head);

- a grinder with attachments or rings with different grains;

- self-tapping screws;

- crosshead screwdriver;

- hammer;

- a set of skins with different grains.

You also need to buy brackets to secure the shelves or metal corners.

To process wood, you need to buy special liquids, for example, with fire-bioprotective properties, stains of the desired shade, varnishes. Varnishes can be purchased immediately with the desired shade, there are also colored ones: green, blue, etc.

How to protect from moisture

Moisture is the main enemy of the cellar. This room often has high humidity. For this reason, a lot of effort should be made to protect the shelves in the cellar from the negative effects of moisture or, at least, slow down the destruction.

So, today there are special antiseptics that can be used to coat wood. Often the material should be coated in several layers. This will create a good moisture barrier. This is about wood. Metal shelves/racks must also be protected from moisture. For this, special primers and paints are used.

Advice! One of the common problems of many cellars is the formation of fungus and mold. It can go on the shelves. Therefore, it would be a good idea to treat all the shelves in your cellar with an antifungal compound.

How to extend the life of shelves in the cellar?

In order for the installed racks in the basement to serve for as long as possible, a number of simple rules should be followed:

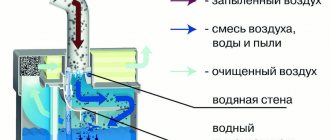

- It is necessary to ensure good operation of supply and exhaust natural ventilation, which directly affects the maintenance of temperature and humidity in the basement.

- The basement, underground or cellar needs to be ventilated and dried well every summer, when supplies are minimal. To do this, the room is left open for 10-14 days.

- If possible, all shelves and racks are taken outside, washed with soap, and then left to dry.

- Metal shelves are cleaned of rust and then painted.

- To avoid the appearance of rusty deposits on cans, it is recommended to cover metal shelves with cardboard or film. At the same time, such protection will prevent the appearance of rust.

- Before treating wooden shelves to prevent them from rotting, they must be thoroughly cleaned of dirt and mold. Only then are they disinfected and coated with special antiseptic compounds. Before installation, they need to be soaked in drying oil.

- If the room is too humid, it is recommended to whitewash the walls with lime several times a season.

- It is necessary to place supplies evenly on the shelves of the racks to avoid overloads and possible collapses.

Copper sulfate

Copper sulfate solution is one of the most effective products used for treating surfaces in basements and cellars. The substance is inexpensive. Preparing the solution is very simple. Blue crystals simply need to be diluted in water, following the instructions on the package.

After this, it can be used to treat walls, metal or wooden shelves. If possible, the racks should be processed in the fresh air. If this is not possible, disinfection should be carried out using personal protective equipment.

Surfaces in damp rooms should be treated annually. This is usually done towards the end of summer, before harvest.

Antiseptics

Often, special antiseptic compounds are used for treatment, which can be purchased in specialized stores. They can be used to treat the entire room, as well as individual areas or shelving.

The peculiarity of antiseptics is that when working with them, you must read the instructions and pay attention to the details. In some cases, the surfaces must be moistened before work, in others, on the contrary, they must be dried well. If you follow these simple rules, you can maintain order in both a small and large cellar.

Impregnations

These compounds penetrate deep into the material and are best suited for combating fungus and mold. If a person plans to build shelving with his own hands, then they should be used to process new shelves.

There are a large number of impregnations that are suitable for different materials. So, you can find means to protect racks from:

- wood;

- bricks;

- concrete;

- metal

They all work effectively and allow you to forget about problems such as mold or mildew. It is recommended to carry out treatment with such impregnations not just once, but after a certain period of time. It all depends on the material.

But not only the processing of shelving helps to keep the underground clean and keep all products in good condition. In order for the shelves to remain reliable and durable longer, you should adhere to a number of rules.

- Make a high-quality ventilation system. If there is good air exchange in the basement, the risk of fungus and signs of rotting will be reduced there. If the location of the cellar allows, it should be regularly ventilated during the warm season. In the summer, it is also recommended to free up as much space as possible from old stocks. This is done not only to free up space for potatoes and other preparations. In such conditions, the shelves will dry out better, excess moisture will disappear, and fungus and mold will die. By autumn, you can safely bring a new crop into the basement.

- Wooden shelving should be inspected regularly. As soon as traces of rot appear on them, they must be treated immediately. In this case, it is necessary to disinfect not only a separate area, but also the entire shelf. After using the antiseptic, the rack must be thoroughly dried and only after that the workpieces must be returned to their rightful place.

- Don't overload the shelves. When arranging a cellar, you need to calculate the location and size of the racks so that all the products can be placed there, even if the year turns out to be unusually fruitful.

- To avoid rust on cans, steel shelves should be additionally protected. You can use self-adhesive or regular film.

By following these simple tips, you can always keep your basement clean and not worry about the condition of your shelving, which will definitely not be damaged by mold or rust.

How to make a wooden shelving unit for your apartment with your own hands

To make such a useful and beautiful product, first take careful measurements. This way you will understand what you can get as a result. Then make a drawing, taking into account the height, width of the shelves, and how the rack is placed. The height can be from floor to ceiling or significantly lower. The width depends on what exactly you will place. Shelves that are too wide are a waste of material, and objects that are narrow will fall off.

The length of the shelves also matters. For example, books and preserved food are very heavy, so the size of the shelf in such cases should not exceed 0.9 m. In other cases, a length of up to 1.5 meters is possible.

The fastening (screws) also needs to be selected taking into account the expected load from 30 to 90 mm.

After constructing the drawing, you calculate the material and fasteners. Buy everything and prepare the tools.

The product can be either stationary or portable, when it can be moved to any place in the room. This is convenient if you like to make rearrangements. If desired, it is possible to make a corner rack.

You will need the following tools and materials:

- wooden beams, slats for constructing a frame;

- wood, plywood, chipboard, plexiglass, plastic;

- screws, screwdrivers, screwdrivers, tape measure;

- hacksaw or jigsaw;

- building level.

Before work, antifungal treatment of wooden parts is carried out, followed by varnishing or painting. This way you will protect the wood from damage and ensure a long service life for your rack. If metal corners are used, they should also be protected from corrosion. To do this, they are painted with enamels or paints.

Algorithm for making a rack:

- frame assembly;

- installation of shelves;

- finishing and decorative works.

In order for the structure to be sufficiently stable, the beams must have a diameter comparable to the load. When assembling, pay attention to right angles in the vertical and horizontal position between the support bars and shelves. Otherwise, you will end up with a pyramidal or trapezoidal structure that may collapse. When assembling, do not overtighten the screws. There is no need for additional mechanical stress. The main parts are first baited and then screwed on, checking the level for compliance.

After assembling the main frame elements, they begin to install the shelves. Before installation, they are carefully adjusted and trimmed as necessary. If you are using chipboard sheets, then glue the edge after cutting. It can be purchased at any specialized store. There should be no crumbling parts. The shelves are placed in the frame and secured without recessing or with it. The second option is more reliable, but it is only suitable for wooden parts. Trim after marking with a hacksaw or jigsaw.

After the final assembly of the rack, you do finishing work: sand, sand the wooden parts. Then be sure to treat it with an antifungal primer, since the slightest dampness will lead to the appearance of fungi, mold and rotting of the structure. Special wood primers will solve this problem.

Precautionary measures

When making shelves, you need to follow individual safety measures, this is especially important when using devices powered by an electrical network:

- The angle grinder must have a protective guard for the disc, and safety glasses must be used during operation.

- Woodworking machines must also have devices that limit access to hazardous areas. It is undesirable to use a tool that has damage in the body, or if the integrity of the electrical wiring insulation is damaged.

- Clothes and shoes must be selected according to the work.

When working with paints, it is advisable to use a respirator, and the painting itself should be carried out in a well-ventilated area. We recommend watching the video in this article: how to assemble a rack with your own hands.

Useful tips

It is not difficult to make shelves in the cellar with your own hands; it is much more difficult to keep the rack intact in the difficult conditions of this underground room. To avoid finding your cans of preserves on the basement floor one “fine” day, you should adhere to the following rules:

- control the operation of the cellar ventilation system; the microclimate and humidity of the basement depend on high-quality ventilation. It has been noted that it is natural (supply and exhaust) ventilation that better regulates the temperature and humidity of the cellar, so it should be given preference over artificial systems.

- Shelves that are aired every year last much longer, rot less, and rust more slowly.

- The wood of the shelves is regularly inspected for rotting. If pockets of rot are found, the shelves in the basement should be disinfected and antiseptically treated.

- Homemade shelves may not support the weight of the cans, so food items on the racks need to be spaced evenly.

- If the basement is very damp, you need to whitewash the walls and ceiling with slaked lime several times a year.

- You should not make shelves wider than 0.75 m, in which case they will sag and you will have to build supports.

Important! Typically, racks and shelves with jars are located to the right of the entrance to the basement, and bins with potatoes and other vegetables are located on the left.

Building shelves for cans of preserves is quite simple: it can be made from scrap materials using simple tools. In order for racks and shelves to serve for a long time, it is necessary to fulfill all the requirements listed above and follow the recommendations given.

Sources

- https://pogrebov.net/obustrojstvo/stellazhi-dlja-pogreba.html

- https://www.vseinstrumenti.ru/bezopasnost/orm/sistemy-hraneniya/stellazhnye/

- https://stroimdom44.ru/kak-sdelat-stellazhi-dlya-pogreba-svoimi-rukami/

- https://ksportal.ru/1018-polki-v-podvale-svoimi-rukami.html

- https://stroy-podskazka.ru/stellazh/v-pogrebe/

- https://arbolit.org/materialy-i-instrumenty/kak-sdelat-polki-v-pogrebe-dlya-banok.html

- https://vdome.club/materialy/svoimi-rukami/kak-sdelat-polki-v-podvale-pogrebe-svoimi-rukami-varianty-foto.html

- https://mirfermera.ru/493-stellazhi-v-pogrebe-svoimi-rukami-kak-pravilno-sdelat.html

- https://PodvalDoma.ru/obustrojstvo/polki-v-pogrebe.html

- https://proriv-gbi.ru/obustrojstvo/polki-v-pogrebe.html

- https://podvalman.ru/vodootvod/polki-i-stellazhi-dlya-pogreba-iz-razlichnyh-materialov.html

- https://StrojDvor.ru/krupnye-konstrukcii/kak-sdelat-stellazh-v-pogrebe-svoimi-rukami/

- https://bouw.ru/article/polki-v-pogrebe-svoimi-rukami

- https://wexy.ru/obustrojstvo/dizajn/kak-sdelat-polki-v-pogrebe-96

- https://2proraba.com/malye-postrojki/xozpostrojki/kak-sdelat-polki-v-pogrebe-dlya-banok.html

[collapse]