Glue guns for home and industrial use must be selected according to weight, capacity, and size so that they are convenient to work with. They can glue parts together, fill cracks and seams, and seal the coating. The tool can replace liquid nails.

Why do you need a glue gun?

For repairFor needlework

The gun is constantly used not only by craftsmen in furniture repair, but also in the work of designers, florists, hand-makers, radio amateurs, and model constructors. The adhesive mixture itself can be used as a material for decorative decorations in the form of beads, nets or large paintings.

What can be glued with a hot glue gun?

A hot glue gun can be used if necessary:

- ensure tightness of joints;

- fill installation cracks and seams;

- glue some wallpaper or any other covering on the floor, walls or ceiling;

- glue the plinth, especially in hard-to-reach places, for example, on the ceiling;

- seal shoes or broken toy;

- repair clothes;

- create wall paintings, postcards or decorative decorations;

- restore, glue decorative gypsum stone (tile) to the wall.

Thanks to the tool, craftsmen receive the same universal tool that can be used to glue any components and materials with reliable hardening within the first three minutes. This glue holds parts made of plastic, leather, wood, cardboard, rubber, ceramics and even metal. The only requirement concerns the surface, which must be clean, dry, and free of grease. It is used for creativity, in modeling, for gluing decorations for interiors.

Among household needs, the gun can be useful for restoring ceramics, porcelain, any other dishes or, for example, gluing linoleum at the joints.

In crafts, you can glue fabric, beads or any other parts for crafts. Depending on the task, the glue in the rods can be transparent, colored, or shiny.

Minor parameters

- Special indicator. Indicates that the device is ready for use.

- Flashlight. Built-in lighting makes it easier to use the tool.

- Performance. The parameter depends on the heating rate of a certain amount of glue. The range is from 5 to 30 grams per minute. Low speed is suitable for small jobs. Large-scale actions or renovations will require higher rates.

- Power off button. If the gun is not equipped with automatic temperature control, then during breaks it must be unplugged from the outlet. With a button this need disappears.

- Additional nozzle. Some models are equipped with nozzles that facilitate the gluing process: narrow for hard-to-reach places, wide for large areas.

- Viewing window. A transparent hole alerts you to residual glue in the rod.

- Drip protection. A small ball is built inside the instrument, which prevents the free flow of the substance.

Device and principle of operation

Before choosing a gun for crafting, modeling or repair needs, you need to understand the technical characteristics. For example, heat guns are used to heat polyurethane mass and can be charged with glue sticks with a diameter of 7 mm (household version) or 11 mm (industrial).

Frame

Visually, this is a standard gun that supplies hot glue from a rod (fixed on the back). The body itself fixes the position of all working parts together and serves as a stand when the gun is not in use. When some of the glue has already melted, you should avoid positioning the gun with its nose up. If the switched-on device is placed on its side, there is a risk of heating the case itself and deforming it.

To choose the best glue gun, pay attention to the presence of a stand (reclines). It can be made of metal or thick plastic. To prevent the body from turning over, it must have three points of support.

The gun itself should be made of hard plastic with a low degree of thermal conductivity, since the internal parts get very hot. The presence of anti-slip pads on the handle also ensures safety. An inspection hole is made to monitor the remaining rod inside the mechanism.

Feeding mechanism

The first heating occurs in 3-5 minutes. The hot glue mixture is supplied by pressing the trigger. The spare wheel acts as a piston (ring pusher), exerting pressure, and pushes the mixture through the nozzle in a dosed manner. The diameter of the glue stick must match the dimensions of the ring.

Guide coupling

This is a rubber tube connecting the heating chamber to the hole where the rod itself is inserted.

The tube has a protective function. It prevents molten glue from getting inside the case. Serves as a kind of temperature bridge. The rod does not heat up or melt more than necessary when not in use. To avoid breaking the coupling, it is better to cut off the remaining part of the rod that needs to be removed from the gun, then pass it through the nozzle. There is no need to try to twist or pull it out.

Heating chamber

This is a metal tube to which a heating element (heating element) is attached. An electric hot glue gun can be made so that the chamber heats up gradually. The performance and power of the tool depends on the characteristics of the heating unit. The larger the volume of the heating unit, the faster the rod will warm up.

Nozzle (nozzle, nozzle)

The task of the part is to dose and shape the dispensed adhesive mass. The nozzle can be direct-flow or have a valve. In the first case, the dosage is controlled by the feeding mechanism. The heat gun with a valve has a protective ball. It partially blocks the flow of glue until the pressure on the trigger is increased. In the first and second cases, too hot glue may leak out, which means there must be a stand to collect such excess.

Replaceable nozzles

You can select the form of glue supplied using a professional gun with removable nozzles.

To avoid burns, there must be a protective casing made of rubber or silicone material.

To remove glue residue after work, run a nozzle over the cardboard.

Design and principle of operation of a glue gun

Externally, a glue gun looks like a toy weapon. This is a plastic device with metal parts, which has a hole for glue cartridges. This is the name given to translucent rods filled with solid glue. The operating principle of the device is as follows: as the thermoelement (thermal unit) heats up, the rod melts and flows after the trigger is pressed.

The body of the gun consists of hard plastic, which prevents overheating and does not make the device too heavy. Some cheap models have thin, fragile plastic, so you need to follow the rules for using them very strictly. Otherwise, the gun will not last long. It is especially important not to overheat the product and not to work with it for longer than the time specified in the instructions.

Main components of the device:

- Heating unit. Inside the thermal chamber there is one or more heating elements, and it itself is located in the barrel. The heated air begins to melt the glue immediately after the heating element reaches the desired temperature. How much it heats up depends entirely on the power of the gun.

- Feeding mechanism. There is a ring pusher here, which operates from a lever connected to the trigger. If you pull the trigger too hard, you can break the gun. Usually, only expensive branded models can be repaired, and mini guns for creativity can no longer be repaired.

- Thrust guide coupling. Thanks to this device, the heated glue is not squeezed back into the device. Usually the coupling is made of rubber, which deteriorates over time. It can be replaced, and some even install a homemade part.

- Nozzle. It shapes the glue, dispenses the melt output, and shuts off the flow if necessary. The nozzle has a shut-off valve, which is responsible for stopping the leakage of glue. But you won’t be able to completely close the hole - the pressure inside will be too high, so a couple of drops of glue will still flow out of the gun. Why does glue flow out in a large stream? Perhaps the shut-off valve is not provided at all in the model or it has broken down.

You need to work with a glue gun correctly. It cannot be placed on its side when it is turned on; you can only install the device on a special stand. You need to put cardboard under the gun, which will “catch” drops of leaking glue. After use, you need to remove the remains of the rod, clean the glue inside the chamber, and clean the nozzle area. The gun should always be cleaned after use, otherwise its service life will be shortened.

It is equally important to observe safety precautions when the glue gun is turned on. Battery-powered or low-power devices are unlikely to cause serious harm, but even they can short circuit if the instructions for use are not followed. Do not use a gun with a damaged body or cord, or if there is any damage!

Advantages and disadvantages

The heated polymer sets well and hardens in a few minutes.

The list of advantages includes:

- high-quality fastening of parts, which is similar to a mechanical connection;

- after removing the remaining glue, no traces remain on the surface;

- hot glue is the only way out if you can’t drill, drill or drive nails;

- the tool successfully levels out dents on a car, and then, after heating the surface, removes it;

- molten glue fills cracks and voids well, levels the layer, seals seams (after hardening, it is moisture resistant);

- environmental safety (no toxins).

You need to work with hot glue carefully to prevent burns.

It is impossible to obtain clear adhesion of parts with plaster, polyethylene and concrete.

Surfaces must be cleaned and dried in advance. Before working on metals, the surface is heated, for example, with a hairdryer. The use of a molten product is unacceptable for heat-sensitive parts that will be subject to further heating.

Scope of application of the glue gun

As soon as glue guns appeared in the construction industry, their practicality and effectiveness were immediately appreciated by representatives of other areas. Now it is used by warehouse workers, store sellers, masters of various types of handicrafts, children to create handicrafts, home craftsmen and other interested parties.

This popularity is due to ease of use, saving time and money, and the ability to glue almost any material:

- wood of any type;

- ferrous and non-ferrous metals;

- paper;

- fabrics;

- plastic;

- ceramics;

- Chipboard and analogues;

- glass, tiles and other materials.

If you decide to use a glue gun, which one to choose becomes the second task, since these devices are widely represented on the market today.

How to choose a glue gun

A pistol with options costs more. It is designed for professional use. In everyday life, some of the functions will not be used.

Important Specifications

Pistols differ in appearance and technical characteristics. For example, power determines the operation of the heating element and the rate of melting of the rod. The quick melting of the glue stick may be inconvenient for general home use, such as furniture repair or decorating with children.

Power and heating rate

For the performance of the tool, pay attention to maintaining the required temperature in the heat chamber, which is provided by the attached heating element. If professional heat guns, as a rule, are equipped with heating elements with 300 W or more, then for amateurs a range from 30 to 150 W is sufficient.

To choose a working tool, look not at the power, but at the performance of the gun. You can choose a device with an automatic power regulator. They first consume 200 W, then the device switches to the standard 40, and then in standby mode it is fixed at 14-16 W.

Melt temperature

Not all materials can withstand high temperatures equally easily. For paper and textiles, it is better to choose glue sticks with a melting point of 105 °C. When working with different parts, you should give preference to dual-mode guns (at 105 and 165 °C).

The simplest glue guns operate at a temperature of 170-200 °C. Most of the rods melt already at 105 degrees, and increased heating only accelerates the melting. For constant use, it is better to choose guns with a temperature regulator.

Power supply

Depending on the power source, the gun can be powered by mains power, a charged battery, or semi-automatic. A cordless glue gun allows the technician to move the required distance from the electrical source and make repairs in the most difficult to reach places. For semi-automatic machines, autonomous operation can take no more than 10-15 minutes due to the heat source.

Among the battery models, you can choose compact heat guns with lithium-ion batteries, the charge of which is restored in 90 minutes of standby mode.

The rod can heat up in 15 seconds, and the weight of the gun itself does not exceed 800 g. More often in work there are networked tools with a connected wire.

Glue stick size

Before working with rods, you need to understand their technical characteristics. For example, they come in different diameters (7 mm and 11 mm). Can be of different colors, shapes (for example, oval). Professional models can be designed with 12, 15 or 43 mm in diameter.

It is important to consider the correspondence of the rod diameters with the size of the heating coupling. This will allow you to operate the device longer. The length of the rods is not important. The larger it is, the less often it will have to be changed. Colored stickers are usually needed to mask seams on painted surfaces (green on green) or for decorative purposes. Transparent rods are universal, black ones are more suitable for sealing surfaces, and yellow ones are more suitable for working with glass.

Compliance must also be observed in the melting temperature mode, since there are rods where the hot melt temperature is at least 150 ° C and not every gun can handle this.

For constant work, it is better to choose a heat gun with adjustable temperature, for example, 105, 165 and 200 degrees. The golden mean is devices with a range of 165-170 °C.

Feed mechanism

Glue guns are classified according to the presence and structure of the trigger. If it is not there, the rod must be fed manually, which is very inconvenient. The trigger feeds the rod due to a pulling or turning mechanism. The rotary version is more convenient, more accurate in dosage and requires less effort.

Availability of attachments

The functionality of the tool depends on the number of attachments. It is better to choose designs with different nozzle shapes, for example, a flat hole lays out glue in a uniform path. It is important to pay attention to the quality of the thread so that the nozzles are attached to the base and can be unscrewed.

Different shapes of nozzles

Additional functions of heat guns

Additional functions and controls are responsible for the comfort of working with the tool.

- The temperature regulator indicates the available modes and the ability to glue different materials.

- The readiness indicator allows you to avoid burning your hands if you want to understand how ready the melted glue is for use.

- The hole (transparent window) allows you to control the stock of the rod.

- Backlight.

- Electronic automatic temperature control protects the structure itself from overheating during inactivity.

- A stand to keep the gun in the correct position during breaks or after work (while it cools down).

- The package includes a case and a heat-protective mat.

Options prevent premature failures. They guarantee work safety.

What to look for in the store

A push-button switch on the case helps prevent the device from overheating (especially if it does not have an electronic regulator). The built-in flashlight is rarely used, but it is needed when working in hard-to-reach dark places. The nipple in the structure of the nozzles saves rods, since it reduces the amount of glue released during a break in operation.

The case itself must be dense, without scratches or cracks. The connected cord must be intact and quite thick. The trigger should be pulled without any extra effort.

In many cases, when you need to quickly connect several parts without nails, screws and other fasteners, a hot glue gun comes to the aid of the master. Hot glue reliably connects metal, plastic, wood, textiles, glass and other materials. Let's take a closer look at this wonderful tool...

A hot glue gun is a simple device. All its main functions boil down to melting the material of the glue sticks and ensuring the dispensing of hot liquid glue. However, various companies offer hot glue guns in a wide price range - from several tens of rubles for simple Chinese-made tools to several hundred dollars for branded models from famous companies.

For a home craftsman who uses a hot glue gun occasionally, there is no point in buying an expensive model. The cheapest tool sold in chain supermarkets or “all for one price” stores will do just fine.

It is possible that such a hot glue gun will break quite quickly, but it is not a pity to replace it.

How does a heat gun work?

Externally, a hot glue gun really resembles a small weapon, which is where its name comes from.

From the back side of the housing 2, a glue rod 5 is inserted into it, which is fed into the heater by pressing the trigger 3. After the heater, liquid glue flows out through the hole in the conical barrel 1. Inspection window 4 allows you to monitor the residue and condition of the glue rod. Using the electrical cord 6, the connection to the electrical network is made.

For a more detailed acquaintance, the glue gun will have to be disassembled. By the way, some cheap models cannot be disassembled; the body parts in them are tightly fastened together.

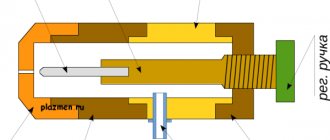

The main element of a hot glue gun is a heating chamber with a conical barrel 1, to which a heater 2 is attached with a metal bracket. In more advanced models, there may be several heaters. The glue rod 5 is fed into the heating chamber by a ring pusher 7, the force to which is transmitted from the trigger 3 through an intermediate lever. Clutch 6 holds the molten glue inside the heating chamber. All components are located in housing 4.

If a hot glue gun is so simple, why do reputable companies charge money? Is it really only for a well-promoted brand? Of course not! Expensive glue guns have a lot of differences.

For example, a BOSCH GKP 200 CE with a power of 500 W costs more than 3,000 rubles. It has two heating elements with electronic temperature stabilization, which ensures fast, uniform heating of the tool and a productivity of 30 grams of glue per minute (almost two standard 11x200 glue sticks per minute).

The high heat capacity of the heating elements allows you to work for some time (up to 10-15 minutes) without connecting to the electrical network, and the detachable electrical cable will provide maximum convenience in this mode. The outlet cone is equipped with a cap to protect against burns and a special valve that prevents spontaneous leakage of glue. The kit also includes replaceable nozzles for changing the diameter and shape of the glue flow and a convenient storage case.

DREMEL 940 glue gun worth about 1,500 rubles. It has an attractive design, productivity up to 18 grams of glue per minute, and a valve to protect against drips.

The main distinguishing feature is the presence of a “hot” mode (up to 200 degrees), which allows you to work with high-temperature polyamide adhesive rods that provide increased gluing strength. The long trigger significantly reduces the effort required to squeeze out the glue. There is also a power switch and a detachable cable for convenient operation without power.

Professional industrial glue guns can even spray hot glue , which is very convenient for quickly and economically covering large surfaces with glue. Such a tool is not readily available to the home craftsman, and its purchase is unlikely to be economically justified.

A cheap hot glue gun provides a productivity of 5-8 grams of glue per minute, takes a long time to heat up, does not have temperature control and protection from drops, but for a home craftsman who uses it a couple of times a month, or even less often, it is the best choice.

Glue sticks

Glue sticks are the main consumable material for a glue gun. Household pistols use rods with a diameter of 7 and 11 mm. Industrial models use large diameter rods (12, 15 and 43 mm). Naturally, you need to purchase exactly those rods that fit your existing hot glue gun.

The length of the rods varies from 5 to 20 cm or more. Short rods are most often sold complete with a heat gun as demonstration rods. The longer the rod, the less often it will have to be changed. The maximum length of the rod used is limited only by ease of use.

By the way, glue sticks aren't actually glue at all. It is a thermoplastic polymer that melts when heated and hardens again when cooled. In household heat guns, ethylene vinyl acetate and, less often, polyamide rods are most often used.

Ethylene vinyl acetate is designated on labels as EVA. This is a durable, lightweight and elastic translucent polymer, has a melting point of about 80 degrees, in a liquid state it is quite fluid and very sticky. When frozen, it is non-hygroscopic and resistant to moisture, oils and various solvents. Home craftsmen are probably familiar with ethylene vinyl acetate as a plasticizing additive in dry construction mixtures.

Polyamide is designated PA. Compared to ethylene vinyl acetate, it is more durable and rigid. Melting point more than 150 degrees. Polyamide can only be used with hot glue guns that have a “hot” mode. A regular glue gun cannot melt a polyamide rod to a working state. When using polyamide rods, it should be borne in mind that in a humid environment the strength of this polymer gradually decreases due to moisture absorption.

Most companies adhere to a certain color coding when producing glue sticks. Translucent matte white, undyed EVA rods are considered universal. Such rods satisfactorily glue almost any materials. In some cases, universal rods can also serve a decorative role.

Naturally, white universal glue will be noticeable on a colored surface. Therefore, a wide range of rods are produced from mass-dyed ethylene vinyl acetate. The color palette is very diverse - red, green, blue, yellow, brown, blue and many others. There are decorative translucent rods with sparkles. These colored rods are also universal.

Among the specialized ones, it is worth mentioning yellow transparent (for paper, cardboard and wood) and gray or black opaque (for sealing seams and insulating electrical wires) rods.

However, such color marking is not mandatory. Therefore, when purchasing, it is better to clarify the purpose of the rods on the packaging.

We will look at how to use a hot glue gun correctly and some of the secrets of this tool in the next article.

We recommend reading

- How to choose a knife for modeling?

- Simple DIY key holder

- How to make an inscription on metal with your own hands? Electrochemical engraving

- What rod diameter should I choose for an external metric thread?

- What hole diameter should I drill for metric threads?

- How to use a blowtorch?

- Engraver with EVERISE attachment set

- How to choose a drill?

- How to drill correctly?..

- How to use a hot glue gun?

How to use a glue gun

Before you start using the gun and inserting the glue stick, you need to prepare the work area. This concerns checking the lace, which should be enough for convenient work with the parts. It is necessary to turn it on only after the rod is fully inserted (all the way). Usually, 2-5 minutes are enough for the first heating of the container, but more precisely should be indicated in the instructions. The clearest indicator that the gun is ready for use is the appearance of a drop of glue on its nose (nozzle).

The melted adhesive must be applied to only one of the surfaces to be joined. The glue hardens very quickly, so all actions must be clear and accurate.

The best professional glue guns

Rating:

- Professional INTERTOOL RT-1012 – the most high-performance. The gun produces 30 grams of the substance per minute. This is convenient when applying glue over a large area so that the melt does not cool down and the surfaces being glued are held together more tightly.

- STANLEY FatMax – fast heating. The device is ready for use in 60 seconds. The temperature is indicated by LEDs: green indicates heating above 170 degrees, red - below.

The power is maintained even when applying glue. The safety shutdown function will automatically turn off the device after 30 minutes of operation.

- Buhnen HB 190 is the lightest. The device weighs 300 grams, so it is comfortable to use. The handle is narrow, profiled. The pistol is characterized by high performance, 12 mm rod, comfortable trigger.

The products are used not only in everyday life, but also for professional work in production. They are suitable for leather, wood, fabric. Widely used in furniture factories for processing joints.

Characteristics

- Power – 80-180 Watt.

- Mains powered.

- Automatic shutdown.

pros

- Great performance.

- Precise glue dosage.

- Switch on the body.

- Glues any materials.

Minuses

- High price.

Security measures

You need to work with a glue gun on a flat, hard surface, previously covered with film or at least newspaper. If the mass is applied to metal or wood, then it can still be removed, but paper or cardboard is not so easy to clean.

Do not touch the nozzle of the gun if the device is turned on and in operating mode. The burn can be very severe. This also applies to the released glue, which, if it comes into contact with the skin, can cause a burn.

The switched on device must not be left unattended, even for a few minutes. A faulty socket needs to be replaced. Complete shutdown of the gun must be done at least once an hour with a break of 5-7 minutes.

A switched off, folded pistol should be stored out of the reach of children.

Best Air Glue Guns

Rating:

- Buhnen HB 700 K Spray is the most accurate. The device is intended for industrial use. The gun applies polyurethane adhesive in spray form. The device is equipped with automatic heating control, which controls the temperature with an accuracy of 1 degree. The handle has a built-in digital display.

- 3M Polygun II is a multi-purpose product. The device is characterized by a wide temperature range, so any fusible adhesive can be applied. High power pneumatic gun, melt strip length 4.8 m. The device weighs 860 grams.

- METABO PowerMaxx KP – practical. Designed to handle even viscous substances due to clamping pressure. The device is protected from leaks due to the automatic reverse motion of the rack. Metal gear extends service life.

Evgeniy Filimonov

Ask a Question

A special feature of the design is the pneumatic glue supply system, which is characterized by high pressure. Therefore, the gun copes with viscous, viscous substances.

Characteristics

Productivity 10-30 grams per minute.

Volume 600 ml.

Battery powered.

pros

- Great power.

- Convenient glue supply system.

- Fastens massive objects of different textures.

- Compact and lightweight.

Minuses

- Massive dimensions.

Some brands and prices

Since after heating the glue begins to flow out of the nozzle, you need to place a container in advance, protecting the surface of the work table. If there is no power button on the case, then the instrument will need to be periodically unplugged (pull out the power cord). Since the body itself can also be heated, its integrity deteriorates over time, starting at the junction with the hot spout. To avoid getting burned, it is better to choose a gun whose body has protective and anti-slip linings, dense plastic with low thermal conductivity. Standard Chinese models are usually designed for rods with a diameter of 7 mm.

Among well-known manufacturers, you can pay attention to Dremel brand products. They operate at high temperatures, have an anti-drip system and a smart switch.

- The Dremel 910 JC is a professional high temperature heat gun without an on/off switch. It works for a very long time (several hours without breaks) without heating the case and losing the hot glue released.

- The Dremel 930 JC is equipped with two heating modes and is switched by a button on the handle. Suitable for active needlewomen. The only negative concerns the low weight of the tool, which is why it can fly off the surface.

- The Dremel 940 is used for home repairs with wood, plastic or ceramics. The device has increased productivity and large dimensions. The rod is heated to 195 °C. The semi-automatic system allows you to pull out the cord and glue parts in hard-to-reach places.

The cost depends on the quality of the case, parts, and protective options. The price for standard models is several hundred rubles. A professional pistol for permanent work can cost more than twenty thousand rubles.

Best Cordless Glue Guns

Rating:

- Bosch Glue Pen 0.603.2A2.020 is the most compact. The device is equipped with a USB connector, thanks to which the product can be easily charged. The battery life is half an hour. Heating time 15 minutes.

- ENGY EGG-16CL – multifunctional. The gun is equipped with two attachments and operates from a charger. The built-in collector collects drops. The product works with metal, plastic and rubber.

- MILWAUKEE C18 PCG/310C is the most powerful. A special feature is high performance at low temperatures. The alloy feed rate is adjustable depending on the requirements.

Battery-powered models make the glue machine mobile and efficient.

Characteristics

- Power 5 Watt.

- Battery powered.

- Drip protection.

- Rod diameter 7 mm.

pros

- High mobility.

- Equipped with a stand.

- Ergonomic trigger.

Minuses

- Requires regular charging.

- Heavy weight.

Lifehacks with a glue gun

You can do many useful things with hot glue:

- Stopper for the sink

. Take a balloon, put it on the gun and release the glue. Place it in the hole in the sink and press tightly. After drying, the ball is removed. - Eraser for a pencil

. Apply a small amount of glue to the edge of the pencil. After hardening, it will completely replace the eraser. - Knife case

. Take a hot glue gun and apply the heated compound to the tip. When hardened, the glue forms a durable cover. - Hemming clothes

. Cut off the excess and apply glue to the edge. It will not only fix well, but will also prevent the threads from fraying. - Case for phone

. After covering the surface with film, draw any patterns with glue. When everything has hardened, the film is removed and the resulting accessory is put on the phone.

Types of glue guns and their prices

Thermal guns are divided into types, depending on their design, functions and other indicators.

So, according to the method of heating the glue, the tool can be divided into:

Gas

Used primarily in field conditions due to its mobility.

The source of energy for heating here is butane gas, one charge of which is enough for an hour to an hour and a half of work.

The gas heater is started by pressing a key (button, lever), which is simultaneously responsible for the piezoelectric ignition and the gas valve.

This tool is refilled from lighter cans.

The cost of gas glue guns is 3 – 4 thousand rubles.

Electric

The design contains a heating element powered by electric current.

The source of the latter can be a household network or a battery.

Network heat gun

The tool is “tied” by a wire to an outlet, and therefore working away from electricity is out of the question.

On the other hand, it does not require recharging and can be used without prior preparation, you just need to wait until it heats up to a certain temperature.

Its cost starts at 250 rubles. and on average is about 1000 - 1500 rubles.

Chinese glue guns of the simplest models can be found at prices below 100 rubles; the reliability and durability of such options raises many doubts.

NOTE:

Among Chinese instruments, you can also find quite noteworthy options at an affordable price.

Rechargeable

Cordless glue guns are more portable, however, they require a fully charged battery.

The operating time without recharging of battery models is about 40 – 60 minutes.

However, the autonomy of such a pistol is only temporary, since the battery must be periodically charged, which again requires an electrical outlet.

The price is approximately 3 - 4 thousand rubles.

According to the method of applying glue, the tool can be divided into:

- Automatic - option with connection to a pneumatic line or electromagnetic system. In both cases, the glue is supplied to the heating element by pressing the start button.

- Semi-automatic - like the next method, provides mechanical feed. Here the rod is pushed towards the heater by a trigger, which can be rotary or fixed. The trigger is connected to a slider that moves along the barrel of the gun, pushing the glue.

- Manual - no trigger at all. Feeding is carried out by pressing the hand on the end of the glue stick.

Pneumatic

A hot glue gun with pneumatic feeding of glue cartridges is a professional tool, when working with which you can fully concentrate on the operation, since there is no need to load your hand to feed the glue stick.

Such models are designed to perform large volumes of work; they often have a power of over 300 W and are connected to a compressor capable of delivering a working pressure of 3–7 bar.

This pneumatic heat gun weighs more than 1 kg and requires simultaneous connection to the electrical network and a pneumatic line.

These are industrial models that are used for finishing and construction work.

High-power 600 W options are used in various furniture factories and factories for the production of windows and doors.

Professional

The more powerful tool is distinguished by the fact that it is capable of heating adhesive stickers within a few seconds, and is equipped with various auxiliary functionality that allows not only to increase labor efficiency, but also to maintain full control over the heating temperature.

Professional heat guns can be loaded with glue sticks, granules, pads and cylinders.

Household glue gun

It has a power that does not exceed 60 W.

To melt a drop of glue, such a tool can take up to 4 minutes of time; this primarily includes mini models with 20 - 25 W ratings.

According to heating temperature, the tool is divided into:

- Low temperature - most often the operating temperature is 110 degrees, sometimes a little higher. Used primarily for working with heat-sensitive materials.

- High temperature – the heating temperature is usually at least 195 degrees.

Glue pen

A separate type of glue gun that should also be mentioned is a glue pen.

This option is great for delicate work, in particular for needlework, their price is approximately 1,200 rubles per piece.

This is a cordless, battery- or AA-powered tool that can use up to 60 glue sticks on a single charge.

Actually, the name itself speaks about the shape of this device, the dimensions of which are comparable to a marker.

What you need to know about glue guns?

When there is a separate power switch on the tool body, it is much more convenient.

Most often it is located at the bottom of the handle, which allows it to be turned off with one hand.

Such a switch will allow you to stop the supply of electricity during breaks in work without having to remove the power plug from the socket.

In addition, such a switch will greatly help if the glue gun does not have an automatic temperature control, but has excess power.

Purpose and operating principle of a glue gun

The glue gun is multifunctional.

Handicraft masters rarely do without it, since in their work such a tool is simply irreplaceable due to its ability to form neat joints, holding elements of different materials together.

A hot-pressure gun can be used to repair various products with fastener-free joints, for example, wooden furniture.

The main purpose of a glue gun is to glue parts together, but in addition, it can be used to successfully seal joints and seams, for example, when laying linoleum, insulate wires and electronic components, and temporarily fix them.

In addition, a glue gun is suitable for filling voids in hard-to-reach areas that are difficult to reach with another tool, such as a brush.

The principle of operation of the gun is to heat up hot melt adhesive with a solid consistency, from which it changes to viscous, and when cooled it becomes solid again, resulting in a reliable connection between the materials being glued together.

This process is called polymerization.

After polymerization of the glue, a joint is formed of such strength that if force is applied, the material being glued will first be destroyed, but not the seam.

How to replace a glue gun?

When the glue gun is missing or broken, and you need to use hot glue, you can do the following:

- A piece of refill is inserted into a ballpoint pen and melted over a fire. The composition will cool quickly, so it needs to be constantly reheated.

- Place small circles of glue on the match. They melt everything by simply lighting a match. This is a suitable option for emergency situations.

- Pieces of glue are melted on a preheated surface, and then a small amount is taken with any stick and applied to the desired location.

Criteria for choosing a glue gun

Modern thermal guns have some nuances in their design. They must be taken into account when choosing a model so that it fully meets your needs:

Performance

This criterion is expressed by the speed of the device. The range of values varies from 5 grams of glue dispensed per minute to 30 grams. Experience shows that high speed is important when working with large structures or areas. Usually 10 to 15 grams of glue per minute is sufficient.

Power

The higher the feed speed of the heat gun and the heating temperature, the more powerful the device.

Power supply

Modern models can operate from a 220 V electrical network, or be equipped with a battery. The second version is relevant for those users for whom the principle of mobility is important when working.

Trigger type

The trigger can operate on either a rotary or slide mechanism. Craftsmen value rotary triggers more for their greater dosing accuracy and ease of use. There are hammerless models where the rod needs to be pushed through with your finger.

Presence of a check valve on the body

This element makes it possible to work in a vertical position. If there is no check valve, then in this position there is a risk of contacts and trigger being flooded with hot mass and failure of the device.

Rod diameter: 7mm or 11mm

The general recommendation is that it is more rational to use 7 mm pistols in needlework, and 11 mm pistols in construction and repair work. But this is not a universal principle; fine work can be done on a construction site, and rough work can be done in the process of creating handicrafts.

Thermal mechanism

This module plays the main function, and the reliability and service life of the glue gun depends on how well it is made. Practice shows that this factor is not identical to the promotion of the brand. Experts recommend purchasing a device with a real warranty from the manufacturer; this is the only safety net.

Working temperature

Modern models often operate at temperatures of 105 degrees C and 200 degrees C. There are modifications that can heat the glue up to 500 degrees C.

Evgeniy Filimonov

Ask a Question

It is believed that increasing the temperature can increase the speed of operation, but you should understand that in this case you will also need skills in operating the device. Otherwise, the quality of work will be low.

Crafts with glue gun

You can make many beautiful and original things with this tool. Interesting crafts using a glue gun:

- Corals

. They are created from interweaving thin wire, which is treated with hot glue. You can use colored rods or then apply paint of a certain shade. - Snowflakes

. A diagram is drawn on paper, and all the contours are covered with glue. Then they are separated from the base. If necessary, use colored varnish or acrylic paint. - Candlestick

. Take a glass and cover it with film. Use a glue gun, apply patterns with glue, allow time to cool. Then remove the cellophane and use the craft for its intended purpose. - Bracelet

. Use a tin can. Glue is applied to the surface in any suitable pattern. Allow time to cool and decorate with decorative elements. - Shoes for Dolls

. The legs are covered with film and glue is applied to form the product. Cover with paint or varnish. Remove and clean sharp corners. - Cat scratcher

. Take ordinary rubber gloves and apply drops of glue. Leave until it hardens and you can pet your pet.