Operating principle of hydraulic cylinder

A simple example of a hydraulic cylinder is a factory automatic system that can create ventilation inside a greenhouse. The operation of such a device is based on the movement of a piston, which begins to work due to the expansion of the liquid in the cylinder under the influence of the sun. The piston a very important part that affects many things.

When the temperature drops, the hydraulic cylinder for greenhouses closes the window, because the liquid returns to its original state with the smallest volume.

A hydraulic cylinder is a universal device that you need to pay handsomely for.

In addition, there are different greenhouse designs that require machines with unique characteristics. For example, you need to lift a massive window in a greenhouse, then you will need a stronger hydraulic cylinder for greenhouses. It is better to make such a device yourself.

When designing a hydraulic cylinder, you can make your own additions. It is important to know that the glued foil speeds up the heating of the device and this improves the process of opening the window.

Hydraulic cylinder for a greenhouse - installation and best brands (85 photos)

Every greenhouse owner sooner or later faces the problem of maintaining an appropriate microclimate inside.

In the cold season, a heating system is used to create a microclimate; in the warm season, ventilation is required.

If the owner is constantly located near the greenhouse, organizing ventilation does not cause difficulties, otherwise it is worth thinking about automating the process.

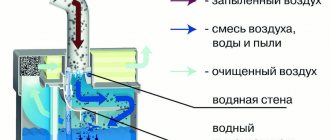

Scheme of automatic ventilation of a greenhouse.

Stages of creating a device

To create a hydraulic cylinder, you can use a pneumatic shock absorber from a car. Typically the shock absorber is located on the hood or tailgate. The shock absorber should not have unique characteristics, the main thing is that there is pressure in the mechanism. The pressure can be checked using the operating rod.

A hydraulic cylinder made from a shock absorber can operate for several years without failure. Creation stages:

- You need to find a ball at the end of the cylinder and cut it so that as much of the holder length remains as possible.

- Then the cylinder needs to be clamped using a vice, but do this through the ends, then the working mechanism will not be damaged.

- In a well-fixed cylinder you need to make a 3 mm hole with a drill.

- After creating a hole, air will begin to escape from the hemp due to pressure.

- A small splash may occur and then there is a risk of shavings getting into your eyes, so it is better to wear glasses or a special mask in advance. After creating the thread in the hemp, the indoor hydraulic cylinder will be ready.

- Next, a thread is formed on the hemp. Most often, operations are carried out only on the outer surfaces of the shock absorber, so there is no need to penetrate inside.

Making a fluid tank

The pneumatic cylinder must contain a fluid reservoir; it is made from a car spare part. In our case, we will analyze the creation of a hydraulic device from a cardan. Creation stages:

- The ears of the cardan must be cut off. This action must be performed carefully and according to calculations for a specific greenhouse, after which you need to weld the end.

- At the other end you need to make two holes. The first is necessary for connection, and the second to create proper air release.

- The most difficult stage in creating a device is cutting the thread. After all, any violation of symmetry can spoil the part and even break it. If you are going to use a large tank, then it is advisable to fill the excess space with metal parts.

Creating a Hose and Spring

As a connecting part of the system, you can use the brake hose of the car. The main thing in choosing a hose is that the threads match. Depending on the properties and characteristics of the hose, the required thread is made on the tank and cylinder.

An interesting fact is that hydraulic cylinders made by hand from shock absorbers can withstand a load of 100 kg. This is enough for the entire greenhouse, not just the window.

But to return the rod to its original position, a spring is needed . The spring must withstand at least 5 kg, then back pressure will be applied to the rod. One of the best options is a simple door spring.

For a special pneumatic cylinder, automotive oil is well suited. Many people may think that it is better to use ether and alcohol to improve the functioning of the mechanism, but this is not true, it only makes everything worse.

If you understand this hydraulic device better, you can understand that it produces an effective and beneficial action in the greenhouse.

Making a hydraulic cylinder is not at all difficult, the main thing is to find the right cylinder and assemble some parts correctly.

You can purchase a indoor piston if you still have unresolved problems with the cylinder. The price of a piston starts from 1000 to 3000 rubles.

Source

Do-it-yourself pneumatic cylinder from a shock absorber - Metalworker's Guide

A hydraulic cylinder in a greenhouse is necessary for the installation of an automatic ventilation system. What is a hydraulic cylinder is known to many, but not to everyone.

For those who are first faced with the need to acquire a hydraulic cylinder for their greenhouse, this equipment can be characterized as a reciprocating mechanism, which in this case helps maintain the optimal temperature in the greenhouse.

There are many types of hydraulic cylinders for greenhouses on sale, but you can make and install one yourself, especially since there are many solution options.

The hydraulic cylinder, as a technical element, is used in many mechanisms, and therefore, to use it for greenhouse ventilation, you can remove it where it is no longer in demand, and also create a completely independent system.

What fluid is suitable for a greenhouse hydraulic cylinder?

The hydraulic cylinder fluid can be oil or paraffin. For example, synthetic fluids are ideal, they are non-flammable and operate over a wide temperature range.

The main indicator when choosing a fluid for a given task is the working pressure in the hydraulic system

Fluid with increased viscosity is used at high pressure, thus reducing the risk of fluid leakage. If the pressure is relatively low, then you should choose a liquid with low viscosity.

The liquid must be of its original consistency in order to last as long as possible. When replacing, it should not be mixed with the liquid that has already served its purpose, but should be protected from the ingress of water, sand, etc.

It is better to pour liquid into the cylinder using a syringe. And then, press the rod all the way so that the liquid begins to come out, so you can be sure that all the air has come out.

Installing a hydraulic cylinder in a greenhouse: do it step by step

Now you need to install the hydraulic cylinder in the greenhouse. The cylinder itself should be protected from direct sunlight; you can wrap it in foil. The hydraulic cylinder should be attached to a fixed frame element. The rod must be attached to the frame on the window.

Thus, the greenhouse vents will be able to open depending on the heating and the space will be ventilated.

To place the device, you should choose vents on the roof, because the side frame will not close under its own weight, as is the case with the horizontal one, and will require the installation of a return spring.

The tank should first be tested for the required volume of liquid by leaving it in the greenhouse and waiting for it to heat up, and then release the excess

Still, there must be air in the tank to avoid excessive expansion of the liquid. Through the same syringe, you can inject a couple of cubes of air.

So, a return spring is necessary if the device is used for a vertical vent, and not the recommended vent on the roof. It is necessary to provide about 5 kg of back pressure on the rod. A door spring will also work.

Sometimes a single hydraulic cylinder is used in two sections.

To provide the greenhouse with proper ventilation, it is necessary to calculate the number of vents based on the number of sections and dimensions. The recommended minimum number of vents is based on one per 2 m2 of greenhouse.

Do-it-yourself automatic greenhouse ventilation system (video)

The system implies its active operation in the summer, when the liquid warms up, therefore in winter the system needs to be heated from the sun's rays, or remove the system and install it before the start of the season.

Attention, TODAY only!

Do-it-yourself hydraulic cylinder from a shock absorber

Growing crops in a heifer gives many advantages to the summer resident, relieving him of a lot of hassle. Heat-loving plants are protected from harmful environmental influences, developing in optimal conditions.

The designs and materials for modern greenhouses create the most comfortable humidity and temperature conditions for growth, however, complete provision of a favorable environment is impossible without ventilation.

The presence of such a device makes the operation of a dacha structure convenient and effective in terms of obtaining a decent, environmentally friendly harvest.

Posts 1 page 30 of 46

ShareNovember 14, 2010 23:40:04

- Author: Vovan - beginner tractor

- Active participant

- From: Engels

- Registered: March 15, 2010

- Invitations: 0

- Posts: 280

- Respect: [+3/-0]

- Positive: [+18/-0]

- Gender: Male

- Age: 28 [1992-01-07]

- Time spent on the forum: 3 days 0 hours

- Last visit: March 8, 2011 19:12:19

Folks, I came up with this idea due to the lack of hydraulic cylinders, and whoever tried to make them himself. If you have had experience, please describe it, parts of the CVS appeared from a Kamaz, so I thought, looking at them, what if I welded the cylinder on one side and connected two fittings, and sealed it on the other so that the piston did not fall out, in theory, I would get a rather powerful cylinder, but short-stroke, single-acting, do you think such a thing can work, at least somehow?? if not then why??

ShareNovember 24, 2010 23:44:37

- Author: Lexus

- Chief Moderator

- From: Chelyabinsk region.

- Registered: November 5, 2009

- Invitations: 0

- Posts: 2071

- Respect: [+132/-3]

- Positive: [+535/-1]

- Gender: Male

- Age: 47 [1973-05-19]

- Time spent on the forum: 1 month 24 days

- Last visit: December 9, 2011 19:07:29

How to make a hydraulic cylinder system yourself?

To build a hydraulic cylinder for a greenhouse, you will need to prepare the following elements:

The material should be selected so that it can be used to construct a cylinder with a diameter of 20 cm.

First of all, you need to bend a cylinder from a sheet of tin or polycarbonate. You can fasten it with ordinary tape. The diameter of the cylinder should be 20 cm, and the length should be approximately 30-35 cm. The lower part will need to be plugged. The easiest way is to use a piece of penoplex.

If the cylinder will be made from a tube, it is recommended to use a piece of plexiglass with a thickness of at least 5 mm. From this material you need to cut a circle of such size that it can cover the cylinder on one side. You will need to prepare two circles. A plug for the hydraulic cylinder will be made from one, and a guide for the rod will be made from the other.

Purpose and principle of operation

Overheating of plants growing in greenhouses can negate all the work that went into growing them. To avoid such situations, greenhouse premises must be regularly ventilated. It is especially important to perform this procedure in cases where the temperature inside the greenhouse reaches critical values. If you do not use a device such as a thermal drive for greenhouses (or a hydraulic cylinder), then constantly monitoring the temperature inside such rooms and ventilating the greenhouse yourself can take a lot of time, which could be spent more profitably. That is why any greenhouse owner who wants to make its maintenance process more efficient and less labor-intensive is seriously thinking about how to make a device for automatically ventilating greenhouses with their own hands.

The operating principle of a hydraulic cylinder for greenhouses is quite simple and is based on the law of physics, according to which a liquid, when heated, expands in its volume, and when cooled, it contracts, returning to its original state. Thus, if you place a liquid in a sealed cylinder equipped with a piston with a rod, then when heated it will begin to expand, which will lead to movement of the piston and, accordingly, the rod, which is rigidly connected to it.

Advantages and disadvantages

Among the advantages that a hydraulic cylinder used to provide ventilation of greenhouse premises in automatic mode has, the following should be highlighted.

- To operate such a device, it does not need to be connected to a power supply.

- A simple design scheme makes it quite easy to make a hydraulic cylinder for a greenhouse with your own hands.

- Such a device does not require constant maintenance.

An automatic ventilation system based on a hydraulic cylinder, despite some disadvantages, is quite often used in personal greenhouses

Naturally, such a device for automatically ventilating greenhouses also has disadvantages.

- When installing such a device on a window frame that rotates on a vertical axis, it is necessary to additionally use a return spring, since such a frame will not lower under its own weight when the volume of working fluid in the hydraulic cylinder decreases.

- If the air temperature drops sharply outside the greenhouse, the hydraulic cylinder will not close the window frame at the same moment; this will happen only after 15–20 minutes, when the oil in its working chamber has cooled.

And a little about secrets...

Have you ever experienced unbearable joint pain? And you know firsthand what it is:

A hydraulic cylinder for a greenhouse is a device that is successfully used and produced on an industrial scale. You can make it yourself with certain skills and the availability of material.

The operating principle of this device is based on the ability of substances to expand when heated. At low temperatures, the substance is in a compressed state and the rod is in a retracted position. As soon as the air temperature begins to rise and reaches a critical value, the liquid or air expands and the rod is set in motion. If the hydraulic cylinder is attached to the window frame, then at high temperatures it will open the window itself. The industry produces hydraulic cylinders for greenhouses in a wide range. The price depends on the complexity of the device, but on average it ranges from 1,500 to 3,000 rubles.