A punctured wheel with a spare tire that has not been repaired in time contributes to the desire to do the tire fitting yourself. But in order for this to be possible, it is necessary to have the appropriate tools, and most importantly, skills. To do your own tire mounting on the road, you need to have 2 mounting blades, as well as a device for tearing off a stuck tire from a rim (many people use a small piece of angle steel with a sledgehammer for this). But this can be done much more conveniently with the help of a jack and a tow rope.

Technology on how to do the right tire fitting with your own hands

A simple algorithm for performing tire fitting procedures is quite accessible for independent implementation, which will save some money.

So, the tool is available and you can begin the preparatory work. First of all, you need to brake the car with the handbrake and additionally engage first gear (if you have a manual transmission). But this is not all the safety measures; before you do your own tire fitting correctly, you should install stops under the undamaged wheels. Experienced drivers have special “shoes” for these purposes, but in extreme cases, ordinary bricks will do.

Next, the technology for dismantling the wheel consists of performing the following transitions:

- Use a wheel wrench to loosen the bolts of the wheel being removed;

- place a jack under a certain area of the car and lift it;

- completely unscrew the wheel mounting bolts;

- remove the wheel from the hub.

Now you can proceed directly to the tire mounting procedure. If there is any air left in the tire, it must be released further:

- clean the disc and tires from dirt;

- wet the circumference of the contact area of the cord with the disc;

- move the tire bead deeper into the rim by applying pressure (if necessary, use a jack with a stop), perform the procedure on both sides of the wheel;

- place the mounting paddle under the cord from the outside of the disc (the pry bar should be placed in the area opposite the nipple);

- pressing the tube from the nipple side, turn the tire cord outward from the disc with a mounting blade from the opposite side;

- using the second pry bar, remove the next section of cord after a gap of 10-15 cm, while the first pry bar must remain in place (perform the operation gradually moving around the entire perimeter).

After removing the tire cord from one side of the disc, you need to take out the inner tube and then proceed according to the need. If the tube needs to be repaired, do it and put the tire back in place. When you need to completely dismantle the rubber, you should remove the tire from the same side of the disk, using the same mounting blades. The work is carried out in the same way as described above - by moving the mount step by step around the perimeter of the disk.

Important! Before you do the correct tire fitting yourself, you should understand that the recommendations listed are most suitable for tires with tubes. In principle, tubeless tires are beaded in a similar way, but the process is different and involves some difficulties, so in this case it is better to contact specialists

Reinstalling the tire is done in the reverse order, with the difference that the cord should now be started from the nipple side

Work with tire irons must be carried out carefully so as not to damage the tire. After this, inflate the tire with air and install the wheel on the hub.

Start tightening the fastening from the top bolt and then diagonally, this way the wheel alignment will be most accurate. The final tightening of the bolts should be done after the machine is completely lowered to the ground.

How to find professionals

When deciding how to choose a tire service, it is recommended to pay attention to several points:

- Price. Often, even in one area, there are several service stations, so the client has the opportunity to choose.

- Appearance. For the sake of economy, you should not choose an unknown office located in the nearest “pavilion”.

- Equipment. All tools and equipment necessary for work must be at the disposal of the craftsmen. The devices must be in good working order and reliable. In good auto repair shops, the balancing device is mounted on a concrete base.

High-quality tire fitting in Moscow is actually not so easy to find. The Vostok-Avto company invites you to use the services of specialists. We only have professional equipment and highly qualified personnel at our disposal.

We provide a guarantee for our services and will provide high quality work. This applies not only to tire fitting, but also to other services provided in our car service center. You can order tire fitting by calling us or filling out the form below.

DIY tire changer tools

How to make a homemade car

2 years ago

Tire fitting tools, valve installation tool

Tools for tire fitting (tool for installing valves) We are on VK: https://vk.com/molodcova8.

3 years ago

A tire changer from the last century for aluminum and steel wheels.

This video was processed in the YouTube Video Editor (https://www.youtube.com/editor)

1 year ago

Mount for homemade tire fitting

Mount for homemade tire fitting Help in developing the channel https://www.donationalerts.ru/r/antifreezzz.

9 months ago

TIRE FITTING LEVEL 80 AND MORE

Hidden nipple https://goo.gl/jvAzKA My Instagram https://instagram.com/kosilov_georg Subscribe to the channel ...

4 years ago

tire mounting. homemade.

homemade tire mount. for that homemade stand. the money stays in the family. .look take at...

5 years ago

homemade manual tire changer

I did it in two days, searching for materials.

1 year ago

Mounting kit for truck tubeless tires. DIY PART 2

Do-it-yourself euro mounts for tubeless rubber.

1 year ago

How to do tire mounting yourself without scratching the rims COOL HANDMADE! Part 1

Continuation of this video with dimensions and explanations here https://www.youtube.com/watch?v=ZHZwbNT9GFw This is my personal homemade product! saves...

2 years ago

Machine for balancing and straightening wheels. Tools #1

Homemade machine for balancing wheels and straightening (assembling) spoked wheels Link to group in VK: https://vk...

4 months ago

Balancing machine SCAD Part 1

Repair of balancing machine. Balancing stand SCAD B-340ET Characteristics Manufacturer Scud Country…

1 year ago

How to do tire mounting yourself without scratching the rims COOL HANDMADE! Part 2

The first part of the video clip on how my installation works is here https://www.youtube.com/watch?v=fUS6yES17I8 Continuation of Homemade tire repair...

3 months ago

DIY SUPER PANEL FOR WHEELS

Join the affiliate program!!! https://yoola.app/r/6115825146256 SUPPORT CHANNEL CARD (UKRAINE, PRIVATBANK) - 4149 4978 5792 9345 WALLET...

3 years ago

Tool for manual tire mounting of truck tires PL-C1000

You can buy this set of tools on the Fenix-Market company website: www.fenix-market.kiev.ua.

4 years ago

Clamping jaw A24 to increase the working range of TROMMELBERG tire changers

4 years ago

DIY tire fitting

5 years ago

homemade tire fitting

homemade devices for removing and installing tires on passenger car rims. 5 minutes per wheel...

2 years ago

DIY tire service

5 years ago

Tire changing machine WiederKraft WDK-752122

1 year ago

Automatic tire changer ANDRMAX AX1426NS

Incredibly fast and efficient large tire changer For removing tubeless truck tires,…

3 months ago

Tire Changing Machine Repair Restoration Part 4 TABLE

I bought a tire changing machine in very poor condition, everything that was out of order and worn out has already been lost...

2 years ago

Mounts for tubeless wheels and DIY tools from Uncle Vanya.

The video presents an inexpensive set of hand tools for beading truck wheels. So…

1 year ago

DIY tire fitting machine

6 months ago

THE CHINESE HAVEN'T THOUGHT OF THIS YET!!

CHANNEL where I will upgrade my CAR: https://vk.cc/97BYwI ️️️I STARTED BUILDING A WORKSHOP, THE WHOLE CONSTRUCTION WILL BE...

1 year ago

DIY tire changing machine. Part 1

In this video I decided to share my experience of making a tire changing machine with my own hands, this is the first...

1 year ago

Do-it-yourself booster for tire fitting

Homemade booster for tire fitting from scrap materials in half a day))

2 years ago

How to make a home tire changing machine with your own hands. Manual Tire Changer

How to make a home tire changing machine with your own hands, a very convenient thing, all that remains is to do the balancing...

1 year ago

homemade tire changing machine

I didn’t make the machine for an exhibition, but to make it functional and mobile, I only used it in its production...

more (1807+ videos)

How to do tire fitting yourself, what tools are needed

Car stethoscope

The wheel is replaced using a jack and a wheel wrench.

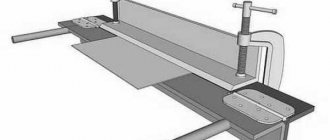

Home tire fitting is usually carried out in the garage. To disassemble and bead a tire, you will need mounts (mounts). Essentially, these are small flat crowbars. In the worst case, chisels are used to remove (put on) the rubber.

Sledgehammers and heavy hammers should not be used to avoid damaging tires, rims and tubes.

Tire mounting must be performed away from the car, since the tire can “play” under the influence of the elasticity of the tire and damage the car body

The driver must also take precautions, as tools can spring back and cause injury for the same reason.

To disassemble a wheel you must:

- Remove one tire bead from the rim. To do this, using a mounting tool, you need to pry the edge of the rubber near the rim and, supporting it with a large screwdriver so that it does not slide back, move it beyond the rim. Before starting work, the rim must be moistened with soapy water to ensure sliding.

- the second pry bar is inserted after 15-20 cm and inserted into the next section of the tire bead and so on until the bead is completely removed

- In the same way, the second side of the tire is freed from the disk.

- the removed rubber is removed by hand

To avoid damage to the body, install tires away from the car.

The new tire is mounted on the rim as follows:

- one side of the rim goes overboard

- the mounting blade is placed between the wheel and the tire, and part of the bead is inserted behind the wheel flange

- with the second blade, after 10-15 cm, the next part of the tire is started by the edge

- the first blade is removed and installed behind the second and so on

- after placing one bead of the tire in the rim groove, the same operations are performed with the second bead of the tire

- At the finish line, the installed tire is inflated

Tire repair is done using “raw rubber” with an electric vulcanizer or using a patch with glue. If the puncture hole size exceeds 12 mm, the tire cannot be repaired.

It is almost impossible to remove tubeless tires without special tools. You can purchase various devices at car service centers or make them yourself.

Defects and beading of tires

The removed rubber is examined using tire fitting equipment - spreaders, expanders, bead turners. During the inspection, puncture sites (if any) are identified. If necessary, local or restorative repairs are carried out.

If the tire is tubed and the tube is punctured, it is vulcanized. For damage with a diameter of less than 3 cm, patches of unvulcanized rubber are applied; for damages with a diameter of less than 3 cm, patches are made of vulcanized rubber.

The method of repairing tubeless tires is also selected depending on the diameter of the puncture. If it does not reach 2 mm in diameter, the damage is injected with paste. Larger punctures are closed with rubber mushrooms or plugs.

The next stage is mounting the wheel. Before this, the old balancing weights are removed. The rim is checked for dents, burrs and pockets of rust.

The brake disc is also checked.

If there are any studs there, they must be cleaned with a special metal brush.

To ensure that the tire fits correctly into the rim, a special lubricating solution is used during installation. The inner side of the tire and the inner tube are sprinkled with talcum powder. After inserting the tube into the tire, slightly inflate it - this will help avoid possible damage during installation.

Check to see if the camera is twisted or pinched. It is permissible to inflate a tire that has already been mounted only in a fence (mounting chamber) or using special devices.

When inflating, the technician monitors the pressure on the pressure gauge. It should be noted that in winter, before installation, the tire is preheated at above-zero temperatures.

During the installation of tires with a directional tread pattern, the direction of the pattern and the location of the wheels on the vehicle are taken into account.

A broken wheel: main signs and diagram of necessary actions

How to weld rims for a car photo and video

The driver can judge whether a tire is punctured by:

- unusual sounds when the car is moving

- a sharp drop in speed

- jerking and skidding of the car when driving on flat sections of the road

DIY tire fitting video tutorial

In such a situation, you must immediately stop, pull to the side of the road, and check the condition of the tire. If it is damaged, you should:

- put the car on the parking brake and first gear. If the car is parked on a slope, then under one of the wheels for insurance it is necessary to place a “shoe” or some kind of handy support (stone, log, etc.)

- turn on the hazard warning lights

- set warning emergency sign

- begin resuscitation measures

If a self-tapping screw gets into the tire, you do not need to remove it, but tighten it until it stops so that the pressure does not drop, and slowly drive to the tire shop.

If the object is inside the wheel and the damage hole is not visible, you need to hang the wheel on a jack and pour water on it, looking closely to see where the bubbles appear. The wire can be detected with a screwdriver by running it like a probe along the wheel.

If possible, the harmful object must be removed, and sealant or tourniquets can be used to seal the hole.

The sealant can be used to seal a hole in a tire.

If the tire has side cuts, it will have to be scrapped. Repairing will not help, the wheel will still be dangerous and can break at any moment. In this case, it must be replaced with a spare one.

To do this, eight operations are performed sequentially:

- the car body is lifted with a jack so that the wheel is raised by 3-4 cm

- fastening nuts are unscrewed

- the wheel is removed from the axle

- spare wheel installed

- tighten the nuts in a diagonal sequence, starting from the top, so that the alignment is not disturbed

- the car is lowered from the jack

- the nuts are finally tightened (with maximum force)

- Checking tire pressure (using a pressure gauge)

Regarding the damaged wheel, it must be repaired as quickly as possible (either at a service station or on your own), because anything can happen on the road, and there will be nothing to replace a broken wheel.

What you need to prepare in advance

tire fitting Any self-respecting motorist has at least a minimum set of wrenches and sockets to perform simple repair and adjustment activities. Tire fitting work also requires the following tools:

- jack - for lifting a car;

- wheel wrench - for unscrewing wheel bolts;

- pressure gauge - to control the pressure in the cylinder;

- pump or compressor - for filling the cylinder with air;

- two mounting blades (mounts) - for beading and dismantling the wheel.

In order to tear the tire from the disc rim, folk craftsmen practice the use of homemade devices, ranging from elementary corners to complex machines.

In addition, you need to prepare a soap solution or silicone grease to facilitate installation work.

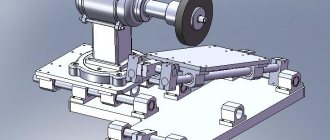

Features of a homemade design

You can create your own tire fitting by taking into account the design features of the machine.

The classic version is represented by the following main components:

- Frame. The basis of the structure is represented by a frame, which is made of rectangular profile metal pipes. It is recommended to place them parallel to each other. The connection is made using a welding machine; the structure can be strengthened with metal corners. In order to ensure long service life of the device, stainless steel should be used, as high humidity can cause corrosion.

- Pipe. It serves as a base for attaching the handle. The pipe used must be strong enough, as it will serve as a lever when carrying out the work of removing the tire from the rim.

- The riser is mounted on the frame. It is designed for installing a wheel rim. It is worth considering that a large load will be placed on this structural element.

All elements used must have high strength, since a strong load occurs when the tire is removed. It is recommended to strengthen the connection with screw fasteners.

Direct assembly process

You can assemble a tire changing machine as follows:

- To make the frame you will need durable profile pipes. They will serve as an excellent basis for the machine.

- A distance of at least 700 millimeters must be maintained between pipes. This ensures the stability of the structure during operation.

- The parallel arrangement of pipes is ensured by using an angle. In addition, they are used to strengthen the structure.

- If desired, you can complement the design with adjustable legs. You can make the device mobile by installing wheels or rollers; in working condition, fixation is carried out using stoppers.

- After creating the base, the metal pipe is fastened. It is recommended to choose a version with a diameter of 20-30 millimeters. A flange is installed at a height of 40–60 centimeters before welding work.

- The next step is to attach the fastening element, which is represented by a steel plate. It will be used as a base when attaching the lever.

- The lever is represented by a design consisting of a shoulder and a paw. The paw is used for direct tire removal.

It is practically impossible to assemble a structure without a welding machine. In addition, the metal should be protected from environmental influences by painting the surface.

Using a homemade machine

Without a special tire changing machine, it is almost impossible to remove or install tires.

If you have it, the work is greatly simplified:

- The wheel is placed on the support frame under the lever. It must remain motionless while performing work.

- The paw is guided to butt the tire with the disc.

- In order to remove the tire, strong pressure is applied to the lever. Under pressure, the tire deforms, causing it to move away from the edge of the disc. This procedure is repeated along the entire rim.

After the tire has partially come off the rim, you can use a regular pry bar. It is best to use a long tool.

Useful tips

When performing tire fitting work, the following recommendations should be taken into account:

- The extreme part of the lining should not be subject to serious mechanical stress. This is due to the fact that if you make a mistake, you can create serious problems for yourself in the future with the installation of tires. The most difficulties arise when installing tubeless tires.

- The edges are lubricated with grease to eliminate the possibility of damage to the rubber. It is worth considering that the tire should be lubricated every time it is installed. By using a lubricant, the likelihood of a rupture in the rubber is significantly reduced.

- At the time of installation, it is recommended to use a soap composition or another with lubricating properties. Their use greatly simplifies the installation process.

- When installing rubber on the disc, you need to ensure that there is no gap between them. This can lead to the tire starting to flatten or the outer part of the rubber to become damaged.

- On sale you can find quite a few different special kits for installing tires. Their use allows you to significantly simplify your work. Special kits include sealing harnesses and mounts of various sizes.

On the Internet you can find a variety of drawings according to which tire changing machines are made.

In most cases, improvised materials are used in construction. The design of a homemade tire changing machine allows for high-quality removal and installation of tires on almost any rim. At the same time, the machine is assembled practically from scrap materials, that is, it will cost a low cost. Considering that the cost of a service station is constantly growing, a homemade machine in the garage will be useful.

Old-fashioned method

In the old days, drivers caught by surprise used tried-and-true remedies.

They were as follows:

- the damaged wheel was lifted with a jack and removed from the car;

- a “spare spare” was installed for a while;

- the edges of the dismantled wheel at the level of the joint with the disk were placed under one of the wheels of the car;

- several impacts were carried out along the entire diameter of the tire;

- the inner edge of the tire on one side was completely torn off the rim (sometimes the impact was replaced by blows from a powerful sledgehammer);

- two mounts were inserted into the weakened gap;

- by successive movements of the tools clockwise or counterclockwise, the rubber was picked out from the disk;

- then manipulations with the mountings were carried out on the other side of the wheel;

- the disc and tire were completely separated from each other.

Then repairs were made, which usually consisted of replacing the tube or tire. The big disadvantages of the method were its labor intensity and the almost inevitable cases of the disk being crushed at the edges.

For tubeless tires such defects are fatal. It will definitely lose its tightness and will not hold air. To prevent this from happening, the damaged disc will have to be straightened or thrown away. In such a situation, the cash costs for a new disk are inevitable.

Stages of car tire fitting

Many car owners can do simple work related to car wheels themselves. For example, replace winter tires with summer tires or vice versa, seal a puncture, replace old wheels with new ones. But there are procedures that require professional skills and specialized equipment, available only in service centers.

For example, this may include:

- alloy wheel repair,

- vulcanization of chambers,

- wheel balancing,

- correction of violations of their geometry,

- inflating tires with nitrogen.

All this can be done professionally only at a good tire shop.

If there is an uneven distribution of weight on the wheels and, as a result, rapid wear of the tires, professional tire fitting and experienced technicians will also be required. The process of servicing a car at a service center consists of several stages.

Adviсe

After separating the tire from the disk, it must be completely dismantled. To do this, it is best to use a long pry bar to which the handle is welded. Having installed the disk on the flange, it is secured using a clamp. Then, using the narrow end of the mount, the edge of the tire is brought out beyond the outer part of the disk. By turning the disk over, the tire is completely dismantled.

At this stage, it is important to pay attention to the following points:

- The edge of the rim should not be deformed. This will significantly complicate the subsequent installation of the tire, especially tubeless.

- To maintain the integrity of the tire being removed, you can lubricate the narrow edge with grease. This will reduce the likelihood of cord or rubber breaking.

- When installing a new tire, it is recommended to use a soap solution.

When installing the tire on the rim, you need to carefully monitor the absence of gaps between them. In addition to the tire changer, it is recommended to purchase a special set that includes sealing harnesses and pry bars of various sizes.

Market analysis and features

A survey of domestic car owners shows that on average they spend up to 2 thousand rubles a year on tire services - and in megacities they visit tire shops less often, but leave more money. On the one hand, life in traffic jams takes its toll, but on the other, the quality of roads in large cities is higher. This means that in Moscow and regional centers, drivers more often buy “new shoes” for their cars, but in small towns there is a high demand for tire repair and balancing.

On average across the country, there is one tire service for every 10-12 thousand cars or 35-40 thousand residents. The larger the locality, the tougher the competition and the higher the cost of services. With the annual growth of the vehicle fleet by 15-18% and with the construction of new microdistricts, new niches are being formed in the market.

“There are interesting and credible studies that prove that the number of tire shops reaches 5 thousand,” says expert Igor Malyugin.