One way to decorate areas is to use forged items. Fences, benches, gazebos, stair railings and other similar structures look very decorative. Moreover, in most cases, these products are not forging in its traditional sense. Most often, this is done not in a forge or with a hammer and anvil, but with the help of some devices that allow you to create a wide variety of patterns and products from metal strips and square rods. To make such products you will need cold forging machines. Some of them you can make with your own hands, others are easier to buy.

What kind of devices are used?

Cold forging is characterized by various curls, bends, twisted rods, etc. Almost every type is made on a separate device - a specific machine. They can be driven manually or electrically. For small volumes “for yourself”, manual cold forging machines are used. Although they are not particularly productive, they are much easier to manufacture. If it is necessary to put production on stream, similar devices are made, but with electric motors. In this case, there is almost no need to physically work, but the complexity of making the device increases significantly. In our material we will talk about manual machines for cold forging.

What devices are used:

- Torsion bars. With their help, tetrahedral rods or strips of metal are twisted in the longitudinal direction. The result is twisted columns, which are also called torsion bars.

This is what a torsion bar and the machine of the same name look like

This is how they make a flashlight

Device for cold forging snail - for forming curls

For bending anywhere and at any angle - bending machines (bending machines)

Machine "Volna" - for the formation of the appropriate relief

Machines for shaping the ends of rods. In this case - crow's foot

For a beginning craftsman, the most relevant machine for cold forging is a snail. Only with its help you can make many interesting things - from a fence and gate to a bench and other similar products. In second place in terms of necessity is a torsion bar machine. It adds variety to the details. All the rest can be purchased or made as you improve and gain skill.

Torsion bar device

This unit is unified with other elements of a universal machine for cold or hot forging. The device includes:

- Hollow chuck with any method of clamping the rod - using three/two jaws, collets, threads, etc.

- A carriage on which a replaceable clamping unit is installed. with a fixed clamping unit, which is designed to fix the opposite end of the rod.

- Actually, a clamping unit with movable ball or wedge type grippers.

- A slider, which, moving along the guides of the frame, will ensure torsion of rods of different lengths.

- The frame on which all the devices listed above are mounted.

- Drive handle or steering wheel - for a manual device.

- Electric motor control panel - for mechanized version.

The general view of such a device is shown in Fig. 2

Figure 2 — Manual machine “Torsion”

As can be seen from the figure, the versatility of the equipment is ensured by the presence of seats for various grips, taking into account the diameter of the rod, since the versatility of the chuck is ensured by its design. All overall dimensions of the device are pre-calculated taking into account the ability to twist workpieces with a certain diameter and length.

For reliable guidance, the cartridge is seated in a plain bearing, which is located on the right side of the frame. It is better if several holes are placed in its upper part to supply lubricant to the points of frictional contact of the cartridge with the bearing. The handle or steering wheel is placed on the cantilever part of the chuck using a hot-press fit (to prevent slipping under load), or splined grooves are cut at the end of the chuck into which the handle will be inserted.

The movable carriage, on which the clamping unit for the passive part of the bar is mounted, should be made with guides, for which you can adapt the corresponding unit from a decommissioned lathe, for example, TV-4. Clamping is done using a pair of standard eccentric grips: this ensures uniform clamping. To reduce wear on the grips, a split sleeve made of normalized medium carbon steel is sometimes provided, which will compress the rod: it is easier to replace than the grips themselves.

The cartridge will require some modification: it is necessary to obtain a through hole in it, intended for introducing the rod into the deformation zone. You can do without this, but in this case the device will have limited functionality.

The frame can be welded from thick-walled profile pipes, or a channel of suitable size can be used.

The manufacture of the Torsion Bar device is advisable for large production volumes of this operation.

Homemade “Snails”

In essence, this is a modernized bending machine (pipe bender), but these improvements make it possible to easily make curls from fairly thick rods (up to 10-12 mm cross-section) and repeat them with a high degree of accuracy.

One of the homemade cold forging machines

These cold forging machines have several designs, but the easiest to implement is the one with a round table with a central leg. A lever with rollers on bearings at the end is movably attached to the leg. They make the bending process easier.

The table surface can be made of steel sheet with a thickness of 10 mm or more. For the leg, you can use any thick-walled round pipe. It is important to make the structure stable, since lateral forces will be applied, so side posts, spacers, and a stable base are needed.

Drawing of a cold forging machine “Snail”

It is easier to make a lever from a square pipe with a thick wall - at least 2-3 mm. The cross-section of the pipe is 25*40 mm or so. Attaching the lever to the leg can be done on a bearing, or you can simply take a small piece of thick-walled pipe of a larger diameter, put it on the leg, and weld a stop strip on the bottom so that the lever does not fall down. The option with a bearing gives easier movement, but if there is lubrication, the second option also works.

Lever mounting option

The shape of the lever is also important. The lever is double, the upper part is working, the lower part is supporting. Wherever there are connections, it is advisable to add reinforcement, since the efforts are significant.

The lever must be reliable, with reinforcement

A mandrel or jig is fixed on the table - the shape along which the curls are bent. They are made in different diameters so that you can make curls of different diameters. Such mandrels can be prefabricated to form a larger number of bends. Each such sample must have rods that are installed in holes in the table. This is how this template is fixed. Also, its shape must be designed in such a way that the end of the rod is well fixed in it.

Variant of conductors for the snail

Often, mandrels are machined from a metal circle of a suitable diameter using a grinder, but there are options made of metal with steel plates welded onto it, curved accordingly.

How to make a similar machine for cold forging is in the next video. There is also a good description of how to bring the ends of the workpiece to a decent state - ordinary raw edges look very rough. There is special equipment for processing them, but, as it turns out, you can do it without it.

Electric drive for machine tools

Classification scheme for the main forging tools.

Materials and tools:

- Asynchronous motor.

- Step-down inverter.

- Bolts with nuts.

- Gear.

- Belt or chain.

- Sheet steel.

- Welding machine.

In both cases, the system for a homemade forging machine works the same way, so there is no point in separating them. The only thing that will distinguish them is the presence of only one gear, because... in the case of a snail, the system works horizontally, and with a torsion bar, it works vertically.

The asynchronous motor is bolted together into one system with a step-down inverter. The rotation speed should reach no more than 5 rpm so that the result is as predictable as possible. The motor is fixed to the tabletop so that the outlet from the inverter is exactly opposite the working machine.

In the case of a torsion bar, it is enough to simply throw on a belt that will set the system in motion. The belt must be made of high-strength material, because... the load on him will be truly enormous.

In the case of a snail, the system is brought under the table, where, using a roller (gear), it is transferred to the horizontal plane and already under the table is combined with the base of the pipe. The pipe itself is brought down in the manner described above.

In any case, when working with an asynchronous motor, it is very important to remember safety precautions. All belts and chains are carefully covered on the human side with 1-1.5 mm sheet steel. If this is not done, there is a high chance of injury.

Torsion bar machine

As already mentioned, these cold forging machines allow you to make longitudinal bends on the rod. This is a relatively simple design. The main task is to fix one end of the rod motionless, attach a lever to the second, with which you can twist the workpiece.

A piece of profiled pipe with a thick wall (at least 3 mm) is suitable as a base. The retainer can be welded from the same rods, leaving a square gap of the required diameter. You can use a properly sized cable clamp (available at a rigging store). Any of these stops is welded to the base.

Cable holder - great for holding rods

see also

Comments 25

It turned out well, but this is for those who have the hands and the desire. I didn’t have one, although I found a bunch of drawings. We bought ready-made machines: spbstanki.ru/ruchnoy-instrument-holodnoy-kovki

Hello. Answer please. Does the curvature and angularity of the cochlea not matter? Will the rod still come out neat?

no, you need to do it as evenly as possible, I had a slight bend on the snail, but the part turns out even more closed

Cold forging for those who understand this is G (to put it mildly), so it doesn’t cost anything and you can’t make money on these semi-finished products, but the manufacturers of these cold forging machines make very good money by selling machines + dies for them for 5000-10000 euros. If you make beautiful things, then only a hammer and a forge, and cold forging is moldings.

I completely agree with you

Is 8 mm thick enough and the rod doesn’t come off? If you twist approximately 8-10 mm square?

I twisted the tenth square, it’s enough, but I would like it higher

And if you weld this bent square onto the snail, will it still be 18mm?

try it, I didn't bother

where did you get such thick metal for the snail and what did you use to cut it with?

Metal 8mm. Left over from my grandfather, cut out by a Bulgarian 125

How lucky I am with it, I bought it for free

Yes, more luck. When I was planning to take up artistic forging, I bought a tool, made mining... All my friends knew and offered everything that was “out of the box”, everything that was relevant. In 4 years we have gained a lot!

Are you still doing forging?

No. I prepared everything: a workplace, tools, fuel... but never got around to it. The season was spent on construction sites, the season was treated, and this one I decided to devote to UAZ. Therefore, due to the change of interests, everything is worth it.

There is no sales market, the material is expensive. Everyone who opened (officially) in the village closed. They asked me to sell everything - it’s a pity.

Maybe I'll do it again. There are machines for “cold” forging from eisenkraft - eisenkraft.ru/ I bought it used. I read certain resources on forging, collecting ideas (I can share). I can take measurements from factory equipment.

Okay, let's start with "you". Yes, our market is not so hot either, and there are plenty of metal workers, I have other work on business trips, it’s true, but all my life on business trips, life even the prospect is not ice at all. So in my free time I do what warms my soul, I hope that everything will be useful, we have a lot of greenhouses, maybe I’ll take care of greenhouses.

My main job is on the computer. And hardware is a hobby. I came in to warm up, I’m doing a “press” with an 8t jack. I just completed the cutting machine, from a 235 mm grinder.

I also want a drilling machine from the “steering rack 2108”. I found the rack, now I need a drill or a motor.

I also thought about making drilling chisels from the river). When you do it, be sure to post it! And with my next paycheck I decided to buy a factory cut-off one, I don’t have any extra grinders yet, it’s too early to buy everything, even if the factory-made ones are more expensive, we used this at work - it’s beautiful))) Why a press? and even at 8 tons?

It’s just that my father had a working jack lying around for about 30 years! And I needed to replace the wheel bearing, and there was beauty with the help of a press. I got into a conversation with a friend, he gives a 120 mm channel “in return”, 6 meters. Of course he knows that I have a glandular disease.

So, as far as expenses go, 3 meters of channel for 160 mm is missing. That's all.

Let's first deal with hot and cold forgings, stampings, bending and other bending. To then decide with feeling and sense whether you need a cold forging machine, and if so, which one.

Let’s put the concepts on the topic of “forging” in the right places and put in order a plan for our further actions. Forging metal with your own hands is no joke, we will approach this issue with all responsibility.

DIY torsion bar

Materials and tools:

- I-beam

- Sheet steel.

- The vice is round and standard.

- Reinforcing rod.

- Bolts with nuts.

- Welding machine.

- Bulgarian.

- Steel rollers.

This machine is used to twist workpieces into spirals, and this is done not in the form of a snail, but in the form of a snake. Manual work with a torsion bar requires a lot of strength, so many people prefer electric options. But in practice, the basis for such an artistic forging machine is always the same:

Torsion bar suspension diagram.

- You will need a piece of I-beam of the desired length. It is advisable to immediately use 1.5-2 m, so as not to look for the 5th corner later. The I-beam must be free of cracks and chips, because the lateral loads on it will be quite serious.

- A vice is fixed on one side, and this is done with bolts, so that if necessary they can be dismantled and replaced or repaired. To make this possible, a 4-5 mm steel plate is welded onto the I-beam, in which holes are made at 4 corners of 10 mm in diameter, through which the bolts will be threaded.

- On the other hand, a similar platform is made from sheet steel, only it is not fixed by welding, but is made movable on steel rollers. This measure allows you to adjust the length of the workpiece being developed. A circular vice is installed on this platform, the fixation in which is carried out using bolts, and the core (fixation point) can be set in motion, for which separate levers are removed.

If there are no levers behind the system, then they should be welded from a steel rod. The design of the torsion bar is quite simple in theory, but in practice it is not easy to make all these fastenings, and even so that the steering wheel can rotate unhindered.

Maybe you need a punch? Main concepts

You've probably already noticed that on our website we love to point out anything that's wrong. Now, too, we will not change ourselves: the concept of “cold forging” in its usual meaning is fundamentally incorrect, read carefully, we will explain.

First, what is forging: it is the processing of metals heated to forging temperature, that is, to the temperature when the metal becomes soft and can be deformed. Blacksmithing is all about forging - with a hammer, an anvil, a forge and mighty bearded blacksmiths wearing leather aprons.

Blacksmithing products are an exclusive and expensive business. And, in general, it is already exotic, if we exclude stamping, which is done automatically and in huge volumes.

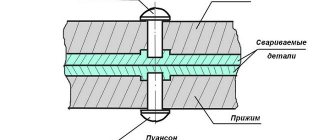

Stamping is the extrusion or deformation of metal using a stamping press with a special matrix - a nozzle at the end. This is what it is - a punch that is made from the highest strength steel. Stamping can be hot, with heating of metals to forging temperature, and cold, without any heating. You don’t have to look far for an example of cold stamping - these are all metal drink cans.

Types of cold forging machines

We reason logically and point by point. You cannot bend metal with your hands, no matter how hard you try. Do-it-yourself cold forging is done only using special machines. It's all about them. This is the first point. One machine is not enough; there are a whole bunch of them. This is the second point. Some of them can be done with your own hands.

We take the rod. There are only two options to bend it:

- Along the axis so that the rod begins to resemble a twisted cord.

- Across the axis in the form of various curls, waves and bends.

All cold forging machines are divided into four groups according to the same principle:

- Torsion bar machines that produce longitudinal helical twisting of rods and various filaments, which we will discuss below.

- Twisters for forming curls and spirals with a narrow center.

- Bending machines for waves and zigzags.

- Stamping machines for flattening the ends of rods in the form of legs, clamps and other patterns.

Making a homemade machine

Recently, metal products created by forging have become very popular due to their attractiveness.

Such products usually have a fairly high price, so it is rare to get all the interior decorations that you would like. In addition to the hot forging method, there is a cold variation. It can be used by creating a cold forging machine with your own hands.

Which machine is most needed?

Do-it-yourself cold forging machine: which one is the most necessary and which one to start with? There is no clear answer to this question; you must decide for yourself. To make a smart decision, let’s go through the main types of machines to have an idea of their functionality and, most importantly, DIY manufacturing methods.

You should remember what materials you will have to work with during the cold forging process: these are metal rods or rods with a diameter of no more than 14 mm, squares and strips with a thickness of approximately 3 to 6 mm with a width of no more than 25 mm.

A complete gentleman's set of machines in the workshop for full-fledged work will look like this:

- twister with snails for obtaining spirals of various radii;

- bender for bending arcs and parts at different angles;

- wave for curved parts and processing of metal pipes;

- globe for obtaining large arcs from profiles;

- flashlight for bending parts;

- volumetric

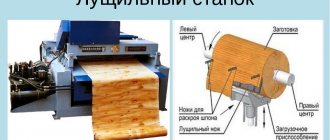

Pipe bending machine

If no one experiences any difficulties when decorating any interior elements with cutting profile pipes, then if it is necessary to bend them, on the contrary, everything becomes more complicated.

Special bending machines for pipes, which you can do yourself in advance, will allow you to carry out such work efficiently and quickly.

Different drawings for the manufacture of this type of equipment can be used, depending on what materials will be used in the work.

At first glance, assembling a production-type machine for cold forging of metal, as in the photo, is difficult.

But if a master has already gained experience working with metal, nothing is impossible for him. The main thing is to choose a solid, stable foundation for the future structure.

For example, it could be a massive metal table made from pipes or profiles.

Since bending of the metal will occur due to the shafts present in the structure, it is necessary to select three such elements.

Each of them is a metal cylinder with thick walls and an axis of rotation. Two cylinders are fixed slightly above the table, and the third, central, is placed above them.

The distance of the two outer cylinders determines the angle at which the pipe will be bent.

In order to be able to change the position of the cylinders if necessary, it is necessary to make additions to the design drawings in the form of stoppers and rollers, which will make this part adjustable.

After the cylinders are fixed, it is necessary to organize a rotation transmission system for them.

For this purpose, they use a chain mechanism from an old car, which can be found on the spare parts market.

It is better if the mechanism is equipped with gears; if not, then they will have to be purchased separately.

The gears are mounted on the two outer cylinders and the tensioner is placed below the shafts in the center. Then one of the outer cylinders is equipped with a handle in order to create a rotating force.

The machine for cold forging of metal products is ready. The following video will help supplement the above material with details.

Making a snail with a lever

Before you begin the practical part of the work, you need to prepare theoretically. We are talking about calculations and drawings of the machine and its parts. Nobody will give you the exact dimensions, because this is an independent design.

Much will depend on the availability of similar materials, the scale of future cold forging work, the dimensions of the room where you are going to work and many other factors. The main thing is the principles that you need to understand in order to make a homemade cold forging machine with your own hands - the most convenient option for you and only you.

Here's what you need to gather before you begin assembly:

- metal plates or tabletop cloth with a thickness of at least 4 mm;

- metal round pipe for a rack or frame;

- metal rod;

- bearings of different calibers;

- drill;

- welding machine;

- hacksaw for metal;

- M8 bolts.

Basic parts

The twister has only four basic parts. Pay special attention to their preparation and, most importantly, installation:

- frame or stand;

- table top;

- main shaft;

- lever arm.

Rack

Only made of metal, no wooden beams. We place it in a thoughtful place so that you have access to the machine from any side. The machine will be subject to heavy loads, so the best option may be a thick-walled pipe or a metal corner.

It is best to concrete the stand directly into the floor, it will be reliable. Externally, this design may resemble a stool. As strong as possible - this is the main principle of producing a countertop stand. Therefore, it is better to connect metal parts by welding.

Tabletop

The most important part of the machine, which is best made from a metal plate with a decent thickness, preferably at least 5 mm. In the production of forging machines with your own hands, you cannot save on the thickness of the metal, because the table top and other basic elements will take on a huge load.

The preferred shape is a circle. You need to make two of these tabletops: the second is needed for bending the rods and placing the snails.

Main shaft

From the same metal plate, cut four right triangles with equal sides. Weld the triangles to the bottom of the structure, and their base is in the center of the circle. Another shaft option is not made from triangles, but from a pipe with thick walls of a suitable diameter. Fasten either with bolts or welding.

Mechanical modification to the snail

Materials and tools:

- Reinforcing rod.

- Sheet steel.

- Belt or chain.

- Bulgarian.

- Welding machine.

There is not always a desire to rotate the workpiece with your own hands, because... This is a very tedious process that takes a lot of effort. It is possible to simplify the machine for artistic forging, using only some knowledge of physics in terms of converting speed into force.

To begin with, a steering wheel is created, which can be represented by any large valve or 3 rods of a thick rod (20 mm) welded together. In the case of rods, small steel plates are welded in the center on both sides, which expand the area of the weld seam, significantly strengthening the structure.

An ordinary round pipe is welded from below, the length of which will extend 10 cm under the tabletop. A similar step must be taken with the profile pipe (a transition is made to a round one), which provides support for the cochlea. Under the table top, a notch is made on each pipe, which allows you to install a metal chain or belt.

There is a very important aspect here: a small thread is made under the steering wheel, and 2-5 times more under the volute. This is done in order to reduce the load on the hands when rotating (the principle is taken from a bicycle, where it is very convenient to overcome high obstacles when the speed is reduced).

Making a torsion bar machine

Torsion treatment is fundamentally different - it is a screw twisting of the rods along. This machine is very easy to make with your own hands. The main thing in it is to ensure a strong fixation of the two ends of the metal rod; the success of screw twisting depends on this.

The clamps have nuts welded into the bolts that are tightened to hold the metal rod.

If your plans include “pump up your biceps and triceps,” be sure to make a torsion bar machine and start twisting the rods by hand. Torsion forging is not for the weak, you will develop excellent muscles in the upper shoulder girdle. But one way or another, it is better to make the lever for rotation longer, it will be easier.

Bends, flashlights, waves and other machines

As you can see, we have collected all other types of cold forging machines in one small section. Why is there such disrespect for them, in contrast to the snail and torsion bar, which we talked about in separate sections? The answer will be honest in the form of advice:

If you decide to make a forging machine with your own hands, opt for two machines: a snail and a torsion bar. Firstly, they are absolutely necessary from a functional point of view, and secondly, they are quite simple to implement independently.

The remaining machines, such as a flashlight or a wave, can be built much later, when you realize that cold forging is for you, and when you have specific creative plans in your head.

But there is a third machine after the volutes and the torsion bar, without which it will not be possible to start cold forging. This is a bending machine. Outwardly, it seems the simplest of all, and its function is the most seemingly simple: bend rods at a certain degree or make waves of different sizes.

There is no need to make a bending machine yourself; it is better to buy it ready-made for two important reasons:

- Wedges and rollers, which are used to change the dimensions of manufactured elements, must be machined to the ideal dimensions. It is almost impossible to do this at home.

- Bending machines are very inexpensive, so the budget saving requirement will be met.

Having at your disposal the three most necessary machines - a self-made volute and torsion bar and a purchased bending machine - you can begin cold forging of almost any complexity. There is one more small issue left to resolve.

Manual drive or electric?

The electric drive can be installed on any machine. Another question is – is it necessary? Again, the decision depends on your plans. The electric drive will allow you to save your own energy. But this is not its main advantage. The torque with electric force will be more uniform, and this will lead to smooth and uniform forging elements.

The number one contender for an electric drive is a torsion bar machine, where it is extremely difficult to maintain uniformity of screw twisting by hand. It's also very easy to do. You will need a drive axle axle shaft of an old car, a differential gear pair, and a protective sleeve. The power of a homemade engine should not be high - no more than three kW and no higher than 900 rpm.

As for the electrification of the remaining machines, decide for yourself. If you plan to do cold forging for your own needs, you are unlikely to need electric traction.

We wish you strong snails, high-quality rods and true connoisseurs of your blacksmithing art.