How to make a homemade gearbox for a walk-behind tractor, photos and drawings

The idea of how to make a homemade gearbox for a walk-behind tractor was taken from the “Modelist-Konstruktor” magazine; the design of the unit was redesigned in accordance with the following requirements: eliminate chain drive from the transmission design, ensure the lowest possible center of gravity. Since the necessary gearbox was missing, the transmission was made from spare parts for gears for the Elektron scooter engine.

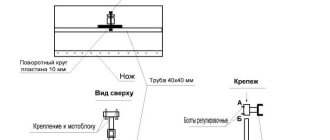

Walk-behind tractor: 1 – engine; 2 – casing; 3 – gas tank; 4 – ignition coil; 5 – switch; 6 – pin for fixing the angle of inclination of the working body (not shown in the top view); 7 – M16 bolt; 8 – axis of fastening of the working body; 9 – working body (plow); 10 – holder; 11 – frame; 12 – carrier with control handles; 13 – wheel with lugs.

Types of gearboxes

There are worm and chain devices.

The differences between them are small, but quite important. The difference lies in the characteristics inherent in the two different types: efficiency; angular velocity; number of gears; number of shafts and ratio between gears. Relatively cheap walk-behind tractors are often equipped with non-separable gearboxes for simplified assembly . In this case, the service life is significantly reduced and additional possibilities are eliminated:

- repair;

- assembly;

- disassembly;

- replacement of parts.

This indicates the low quality of the material used to manufacture the gearbox, and that most of the parts will not be sleeved. The diagram will give an idea of the principle of its operation and service life.

Expensive walk-behind tractors are equipped with gearboxes that are more complex in design and allow further assembly and disassembly. Maintenance can be carried out by correcting all the shortcomings in the operation of the device.

Repairs are carried out in order to extend the service life. It is recommended to replace faulty parts with more expensive ones. Timely lubrication will also extend the service life.

In most cases , the gearbox converts speeds , that is, the angular speed is quickly and efficiently transformed into a low one. There will be a high angular velocity on the input shaft, and a low one on the output shaft.

To prevent unexpected breakdowns, regular high-quality maintenance . When changing speed in steps, the gearbox is called a gearbox. When a step system is not used, the device is called a variator.

Motoblock gearboxes: what is more reliable - a chain, gears or a worm?

The gearbox is the most important part in the design of a walk-behind tractor; a properly selected engine-gearbox combination is the key to long and successful operation. The gearbox is used to transmit torque from the engine through the clutch to the wheels and convert high angular speed on the input shaft to the required speed on the output shaft. There are three main types of gearboxes: worm, chain and gear, as well as a “hybrid” gear-chain version.

Light motor cultivators are equipped with engines with a vertical shaft and use a worm gear, which is compact and does a good job of cultivating previously cultivated land, but use on virgin soil (as well as installing a plow or trailer) can lead to its breakdown due to increased load, as as this design typically uses a brass gear. Another disadvantage of the worm gear is the lack of reverse (reverse). Low efficiency, heating and increasing output shaft play during operation reduce the service life of this unit.

The use of a chain gear in a walk-behind tractor is one of the most popular solutions; it has sufficient service life at a low cost. Moreover, if the housing is made dismountable, then the most common breakdowns (stretched or broken chain, damage to sprocket teeth, or cutting off a key on the drive shaft) can be easily resolved in a service center or even independently (if you have spare parts and certain skills). The narrow housing of the chain gear gives an advantage when carrying out certain types of agricultural work.

The gear reducer has the most reliable design; it is designed for long-term operation, incl. commercial (with proper maintenance and compliance with the manufacturer’s operating recommendations). The use of high-quality metal for the production of gears and their processing on high-tech equipment provides a serious advantage over gearboxes of other designs. A relative disadvantage of a gear transmission is its price, which significantly affects the final cost of the walk-behind tractor.

A gear-chain reducer is a compromise option, which, when installed on a motor-cultivator, increases its performance characteristics (compared to chain and worm gear), and when installed on a walk-behind tractor, slightly reduces the cost of the latter.

Types of gear units

The transmission of rotational motion from the motor shaft to the actuator shaft can be carried out by direct connection of the axes, if the speed and power of rotation of the engine are acceptable for operation, and the axes of the drive and driven shafts coincide. Such cases are extremely rare, and with several attachments for different purposes, direct transmission absolutely cannot be used. To match the speed and power of the drive and driven shafts, 4 types of mechanisms and their combinations are used. Main types of gears:

- belt;

- chain;

- gear;

- worm

The worm gear is structurally limited by the speed-reducing function; the rest can be used in both downshifts and overdrives. In addition, such a gearbox always has a driven axis perpendicular to the drive shaft. This scheme is called an angular gearbox. In addition to the worm gear, you can change the direction of the axis using a spatial planetary mechanism. Belt and chain drives keep the driven axis parallel to the engine axis. In simple devices, reverse is possible only when the rotation of the engine changes.

Motoblocks use engines with a high number of revolutions per minute, which can be verified in the product data sheet. This means that you need to make a gearbox with your own hands to reduce the speed, and it is better to choose what type of homemade gearbox for a walk-behind tractor, knowing the characteristics of each type.

Belting

The pulley or belt that transmits rotation from shaft to shaft is familiar to every motorist who has looked under the hood of the engine compartment. The rotation speed reduction coefficient is determined by dividing the radius of the small driven wheel by the radius of the large driving wheel.

Chain

pros

- Low price.

- A simple design that can be easily repaired at home.

Minuses

- The rotation speed of the lower shaft is excessive, it ranges from 140 rpm. Excessive speed leads to the fact that the gearbox crushes the soil too much, making it dense and unsuitable for planting.

- Due to heavy load, the chain stretches over time.

Manufacturing or selection of ready-made structures

With access to a wide range of components: a junkyard of old equipment or abandoned property of a repair shop, it is possible to manufacture a gearbox with an accurate selection of the gear ratio.

However, such a complex structural element requires serious metal processing equipment. You can select a housing of the appropriate size, drill holes for the shafts on the bearings, and assemble the structure no worse than the factory one.

However, experience shows that the selection of ready-made structures with minor modifications is much more effective. As an example, consider a homemade walk-behind tractor based on an engine from an IZH motorcycle.

A proprietary gearbox is used, with the ability to change speeds. The standard gear ratio is not enough, although a small sprocket on the output shaft of the gearbox, combined with a large sprocket from the drive wheel, already provides a good reduction in speed.

The shaft, installed in the bearing podium, is equipped with another small sprocket, which, using a second chain, transmits torque to the wheels. In turn, a large diameter star is installed on the drive axle.

The result is a design with two-stage rev reduction and solid torque. By using the motorcycle gearbox, you can select the required speed without using the throttle. The engine almost always runs at idle speed, which prolongs its service life.

No less popular is the use of a ready-made gearbox from the Ant scooter.

It is not necessary to use the entire wheeled platform; it is enough to install your rollers on the bridge. By using the gearbox from the selected power plant, you will get the optimal ratio of power and speed.

Video: modification of the gearbox of the Neva walk-behind tractor.

Gear-chain

pros

- The most efficient soil treatment due to optimal rotation of the output shaft. Rotation ranges from 80 to 120 rpm.

- You can use any mounted or trailed equipment. Low speed allows you to work with a weeder, plow and other equipment.

- High reliability and excellent performance.

- The operation of the gearbox is quiet and soft.

- The optimum ratio of price and quality.

Minuses

- Repairs are more difficult and more expensive than other types of gearboxes.

- Some gear-chain gearboxes have only one gear, making it difficult to select the optimal speed.

Types of mechanisms

According to the method of operation and action, all transforming mechanisms for walk-behind tractors are divided into several types:

- angular;

- downward;

- reverse with reverse speed (reverse gearbox);

To redirect rotational energy from a vertical drive to a horizontal plane, an angular gearbox using bevel gears (bevel gearbox) is used.

Reducing the number of revolutions and increasing the power of the drive mechanism is provided by reduction gearboxes, or creepers for the walk-behind tractor. They are considered the most reliable for operating a diesel or gasoline air-cooled walk-behind tractor. This allows them to be used for particularly difficult work - for example, plowing heavy soil or harvesting potatoes using a potato digger.

What types of gearboxes are there for a walk-behind tractor?

Gearboxes are divided into types:

- angular;

- downward;

- gear;

- worm;

- chain;

- combined.

All of them find their application on walk-behind tractors of various types.

Angular

The angular gearbox for the walk-behind tractor ensures the coupling of the engine with the transmission and attachment mechanism. Another device is also used, if modified. The corner device consists of the following parts:

- flange;

- flange mounting;

- bearing;

- frame;

- pulley;

- belt;

- steel washer;

- pulley fastening;

- key;

- rotor shaft.

You can make this device yourself. Before work, it is necessary to take into account the conditions in which he will work. These are radial and axial loads at the ends of the shafts. The load depends on the type of lubricants and temperature. It is best to choose a factory-made case. Bearings of the required size are selected for the shaft.

Downward

A reduction gearbox for a walk-behind tractor, either self-made or industrially manufactured, is designed to increase the power of an agricultural unit. This may be necessary when operating the walk-behind tractor on sandy soil, when the wheels begin to slip. It is used on gasoline and diesel vehicles equipped with an air cooling system.

You can reduce the number of revolutions and increase the power of the drive mechanism using reduction gearboxes, which are sometimes called creepers for a walk-behind tractor. They are considered the most reliable for operating a diesel or gasoline air-cooled walk-behind tractor. When the unit is operating, the number of revolutions decreases. This allows you to use the walk-behind tractor for particularly difficult work, for example, plowing heavy soil or harvesting potatoes using a potato digger.

Gear

A gear converter with a differential is used in heavy-duty walk-behind tractors. It is well suited to engines with a vertical crankshaft. The gearbox produces little noise during operation and has high performance. It is capable of functioning in straight and angular patterns. Gears are used both bevel and cylindrical. The device requires the constant presence of oil in the crankcase, but this feature is compensated by its high power.

On heavy units, the gear converter is often equipped with a gearbox. This transmission allows the walk-behind tractor to move in reverse. Reverse occurs during reverse rotation of the gears in the housing. This is achieved by changing the position of the lever outside the housing.

Gear reducer is the best choice for heavy agricultural machinery. An engine equipped with this mechanism runs longer than with a worm version.

Worm

Worm gearboxes are widely used in mini-tractors and walk-behind tractors. This model has gained popularity due to its long period of trouble-free operation and high reliability. The worm-type device has a reverse, allowing the unit to move in reverse. A distinctive feature of this converter is the presence of a special screw and worm wheel. The thread profile on the parts is trapezoidal. They are made from high-strength materials.

The screw can have a four-start thread or a two-start thread. It matches the thread on the gear. The teeth on high-quality parts are made of anti-friction steel. The efficiency of the device is high. Its advantages:

- the gearbox allows you to extend the service life of the engine;

- creates little noise during operation;

- The device consists of only 2 parts;

- has a large gear ratio;

- has a smooth ride;

- high self-braking effect.

All positive qualities appear with precise assembly and adjustment of the mechanism.

Chain

A chain device must have a chain in its design. Sometimes it occurs not just one, but in several pieces. The gear chain is put on the sprockets and ensures their rotation. The device is easy to use, has a reverse function and a high degree of reliability. The operating principle is similar to a belt mechanism. Changing the gear ratio is easy by changing the sprocket sizes. They work like a bicycle, but in reverse: the small one is the driving sprocket, and the large one is the driven sprocket.

Reliability of operation is ensured by the quality of the metal of the sprockets and the strength of the chain. When making your own gearbox, you should use motorcycle sprockets; they are much stronger than bicycle sprockets. The design of the product is simple and reliable, it has a reverse function. The chain requires constant lubrication and tightening. Its rupture is a common cause of gearbox failure. To repair, you need to change the chain.

Combined

The combined gearbox combines gear and worm, worm and cylindrical gears. It can be single-stage or multi-stage. The single-stage mechanism has a gear ratio of up to 7. The body is made of cast iron or welded aluminum. Two-stage devices have a gear ratio of up to 40, three-stage - up to 150.

All of them are designed to change the speed of rotation of the engine shafts and the power take-off shaft. All types of gears are placed in a single housing. The combined mechanism is the most practical. Despite its small size, it has high quality and low cost.

What is a gearbox?

This mechanism is a transmission link that is located between the rotational devices of an electric motor or internal combustion engine to the final operating unit.

The main characterizing indicators of the gearbox are:

- transmitted power;

- efficiency;

- number of driving and driven rotary shafts.

Gear or worm gears are fixedly attached to the rotational devices of this mechanism , which transmit and regulate movement from one to another. The housing has holes with bearings on which the shafts are located.

Features of the gearbox and its influence on the design of the mini tractor

DIY lugs for a walk-behind tractor made from car wheels

Reducing gearbox for a mini tractor: possible breakdowns

- Excessive physical stress, as a result of which shafts and gears can overheat in spare parts, and gear teeth can break. In the latter case, the breakdown can be diagnosed due to characteristic shocks in the chassis area and the inability to reduce the speed to the desired level.

- Improper care or lack thereof. Inspection of a mini tractor also includes checking the main parts related to the wheelbase and engine, so gearbox faults will be detected fairly quickly.

- Incorrect selection of consumables: lubricants, etc.

Important! If you have to change the gearbox in the event of a breakdown, you should select the correct gear ratio so that the operation of the device is not unbalanced.

Assembly of a reduction gearbox: what needs to be taken into account?

- The rated power required by the device.

- Torque.

- Gearbox installation angle.

- Number of revolutions per minute.

- Load on the shafts of the spare part along the axis and radius.

- Limits of temperature arising during operation.

- Type of lubricant required.

- Switching cycle (full or variable).

Hitch

A homemade walk-behind tractor or motor-cultivator is complemented with all kinds of attachments. This is done in order to expand:

- functional;

- application area;

- seasonality of work performed.

Thanks to the possibility of layout, the homemade product can be used in any season, even in winter, which allows you to use the equipment all year round. In addition to plowing and cultivating with attached equipment, they plow the land, plant and hill up crops, dig up potatoes, as well as clean up areas and prepare haylage. If, in addition to the walk-behind tractor, you make a trailed trolley, then it will also be able to perform transport functions, helping to transport heavy, bulky loads. Due to the high cost of mounting equipment, many try to make their own inventions using drawings, sketches, and original videos. But if you make a single-point trailer hitch on a walk-behind tractor, you can buy new equipment, for example, from a Neva walk-behind tractor.

Potato Digger

Making a homemade potato digger begins with preparing the carriage body, welded from wire and thin twigs. The sketch presented here will help you understand this process (you can also use the video).

Fig.4.

Roaring potato digger A shovel made of steel sheet and repeating the shape of the potato digger body is installed on the homemade axis in front of the carriage. At the back, extension rods are welded to it, slightly bent to the bottom. A description of the parts is shown in detail in the diagram. This design is great for the garden.

Peculiarities

Chain gearboxes can be different, but mostly they are dismountable, that is, they have a bolted connection. This makes it possible to carry out easy visual diagnostics, identify any deviations in gears and chains in a timely manner, and the lubricant will be conveniently applied to the mechanism.

The main advantages of chain gearboxes include:

- Availability of reverse function;

- Simple operation;

- High level of conveyor reliability.

The most common failures of chain gearboxes are associated with chain rupture or stretching. These faults are very easy to fix even by people who do not have special technical skills. This is a big plus, since repairing a chain gearbox does not require contacting a specialist.

The gearbox has a fairly simple structure. Among its components, we can note a chain and two sprockets, upper and lower. The lower sprocket is located on the working shaft, due to which the mechanism operates, in which lubricant is used to reduce its wear. A manual chain reducer works on the same principle. The existing gear ratio on the stars allows you to increase the force on the cutters. This version has a thin body, as this ensures maximum penetration of the cutters. The housing is equipped with holes with bearings, and the shafts are located on them. Below we will describe the process of how to assemble a chain gear yourself and carry out calculations.

Build process

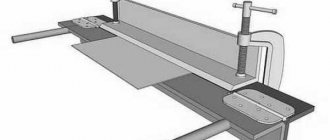

It will be better to start making a homemade gearbox by installing the drive sprocket of the first stage of the gearbox on the output shaft. The star can be attached in different ways, in each design individually. Can be fixed with a key, flange, or spot welding. The driven shaft is assembled using 2 axle shafts. Their ends require counter flanges. Between the flanges, you need to install the 2nd stage driven sprocket in its place, after which you can assemble the axle shafts into a whole structure using a bolt connection.

To organize the protection of the chain transmission, the 2nd stage gear unit is protected with a protective housing. In addition to its protective function, it serves as a reservoir in which the liquid is located. It is capable of ensuring smooth operation and helping to reduce wear of parts due to friction.

The housing must have coaxial mounting slots where bearings are installed, which serve as shaft support. To install the driven shaft, conventional ball bearings having a cylindrical housing are required.

Due to the design feature, the eccentric is able to change its location by an angle in the socket, up to 15°. Along with it, the location of the drive gear shaft also changes, which allows you to adjust the amount of chain tension.

When the mechanism operates, the calculation is that the teeth of the 2nd stage driven sprocket are immersed in the oil in the container to form a lubricant. Due to rotation, the lubricant is evenly distributed over all chain transmission units.

You can create a seal around the casing. To do this, it is necessary to install standard sealing gaskets and seals on the bearing seats and on the housing split line. They can be selected without much difficulty, because all sizes in the design have standards.

In order for a self-made gearbox to have a sealed housing, you will have to put in more effort. When non-standard products or outdated types of shells are used, it will be more difficult to find seals on them. For these purposes, you can use special oil-resistant sealants.

Walk-behind tractors with a gear reducer and a reduction gearbox for a walk-behind tractor

A reduction gearbox for a walk-behind tractor, in common parlance a speed reducer, is installed on modern air-cooled diesel and gasoline walk-behind tractors. Thanks to this, the user can use the walk-behind tractor on particularly heavy soils for plowing and digging up potatoes. The reduction gear helps with wheel slipping when there is not enough own power.

Motoblocks with gear reducer

To understand what a gear reducer is, let’s look at the structure of the transmission. It transmits torque from the engine to the wheels, and changes the speed and direction of movement of the walk-behind tractor. The transmission consists of a gearbox, differential, gearbox and clutch. Transmission units can be gear, chain, belt, or a combination of one or the other. The gear transmission consists of bevel and spur gears (gear reducer). It is used on some models of cars and heavy walk-behind tractors. The figure shows the gear transmission of the Ugra NMB-1 walk-behind tractor, which uses a gear reducer.

Gearbox manufacturing process

Do-it-yourself angular gearbox.

do-it-yourself angular gearbox which gearbox to use for a homemade tractor This is the first quantity required to perform the calculation. The value is not constant, with the addition of “gas” the number of revolutions increases. Basic value: idle speed +10%.

Next, the rotation of the suspension axles is calculated. Knowing the size of the wheels, it will be possible to calculate the amount of run-out per revolution. The number of axis revolutions is calculated to ensure a comfortable speed - 3-5 km/h, which is the second value for design.

For example, idle speed +10% is 600 rpm. The required wheel axle speed for 3 km/h is 200 rpm. So, the gear ratio should be 3:1. The rotation speed of the axis is reduced by three times in relation to the speed of the motor shaft, and the torque increases accordingly by three times. Gearbox types:

Gear - use the ratio of the number of teeth of the driven and driving gears. The device operates on the principle of steam in the gearbox

It doesn’t matter what shape the gears have - the teeth can be straight or oblique. The bevel gear is used when the walk-behind tractor requires an angular gearbox

It all depends on the location of the motor. If alignment is ensured between the motor shaft and the wheels, an angle is not required. A worm drive is needed to create a large gear ratio when there is a large difference between the revolutions of the drive axle and the engine. This design is more difficult to manufacture and maintain. The solution is optimal if the motor shaft is perpendicular to the wheel axis. Chain gearboxes work like a bicycle, but in reverse. The leading one is a smaller star. The reliability of the design is determined by the quality of the gear metal and the strength of the chain. A simple set from a bicycle may not withstand the load, so more durable ones are used - motorcycle ones. Belt devices are the simplest to manufacture. They are also the most unreliable and weak. Large torque is not transmitted, as the belts will slip. But the shock load on the engine is reduced - the design is more gentle on the drive shaft, jerks are smoothed out. Slippage is eliminated by installing a timing belt. In this case, you need to find a pair of toothed pulleys, for example, from an automobile timing system. Combined system. A device with a chain and gear drive can be manufactured in one housing, although the calculations in this case are more complex. But it is possible to transmit enormous torque with low engine power.

When choosing any design, do not forget about the following rules:

- do not allow distortions between the driven and driving parts;

- Bushings cannot be used, only bearings.

Any device other than a belt one must be constantly lubricated, therefore it must be in a box. The sealed housing will protect against dirt and dust, the ingress of which is inevitable during field work. Oil seals are installed on the shafts.

As an example, we can take factory products for Soviet agricultural machinery. The chain drive is not so sensitive to lubrication, but the chain must be cleaned and lubricated regularly.

Finalization of the finished design

An example for us will be a homemade unit based on an IZH motorcycle engine. A “native” gearbox with the ability to change speeds is used. The standard gear ratio is missing, but a small sprocket on the output shaft of the gearbox with a large sprocket from the drive wheel already provides a good reduction in the speed.

Another small sprocket is put on the shaft, which is installed in the bearing podium, which transmits torque to the wheels using a second chain. The drive axle, in turn, is equipped with a large diameter star. The result was a design with a 2-stage speed reduction and high torque.

Using a motorcycle gearbox, you can select the required speed without using the throttle. The engine almost always runs at idle speed, which extends its service life.

No less popular is the ready-made gearbox from the Ant scooter. There is no need to use the entire wheeled platform; installing your rollers on the bridge will suffice. By using the gearbox from the selected engine, you will get the optimal ratio of speed and power.