A drainage pump is a unit that is used by residents of country houses and dachas to pump out waste and groundwater that floods basements, inspection pits in garages, trenches and living quarters. The compact drainage pump allows you to quickly get rid of large volumes of water from various artificial and natural reservoirs. Below we will consider the design of the unit, the features of its selection and self-repair.

Drainage pump design - device design

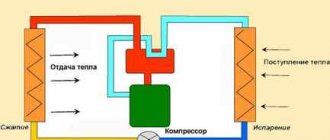

One of the main advantages of a sump pump is its simplicity of design. The unit for pumping water from a well consists of a housing, an electric motor and a pump unit. The last element is responsible for the uninterrupted supply and pumping of liquid. Blades or an impeller are installed on the pump shaft. The shaft is fixed in the bearing units of the device.

The motor design includes a rotor and a stator, and the design of the pump unit includes a suction pipe and a discharge pipe. The automatic control unit consists of an overheat protection relay, a thermostat and a circuit breaker.

The blades of the device are made of durable technical polymer that is resistant to corrosion and mechanical damage. Some modern dirty water models are equipped with steel blades, which are more durable than polymer parts.

All pump parts are housed in a durable metal casing. The body of the submersible drainage unit is made of stainless steel, and the body of the surface unit is made of cast iron or composite alloys.

GILEKS Drainer 350/17 – unsinkable performance

GILEX Drainer 350/17

GILEKS Drainer 350/17 A submersible device designed to work with clean water. Allows you to filter particles up to 6 mm, plunging into the depth of 8 m. At the same time, the throughput of the device is 21 cubic meters per hour. Withstands the temperature of the pumped liquid from +1 to +35 degrees.

The pump is installed horizontally, equipped with a float switch to protect against dry running and an automatic water level control system.

The body of the Drainer is made of plastic. The device operates at a voltage of 220 W (50 Hz), and the length of the power cord reaches 10 m.

Advantages:

- high engine power and performance

- high pressure and pumping speed

- removable elements

- Possibility of disassembling the bottom to clean the filter in front of the impeller

- can stand at the bottom of the source thanks to the “skirt” base

Flaws:

- unreliable fastening of the plastic impeller

- massive parameters, does not fit into narrow spaces

Current prices

Drainage pump Gilex pumping out a septic tank for 120 meters

Drainage pumps | TOP 10 Best: choosing assistants for pumping clean and dirty water + Reviews

Operating principle of the drainage pump

The drain pump works on a very simple principle. Immediately after connecting the unit to the electrical network, the engine starts, which drives the shaft with blades. Water under high pressure enters the device through the suction pipe, after which the blades act on it. The latter pushes the liquid through the pump unit into the discharge pipe. From there, the water is pushed into the outlet pipe.

For the pump to operate more efficiently, the water must contain a minimum of solid particles. The unit can be used for sewage in a private house only if the diameter of the fractions in the water composition does not exceed 1.2 cm.

The immersion depth of the drainage device is also of great importance. In practice, the shallower the depth, the better, because in extreme cases it will be easier to pull out the equipment and fix the problem in a timely manner.

Wilo Drain TM 32/7 – budget and mobile

Wilo Drain TM 32/7

Wilo Drain TM 32/7 Low-power submersible device, lightweight, compact, ideal for household needs. Suitable for stationary work (connected to a pipeline) and easily transported from place to place (connected to a hose).

The electric motor is equipped with a cooling jacket. Additionally, protection is implemented in the form of a thermal relay and end seals on the pump and motor sides. Withstands a maximum operating pressure of 10 atmospheres, therefore, despite the IP68 protection class, it is not recommended to immerse the device deeper than 1 m.

Advantages:

- fits even into narrow openings due to its compact dimensions

- silent engine

- easy to transport due to its weight of less than 5 kg

- automatic operating mode

Flaws:

- short cable length

- low power

Current prices

Wilo TM 327 drain pump with float switch

Drainage pumps | TOP 10 Best: choosing assistants for pumping clean and dirty water + Reviews

What is the difference between a drainage pump and a fecal pump?

Drainage and fecal units are quite similar to each other, both in design and operating principle. However, there are a number of differences between them.

The main difference between a drainage pump and a fecal pump is the size of the particles that can get inside the device. Most drainage devices are designed for clean water with fractions whose size should not exceed 1.2 cm.

Fecal units can be used for contaminated water that contains solid fractions with a diameter of more than 10 cm. A more powerful fecal pump for industrial needs is capable of absorbing particles with a diameter of more than 12 cm.

The second difference lies in the sources for which both types of equipment can be used. Drainage units are intended for the basement, for barrels and other tanks in which more or less clean water accumulates. Often such units are used for a swimming pool located outdoors. Fecal appliances are used only for cleaning cesspools with large amounts of sand, lime and debris.

Grundfos Unilift KP 150-A1 – low-power and compact

Grundfos Unilift KP 150-A1

Grundfos Unilift KP 150-A1 A single-stage submersible apparatus from the Danish company Grundfos is designed for pumping dirty liquid with inclusions up to 10 mm without fibers, as well as clean liquid.

Used to drain water from washing machine drains, sewage and drainage of flooded rooms (maximum temperature of pumped water is +50 degrees). Despite its low power, it easily pumps water from ponds, stakes, and wells.

The model allows for easy cable replacement thanks to molded wire contacts. The base is removable, without threads, which helps when cleaning from dirt. There are additional filter holes at the bottom, a float on a flexible cable.

Advantages:

- stainless steel housing

- degree of protection IP68

- the outlet pipe is directed upwards

- Can be completely immersed in liquid medium

- cooled by pumped water

- compact and lightweight

Flaws:

- low power

- from a depth below 4 m low pressure

- no check valve

Current prices

Overview Drainage pump GRUNDFOS UNILIFT AP, UNILIFT KP

Drainage pumps | TOP 10 Best: choosing assistants for pumping clean and dirty water + Reviews

Drainage pump - how to choose a suitable unit?

When choosing a drainage pump for a summer house or private home, you should adhere to certain criteria. Among the most important factors it is necessary to highlight:

- Operating conditions of the device - when purchasing, you need to remember that the efficiency and duration of operation of the drainage pump depends on the degree of water contamination. Dirt, lime and sand can quickly damage even the most powerful household units;

- The pressure created by the device - when calculating, you need to remember that one vertical meter is equal to 10 horizontal meters. If the depth of the basement or inspection hole is more than 5 meters, then the pump pressure according to the passport should be approximately 45–50 m;

- Dimensions and noise level during operation - for pumping water out of a small basement, a small pump is best. The mini unit operates quietly, is reliable, easy to connect and durable;

- Availability of protection against dry running - experts advise buying equipment with a built-in float. With the necessary automation, it is better to choose units equipped with a water flow relay and with a vertical switch;

- Pump drive - when buying a manual device, you should remember that pumping out water with it will take a lot of time and effort. Units with electric motors will be better and easier to operate. With high performance, they consume a minimum of electricity and are easy to install, operate and maintain.

The listed factors will help you determine the appropriate option for use in your home and household, and not overpay for it.

KARCHER SP 5 Dirt – the best choice for dirty water

Karcher SP 5 Dirt

KARCHER SP 5 Dirt Low-power, compact (weighs less than 5 kg) pump, designed specifically for working with contaminated liquids containing fractions with a diameter of up to 20 mm. The kit optionally includes a pre-cleaning filter, which protects the impeller from the ingress of too large particles.

The submersible device has float switch and switching level options, which allows you to automate the drainage process. Another feature is the Quick Connect function for quickly connecting 1 ¼-inch hoses.

The device is able to operate in manual (provides a minimum level of residual water) and automatic (reacts to the water level) modes. Installed in a vertical position.

Advantages:

- a good middle-class model for cleaning cellars and garden ponds

- The service life of the device is extended due to the presence of a ceramic contact sealing ring with an oil chamber

- Easy to carry and hold thanks to the special handle

- height can be adjusted

Flaws:

- no adapter for connecting 1 ½ inch hoses

Current prices

Review Drainage pumps for dirty water Karcher SP Dirt

Drainage pumps | TOP 10 Best: choosing assistants for pumping clean and dirty water + Reviews

Criterias of choice

To use a drainage pump for domestic purposes, it is important to choose the right model, since low-power units will not be able to provide the required pressure in the water supply system, and overly powerful ones will run “idle,” therefore, parts will wear out faster and fail.

When choosing a drainage pump, you need to pay attention to the operating conditions, performance, power and other technical features of the selected model.

Characteristics of the pumped medium

Before buying a pump, you need to analyze what kind of liquid it will have to pump out, with what level of contamination and temperature. The water should be relatively clean, without high concentrations of silt, sand, algae and stones.

Submersible pumps must be stable on the bottom surface. Therefore, the equipment is first placed in a vat or container of the appropriate size, on a special tiled base. Each model is designed to work in a specific environment.

According to the degree of contamination of the pumped water, all pumping drainage equipment is divided into the following groups:

- For clean or slightly contaminated liquids: the permissible diameter of solid particles should not exceed 5 mm.

- For moderately polluted water: the permissible size of solid impurities is 25 mm.

- For rain, melt or heavily contaminated water: the size of large particles can vary between 25-38 mm.

You need to pay attention not only to the size of solid particles, but also to the chemical composition of the liquid and its temperature. Aggressive compounds can adversely affect the power and performance of equipment.

Materials used for manufacturing

The service life of drainage equipment directly depends on the quality of the materials used in manufacturing. Modern manufacturers most often use plastic or metal to construct the housing.

In the first case, the cost of the pump will be more acceptable, which in most cases is the decisive factor when purchasing. But plastic cases are less resistant to mechanical and chemical influences than metal ones. The results of social surveys showed that plastic often cracks and deforms. In such cases, the pumps can no longer be repaired.

The best materials for making cases are stainless steel and cast iron, which are able to interact with almost all environments.

An equally important detail that is worth paying attention to is the material from which the pump blades are made. They can be made from a special innovative technical polymer or stainless steel. It is preferable to buy products made from the first material. The impurities present in the polymer make it resistant to mechanical stress and aggressive environments. The most significant drawback is that they cannot be repaired. Metal blades wear out faster and must be replaced, so their cost is lower.

Circuit breaker type

Most models of modern equipment are equipped with automatic switches that start the mechanism when the water level rises to a predetermined level.

According to this principle, devices are:

- Float The most durable, simplest in design and budget device segment.

- Built-in electronic sensor. It has a complex device and is expensive.

Automatic shutdown of the pump prevents its “idle” operation, which can lead to serious breakdowns and rapid wear of parts.

AL-KO Drain 20000 HD – copes with the dirtiest water

AL-KO Drain 20000 HD

AL-KO Drain 20000 HD Powerful model for pumping and pumping out dirty water with a grain size of up to 38 mm and an impurity content of up to 5% - this type of pollution usually occurs in tanks and construction pits.

The kit includes a universal elbow fitting and a combination nipple. The pump elements are protected by a four-level sealing system. The device is equipped with a float switch and the outlet size is 2 inches.

Advantages:

- steel body is protected from corrosion

- The motor shaft is made of chromium-nickel steel

- light weight, comfortable handle, long cord

- there is thermal protection for the engine

Flaws:

- not suitable for pumping salty liquids, sand or aggressive chemicals

Current prices

AL-KO Drain 7500 (AL-KO Drain 7500) - drainage pump - video review of the younger model

Drainage pumps | TOP 10 Best: choosing assistants for pumping clean and dirty water + Reviews

Advantages compared to other pumps

- Affordable price

(At a relatively low cost, the drainage pump has quite a lot of power. Some models are capable of pumping up to 8 cubic meters of liquid per hour. The pump pressure is about 7 m. Such technical characteristics allow the device to be used in everyday life. For example, using a drainage pump you can It's easy and quick to change the water in your home pool.) - Simplicity and ease of operation

(Surface pumps are easy to install and dismantle. Submersible type devices require more time to install, but can be easily handled without assistance. The drainage pump operates silently and is lightweight. Compact dimensions allow you to quickly move the device from one place to another other.) - Long service life.

(Drainage pumps are very reliable. They have a simple design, the parts of which, if the operating rules are followed, rarely fail. If the level of the pumped liquid reaches a certain value, the drainage pump will automatically turn off. This function allows you to extend the life of the device, prevent motor breakdown and save energy. )