- a method for producing polymer coatings with high protective and decorative properties. This painting method was developed in the 1950s. Powder coating is a popular alternative to liquid coatings for heat treatable parts.

The essence of the powder coating method

Powder paint is sprayed onto the cleaned product. During the spraying process, powder paint particles are electrically charged from an external source or by electrification during friction. An electric field transfers powder paint particles to the object being painted, which has an opposite charge. Powder paint particles that have not settled on the product are captured in the spraying spray chamber and can be used for re-spraying, which is impossible when using conventional liquid paints. Next, the product coated with powder paint is transferred to a polymerization chamber to “bake” the paint.

In the process of forming the coating from the applied powder layer, a monolithic high-quality coating is created on the surface of the product.

The coating formation process is carried out by heating a layer of powder paint until it melts, forming a monolithic layer. During subsequent processing, a hard film is formed as a result of hardening (for thermoset materials) or cooling (for thermoplastic materials) of the layer.

Melting of powder paints is divided into three stages: 1) the powder melts and passes into a viscous-fluid state; 2) a monolithic layer of melted powder particles is formed; 3) the surface to be painted is wetted with the molten polymer, as a result of which a coating is formed.

Main Applications

- painting of any metal components for products;

- painting finished metal products that can withstand heating up to 200 degrees Celsius;

- painting ceramics and wall stones;

- painting MDF, glass.

The list of products that can be painted with powder paints is quite wide. There are industries where the rate of consumption of powder paints is growing particularly rapidly. An example is the coating of the internal surface of pipes for oil drilling and oil pumping, operating in conditions where factors such as high pressure, high temperatures and the presence of corrosive media can have a destructive effect on almost all coatings (with rare exceptions).

Powder coating equipment

Powder paints are applied to parts either by electrostatic spraying, or by immersing them in a fluidized layer of powder paint (with or without electrification of the particles), or by flame spraying.

In the early 70s, the Swiss company GEMA was the first in the world to successfully introduce a high-voltage cascade into a paint gun.

Polymerization ovens are used to bake powder paint. A polymerization oven is a closed chamber, the internal working volume of which is heated to the temperature required for polymerization. The product to be painted is placed inside the chamber, where polymerization of the powder coating occurs.

Powder coating is the most modern and technologically advanced method of coating metal surfaces.

Products painted in this way are not subject to abrasion and scratches. They are more difficult to damage, which means the metal will not rust. In addition, powder coating is not destroyed by ultraviolet radiation.

In this article we will talk about the advantages of the powder painting method and the technological process.

Why not liquid paints?

When high quality painting is not required, the airless spray method is used. The equipment for it is relatively inexpensive, and the technology produces results of acceptable quality. But “acceptable” is the key word here, so the method is not suitable for industrial painting of products with high requirements for appearance.

Disadvantages of spray technology for the production of metal products:

- The process is highly labor-intensive and it is impossible to automate a number of stages.

- Uneven layer, color and high risk of paint defects.

- High losses of painting material, which increase the cost of work.

- The formation of toxic fog in the air, which is harmful to human health and imposes increased safety requirements.

Therefore, modern production uses more advanced methods.

Powder coating technology for metal products

Powder coating technology consists of three stages: surface preparation, powder application and oven polymerization.

Product surface preparation

Preparation is carried out on an automated line of 5 baths.

Degreasing.

At a temperature of 60°C, the surface is coated with a chemical composition that removes contaminants from it.

Washing with technical water.

Chemical and foam residues are removed from the surface of the product.

Demineralization of the surface with water with an electrical conductivity of 100 µS.

Salts are removed from the metal, which previous cleaning stages cannot remove. The durability of the powder coating depends on this stage.

Passivation.

A conversion layer is created on the surface, which increases adhesion.

Demineralization of the surface with water with an electrical conductivity of 500 µS.

After cleaning, the metal products are dried in a chamber at a temperature of 100−120°C.

Powder coating of the product

For powder painting, finely dispersed polymer coloring powder is used. Spraying is carried out in a painting booth. Level areas are painted automatically using a system of 12 Gema automatic guns. The most difficult areas - bends and welds - are processed manually.

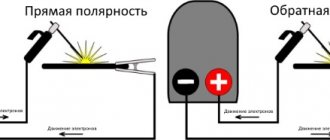

Before painting, the metal product is charged with a negative electrical charge. The polymer powder receives a positive electrical charge. An electrostatic effect occurs and the powder itself adheres to the iron.

Polymerization of paint powder

Previously, closed furnaces were used in metallurgy, but this method significantly reduced the productivity of the process. That's why today we use modern continuous furnaces. At this stage, the powder is heated, melted, and then, upon cooling, forms a dense polymer layer that performs both a protective and decorative function.

The technology used in our workshops is virtually waste-free. Some of the painting powder is not electrified during the production process, but does not go to waste. It can be reused for painting products with reduced requirements for appearance.

Necessary technical equipment

First of all, you should independently choose the right room where the painting work will be carried out.

Next, you will need to prepare the necessary equipment, namely:

- oven for polymerization of powder mixture;

- uninterruptible power supply (normally 25 kV);

- nozzle for powder painting;

- material intended for painting.

The work will require special diligence and caution when performing it, and you must also follow the rules specified in the instructions.

Production of ovens for drying powder coating

The main stage in powder painting yourself is its polymerization. Its durability on a metal surface depends on proper and complete drying of the paint.

Since professional polymerization furnaces are quite expensive, you can try to make a furnace yourself using improvised materials.

To make a stove measuring 2m×1m×1m you will need:

- profile pipe;

- non-flammable thermal insulation material (for example, basalt slab);

- metal in the form of sheets, they can be ordered immediately according to the required sizes;

- diametrical cross-section fan (tangential);

- heating heating elements.

Description of making a stove yourself:

- You need to make a frame from profile pipes and place thermal insulation material inside.

- Cover the walls around the perimeter of the frame with sheet metal. Gypsum fiber is suitable for exterior finishing.

- To ventilate the air in the furnace, install a tangential fan by welding a wide inlet and a narrow outlet of air flow.

- It is worth installing a fan in the oven, which absorbs air from above the structure, and then passes this air through the heating elements and the already heated air below is distributed along the entire perimeter of the oven. The main part of the fan should not be in the furnace structure itself, as this may damage the winding.

- Heating elements should be installed along the furnace walls parallel to each other and covered or insulated.

- When installing an electrical panel, you need to be especially careful, and it would be better to entrust this work to a specialist.

The finished device will have a production capacity of 12 kW when heating air and 6 kW during main operation.

Gun as a painting tool

Certain devices are designed for powder painting, for example, a spray gun. But since this equipment is not cheap and is not used so often, you can make your own gun for spraying powder paint.

To make such a pistol yourself will require no more than 10 minutes of time.

Instructions for making a spray gun for powder painting:

- You will need a regular clean plastic bottle, approximately 1.5 liters.

- LMB needs to fill this bottle 1/3 full and screw it with a metal stopper, having previously made many small holes in it.

- The positive wire from the electric current must be connected to the metal plug. A current converter that can produce 25,000 volts of uninterrupted voltage is suitable for this. They are often used in water heaters and heating boilers, electric shock guns, and in electric ignition of a gas stove.

Extreme care must be taken when making the converter, so it is best to leave this work to an electrician.

Key points before starting work

- To work, you will need a room with excellent light. You can even install additional fluorescent lamps.

- It is necessary to ensure good ventilation, and for your own protection you need to use respirators or, as a last resort, a gauze bandage.

- To collect residual material, you need special equipment, or you can use an unnecessary but still working vacuum cleaner.

Advantages of metal powder coating

- Environmentally friendly.

The coatings do not contain toxins and heavy metals that are hazardous to human health. Children and allergy sufferers can come into contact with them without consequences. - Variety of decor options.

You can create both a smooth coating and shagreen, antique, moiré and other types of finishes. - Resistance to mechanical damage.

The paint layer is preserved even when the surface is deformed.

Painting technique

The process of painting paintwork materials can be divided into 3 stages.

Preparatory stage

At this stage, you need to carefully prepare the surface for painting yourself. To do this, you need to follow these painting recommendations:

- Clean the surface of the part yourself from dirt using a clean rag before painting. If the part cannot be cleaned simply with a rag, it is necessary to soak the part in an alkaline solution, and then repeat the cleaning.

- Clean rust from metal parts yourself using a metal brush or sandpaper.

- To increase the adhesion of the surface of the part during painting, it is necessary to degrease the metal part.

- Using an inorganic-based coating material, prime the part. This layer of paint will further protect against air and moisture getting under the powder coating.

- To avoid corrosion on the metal, it is necessary to cover the part on top with a passivation layer of chromium and sodium nitrate.

- Dry the part yourself well in a manufactured oven.

The stage of painting parts with powder paint

During the painting process, you need to independently place the metal part in the spraying compartment, and attach the negative wire from the electrical converter to it.

To check for sufficient voltage, sparks will serve as an indicator, which should appear when you bring the metal cap on a bottle of paint to the part at a distance of 2-3 cm.

To paint with a powder mixture yourself, you need to press on the bottle of paint, and under the influence of high-voltage electricity, the mixture itself is electrified and lies in a dense layer on the surface of the part.

Since the mixture will scatter in all directions, you need to lay something on the floor yourself, for example, newspaper or cardboard, so that later the paintwork can be carefully collected.

Product polymerization stage

At this stage, the painted part must be placed independently in an already manufactured chamber for drying the paint. In this case, you must follow the clear instructions for the paint you choose.

For a good result, you must independently ensure that all parts of the part are heated evenly, and also observe the exact time for drying the paint layer.

Making a polymerization oven yourself will significantly save your budget, but it is worth considering that this work is quite painstaking and time-consuming.

The main advantages of powder-coated corrugated sheets

The material is universal and suitable for arranging roofing, facade, gate, and enclosing structures. There are 250 color options according to RAL , and in order for the roof and fence to be made in the same color scheme, accompanying fittings are selected for the profiled sheets. The customer decides what the design will look like. The catalog presents powder-coated corrugated sheets at manufacturer's prices . Among the practical properties:

- resistance to corrosion processes;

- reliability (zinc coating layer 100-200 g/sq. m, paint - from 45 microns);

- resistance to mechanical damage

- preservation of characteristics at temperatures -60-+150°C.

- wide range of RAL colors

- Possibility of painting in two different colors

Structures made of corrugated sheets with powder coating last more than 25 years without causing problems in operation and maintenance.

©Steel Partner

Powder painting of metal products

Advantages of powder coating equipment

The list of strengths is distinguished by its considerable size. It is necessary to consider in more detail exactly what main advantages you can count on: • Powder paint is consumed extremely economically and it is possible to achieve minimal costs for its purchase. 95% of unused composition can be reused. • The technology for performing the work involves a high degree of automation of all processes in the powder painting area. • Minimum application time on the surface. Hardening occurs in half an hour. • High quality of the created coating. Powder paint adheres reliably and practically does not wear off over time. • The average composition has an increased viscosity index and more effectively resists adverse environmental factors.

How much does powder coating equipment cost?

Quite often our clients have questions about the cost of the products presented in the catalogue. As practice shows, this point greatly depends on the characteristics of the installations, as well as a number of other factors. Equipment for powder painting of metal can be compact or in the form of flow lines. The second option involves a high cost and is recommended for an annual program of 50 thousand or more thousand square meters of painted surface. The performance of the model is one of the main components of the price. Powder painting, the equipment for which our company sells, can use additional technologies. To increase efficiency, sometimes it is necessary to purchase certain accessories.

How to order painting equipment?

Our company adheres to a customer-oriented interaction policy. to buy equipment for powder painting , since the price of this equipment is quite affordable. To order it, you must fill out the purchase form. If you have any questions, you should contact an employee and clarify the points of interest. We supply equipment for powder painting to the cities of Syktyvkar, Moscow, Izhevsk, Stavropol, Astrakhan, Bryansk, Volgograd, Voronezh, Kaliningrad, Kirov, Kursk, Lipetsk, Orel, Pskov, Ryazan, Saratov, Tambov, Tula, Yaroslavl, Saransk, Krasnodar, Arkhangelsk, Belgorod, Vladimir, Vologda, Ivanovo, Kaluga, Kostroma, St. Petersburg, Murmansk, Novgorod, Penza, Rostov-on-Don, Samara, Smolensk, Tver, Ulyanovsk.