Laser cutting is the most advanced, but also expensive technology. But with its help you can achieve results that are beyond the power of other metal processing methods. The ability of laser beams to give any material the desired shape is truly limitless.

The unique capabilities of the laser are based on the following characteristics:

- Clear directionality - due to the ideal directionality of the laser beam, the energy is focused at the point of impact with a minimum of losses,

- Monochromaticity - the laser beam has a fixed wavelength and a constant frequency. This allows it to be focused with ordinary lenses,

- Coherence – laser beams have a high level of coherence, so their resonant vibrations increase the energy by several orders of magnitude,

- Power - the above properties of laser beams ensure that the energy of the highest density is focused on a minimal area of material. This allows you to destroy or burn through any material in a microscopically small area.

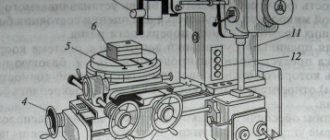

Design and principles of operation

Any laser device consists of the following components:

- energy source;

- working body that produces energy;

- an optical amplifier, a fiber-optic laser, a system of mirrors that amplify the radiation of the working element.

The laser beam produces precise heating and melting of the material, and after prolonged exposure, it evaporates. As a result, the seam comes out with an uneven edge, evaporating material is deposited on the optics, which reduces its service life.

To obtain smooth thin seams and remove vapors, the technique of blowing melt products from the laser impact zone with inert gases or compressed air is used.

Factory laser models equipped with high-grade materials can provide good indentation rates. But for household use they are too expensive.

Models made at home are capable of cutting into metal to a depth of 1-3 cm. This is enough to make, for example, parts for decorating gates or fences.

Laser cutting of metal

Depending on the technology used, there are 3 types of cutters:

- Solid state. Compact and easy to use. The active element is a semiconductor crystal. Low-power models have quite affordable prices.

- Fiber. Glass fiber is used as the radiation and pumping element. The advantages of fiber laser cutters are high efficiency (up to 40%), long service life and compactness. Since little heat is generated during operation, there is no need to install a cooling system. It is possible to produce modular designs that allow you to combine the power of several heads. The radiation is transmitted via flexible optical fiber. The performance of such models is higher than solid-state ones, but their cost is higher.

- Gas. These are inexpensive but powerful emitters based on the use of the chemical properties of gas (nitrogen, carbon dioxide, helium). With their help you can weld and cut glass, rubber, polymers and metals with a very high level of thermal conductivity.

Questions and answers

Problems with Bluetooth connection - I can’t connect my smartphone.

If you have trouble connecting your device via Bluetooth, follow these steps:

- Disconnect and then reconnect the device's power source to restart the device. During this time, only one red LED will be lit. If the light is blue, the engraver is faulty.

- Launch the NEJE application, the connection should be established within 5 seconds.

- If your mobile phone still does not connect, check whether the location feature on your mobile phone is enabled. Some smartphones need to turn on the location feature to search for Bluetooth, otherwise the device will not be found.

- Try running the NEJE application from another phone.

- Check in the gadget settings whether the Laser Carver application is installed.

What materials can an engraver work with?

As a rule, those materials that can be burned with a lighter are suitable. 7W and 20W laser modules can engrave metal. It is recommended to use non-ferrous metals, such as aluminum. Before engraving, you need to make sure that the focal length is set to the best value.

How to replace the laser module?

To replace the laser head, you need to turn off the power to the machine, unscrew the screw securing the laser, and replace the module.

How to adjust lens focusing?

Be sure to wear safety glasses before adjusting the focal length. After that:

- Place the object you will engrave on under the laser and adjust the distance between the lens and the surface to be treated. It should be between 30 and 50 mm;

- Rotate the focusing head until a small dot is visible on the surface of the material.

Homemade household laser

To carry out repair work and manufacture metal products at home, do-it-yourself laser cutting of metal is often required. Therefore, home craftsmen have mastered manufacturing and successfully use hand-held laser devices.

In terms of manufacturing cost, a solid-state laser is more suitable for household needs.

The power of a homemade device, of course, cannot even be compared with production devices, but it is quite suitable for use for domestic purposes.

How to assemble a laser using inexpensive parts and unnecessary items.

To make a simple device you will need:

- laser pointer;

- battery-powered flashlight;

- CD/DVD-RW writer (an old and faulty one will do);

- soldering iron, screwdrivers.

How to make a handheld laser engraver

Mini engravers

NEJE DK-8-KZ

A good laser engraver with the ability to use bmp formats when creating a jpg layout. The device requires a standard USB adapter or mobile power source to operate. The NEJE Scanner application helps to automatically convert any pictures, preparing a diagram for further engraving on objects.

Pros:

- Functionality

- Control via mobile devices

- Possibility of autonomous operation

- Universal board

Minuses:

- Limited power

VIEW ON ALIEXPRESS

TwoWin 3W laser machine

Automatic high-speed engraver with 3000 MW laser power. This indicator is enough for comfortable work on wood, cardboard, leather and polymers. The device is made of aluminum and high-strength ABS plastic. Provides engraving with an accuracy of 0.01 mm to a depth of 1 mm.

Pros:

- Price

- Fast engraving

- Accuracy

- Possibility to replace the laser

Minuses:

- The machine requires stopping every 30 minutes of operation

- Not suitable for hard surfaces such as metal, glass or stone

VIEW ON ALIEXPRESS

TwoWin 3000 MW CNC

Laser engraving machine with compact dimensions and convenient connection system. The working area is well protected from impacts using a housing and special screens. The package includes a flash drive with software, a data cable, a power supply, and two wooden plates for testing the device.

Pros:

- Positioning accuracy

- Reliability

- Availability

- Maintenance free

Minuses:

- Not suitable for industrial use

- English manual

VIEW ON ALIEXPRESS

Laser cutter manufacturing process

- You need to remove the red diode from the computer disk drive, which burns the disk when recording. Please note that the drive must be a write drive.

After dismantling the upper fasteners, remove the carriage with the laser. To do this, carefully remove the connectors and screws.

To remove the diode, you need to unsolder the diode mountings and remove it. This must be done extremely carefully. The diode is very sensitive and can be easily damaged by dropping it or shaking it sharply.

- The diode contained in it is removed from the laser pointer, and the red diode from the disk drive is inserted in its place. The pointer body is disassembled into two halves. The old diode is shaken out by picking it up with the tip of a knife. Instead, a red diode is placed and secured with glue.

- It is easier and more convenient to use a flashlight as a body for a laser cutter. The upper fragment of the pointer with a new diode is inserted into it. The glass of the flashlight, which is an obstacle to the directed laser beam, and parts of the pointer must be removed.

Laser pointer

When connecting the diode to battery power, it is important to strictly observe the polarity.

- At the last stage, they check how securely all the laser elements are fixed, the wires are connected correctly, the polarity is observed and the laser is level.

The laser cutter is ready. Due to its low power, it cannot be used when working with metal. But if you need a device that cuts paper, plastic, polyethylene and other similar materials, then this cutter is quite suitable.

Specifications

| Options | Characteristics |

| Laser power | 5.5 W. |

| Work surface size | 170 x 170 mm. |

| Amount of points | 2266 x 2266 |

| Single point size | 0.075 mm. |

| Laser wavelength | 450 nm. |

| Depth of cut | 3 – 8 mm. |

| Focal length | 30 – 50 mm |

| Laser beam type | Focus point |

| Lens material | D-ZK3 |

| Laser module weight | 202 |

| Laser module heatsink dimensions | 30 x 80 mm |

| Laser head fan dimensions | 30 x 10 mm |

| Fan speed | 15000 rpm |

Engraves on:

- MDF;

- cork tree;

- paper;

- tree;

- fabrics;

- plastic;

- skin;

- plywood;

- foam board

- anodized aluminum.

Does not work with materials such as:

- steel;

- glass;

- stone;

- ceramics;

- on various reflective and transparent materials.

How to increase laser power for metal cutting

You can make a more powerful laser for cutting metal with your own hands by equipping it with a driver assembled from several parts. The board provides the cutter with the required power.

The following parts and devices will be needed:

- CD/DVD-RW writer (an old or faulty one will do), with a writing speed of more than 16x;

- 3.6 volt batteries – 3 pcs.;

- 100 pF and 100 mF capacitors;

- resistance 2-5 Ohm;

- collimator (instead of a laser pointer);

- steel LED lamp;

- soldering iron and wires.

You cannot connect a current source to the diode directly, otherwise it will burn out. The diode draws power from current, not voltage.

Laser collimator

The beams are focused into a thin beam using a collimator. It is used instead of a laser pointer.

Sold at an electrical goods store. This part has a socket where the laser diode is mounted.

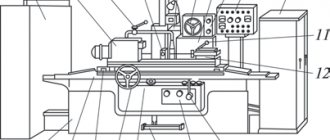

Professional laser machines

HCZ 6090

A professional engraver, with the help of which full-fledged production is launched. Provides the necessary accuracy and speed of applying images, and is also suitable for cutting parts from blanks. For normal operation over a long period of time, the device is equipped with a cooling system and moisture protection.

Pros:

- Accuracy

- Power

- Ability to work continuously

- Support for popular formats

Minuses:

- Difficult to set up

- Requires periodic maintenance

VIEW ON ALIEXPRESS

Assembly Tips

To check the operation of the driver, use a multimeter to measure the current supplied to the diode. To do this, connect a non-working (or second) diode to the device. For most homemade devices, a current of 300-350 mA is sufficient.

If you need a more powerful laser, the indicator can be increased, but not more than 500 mA.

It is better to use an LED flashlight as a homemade housing. It is compact and convenient to use. To prevent the lenses from getting dirty, the device is stored in a special case.

Important! A laser cutter is a kind of weapon, so it should not be pointed at people, animals, or given to children. Carrying it in your pocket is not recommended.

It should be noted that do-it-yourself laser cutting of thick workpieces is impossible, but it can cope with everyday tasks.

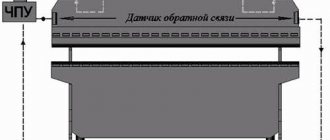

Distinctive features of the model

The NEJE Master 2s 20 W engraving machine, unlike the NEJE Master model, has a built-in wireless connection function. This makes it possible to control the device from mobile phones and tablets running Android OS, as well as iPhone and iPad. In addition, the processor firmware for version 2s has been updated to GRBL1.1F.

The model supports the scanner function. So, using a wireless connection, you can scan any image (for example, using a phone), transfer it to the program and output it for engraving. This can be either handwritten text or a photo.

A similar model differs from the one under consideration in its larger working area (255 x 440 mm).

Laser cutting stages: pick up the workpieces 1–7 days after contacting us

The speed of metal processing directly depends on the volume and complexity of the order

Coordination of details

Leave a request on the website or call us by phone. +7 (495) 988-09-04 – we will advise you in detail on all questions that arise regarding laser cutting, and also discuss the terms of cooperation

Formulation of the problem

Discuss the technical specifications for cutting with one of our specialists - we will analyze the specifications and advise you on how to save money without sacrificing quality. If you don’t have one, we’ll help you prepare for free.

Fulfillment of an order

Sign the contract, pay for the services in a convenient way and transfer the metal to our warehouse. After this, we will begin carrying out the required work, then we will notify you of readiness

Transfer of workpieces

Pick up the order yourself or use the services of a transport company - if necessary, we will recommend a profitable option for delivering the workpieces to your site. We will be grateful for your feedback