In this article:

- Overpass design

- The need to design racks for process pipelines

- Features of designing overpasses

- General provisions for designing racks for process pipelines

Designing pipeline racks is a rather complex process, which is due to the presence of many specific nuances in the work. But first of all, it is necessary to take into account the requirements for the strength of the future structure and the conditions of its operation.

Based on this, only highly qualified specialists who have a clear understanding of the rules for designing these structures can cope with the task. Only if you contact a specialized company can you count on a decent result.

Overpass design

To implement a variety of technological processes and adequate operation of equipment at industrial facilities that are classified as hazardous industries, it is necessary to ensure an uninterrupted supply of various liquid, gaseous and bulk products (vaporous substances, water, lubricants, various gases, etc.). This problem is solved by installing pipelines. Such transport networks can be mounted on overpasses and on separate supporting structures.

The design of pipeline racks should be considered from an analysis of structures, which often mean completely wrong structures. If they have nothing to do with transportation, then they cannot be considered in this context.

What is a technological overpass? It is a complex oblong structure, consisting of support and span structures and intended for installation of utility networks above the ground. The need for an overpass arises when existing buildings are distributed on the surface and cannot be changed. In this case, only the overhead path remains: for example, when connecting complex passages or organizing a road detour. Technological overpasses protect from precipitation because they are closed.

Due to the wide variety of applications of supporting structures and overpasses, several types of these structures are distinguished, depending on the design, dimensions and shapes. They differ:

- by height of the upper supports: high and low;

- according to the design of load-bearing elements: supports, foundation, spans.

- by material of manufacture: steel, reinforced concrete, mixture of steel and reinforced concrete.

List of structures that are usually used in the construction of technological overpasses:

- lifts - a single or prefabricated element made of reinforced concrete. To attach it to the pipe, frames with a U-shaped section are required

- columns - made of steel or reinforced concrete;

- the foundation necessary to support the supporting elements is a glass type, consisting of a monolith or reinforced concrete;

- rod structures (trusses) – designed for spans, made of metal;

- support beams, inserts - of various lengths, reinforced concrete is used;

- service parts for pipeline fittings - bridges and small platforms, stairs made of steel (angular, expanded, round, etc.);

- paints and varnishes for protection against corrosion and other damage to metal structures.

In addition to the listed options, there are also supporting, suspended or mixed overpasses. They can consist of one, two or several tiers. Design engineers decide whether to install beam fastenings to load-bearing structures. Decisions are made on the choice of one of the types of overpasses on an individual basis. This is influenced by production features, future load on the structure, and its length.

If the rack is intended to serve a pipeline route, it is important to take into account the future conditions of its operation. In addition, they pay attention to the wishes of the project customer and the technological features of the design.

Prices for pipeline supports OST 36-146:

| Pipeline outer diameter, dn | Execution | h | B | S | I-beam profile number | Weight, kg, no more | Allowable load, kN | Price without VAT | ||

| Vertical, Qy | Axial, Рz at | |||||||||

| Px=0.5Pz | Рх=0.2Рz | |||||||||

| 18-45 | ASOO | 70 | 50 | 5 | — | 0,60 | 2 | 1,5 | 2 | 60.00 rub. |

| ACIO | 100 | 0,70 | 1 | RUB 70.00 | ||||||

| 57-89 | AII | 100 | 100 | — | 20 | 1,80 | 4 | — | — | RUB 180.00 |

| AI2 | — | 3,60 | 3.0 | 7 | RUB 360.00 | |||||

| AC11 | 6 | — | 1,70 | — | — | RUB 170.00 | ||||

| ACI2 | 3,40 | 3 | 7 | RUB 340.00 | ||||||

| A2I | 150 | 135 | — | 30 | 3,10 | — | — | RUB 310.00 | ||

| A22 | 6,20 | 3 | 7 | RUB 558.00 | ||||||

| AC2I | 100 | 6 | — | 2,20 | — | — | RUB 220.00 | |||

| AS22 | 4,40 | 3 | 7 | RUR 440.00 | ||||||

| 108-159 | B12 | 100 | 100 | — | 20 | 4,00 | 9,5 | 18 | 35 | RUB 400.00 |

| BS12 | 6 | — | 3,80 | RUB 380.00 | ||||||

| B22 | 150 | 135 | — | 30 | 7,00 | RUB 630.00 | ||||

| BS22 | 100 | 6 | — | 5,00 | RUB 450.00 | |||||

| Pipeline outer diameter, dn | Execution | h | B | B.I. | Bolt dimensions d×l | Weight, kg, no more | Allowable load, kN | Price without VAT | ||

| Vertical, Qy | Axial, Рz at | |||||||||

| Px=0.5Pz | Px=0.2Pz | |||||||||

| 18 | ACOO | 70 | 50 | — | 1 | 2 | I.5 | 2 | RUB 300.00 | |

| 25 | ||||||||||

| 32 | ||||||||||

| 38 | ||||||||||

| 45 | ACIO | 100 | 1,10 | 1 | RUB 330.00 | |||||

| 57 | AII | 106 | 100 | I42/100 | MI2x40 | 2,60 | 4 | — | — | RUB 364.00 |

| AI2 | 5,20 | 3 | 7 | RUB 520.00 | ||||||

| ACII | 2,50 | — | — | RUB 350.00 | ||||||

| ACI2 | 5,00 | 3 | 7 | RUB 500.00 | ||||||

| A2I | 156 | 135 | 3,90 | — | — | RUB 468.00 | ||||

| A22 | 7,80 | 3 | 7 | 702.00 rub. | ||||||

| AC2I | 100 | 3,00 | — | — | RUB 420.00 | |||||

| AC22 | 6,00 | 3 | 7 | RUB 600.00 | ||||||

| 76 | AII | 106 | 100 | 160/113 | 2,70 | — | — | RUB 378.00 | ||

| AI2 | 5,40 | 3 | 7 | RUB 540.00 | ||||||

| ACII | 2,60 | — | — | RUB 364.00 | ||||||

| ACI2 | 5,20 | 3 | 7 | RUB 520.00 | ||||||

| A2I | 156 | 135 | 4,00 | — | — | RUR 480.00 | ||||

| A22 | 8,00 | 3 | 7 | RUR 720.00 | ||||||

| AC2I | 100 | 3,10 | — | — | RUR 434.00 | |||||

| AC22 | 6,20 | 3 | 7 | RUB 620.00 | ||||||

| 89 | AII | 106 | 100 | 179/127 | MI2x40 | 2,80 | — | — | RUB 392.00 | |

| AI2 | 5,60 | 3 | 7 | RUB 560.00 | ||||||

| ACII | 2,70 | — | — | RUB 378.00 | ||||||

| ACI2 | 5,40 | 3 | 7 | RUB 540.00 | ||||||

| A2I | 156 | 135 | 4,10 | — | — | RUR 492.00 | ||||

| A22 | 8,20 | 3 | 7 | RUB 1,148.00 | ||||||

| AC2I | 100 | 3,20 | — | — | RUR 448.00 | |||||

| AC22 | 156 | 100 | 6,40 | 4 | 3 | 7 | RUB 640.00 | |||

| 108 | B12 | 108 | 100 | 200/141 | M16×50 | 7,90 | 9,5 | 18 | 35 | RUB 711.00 |

| BS12 | 7,70 | RUB 693.00 | ||||||||

| B22 | 158 | 135 | 10,90 | RUB 981.00 | ||||||

| BS22 | 100 | 8,90 | RUR 801.00 | |||||||

| 133 | B12 | 108 | 100 | 250/177 | 8,70 | 18 | 35 | RUB 783.00 | ||

| BS12 | 8,50 | RUB 765.00 | ||||||||

| B22 | 158 | 135 | 117,00 | RUB 10,530.00 | ||||||

| BS22 | 100 | 9,70 | RUR 873.00 | |||||||

| 159 | B12 | 108 | 100 | 275/194 | M16×50 | 9,30 | 9,5 | 18 | 35 | RUR 837.00 |

| BS12 | 9,10 | RUB 819.00 | ||||||||

| B22 | 158 | 135 | 12,30 | RUB 1,107.00 | ||||||

| BS22 | 100 | 10,30 | RUB 927.00 | |||||||

| Pipeline outer diameter, dn | Execution | h | h1 | h2 | Weight, kg, no more | Allowable load, kN | Price without VAT | ||

| Vertical, Qy | Axial, Рz at | ||||||||

| Px=Pz | Px=0.5Pz | ||||||||

| 57 | AII | 100 | 110 | 98 | 1,30 | 2,5 | 5,5 | 8 | RUB 182.00 |

| AI2 | — | 2,60 | 15 | RUB 364.00 | |||||

| A2I | 150 | 160 | 148 | 1,80 | 5,5 | 8 | RUB 252.00 | ||

| A22 | — | 3,60 | 15 | RUR 432.00 | |||||

| 76 | AII | 100 | 107 | 98 | 1,30 | 3 | 5,5 | 8 | RUB 182.00 |

| AI2 | — | 2,50 | 15 | RUB 350.00 | |||||

| A2I | 150 | 157 | 148 | 1,80 | 5,5 | 8 | RUB 252.00 | ||

| A22 | — | 3,50 | 15 | RUB 420.00 | |||||

| 89 | AII | 100 | 106 | 98 | 1,20 | 5 | 5,5 | 8 | RUB 168.00 |

| AI2 | — | 2,50 | 15 | RUB 350.00 | |||||

| A2I | 150 | 156 | 148 | 1,70 | 5,5 | 8 | RUB 238.00 | ||

| A22 | — | 3,50 | 15 | RUB 420.00 | |||||

| 108 | AII | 100 | 115 | 95 | 1,50 | 6 | 10 | 13 | RUB 210.00 |

| AI2 | — | 3,00 | 30 | 45 | RUB 360.00 | ||||

| A2I | 150 | 165 | 145 | 2,10 | 8 | 10 | RUB 294.00 | ||

| A22 | — | 4,20 | 25 | 38 | RUR 462.00 | ||||

| 133 | AII | 100 | 111 | 95 | 1,50 | 8 | 10 | 13 | RUB 210.00 |

| AI2 | — | 3,00 | 30 | 45 | RUB 360.00 | ||||

| A2I | 150 | 161 | 145 | 2,00 | 8 | 10 | RUB 280.00 | ||

| A22 | — | 4,10 | 25 | 38 | RUR 451.00 | ||||

| 159 | AII | 100 | 109 | 95 | 1,50 | 10 | 10 | 13 | RUB 210.00 |

| AI2 | — | 3,00 | 30 | 45 | RUB 360.00 | ||||

| A2I | 150 | 159 | 145 | 2,00 | 8 | 10 | RUB 280.00 | ||

| A22 | — | 4,10 | 25 | 38 | RUR 451.00 | ||||

| 219 | AII | 100 | 159 | 95 | 2,70 | 25 | — | — | RUB 378.00 |

| AI2 | — | 6,10 | 60 | 85 | RUB 549.00 | ||||

| AI3 | 95 | 11,00 | 80 | 110 | RUB 902.00 | ||||

| B12 | 104 | — | 7,00 | 60 | 85 | RUB 630.00 | |||

| B13 | 95 | 11,90 | 80 | 110 | RUB 975.80 | ||||

| A2I | 150 | 209 | 145 | 3,40 | — | — | RUR 408.00 | ||

| A22 | — | 7,30 | 50 | 70 | RUB 657.00 | ||||

| A23 | 145 | 13,30 | 70 | 95 | RUB 1,090.60 | ||||

| B22 | 154 | 209 | — | 8,20 | 25 | 50 | 70 | RUB 738.00 | |

| B23 | 145 | 14,20 | 70 | 95 | RUB 1,164.40 | ||||

| 273 | AII | 100 | 140 | 95 | 2,60 | 25 | — | — | RUB 364.00 |

| AI2 | — | 7,10 | 40 | 60 | 85 | RUB 994.00 | |||

| AI3 | 95 | 13,30 | 80 | 110 | RUB 1,862.00 | ||||

| B12 | — | 8,10 | 60 | 85 | RUB 1,134.00 | ||||

| B13 | 95 | 14,30 | 80 | 110 | RUB 2,002.00 | ||||

| A2I | 150 | 190 | 145 | 3,20 | 25 | — | — | RUB 384.00 | |

| A22 | — | 9,00 | 40 | 50 | 70 | RUB 1,260.00 | |||

| A23 | 145 | 16,60 | 70 | 95 | RUB 2,324.00 | ||||

| B22 | — | 10,00 | 50 | 70 | RUB 1,400.00 | ||||

| B23 | 145 | 17,60 | 70 | 95 | RUB 2,464.00 | ||||

| 325 | AII | 100 | 131 | 90 | 3,30 | 50 | — | — | RUB 396.00 |

| AI2 | — | 6,90 | 70 | 60 | 85 | RUB 966.00 | |||

| AI3 | 90 | 12,80 | 80 | 110 | RUB 1,049.60 | ||||

| B12 | — | 7,90 | 60 | 85 | RUB 711.00 | ||||

| B13 | 90 | 13,80 | 80 | 110 | RUB 1,131.60 | ||||

| A2I | 150 | 181 | 140 | 4,20 | 50 | — | — | RUR 462.00 | |

| A22 | — | 8,70 | 70 | 50 | 70 | RUB 783.00 | |||

| A23 | 140 | 16,20 | 70 | 95 | RUB 1,328.40 | ||||

| B22 | — | 9,70 | 50 | 70 | RUR 873.00 | ||||

| B23 | 140 | 17,20 | 70 | 95 | RUB 1,410.40 | ||||

| 377 | AII | 100 | 126 | 90 | 3,20 | 50 | — | — | RUB 384.00 |

| AI2 | — | 6,70 | 70 | 60 | 85 | RUB 549.40 | |||

| AI3 | 90 | 12,50 | 80 | 110 | RUB 1,025.00 | ||||

| B12 | — | 7,70 | 60 | 85 | RUB 631.40 | ||||

| B13 | 90 | 13,50 | 80 | 110 | RUB 1,107.00 | ||||

| A2I | 150 | 176 | 140 | 4,10 | 50 | — | — | RUR 451.00 | |

| A22 | — | 8,60 | 70 | 50 | 70 | RUB 705.20 | |||

| A23 | 140 | 15,70 | 70 | 95 | RUB 1,287.40 | ||||

| B22 | — | 9,60 | 50 | 70 | RUR 787.20 | ||||

| B23 | 140 | 16,70 | 70 | 95 | RUB 1,369.40 | ||||

| 426 | AII | 100 | 122 | 90 | 4,60 | 60 | — | — | RUB 506.00 |

| AI2 | — | 9,80 | 80 | 90 | 125 | RUB 803.60 | |||

| AI3 | 90 | 18,30 | 120 | 170 | RUB 1,500.60 | ||||

| BI2 | — | 11,20 | 90 | 125 | RUB 918.40 | ||||

| BIZ | 90 | 19,70 | 120 | 170 | RUB 1,615.40 | ||||

| A2I | 150 | 172 | 140 | 6,10 | 60 | — | — | RUB 549.00 | |

| A22 | — | 12,50 | 80 | 80 | 110 | RUB 1,025.00 | |||

| A23 | 140 | 23,20 | 105 | 150 | RUB 1,902.40 | ||||

| B22 | — | 13,90 | 80 | 110 ‘ | RUB 1,139.80 | ||||

| B23 | 140 | 24,60 | 105 | 150 | RUB 2,017.20 | ||||

| 530 | AII | 90 | 6,30 | 80 | — | — | RUB 567.00 | ||

| AI2 | — | 13,70 | 120 | 110 | 145 | RUB 1,123.40 | |||

| AI3 | 100 | 143 | 90 | 25,10 | 150 | 200 | RUB 2,058.20 | ||

| B12 | 100 | 143 | — | 16,40 | 110 | 145 | RUB 1,344.80 | ||

| B13 | 90 | 27,80 | 150 | 200 | RUB 2,279.60 | ||||

| A2I | 150 | 193 | 140 | 8,00 | 80 | — | — | RUR 720.00 | |

| A22 | — | 17,10 | 120 | 100 | 130 | RUB 1,402.20 | |||

| A23 | 140 | 30,90 | 140 | 180 | RUB 2,533.80 | ||||

| B22 | — | 19,80 | — | — | RUB 1,623.60 | ||||

| B23 | 140 | 33,60 | 140 | 180 | RUB 2,755.20 | ||||

| 630 | AII | 100 | 135 | 90 | 6,20 | 80 | — | — | RUB 558.00 |

| AI2 | — | 13,30 | 110 | 145 | RUB 1,090.60 | ||||

| AI3 | 90 | 24,40 | 120 | 150 | 200 | RUB 2,000.80 | |||

| B12 | — | 16,00 | 110 | 145 | RUB 1,312.00 | ||||

| B13 | 90 | 27,10 | 150 | 200 | RUB 2,222.20 | ||||

| A2I | 150 | 185 | 140 | 7,90 | 80 | — | — | RUB 711.00 | |

| A22 | — | 16,60 | 120 | 100 | 130 | RUB 1,361.20 | |||

| A23 | 140 | 30,20 | 140 | 180 | RUB 2,476.40 | ||||

| B22 | — | 19,30 | 100 | 130 | RUB 1,582.60 | ||||

| B23 | 140 | 32,90 | 140 | 180 | RUB 2,697.80 | ||||

| 820 | AI2 | 100 | 125 | — | 17,00 | 200 | 125 | 160 | RUB 1,394.00 |

| AI3 | 90 | 31,10 | 175 | 220 | RUB 2,550.20 | ||||

| B12 | — | 20,50 | 125 | 160 | RUB 1,681.00 | ||||

| B13 | 90 | 34,60 | 175 | 220 | RUB 2,837.20 | ||||

| A22 | 150 | 175 | — | 21,30 | 115 | 150 | RUB 1,746.60 | ||

| A23 | 140 | 38,80 | 165 | 210 | RUB 3,181.60 | ||||

| B22 | — | 24,80 | 115 | 150 | RUB 2,033.60 | ||||

| B23 | 140 | 42,30 | 165 | 210 | 3 468,60 | ||||

| 1020 | AI2 | 100 | 161 | — | 27,60 | 340 | 140 | 175 | RUB 2,263.20 |

| AI3 | 90 | 49,30 | 200 | 250 | RUB 4,042.60 | ||||

| B12 | — | 37,30 | 140 | 175 | RUB 3,058.60 | ||||

| B13 | 90 | 59,00 | 200 | 250 | RUB 4,838.00 | ||||

| A22 | 150 | 211 | — | 33,30 | 130 | 165 | RUB 2,730.60 | ||

| A23 | I40 | 59,00 | 185 | 235 | RUB 4,838.00 | ||||

| B22 | — | 43,00 | 130 | 165 | RUB 3,526.00 | ||||

| B23 | 140 | 68,70 | 185 | 235 | RUB 5,633.40 | ||||

| 1220 | AI2 | 100 | 150 | — | 26,80 | 400 | 140 | 175 | RUB 2,197.60 |

| AI3 | 90 | 47,90 | 200 | 250 | RUB 3,927.80 | ||||

| B12 | — | 36,40 | 140 | 175 | RUB 2,984.80 | ||||

| B13 | 90 | 57,50 | 200 | 250 | RUB 4,715.00 | ||||

| A22 | 150 | 200 | — | 32,50 | 130 | 165 | RUB 2,665.00 | ||

| A23 | 140 | 57,60 | 185 | 235 | RUB 4,723.20 | ||||

| B22 | — | 42,10 | 130 | 165 | RUB 3,452.20 | ||||

| B23 | 140 | 67,20 | 185 | 235 | RUB 5,510.40 | ||||

| 1420 | AI2 | 100 | 142 | — | 32,50 | 450 | 150 | 190 | RUB 2,665.00 |

| AI3 | 90 | 58,20 | 210 | 270 | RUB 4,772.40 | ||||

| B12 | — | 44,30 | 150 | 190 | RUB 3,632.60 | ||||

| BI3 | 90 | 70,00 | 210 | 270 | RUB 5,740.00 | ||||

| A22 | 150 | 192 | — | 39,50 | 140 | 180 | RUB 3,239.00 | ||

| A23 | 140 | 70,30 | 200 | 250 | RUB 5,764.60 | ||||

| B22 | — | 51,30 | 140 | 180 | RUB 4,206.60 | ||||

| B23 | 140 | 82,10 | 200 | 250 | RUB 6,732.20 | ||||

| Pipeline outer diameter, dn | Execution | h | B | B.I. | Bolt dimensions d×l | Weight kg, no more | Permissible loads, kN | Price without VAT | ||

| Vertical Qy | Axial Рz at | |||||||||

| Px=Pz | Px=0.5Pz | |||||||||

| 57 | AII | 102 | 50 | 142 | MI2×40 | 2,10 | 2,5 | 3 | 5,5 | RUB 323.40 |

| AI2 | 4,20 | 15 | RUB 508.20 | |||||||

| A2I | 152 | 2,50 | 3 | 5,5 | RUB 385.00 | |||||

| A22 | 5,20 | 15 | RUB 572.00 | |||||||

| 76 | AII | 101 | 160 | 2,20 | 3 | 3 | 5,5 | RUR 338.80 | ||

| AI2 | 4,30 | 15 | RUB 520.30 | |||||||

| A2I | 151 | 2,70 | 3 | 5,5 | RUR 415.80 | |||||

| A22 | 5,30 | 15 | RUB 583.00 | |||||||

| 89 | AII | 100 | 179 | 2,20 | 5 | 3 | 5,5 | RUR 338.80 | ||

| AI2 | 4,50 | 15 | RUB 544.50 | |||||||

| A2I | 150 | 2,80 | 3 | 5,5 | RUB 431.20 | |||||

| A22 | 5,50 | 15 | RUB 577.50 | |||||||

| 108 | AII | 103 | 80 | 200 | MI6×50 | 5,40 | 6 | 10 | 13 | RUB 567.00 |

| AI2 | 6,90 | 30 | 45 | RUB 724.50 | ||||||

| A2I | 153 | 6,00 | 8 | 10 | RUB 630.00 | |||||

| A22 | 8,10 | 25 | 38 | RUB 850.50 | ||||||

| 133 | AII | 101 | 250 | 6,30 | 8 | 10 | 13 | RUB 661.50 | ||

| AI2 | 7,80 | 30 | 45 | RUB 819.00 | ||||||

| A2I | 151 | 6,80 | 8 | 10 | RUB 714.00 | |||||

| A22 | 8,90 | 25 | 38 | RUB 934.50 | ||||||

| 159 | A11 | 101 | 275 | MI6×50 | 6,90 | 10 | 10 | 13 | RUB 724.50 | |

| AI2 | 8,40 | 30 | 45 | RUB 882.00 | ||||||

| A2I | 151 | 7,40 | 8 | 10 | RUB 777.00 | |||||

| A22 | 9,50 | 2b | 38 | RUB 997.50 | ||||||

| 219 | AII | 109 | 200 | 365 | M20×60 | 13,40 | 25 | — | — | RUB 1,098.80 |

| AI2 | 16,80 | 60 | 85 | RUB 1,377.60 | ||||||

| AI3 | 21,70 | 80 | 110 | RUB 1,779.40 | ||||||

| A2I | 159 | 14,10 | — | — | RUB 1,156.20 | |||||

| A22 | 18,00 | 50 | 70 | RUB 1,476.00 | ||||||

| A23 | 24,00 | 70 | 95 | RUB 1,968.00 | ||||||

| 273 | AII | 103 | 420 | 15,10 | 25 | — | — | RUB 1,238.20 | ||

| AI2 | 104 | 19,60 | 40 | 60 | 85 | RUB 1,607.20 | ||||

| AI3 | 25,80 | 80 | 110 | RUB 2,115.60 | ||||||

| A2I | 153 | 15,70 | 25 | — | — | RUB 1,287.40 | ||||

| A22 | 154 | 21,50 | 40 | 50 | 70 | RUB 1,763.00 | ||||

| A23 | 29,10 | 70 | 95 | RUB 2,386.20 | ||||||

| 325 | AII | 102 | 470 | 17,40 | 50 | — | — | RUB 1,426.80 | ||

| AI2 | 21,00 | 70 | 60 | 85 | RUB 1,722.00 | |||||

| AI3 | 26,90 | 80 | 110 | RUB 2,205.80 | ||||||

| A2I | 152 | 18,30 | 50 | — | — | RUB 1,500.60 | ||||

| A22 | 22,80 | 70 | 50 | 70 | RUB 1,869.60 | |||||

| A23 | 30,30 | 70 | 95 | RUB 2,484.60 | ||||||

| 377 | AII | 101 | 525 | 19,10 | 50 | — | — | RUB 1,566.20 | ||

| AI2 | 22,60 | 70 | 60 | 85 | RUB 1,853.20 | |||||

| AI3 | 28,40 | 80 | 110 | RUB 2,328.80 | ||||||

| A21 | 151 | 20,00 | 50 | — | — | RUB 1,640.00 | ||||

| A22 | 24,50 | 70 | 50 | 70 | RUB 2,009.00 | |||||

| A23 | 31,60 | 70 | 95 | RUB 2,591.20 | ||||||

| 426 | AII | 101 | 200 | 575 | M20x60 | 22,10 | 60 | — | — | RUB 1,812.20 |

| AI2 | 27,30 | 80 | 90 | 125 | RUB 2,238.60 | |||||

| AI3 | 35,80 | 120 | 170 | RUB 2,935.60 | ||||||

| A2I | 151 | 23,60 | 60 | — | — | RUB 1,935.20 | ||||

| A22 | 30,00 | 80 | 80 | 110 | RUB 2,460.00 | |||||

| A23 | 40,70 | 105 | 150 | RUB 3,337.40 | ||||||

| 530 | AII | 103 | 300 | 705 | 36,50 | 80 | — | — | RUB 2,993.00 | |

| AI2 | 43,90 | 120 | 110 | 145 | RUB 3,599.80 | |||||

| AI3 | 55,30 | 150 | 200 | RUB 4,534.60 | ||||||

| A2I | 153 | 38,20 | 80 | — | — | RUB 3,132.40 | ||||

| A22 | 47,30 | 120 | 100 | 130 | RUB 3,878.60 | |||||

| A23 | 61,10 | 140 | 180 | RUB 5,010.20 | ||||||

| 630 | AII | 102 | 300 | 805 | M24×80 | 41,00 | 80 | — | — | RUB 3,362.00 |

| AI2 | 48,10 | 120 | 110 | 145 | RUB 3,944.20 | |||||

| AI3 | 59,20 | 150 | 200 | RUB 4,854.40 | ||||||

| A2I | 152 | 42,70 | 80 | — | — | RUB 3,501.40 | ||||

| A22 | 51,40 | 120 | 100 | 130 | RUB 4,214.80 | |||||

| A23 | 65,00 | 140 | 180 | RUB 5,330.00 | ||||||

| Pipeline outer diameter Dn | Execution | h | Weight, kg, no more | Permissible loads, kN | Price without VAT | ||

| Vertical Q | Axial Рz at | ||||||

| Px=Pz | Px=0.5Pz | ||||||

| 57 -76 | A.I. | 100 | 1,4 | 3 | 2 | 2,5 | RUR 255.00 |

| A2 | 150 | 1,6 | RUB 270.00 | ||||

| BI | 100 | 0,5 | — | 2 | 2,6 | RUB 187.50 | |

| B2 | 150 | 0,7 | RUB 202.50 | ||||

| 89 -108 | A.I. | 100 | 1,9 | 6 | 6 | 7,5 | RUR 292.50 |

| A2 | 150 | 2,2 | 4,5 | 5,5 | RUB 315.00 | ||

| BI | 100 | 0,7 | — | 6 | 7,5 | RUB 202.50 | |

| B2 | 150 | 1 | 4,5 | 5,5 | RUB 225.00 | ||

| 133-159 | A.I. | 100 | 3,2 | 10 | 14 | 17 | RUB 390.00 |

| A2 | 150 | 3,8 | 11 | 13 | RUB 435.00 | ||

| BI | 100 | 1,3 | — | 14 | 17 | RUR 247.50 | |

| B2 | 150 | 1,9 | 11 | 13 | RUR 292.50 | ||

| 219 | A.I. | 100 | 7 | 40 | 35 | 43 | RUB 675.00 |

| 273 | A2 | 150 | 8,8 | 26 | 32 | RUR 810.00 | |

| BI | 100 | 3 | — | 35 | 43 | RUB 375.00 | |

| B2 | 150 | 4,3 | 26 | 32 | RUB 472.50 | ||

| 325 | A.I. | 100 | 12,9 | 70 | 48 | 61 | RUB 1,057.80 |

| A2 | 150 | 14,7 | 41 | 51 | RUB 1,249.50 | ||

| BI | 100 | 4,3 | — | 48 | 61 | RUB 472.50 | |

| B2 | 150 | 6,1 | 41 | 51 | RUB 607.50 | ||

| 377 | A.I. | 100 | 20,2 | 80 | 85 | 110 | RUB 1,656.40 |

| 426 | A2 | 150 | 23,2 | 70 | 90 | RUB 1,972.00 | |

| BI | 100 | 7,5 | — | 85 | 110 | RUB 712.50 | |

| B2 | 150 | 10,5 | 70 | 90 | RUB 861.00 | ||

| 530 | A.I. | 100 | 34,1 | 120 | 100 | 120 | RUB 2,796.20 |

| A2 | 150 | 37,7 | 90 | 100 | RUB 3,091.40 | ||

| BI | 100 | 9,1 | — | 100 | 120 | RUR 746.20 | |

| B2 | 150 | 12,8 | 90 | 100 | RUB 1,049.60 | ||

| 630 | A.I. | 100 | 60,4 | 120 | 205 | 250 | RUB 4,952.80 |

| A2 | 150 | 66,3 | 180 | 230 | RUB 5,436.60 | ||

| BI | 100 | 16,7 | — | 205 | 250 | RUB 1,369.40 | |

| B2 | 150 | 22,6 | 180 | 230 | RUB 1,853.20 | ||

| Pipeline outer diameter, dn | Execution | h | Weight kg, no more | Permissible loads, kN | Price without VAT | |

| Vertical Qy | Axial Pz, at Px=0.2Pz | |||||

| 57 | A.I. | 100 | 0,5 | 2,5 | 10 | RUB 137.50 |

| A2 | 200 | 1 | RUB 175.00 | |||

| 76 | A.I. | 100 | 0,5 | 3 | RUB 137.50 | |

| A2 | 200 | 1 | RUB 175.00 | |||

| 89 | A.I. | 100 | 0,7 | 5 | 20 | 152.50 rub. |

| A2 | 200 | 1,4 | 30 | RUR 205.00 | ||

| 108 | A.I. | 100 | 0,7 | 6 | 20 | 152.50 rub. |

| A2 | 200 | 1,4 | 30 | RUR 205.00 | ||

| 133 | A.I. | 100 | 0,9 | 8 | 30 | 167.50 rub. |

| A2 | 250 | 2,1 | 50 | RUR 257.50 | ||

| 159 | A.I. | 100 | 0,9 | 10 | 30 | 167.50 rub. |

| A2 | 250 | 2,1 | 50 | RUR 257.50 | ||

| 219 | A.I. | 150 | 1,6 | 20 | 50 | RUB 220.00 |

| A2 | 250 | 2,6 | 75 | RUB 295.00 | ||

| 273 | A.I. | 200 | 2,1 | 25 | 60 | RUR 257.50 |

| A2 | 300 | 3,1 | 40 | 90 | RUB 332.50 | |

| 325 | A.I. | 200 | 2,1 | 25 | 50 | RUR 257.50 |

| A2 | 300 | 3,1 | 40 | 80 | RUB 332.50 | |

| 377 | A.I. | 200 | 2,8 | 30 | 70 | RUB 310.00 |

| A2 | 300 | 4,3 | 50 | 100 | RUR 422.50 | |

| 426 | A.I. | 200 | 2,8 | 30 | 60 | RUB 310.00 |

| A2 | 300 | 4,3 | 50 | 90 | RUR 422.50 | |

| 530 | A.I. | 250 | 4,6 | 50 | 80 | RUR 445.00 |

| A2 | 400 | 7,4 | 70 | 120 | RUB 655.00 | |

| 630 | A.I. | 250 | 4,6 | 60 | 65 | RUR 445.00 |

| A2 | 400 | 7,4 | 80 | 120 | RUB 655.00 | |

| 820 | A.I. | 400 | 12,7 | 100 | 120 | RUB 1,052.50 |

| Pipeline outer diameter, dn | Execution | Weight kg, no more | Permissible loads, kN | Price without VAT | |

| Vertical Qy | Axial Pz, at Px=0.2Pz | ||||

| 1020 | A | 25 | 150 | 100 | RUB 2,050.00 |

| B | 34,7 | RUB 2,845.40 | |||

| 1220 | A | 35,3 | 200 | 150 | RUB 2,894.60 |

| B | 44,8 | RUB 3,673.60 | |||

| 1420 | A | 38,9 | 250 | 130 | RUB 3,189.80 |

| B | 50,7 | RUB 4,157.40 | |||

| Outer; pipeline diameter Dn | Execution | d | Weight, kg*, no more, support design | Permissible axial load Pz** for supports version B, kN | Price without VAT | |

| A. B | V, G | |||||

| 25 | A; B; | M10 | 0,1 | 0,1 | 0,4 | RUR 257.50 |

| 32 | IN; G | 0,1 | 0,1 | RUR 257.50 | ||

| 38 | 0,2 | 0,1 | 0,8 | RUR 265.00 | ||

| 45 | 0,2 | 0,1 | RUR 265.00 | |||

| 57 | A; B; | MI2 | 0,3 | 0,2 | 5 | RUR 272.50 |

| 76 | IN; G | 0,4 | 0,3 | RUB 280.00 | ||

| 89 | 0,4 | 0,3 | RUB 280.00 | |||

| 108 | MI6 | 0,8 | 0,6 | RUB 310.00 | ||

| 133 | 1 | 0,7 | 10 | RUB 325.00 | ||

| 159 | M20 | 1,8 | 1,3 | RUB 385.00 | ||

| 219 | A; B | 2,2 | — | 20 | RUR 415.00 | |

| 273 | 2,6 | RUR 445.00 | ||||

| 325 | 3 | RUR 475.00 | ||||

| 377 | M24 | 5 | 30 | RUB 550.00 | ||

| 426 | 5,5 | RUB 605.00 | ||||

| 530 | 6,6 | RUB 726.00 | ||||

| Pipeline outer diameter, dn. | Execution | h | dн | Weight, kg, no more than supports | Permissible loads, kN | Price without VAT | ||

| Vertical Qy | Axial Pz at | |||||||

| Px=Pz | Px=0.5Pz | |||||||

| 57 | A.I. | 100 | 45 | 1,2 | 1 | 1,5 | 2 | RUB 290.00 |

| A2 | 150 | 1,4 | RUB 305.00 | |||||

| 76 | A.I. | 100 | 57 | 1,5 | 2 | 2 | 2,5 | RUB 312.50 |

| A2 | 150 | 1,8 | RUB 335.00 | |||||

| 89 | A.I. | 100 | 76 | 2,2 | 2,5 | 4 | 5 | RUB 365.00 |

| A2 | 150 | 2,6 | RUB 395.00 | |||||

| 108 | A.I. | 100 | 2,3 | 3 | 4 | 5 | RUB 372.50 | |

| A2 | 150 | 2,6 | RUB 395.00 | |||||

| 133 | A.I. | 100 | 108 | 4,2 | 6 | 8 | 10 | RUB 504.00 |

| A2 | 150 | 4,8 | RUB 576.00 | |||||

| 159 | A.I. | 100 | 4,3 | 8 | 8 | 10 | RUB 516.00 | |

| A2 | 150 | 4,9 | RUB 588.00 | |||||

| 219 | A.I. | 100 | 159 | 10,3 | 20 | 20 | 25 | RUR 844.60 |

| A2 | 150 | 11,6 | RUB 951.20 | |||||

| 273 | A.I. | 100 | 11,5 | 20 | 20 | 25 | RUB 943.00 | |

| A2 | 150 | 12,8 | RUB 1,049.60 | |||||

| 325 | A.I. | 100 | 219 | 20,1 | 25 | 25 | 30 | RUB 1,483.38 |

| A2 | 150 | 22 | RUB 1,623.60 | |||||

| 377 | A.I. | 100 | 273 | 34,4 | 35 | 40 | 50 | RUB 2,538.72 |

| A2 | 150 | 37,4 | RUB 2,760.12 | |||||

| 426 | A.I. | 100 | 35,9 | 35 | 40 | 50 | RUB 2,649.42 | |

| A2 | 150 | 38,9 | RUB 2,870.82 | |||||

| 530 | A.I. | 100 | 325 | 47,3 | 40 | 80 | 100 | RUB 3,490.74 |

| A2 | 150 | 50,9 | RUB 3,756.42 | |||||

| 630 | A.I. | 100 | 426 | 86,8 | 70 | 120 | 140 | RUB 6,405.84 |

| A2 | 150 | 92,7 | RUB 6,841.26 | |||||

| Pipeline outer diameter, dn. | Execution | Weight** kg, no more | Permissible load, kN | Price without VAT |

| 57 76 89 | A.I. | 0,4 | 3 | |

| A2 | 0,6 | RUB 245.00 | ||

| 108 133 159 219 | A.I. | 0,9 | 15 | RUR 267.50 |

| B1* | 1,7 | RUB 340.00 | ||

| A2 | 2,2 | RUB 352.00 | ||

| B2* | 3 | RUB 420.00 | ||

| 273 325 377 426 | A.I. | 3,4 | 40 | RUB 476.00 |

| B1 | 7,1 | RUB 639.00 | ||

| A2 | 6,6 | RUB 594.00 | ||

| B2 | 10,3 | RUR 844.60 | ||

| 530 630 820 1020 | A.I. | 7,4 | 100 | RUB 666.00 |

| B1 | 14 | RUB 1,148.00 | ||

| A2 | 12,6 | RUB 1,033.20 | ||

| B2 | 19,2 | RUB 1,574.40 | ||

| 1220 | A.I. | 16,2 | 160 | RUB 1,328.40 |

| B1 | 27 | RUB 2,214.00 | ||

| 1420 | A2 | 18,8 | RUB 1,541.60 | |

| B2 | 29,7 | RUB 2,435.40 |

| Pipeline outer diameter, dn | Execution | Roller length | Weight, kg, no more | Price without VAT |

| 219 | AII | 300 | 17,5 | |

| XII | 27,1 | |||

| AI2 | 320 | 39,9 | RUB 3,271.80 | |

| AI3 | 62,5 | RUB 5,125.00 | ||

| B12 | 40,8 | RUB 3,345.60 | ||

| B13 | 63,4 | RUB 5,198.80 | ||

| X12 | 49,5 | RUB 4,059.00 | ||

| X13 | 72,1 | RUB 5,912.20 | ||

| 273 | AII | 300 | 17,4 | RUB 1,426.80 |

| XII | 28,8 | RUB 2,361.60 | ||

| AI2 | 320 | 40,9 | RUB 3,353.80 | |

| AI3 | 64,8 | RUB 5,313.60 | ||

| B12 | 41,9 | RUB 3,435.80 | ||

| B13 | 65,8 | RUB 5,395.60 | ||

| XI2 | 52,3 | RUB 4,288.60 | ||

| XI3 | 76,2 | RUB 6,248.40 | ||

| 325 | AII | 300 | 18,1 | RUB 1,484.20 |

| XII | 31,1 | RUB 2,550.20 | ||

| AI2 | 320 | 40,7 | RUB 3,337.40 | |

| AI3 | 64,3 | RUB 5,272.60 | ||

| B12 | 41,7 | RUB 3,419.40 | ||

| B13 | 65,3 | RUB 5,354.60 | ||

| X12 | 53,7 | RUB 4,403.40 | ||

| X13 | 77,3 | RUB 6,338.60 | ||

| 377 | AII | 300 | 18,1 | RUB 1,484.20 |

| XII | 32,9 | RUB 2,697.80 | ||

| AI2 | 320 | 40,5 | RUB 3,321.00 | |

| AI3 | 64 | RUR 5,248.00 | ||

| B12 | 41,5 | RUB 3,403.00 | ||

| B13 | 65 | RUB 5,330.00 | ||

| XI2 | 55,3 | RUB 4,534.60 | ||

| XI3 | 78,3 | RUB 6,420.60 | ||

| 426 | AII | 300 | 19,5 | RUB 1,599.00 |

| XII | 35,9 | RUB 2,943.80 | ||

| AI2 | 320 | 43,6 | RUB 3,575.20 | |

| AI3 | 69,3 | RUB 5,682.60 | ||

| B12 | 45 | RUB 3,690.00 | ||

| B13 | 71,2 | RUB 5,838.40 | ||

| X12 | 60 | RUB 4,920.00 | ||

| X13 | 86,2 | RUB 7,068.40 | ||

| 530 | AII | 400 | 27 | RUB 2,214.00 |

| XII | 55,2 | RUB 4,526.40 | ||

| AI2 | 420 | 60,2 | RUB 4,936.40 | |

| AI3 | 91,9 | RUB 7,535.80 | ||

| B12 | 61,5 | RUR 5,043.00 | ||

| B13 | 94,6 | RUB 7,757.20 | ||

| X12 | 88,4 | RUB 7,248.80 | ||

| X13 | 120,1 | RUB 9,848.20 | ||

| 630 | AII | 400 | 26,8 | RUB 2,197.60 |

| XII | 59,6 | RUB 4,887.20 | ||

| AI2 | 420 | 59,8 | RUB 4,903.60 | |

| AI3 | 91,2 | RUB 7,478.40 | ||

| B12 | 61,5 | RUR 5,043.00 | ||

| B13 | 93,9 | RUR 7,699.80 | ||

| X12 | 92,6 | RUB 7,593.20 | ||

| X13 | 124 | RUB 10,168.00 | ||

| 820 | A12 | 63,5 | RUR 5,207.00 | |

| A13 | 97,9 | RUB 8,027.80 | ||

| BI2 | 67 | RUB 5,494.00 | ||

| BI3 | 101,4 | RUB 8,314.80 | ||

| 1020 | A12 | 620 | 95 | RUB 7,790.00 |

| A13 | 146,4 | RUB 12,004.80 | ||

| B12 | 104 | RUB 8,528.00 | ||

| B13 | 156,3 | RUB 12,816.60 | ||

| 1220 | AI2 | 620 | 94,5 | RUB 7,749.00 |

| AI3 | 145,2 | RUB 11,906.40 | ||

| B12 | 104,1 | RUB 8,536.20 | ||

| B13 | 154,8 | RUB 12,693.60 | ||

| 1420 | AI2 | 620 | 100 | RUB 8,200.00 |

| AI3 | 155 | RUB 12,710.00 | ||

| B12 | 112 | RUB 9,184.00 | ||

| B13 | 167 | RUB 13,694.00 |

The need to design pipeline racks

The design of pipeline racks can occur for various reasons. Successfully solving this problem makes it possible to:

- increase the service life of the installation;

- reduce costs for construction and installation work;

- reduce investments in reconstruction;

- increase the safety and reliability of the design;

- optimize the delivery and transportation of building materials;

- include repairs and modernization in future spending.

As you may have noticed, developing a technological rack project requires a lot of experience and a wide range of knowledge. We recommend choosing a contractor only from organizations that have SRO approval and have long established themselves in this field.

How does a fixed support for pipelines work?

Fixed structures are necessary in cases where rigid fastening of the system is required. In this way, it is possible to prevent its shifts in any of the possible directions.

Fixed elements are used in the installation of pipelines, which are installed in the following ways:

During the installation of sections of the system, the supporting structures are fixed using reinforced concrete frames. You need to understand that the latter are located at different distances from each other, dividing communications into segments. The length of the segment is related to the characteristics of the special compensators installed on it.

During both external and underground installation of communications, fixed elements are actively used. If a channelless method is used for laying underground, choose supports with high-quality waterproofing. Usually the role of the latter is played by a polyethylene shell. When it comes to external installation, galvanized waterproofing is preferred.

For a fixed installation method, the following elements are used:

- steel pipe;

- steel sheet obtained by hot rolling;

- polyurethane foam (PPU);

- heat-resistant tape;

- galvanized shell;

- centralizer;

- polyethylene shell.

For the manufacture of fixed steel supports for pipelines, the most durable and reliable grades of this metal are used.

The steel sheets used in this case can be of three types - it all depends on the quality:

- ordinary;

- low alloy;

- structural (considered the highest quality).

A centralizer is an element that simplifies the alignment of pipe ends before connecting pipeline elements. Today there are two types of centralizers:

In accordance with the name, external ones perform alignment from the outside of the pipe and can be:

- link;

- eccentric;

- hydraulic jacks.

The first ones are necessary for centering pipes with a cross-section in the range of 57–2,224 mm. Unlike other models, they have increased resistance to low temperatures, since they are made from frost-resistant steel. Eccentric centralizers can be used when working with pipes of any cross-section. The latter type is used exclusively when aligning pipes with very large weights or when there are deformations on them. Such devices provide a force of 12 tons.

If we talk about internal centralizers, they are distinguished by one important feature: they allow long-term welding of pipes from the inside. As a result, the quality of seams is significantly improved. However, these products also have disadvantages, the main one of which is their heavy weight, that is, their transportation is impossible without special equipment.

Fixed support structures for pipelines are used in construction:

- main gas or oil pipelines;

- various types of communications at enterprises;

- pipelines to nuclear power plants and thermal power plants.

In addition, it is the fixed elements that are used in the construction of communications in regions with low temperatures, thus increasing the service life of the entire structure.

These elements are installed in systems used in completely different areas. They divide the entire system into separate segments in which bellows-type compensators are installed. The latter are designed to protect the pipeline from deformation that is possible when the ambient temperature drops.

Fixed supports of steel process pipelines are welded to platforms and mounted to the pipe using fasteners. To achieve the greatest reliability, metal plates are also welded close to the ends of the clamp.

Features of designing overpasses

It is impossible to describe in a nutshell how pipeline racks are designed. This is a rather complex and lengthy process that depends on various conditions. It is possible to competently increase the lifespan of a structure if, at the preliminary stage, you pay attention to:

- the force with which the pipes act on supports and other load-bearing parts;

- characteristics of materials transported to the site;

- environmental conditions (precipitation, temperature, moisture).

This is interesting!

“Insulation of sewer pipes: understanding the principles and materials”

More details

As mentioned above, each overpass has features that must be taken into account when designing expansion joints (temperature blocks). They are necessary to reduce the load and prevent the occurrence of deformations under temperature and atmospheric influences.

Otherwise, under strong influence and heating of the walls, the pipes will be under dangerous pressure, which provokes destruction. The physicist Hooke describes the processes and consequences of this in the law of strength of materials. In the absence of a compensator, the pipeline does not lengthen as the temperature increases.

Exclusively temperature changes and the selected material for the manufacture of pipes (elongation and elasticity characteristics) affect the compressive stress in the pinched state of the pipeline. From this we can conclude that pipes made of the same material, but intended for water and heat supply, will have different voltages. Because in this case the difference in temperatures will be significant. If internal stress decreases, there are fewer expansion joints, and the distance between sections increases.

Do not forget about one condition that must always be taken into account when creating a project. Every structure needs reconstruction or repair over time. So it is recommended to plan future work at the earliest stages. It will be necessary to organize the passage of construction vehicles and an area for placing auxiliary equipment. The weight of building materials and workers is also taken into account.

As statistics and experience show, most often early reconstruction of a facility is required due to an initially negligent attitude towards project development and construction and installation work. Consider the design of pipeline racks carefully to reduce the risk of premature deformations and failures.

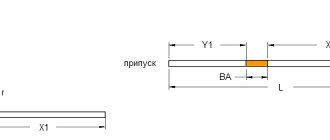

movable pipeline support and its support unit

Because I think these calculations have already been done, and the results are presented in textbooks. After all, above the tables are the characteristics of the pipes: diameter, temperature, pressure. I suspect that with my dubious calculations I will not discover anything new.

And if you follow only SNiPs, then you yourself know that you will not find much there that applies specifically to your task. Moreover, it seems to me that what is written in your SNiPs is even more vague than in ours, although you don’t have that many of them. Keep these pieces of paper carefully on your chest - and if something goes wrong in connection with such methods of work and decision-making, and they will definitely start looking for someone to blame - immediately take out all these pieces of paper and cover yourself.

On the topic: the distances between supports, the need to install them, as well as the need to install compensators and everything else - is determined in each specific case by the project with calculations. Otherwise, you will get stuck and, at best, you will simply hear a lot of new things about yourself and fix all your mistakes for free.

Well, what the author is asking about is not a compensator. Just walking around the driveway vertically.

The group of inventions relates to the field of construction of overhead pipelines. The pipeline support contains interacting moving and fixed parts. The moving part includes a semi-cylindrical cradle with semi-circular stiffening ribs on the outer side of the cradle, detachable half-clamps for fixing the pipeline in the cradle, side cheeks rigidly welded to the cradle and movably attached to the base of the support by means of a hinged connection.

They didn't need to move the pipe over the driveway. Just an area sandwiched between 2 fixed frames. The supports themselves in this case - as long as they are not on welded seams - are at a reasonable distance from the seam. This is not a compensator.

Concrete works

But the supports themselves will actually be stationary and take axial loads from sections of the route to the right to the next stationary support and to the left. Therefore, he will not find what he is looking for - there is only a norm in this case, the distance from the welded joint of the outlet.

Best regards, VA. VA, it’s very similar to the truth, this is probably how it is. Woman, if only everything were so simple. For example, do you often force the director to give a receipt for his decisions? Pavlik, laying a meter-long metal truss is also not the cheapest option.

Work on the installation of foundations for supports and trestles for pipelines during the construction of oil and petrochemical industry enterprises is a complex and labor-intensive process, which also depends on climatic conditions. A successful solution that simplifies the design of foundations is the use of pile foundations, which make it possible to completely eliminate excavation work and use industrial methods of work. Tower Construction in

And also pillars under it on both sides, each 7 meters high. Okay, be that as it may, I have already completed the project and handed it over to the customer! IP Forum.